Clutch device VAZ 2107

The clutch is controlled by a pedal inside the cabin. When you press it, the clutch is disconnected from the gearbox, and when you press it, it engages. This ensures a smooth start of the car from a standstill and silent gear shifting. The node itself consists of a large number of elements interacting with each other. The VAZ 2107 is equipped with a single-disc clutch with a central spring .

Clutch basket

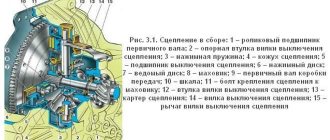

The clutch consists of two discs and a release bearing. The clutch used on the VAZ 2107 is simple and reliable. The pressure (drive disk) is installed on the flywheel. Inside the basket there is a driven disk connected to the gearbox input shaft with special splines.

The clutch can be single-disc or multi-disc. The first is considered more reliable. The clutch functions as follows. When you press the pedal, the release bearing mounted on the input shaft pulls the petals of the basket towards the engine block. As a result, the basket and driven disk are disengaged, and it becomes possible to change speeds.

For the VAZ 2107, wheels from the VAZ 2103 (for engines up to 1.5 liters) and VAZ 2121 (for engines up to 1.7 liters) are suitable. Externally they are very similar and have a diameter of 200 mm. These discs can be distinguished by the width of the linings (29 and 35 mm, respectively) and the presence of a 6 mm mark in one of the grooves of the VAZ 2121 damper.

Clutch disc

The driven disc is sometimes called a drum. There are pads glued to it on both sides. To increase elasticity, special slots are made on the disk during the manufacturing process. In addition, the drum is equipped with eight springs located in the plane of the disk. These springs reduce the frequency of torsional vibrations and reduce dynamic loads.

The drum is connected to the gearbox, and the basket is connected to the engine. During movement, they are pressed tightly against each other, rotating in the same direction.

The single-disk scheme used on the VAZ 2107 is distinguished by its reliability, comparative cheapness and ease of maintenance. This clutch is easy to remove and repair.

The driven disk for a 1.5 liter engine has dimensions of 200x140 mm. It can also be installed on a VAZ 2103, 2106. Sometimes a drum from a Niva (VAZ 2121) is installed on a VAZ 2107, differing in size (200x130 mm), a reinforced damper system and a large number of rivets.

Release bearing

The release bearing, being the most vulnerable element of the clutch, turns the rotation gear on and off. It is located in the middle of the disc and is rigidly connected to the pedal through a fork. Each press of the clutch pedal loads the bearing and shortens the bearing's life. Do not press the pedal unnecessarily. A bearing is installed on the gearbox drive shaft guide.

In the clutch kit, the release bearing is designated 2101. A bearing from a VAZ 2121, designed for high loads and having an increased service life, is also suitable. However, in this case, you will also need to replace the basket, since pressing the pedal will require great effort.

Clutch fork

The fork is designed to disengage the clutch when the clutch pedal is pressed. It moves the release bearing and, as a result, the inner edge of the spring.

Most often, if the fork is faulty, it becomes impossible to disengage the clutch. However, sometimes it continues to malfunction. If you do not replace the fork right away, you will have to replace the entire clutch assembly later.

Clutch VAZ 2107

The vehicle's handling largely depends on the serviceability of the VAZ 2107 clutch mechanism. How often this mechanism will have to be repaired is influenced by the quality of the roads and the driver’s experience. For beginners, as a rule, the clutch fails quite quickly, and repairing and replacing the unit is quite labor-intensive.

Purpose of the clutch

The main task of the clutch is to transmit torque from the engine to the drive wheels of the car.

The clutch serves to transmit torque from the engine to the main gear and protect the transmission from dynamic loads

Initially, it was intended for short-term separation of the engine and the main gear during smooth starting and gear shifting. The VAZ 2107 clutch has the following characteristic properties:

- has the smallest permissible moment of inertia of the driven disk;

- removes heat from rubbing surfaces;

- protects the transmission from dynamic overloads;

- does not require a lot of pressure on the pedal when controlling the clutch;

- It is compact, maintainable, quiet, easy to maintain and maintain.

The design and principle of operation of the VAZ 2107 clutch

Clutch VAZ 2107:

- mechanical (driven by mechanical forces);

- frictional and dry (torque is transmitted due to dry friction);

- single-disk (one slave disk is used);

- closed type (the clutch is constantly on).

When you press the pedal, the force is transmitted hydraulically to the pressure bearing, which releases the driven disc.

