To maintain optimal operation of the power unit in any car, many sensors and regulators are used. The domestic “Sevens” were no exception. What functions do the VAZ 2107 fan switch sensor and antifreeze temperature sensor perform, how to check and replace these devices? You will find the answers below.

Purpose of the temperature sensor VAZ 2107

The sensor monitors the temperature of antifreeze in the main cooling radiator of the VAZ 2107 and transmits the signal to the dashboard. In its lower left corner there is a dial indicator for the antifreeze temperature.

Sensor showing coolant temperature VAZ 2107

If the temperature rises above 95 degrees, this means only one thing: the cooling system is not doing its job and the engine is close to overheating.

The temperature sensor of the VAZ 2107 transmits a signal to the dashboard

Replacing the antifreeze sensor on a VAZ 2107

First of all, it should be said that the temperature sensors on the VAZ 2107 cannot be repaired. The reason is simple: this device does not contain parts and materials that the driver could purchase and replace himself. In addition, the body of the temperature sensor is not dismountable, so it is simply impossible to get to the insides of this device without breaking it. Here's what you need to replace it:

- new temperature sensor VAZ 2107;

- 30mm socket with a long wrench (or a regular spark plug wrench);

- container for draining coolant.

Sequence of operations

- The car is placed on a viewing hole or on an overpass. Place a container under the drain hole, unscrew the plug, and drain the antifreeze.

A small basin is ideal for draining antifreeze from a VAZ 2107 - The contact wires are removed from the sensor. They must be carefully pulled towards you.

The red arrow shows the contact cap of the VAZ 2107 sensor - The sensor is unscrewed with a socket by 30 (remember that under the sensor there is a very thin o-ring that can be easily lost).

- A new one is screwed in place of the unscrewed sensor (and when screwing in a new sensor, you should not use too much force, especially if the driver of the socket head is very long: the thread in the sensor socket is easily torn off).

- The cap with the contact wires is put back on the sensor, and new antifreeze is poured into the expansion tank.

Video: replacing the coolant sensor on a VAZ 2107

Temperature sensors used

A coolant temperature sensor is used to inform the driver about the thermal state of the engine. It sends a signal directly to the instrument panel. If the temperature is close to critical, the driver has the opportunity to find out about it in time and take preventive measures.

The fan switch sensor is used to maintain the normal thermal conditions of the power plant. It ensures that the motor temperature is within a narrow range. Failure of the meter can result in engine overheating and antifreeze boiling.

The fuel temperature sensor is not present on all VAZ 2107 cars. Cars with a carburetor do not need this meter. On the VAZ 2107, the injector fuel temperature sensor appeared in 1995. Outside air and interior temperature sensors are not included in the basic configuration of the VAZ 2107. Therefore, car owners independently upgrade their cars by supplementing them with the listed meters.

For injection system

Forced fuel supply in the "seven" for the Russian market