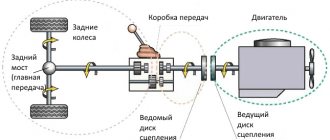

Cohesion can be roughly represented in the form of four components:

- driving or active part (crankshaft flywheel 6, basket with casing 8 and steel pressure disk 7);

- driven or passive part (slave or passive disk 1);

- inclusion elements (springs 3);

- shutdown elements (levers 9, fork 10 and pressure bearing 4).

The basket casing 8 is bolted to the flywheel, connected by damper plates 2 to the pressure disk 7. This creates conditions for transmitting constant torque from the flywheel through the casing to the pressure disk, and also ensures that the latter moves along the axis when the clutch is turned on and off. The driving part rotates constantly when the engine is running. The passive disk moves freely along the splines of the input shaft 12 of the gearbox. The hub is connected to the driven disk through damper springs 3 and due to this has the possibility of a certain elastic rotation. This connection dampens torsional vibrations that occur in the transmission due to engine operation at different speeds and corresponding dynamic loads.

When the pedal 5 is depressed, the passive disk 1, with the help of springs 3, is clamped between the flywheel 6 and the pressure disk 7. The clutch is engaged and rotates together with the crankshaft as a single unit. The rotational force is transmitted from the active to the passive part due to the friction that occurs on the surface of the friction linings of the driven disc, flywheel and pressure plate.

When pedal 5 is pressed, the hydraulic fork moves the clutch with the pressure bearing towards the crankshaft. Levers 9 are pressed inward and pull pressure plate 7 away from driven disk 1. Springs 3 are compressed. The active rotating part is disconnected from the passive one, no torque is transmitted, and the clutch is disengaged.

When the clutch is engaged, the driven disc slips relative to the smooth surfaces of the flywheel and pressure plate, so the torque increases gradually. This allows the car to move away smoothly and protects transmission components during overloads.

Clutch hydraulic drive device

The transmission of torque from the engine to the drive wheels is carried out using a hydraulic drive.

The clutch hydraulic drive transmits force from the pedal to the clutch fork.

The hydraulic drive plays an important role when starting the vehicle and changing gears. It includes:

- pedal;

- master and slave cylinders;

- pipeline and hose;

- pusher;

- clutch engagement and release fork.

The hydraulic drive allows you to smoothly engage and disengage the clutch without exerting much effort when pressing the pedal.

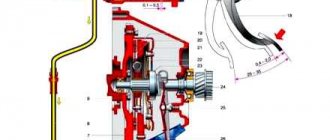

Clutch master cylinder

The clutch master cylinder (MCC) increases the pressure of the working fluid when you press the pedal. Due to this pressure, the clutch fork rod moves.

The clutch master cylinder converts the force from pressing the pedal into working fluid pressure, which moves the clutch on/off fork rod

The pusher piston 3 and the master cylinder piston 5 are located in the main cylinder body. The use of an additional pusher piston reduces the radial force on the main cylinder piston when the pedal is pressed. In this case, the sealing ring 4 is pressed against the walls of the cylinder mirror and improves the sealing of the pistons. To ensure tightness inside the cylinder, there is an o-ring 12 located in the groove of the piston 5.

For additional sealing of the piston, an axial hole is drilled in its guide part 9, connected to the ring groove by 12 radial channels. As the pressure in the working space of the GCS increases, it reaches the inner part of the ring 12 and expands it. Due to this, the tightness of the master cylinder piston increases. At the same time, ring 12 acts as a bypass valve, through which the working part of the cylinder is connected to the reservoir with the working fluid. When the pistons reach their extreme position at the plug 11, the sealing ring 12 opens the compensation hole.

Through this hole, when the clutch is engaged (when the RCS piston creates excess back pressure), part of the fluid passes into the reservoir. The pistons are returned to their original position by a spring 10, which at one end presses on the plug 11, and with the other on the guide 9 of the piston 5. All internal parts of the GCS are fixed with a retaining ring 2. On the mounting side, a protective cover is put on the GCS, protecting the working part of the cylinder from dirt. .

Most often, the o-rings on the master cylinder wear out. They can always be replaced from the repair kit. In case of more serious malfunctions, the GCS changes entirely.

If the compensation hole becomes clogged, excess pressure will be created inside the drive system, which will not allow the clutch to fully engage. She will slip.

Clutch slave cylinder

The clutch slave cylinder (CLC) is attached with two bolts to the gearbox housing in the area of the clutch housing. This arrangement of the RCS leads to the fact that dirt, water, and stones often get on it from the road. As a result, the protective cap is destroyed and wear of the O-rings is accelerated.

The slave cylinder is secured with two bolts to the gearbox

When you press the pedal, pressure is created in the clutch hydraulic drive, which is transmitted to piston 6. The piston, moving inside the cylinder, moves the pusher 12, which, in turn, turns the clutch engagement and release fork on a ball joint.

It is very important to observe the dimensions of the internal mirror of the main and working cylinders. When factory assembled, they are equal to each other - 19.05+0.025–0.015 mm. Therefore, the sealing rings on the pistons of both cylinders are completely interchangeable. If you need to make the clutch pedal softer, you need to buy a foreign analogue of the working cylinder with a smaller diameter of the working cavity. If the diameter is larger, then the pressure on it will be less. Therefore, in order to overcome the elastic force of the basket friction springs, greater force must be applied. Therefore the pedal will be tighter.

Composition of the VAZ 2107 clutch kit

The VAZ 2107 clutch kit consists of:

- baskets;

- driven disk;

- pressure bearing.

According to VAZ regulations, these elements are not repaired, but are immediately replaced with new ones.

Read how to bleed the clutch on a VAZ 2106: https://bumper.guru/klassicheskie-modeli-vaz/stseplenie/kak-prokachat-stseplenie-na-vaz-2106.html

Basket

The basket has the most complex device in the clutch kit. It consists of many parts that require correct and precise assembly. The basket is assembled only in factory conditions and is not repaired even in specialized car repair shops. If wear or serious defects are detected, the basket is replaced with a new one. Main cart malfunctions:

- loss of elasticity due to sagging springs;

- mechanical damage and fracture of damper plates;

- the appearance of wear marks on the surface of the pressure plate;

- kinks and cracks in the basket casing;

- other.

Usually the entire clutch is replaced, so the replacement kit includes a driven disc, pressure plate and pressure bearing

The service life of the clutch is determined by the life of the basket, driven disk or pressure bearing. Therefore, to avoid the cost of repeated repairs, the coupling is always replaced as a set.

Driven disk

The driven disk is designed to transmit torque from the engine flywheel to the transmission input shaft and can briefly disconnect the gearbox from the engine. The technology for manufacturing such disks is quite complex and requires the use of special equipment. Therefore, it is impossible to repair the disk yourself. It is replaced with a new one when:

- wear of friction linings;

- wear of the internal splines of the hub;

- detecting defects in damper springs;

- loosening the sockets under the springs.

Pressure bearing

The pressure bearing is designed to retract the pressure plate from the driven one and is activated when the clutch pedal is pressed. Its malfunctions are usually accompanied by whistling, knocking and other sounds. When the rollers jam, the supporting working surface or the seat in the cup wears out, the pressure bearing assembly is replaced.

Clutch selection

When purchasing a new clutch kit for the VAZ 2107, experts recommend being guided by the following criteria. When assessing the driven disk:

When choosing a basket, you should pay attention to the following points:

The most popular brands are the following.

The choice of clutch should be approached comprehensively and the choice should be made after examining the product and receiving expert advice.

labavto.com

If the car starts to slip under load, most likely the problem is in the clutch. It is dangerous to move with a faulty unit, so it should be changed as quickly as possible. The article provides detailed instructions on how to replace a VAZ 2107 clutch, which device to choose, and also includes a video demonstrating the process.

Clutch replacement

If the clutch begins to slip, it needs to be replaced. It is more convenient to do this on a lift or overpass. As a last resort, you can use a jack with mandatory protective stops. To replace you will need:

Removing the gearbox

When replacing the clutch on a VAZ 2107, the gearbox does not need to be completely removed, but only moved enough so that the input shaft disengages from the basket. However, most often the box is completely dismantled. In addition to convenience, this allows you to check the condition of the crankcase and seals. The gearbox is removed as follows:

Removing the disc basket

After dismantling the gearbox, the basket with the disc is removed in the following order.

Removing the release bearing

After the basket, the release bearing is removed. This is done as follows.

After removal, the retaining ring is checked for damage and, if necessary, replaced with a new one. If the ring, unlike the bearing, is in good condition, it can be reused with a new bearing.

Installing the drive cage

With the clutch and gearbox removed, the condition of all exposed components and parts is usually checked. The disc and flywheel mirrors should be lubricated with a degreaser, and CV joint-4 grease should be applied to the shaft splines. When installing the basket, you should pay attention to the following points.

Why is it impossible to bleed the clutch of a VAZ-2107

The reason why you cannot bleed the clutch on a VAZ 2107 may be:

This condition of the clutch cylinders can cause unsuccessful bleeding. It will block the fluid supplied to the working cylinder installed on the gearbox

- clogging of the hydraulic circuit;

- malfunction of the hydraulic drive cylinders;

- bending of the hose or circuit tube;

- air intake from outside.

To solve the problem, you need to inspect the circuit for kinks and/or leaks. If they are, the hose or tube should be corrected/replaced. If not, try to blow out the circuit and change the fluid. To do this, you need to open the fitting, drain the old fuel fluid by pumping or pressure, unscrew the fitting completely and blow out the circuit with a pump or compressor.

To make the connection, you can use a tank plug with a hole into which the tubeless tire nipple is inserted. This cap must be screwed on instead of the original one, connected to a pump or compressor and supplied with air pressure. It will blow out all deposits through the fitting hole.

Then you need to screw in the fitting, fill in fresh fluid and pump the circuit according to the instructions. Bleeding the clutch on a VAZ 2107 should be done using one of the methods described above. If this does not help, you need to diagnose the cylinders and replace the faulty part with a new one.

How to change the clutch disc on a VAZ 2107?

Many VAZ 2107 car owners carry out repair work on their car on their own. And the clutch mechanism is no exception. Although this task is labor-intensive and cannot be called simple, the owners of 2107 have long learned to do it on their own. Today we will tell you how to replace the clutch disc of a VAZ 2107: the video will be presented at the end of the material.

The clutch in a vehicle plays the role of ensuring smooth gear shifting by briefly disconnecting the VAZ engine from the transmission system. It is precisely because the car has a clutch that it can move off smoothly without overloading the engine and helping to increase the service life of most of its elements. This includes the gearbox itself.

VAZ 2107 car

Adjusting the clutch of VAZ 2107, 2105, 2104 cars

Correct and precise operation of the clutch on VAZ 2107, 2105, 2104 vehicles is ensured by certain adjustments to its drive. There are two of them: adjusting the gap between the pusher and the piston of the clutch master cylinder and adjusting the free play of the clutch pedal.

Adjusting the clutch drive of a VAZ 2107, 2105, 2104

— Adjusting the gap between the pusher and the piston

The gap between the pusher and the clutch master cylinder piston is 0.1 - 0.5 mm. It is regulated by rotating the clutch pedal free travel limiter. In this case, a certain free play of 0.4 - 2.0 mm is formed at the clutch pedal, which the driver selects when starting to press the pedal.

The gap between the pusher and the piston, free travel of the clutch pedal for VAZ 2104, 2105, 2107

It is measured with a ruler or tape measure, which is installed from the floor to the middle of the lower part of the pedal platform. We move the platform with our hand relative to the ruler scale by pressing the pedal. If there is a gap, at first the pedal moves very easily, and then with difficulty. If there is no gap, turn the pedal travel limiter out a little. We ensure that the free movement along the ruler fits within the required two millimeters.

This gap is necessary for the clutch to disengage completely. If it is missing, then the piston will not be able to fully return to the rear position when the pedal is released and in the working cavity of the master cylinder, and excess pressure will remain in the entire drive. As a result, the clutch will not disengage completely, since the release bearing will press on the leafs of the pressure spring, and the discs will slip (not be fully pressed against the flywheel). Increasing this gap will lead to the fact that the clutch will not disengage completely and will “drive” (the discs do not fully move away from the flywheel).

— Adjustment of clutch pedal free play

(the gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring)

It is adjusted by a nut on the clutch slave cylinder pusher. With proper adjustment, the free play of the clutch release fork is 4–5 mm (checked by hand: the fork is pulled away from the stop against the adjusting nut on the pusher), and the free play of the clutch pedal is 25–35 mm. It is necessary to unscrew the lock nut on the pusher and rotate the adjusting nut to set the required free play of the fork. The pedal free play of 25 - 35 mm (until the clutch is disengaged) can be checked using a ruler. It is this value that means there is a gap between the release bearing and the plane of the pressure flange of the clutch “basket” pressure spring.

Free movement of the clutch slave cylinder pusher for VAZ 2104, 2105, 2107 cars

In the absence of this gap, the release bearing presses on the pressure spring of the “basket” - the clutch “slips”. With an increased gap, it “leads.”

The clutch pedal free play of 0.4 – 2.0 mm is included in the pedal free play of 25 – 35 mm. That is, 25 - 35 mm is the total required size.

Notes and additions

— The clutch on VAZ 2104, 2105, 2107 cars is of a constantly closed type, that is, constantly engaged: when the pedal is released, the driven disk is pressed by the drive to the flywheel and rotates with it, as well as the release bearing and the input shaft of the gearbox. There is a gap of 1.5 - 2.0 mm between the release bearing and the lining of the thrust flange of the clutch basket pressure leaf spring. This gap is selected when the driver begins to press the pedal.

— The full travel of the clutch pedal on VAZ 2104, 2105, 2107 cars is 140 mm.

— After adjusting the clutch drive, check for smooth gear shifting. Particular attention to reverse gear. The smoothness of its activation is an indicator of successful adjustment.

Clutch disc cost

How much does it cost to replace a clutch disc (hereinafter referred to as DS)? This question was probably asked by every car owner who encountered a breakdown of this element. We will try to give you the most current figures, those that are found on the market.

Today, on the Ukrainian car market it is quite possible to purchase a domestically produced DS for 2107 for an average of 210 hryvnia. If you're lucky, you'll find it cheaper. But, depending on the stores, this price can vary and reach 250 hryvnia.

In Russian car stores this element costs about 500 rubles. This cost is average, so you can find DS both cheaper than this price and more expensive (mostly up to 700 rubles).

We make a replacement

If you decide to change the element yourself, but do not have enough knowledge and experience to do this, then it does not matter. Many motorists use the instructions on our website when carrying out certain repair work for the first time - and most of them are satisfied with the results. Even if you have never changed this element, just follow the instructions and you will succeed. But if you are not confident in your abilities and open the hood of the car only to add washer fluid to the expansion tank, then it is better to entrust this matter to specialists.

New DS for VAZ 2107

When do you need to change the DS? This may be needed in several cases:

The process of replacing the DS involves dismantling the gearbox. However, we have a simpler option. We will look at the process of changing the clutch component without removing the transmission.

Sorry, there are no surveys available at this time.

What will you need?

Prepare everything you may need during the repair process, namely:

We will need rags and gasoline to lubricate the DS, and a mandrel to center it. It is not expensive and is sold in any car store. When replacing the DS, this point is very important, since the new element necessarily requires alignment. Having collected everything you need, you can start working.

Replacement instructions

If you decide to replace the DS yourself, then you will need the help of another person. You need to drive onto a hole or overpass, otherwise the repair will not be possible.

Important: do not forget to center the disk when it is already installed. To do this, use a special mandrel. If the DS is installed correctly on the mechanism, the mandrel will move freely into and out of the bearing when the basket mounting bolts are tightened. Don’t forget to also coat the gearbox input shaft splines with a thin layer of lubricant. Don't forget to also adjust the pedal free play.

Replacing the Clutch of a VAZ 2107 Injector

You can leave your wife, your job, your homeland, but don’t you dare leave the clutch!

The clutch system is a fairly simple mechanism that not only serves as a transmission link between the engine and gearbox, but also removes excess load from both of these units. Of course, such work is not in vain for the clutch system itself, but that’s why it contains consumables, so that you can spend money on replacing them, and not on a global car repair.

The clutch system's job is to mechanically connect the engine to the manual transmission when needed, and disconnect them when it is necessary to change gears. In essence, the task of the clutch does not change, whether it is a clutch on a VAZ 2107 or a Lexus, only the technical details differ.

Tips and recommendations for replacing the VAZ 2107-2101 clutch

The most important advice is to use only original numbered spare parts during this procedure. Even during repair work to repair or replace individual elements of the system, it is also worth using exclusively high-quality parts. This will not only help to avoid problems with breakdowns in the future, but will also not hit the owner’s wallet too hard, because the overpayment for a high-quality spare part when owning an AvtoVAZ car is insignificant compared to a cheap analogue.

Also, when carrying out these works without dismantling the box, a prerequisite is the presence of a hole in the garage or a lift, since the narrow cramped space under the hood will actually not allow work to be done from the top of the car.

Which clutch is better to choose for a VAZ 2107-2101

There are many samples of various auto parts manufacturers on the market. In some cases, the seats for the main system may differ, because for the VAZ model, when replacing the VAZ 2105 clutch, units from other classic models of domestic manufacturers are suitable. In addition, the manufacturer continues to produce spare parts.

However, in addition to various replacement models, there are also a large number of counterfeit products on the market, which in their geometric parameters correspond to original spare parts, but their technical characteristics do not stand up to criticism.

The most reliable purchase option. products of the manufacturer AvtoVAZ, which can be easily checked on information resources by serial and serial number. Such products are the least counterfeit; at a higher cost compared to competitors, the likelihood of running into a fake is less. Also, official suppliers of components for the plant itself have a reputation for reliable units, because for some models, from VAZ 2101 to VAZ 2103, the plant stopped producing spare parts, transferring this function to contractors.

When carrying out repair work on the clutch assembly, these components can also be checked on the VAZ 2107 for identification numbers, which makes the purchase safer. With proper care and a calm driving style, original spare parts are quite capable of overcoming the threshold of 100 thousand kilometers or more than 5 years of operation without any repairs.

In addition, simple rules for purchasing both the entire system and its individual parts:

Official manufacturers also, in addition to high-quality assembly, have various marks in the form of embossing or stamping of the batch, company logo or other identification marks.

In addition to domestic suppliers, classic models are suitable for products of some foreign manufacturers, for example, Luk or Valeo. Such products are also very popular, despite their high cost. However, at a high price, the service life of these units is incomparably higher, and the likelihood of technological defects is much lower compared to domestic competitors. At the same time, foreign units are also very popular with unscrupulous manufacturers, so the choice of such products must be approached very carefully.

READ How to Remove a VAZ 2107 Beard

Basic faults

It should be noted right away that the driven disk and release bearing are consumables, the long service of which should not be counted on. The integrity of the flywheel is much more important; its price is much higher and replacement is more difficult.

The main clutch malfunctions on a VAZ:

Difficult gear shifting means that the clutch does not disengage completely, that is, the driven disc continues to turn when the pedal is pressed. There may be several reasons for this situation:

Once the cause has been found, you can solve the problem: replace the driven disk, troubleshoot the input shaft, install the release bearing at the required distance from the clutch basket, add hydraulic fluid and bleed the system.

Clutch slipping is the asynchronous movement of the flywheel and driven disk when the clutch is fully engaged (when the pedal is not pressed). Causes:

Depending on the problem, the solution will be appropriate: checking and replacing oil seals from which oil may leak, adjusting the clutch, repairing and cleaning the master cylinder.

Jerking and vibration when the clutch operates is a rather unpleasant sign. Possible causes of jerking when moving:

With such a problem, diagnostics is needed. In the best case, everything can be done by replacing the driven disk; in the worst case, the entire clutch will have to be changed.

If, when engaging or disengaging the clutch, you hear grinding, rattling, knocking and other sounds that should not be there, this may be a manifestation of the following problems:

After diagnosis, broken parts must be replaced with new ones. If the problem is in the spline connection of the driven disk, it is necessary to check the condition of the gearbox shaft.

And finally, if you release the pedal and the clutch does not engage, the reason must be sought in the hydraulics:

The easiest way is to add fluid to the reservoir and bleed the clutch system. If the problem is not solved, it is necessary to dismantle the master and slave cylinders and replace the repair kits.

Why it stalls - reasons and their elimination

The clutch usually slips due to the following:

- There is no gap between the pressure bearing and the fifth basket;

- the clutch drive is not adjusted;

- oil gets on the discs;

Depending on the cause of this problem, the repair progress is determined. If the problem is with the diaphragm spring, it will have to be replaced with another one. When the friction linings wear out, the driven disk is replaced. When repairing/removing linings, the gaskets are checked. If they are in poor condition, they are also replaced with new ones. If oil gets on the driven disc, you will need to treat it with kerosene and clean it with fine sandpaper.

Disc oiling

Grease may get on any side of the flywheel and pressure plate due to an increased oil level in the gearbox housing or a leak in the rear crankshaft bearing. To solve the problem, diagnostics are performed and the cause of the leak is eliminated - the seals are replaced, then the spare parts are cleaned.

Read, it may come in handy: Polyurethane silent blocks in the suspension

The free stroke according to technical conditions is 30-35 mm, the full stroke is 140 mm. Any deviation from the norm is associated with a malfunction of the transmission and requires adjustment work. The parameter is checked using a ruler. To do this, determine the distance from the pedal to the center of the platform. The adjustment is made on a pit or lift using open-end wrenches 13 by 17 mm and 17 by 19 mm. We clean the adjusting rod and nuts with a brush and treat them with WD-40. Next, the lock nut is loosened, and by rotating the adjusting nut we change the gap. If the free play needs to be reduced, we lengthen the thrust; if it is increased, we shorten it. After completing the work, tighten the locknut.

Damaged release clutch

Replacing the clutch basket

Replacing the basket is done less frequently than replacing the driven disk. The basket needs to be changed if the drive disk overheats (then colored spots appear on it), breakage or wear of the diaphragm blades and springs. To access the clutch, you need to remove the gearbox.

When dismantling the clutch itself, you need to unscrew the basket bolts from the flywheel. To distribute the load evenly, the bolts are unscrewed 1-2 turns in turn. After removal, the basket must be inspected for wear of the disk, integrity of the springs, and diaphragm.

Replacing the VAZ clutch cable

VAZ cars have both front- and rear-wheel drive, and they also have different clutch drives. If all VAZ-Classic cars have a hydraulic drive, then in many cars with front-wheel drive (2108-2115) the release is controlled by a mechanic, and the control element is a cable. Like all parts, the clutch cable (TC) wears out over time and must be replaced periodically. Reasons for car failure:

READ Kalina Car Doesn't Start What's the Reason

If the car itself is intact, but the clutch , you can try to lubricate the cable. Litol or another lubricant is suitable as an oil, but it should be noted that this is a temporary measure, and you still need to prepare for replacing the VAZ clutch cable. Changing a car on a Lada 2108-2115 is very simple:

In order to remove the car, we pull it into the engine compartment, then install a new part, adjust the cable tension with the nuts on the bracket.

VAZ 2115

If there are slight design differences between the VAZ 2109 and VAZ 2114 in the power unit and transmission, then in the engine and transmission parts there is absolutely no difference between 2114 and 2115, the cars differ only in the body:

Accordingly, replacing the VAZ 2115 clutch is carried out in the same way as on a VAZ 2114 car.

Replacing the clutch disc

The driven disc is a consumable that must be worn out for the rest of the clutch to work properly. Problems with the driven disk are wear of the friction linings, damper springs, and splined connection to the gearbox shaft. When inspecting, you need to pay attention to the condition of the rivets (they should not protrude above the surface of the friction circle), the presence of cracks, rust in the center, and traces of oil. And an important sign of a problem will be a burning smell - the friction material is burning due to clutch slippage.

Experts recommend choosing the clutch basket and driven disc from the same manufacturer. It often happens that the friction material and, for example, the power of the basket springs are specially selected according to parameters to give the optimal effect. This is where many fans of a sporty driving style make a mistake when they install a three-leaf driven disc without replacing the remaining clutch elements.

Simultaneously with replacing the clutch, it is necessary to check the crankshaft oil seal. Servicemen often recommend changing it at the same time as the clutch disc, “so as not to have to get up twice.”

When installing the clutch on the flywheel, the driven disk is centered using a special mandrel, which is inserted into the flywheel bearing. After this, the basket is installed on the guide pins so that the mounting holes on it and the flywheel match. As with dismantling, the bolts are tightened one at a time, each one needing to be tightened 1-2 turns at a time. After this, the mandrel for centering the driven disk can be removed.

Lubricate the gearbox shaft before installation, then install the gearbox. Next, the sequence of actions is the reverse of removal.

Replacing the master and slave cylinders

The master cylinder creates pressure in the hydraulic system, transmitting force from the pedal pusher to the working cylinder rod. It lasts a long time, and the repair kit often requires replacement, rather than the cylinder itself. The slave cylinder serves to transmit force to the clutch fork pusher. Hydraulic fluid from the master cylinder presses against the piston in the slave cylinder and operates the fork.

Their malfunctions are manifested by dips or tight movement of the clutch pedal, difficult operation of the gearbox (gears are switched with a crunching sound, vibration). Visually, a problem with the main or working cylinder can be seen by fluid leaks.

The clutch cylinder is replaced if the “mirror” of the cylinder or its other elements are damaged, which happens quite rarely. Replacement parts wear out much more often, and then you can simply install a new repair kit.

Replacing the master cylinder, video

The master cylinder is located next to the brake booster, below the brake reservoir. Its dismantling is done in the following order:

After dismantling, you need to inspect the cylinder for wear of metal parts and rubber gaskets. If necessary, replace the repair kit or install a new cylinder. Installation is done in reverse order.

Replacing the working cylinder, video.

The slave cylinder is located next to the gearbox, on the clutch housing. It can be accessed both from below and from the engine compartment. Dismantling procedure:

Often, problems with the drive are caused by low-quality hydraulic fluid. When working, pay attention to its color and consistency. Often wear products accumulate in the liquid and they begin to act as an abrasive.

How to adjust the clutch on a VAZ 2101-VAZ 2107?

Introduction! Before you start adjusting, you need to explain in more detail how the clutch is adjusted; for this, read the important information below:

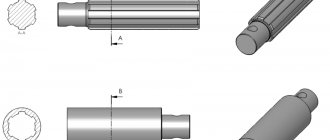

Firstly, the clutch can be adjusted from inside the car; for this purpose, a bracket is installed on the clutch pedal itself, on which a pusher (indicated by the letter “A”) of the clutch master cylinder is installed, and due to this pusher and the nuts located on it, the clearance can be adjusted between the pusher itself and the clutch master cylinder piston.

Note! From inside the car, the clutch is adjusted only for the initial free play of the pedal, that is, the initial free play of the clutch pedal should be “0.4 - 2.0 mm”, if it is less or there is none at all, then adjust it using the pusher nuts indicated under the letter "A" in the photo above!

Secondly, the clutch is adjusted from below the car, but in this case you need to measure the free play of the clutch fork pusher, which is indicated by the letter “B”, and it is adjusted within the range of “4 - 5 mm”.

Replacing the clutch on a VAZ 2107 car

Any VAZ 2107 car owner, when driving his car, must be sure that it is in full working order. Problems with such an important mechanism as the clutch will primarily affect the quality of the braking system. That is why if you notice that the gears suddenly begin to shift with force, immediately check the condition of the clutch. If necessary, it must be urgently replaced.

Preparatory work

In order to replace the clutch on a VAZ 2107, you will need access to the gearbox and engine from below, so you need to use a special lift or a so-called inspection hole. Before starting work, be sure to remove the negative terminal from the battery and you can proceed.

First remove the air filter and unscrew the starter.

Now we can work on the gearbox on the VAZ 2107. We will need to dismantle its lever. We will not remove the box itself. Press it with a screwdriver and pull out the locking sleeve located in the groove of the lever rod. You can take it out, unscrew the bolts and dismantle the front floor.

Classic step-by-step instructions for replacing the VAZ-2107 clutch

In various blogs you can find proposals from craftsmen for quickly replacing the clutch on a VAZ-2107, but experts do not recommend experimenting. The machine is a structure with a complex structure, so manipulations that do not comply with traditional generally accepted repair technology can lead to breakage of other parts.

The factory mechanism of the VAZ-2107 is equipped with a carburetor; the car is equipped with an injector independently. Instructions for replacing the VAZ-2107 carburetor clutch consists of the following sequential steps:

- Find the terminals on the battery and carefully remove them. You cannot leave components in their place, otherwise this may cause a short circuit.

- Set aside the mats and other coverings located inside the car on the floor, near the gear lever. Disconnect the shift knob from the transmission. This is not difficult to do if you know a little secret - press the part down and, using a screwdriver with a thin tip, pry the white plastic sleeve and pull it out.

- Take a position under the car - it is recommended to carry out repair work yourself when the car is driven into a viewing hole or raised onto an overpass.

- Assess the condition of the components being removed, how worn they are, whether there are any defects or damage, chips, or cracks. Pay special attention to the clutch master cylinder, it can also fail, but sometimes just installing a new clutch cable is enough.

- Unscrew the exhaust pipe from the resonator. Disconnect the working cylinder of the clutch mechanism from the VAZ-2107 gearbox housing. You should not take the simple route of removing the hose through which the coolant is supplied; as a result, air will penetrate into the system and everything will end with mandatory bleeding.

- Remove the cardan from the gearbox fasteners, unscrew the nuts and bolts that secure the wiring.

- Remove the 2 bottom nuts that secure the transmission to the engine block. Do the same with the bolts securing the starter to the gearbox.

- Finally, you can remove the gearbox, it is better if you have an assistant nearby. Pull the box slightly towards you, but do not overdo it, the work must be done carefully.

- Remove the clutch basket. If you need to replace the disk, remember which side it should be against the surface.

- After the device is completely disassembled, proceed with the installation of new components. If the part is very worn out, but is not yet falling apart, you still need to replace it; don’t go cheap trying to save an extra 200 rubles.

- If the antennae on the basket are broken, your task is to rivet new ones. Wear and tear always occurs from the inside, so examine the interior carefully. It is customary to check the condition of the disk based on the geometric parameters stated in the instructions for use of the VAZ-2107.

- Assembly is carried out in the reverse order of these instructions. When fixing bolts and nuts, give preference to tight and reliable connections. For best results, apply transmission oil or nigrol to the bolts and nuts. Regular oil should not be used under any circumstances, it burns out quickly and it will be impossible to unscrew the fasteners later.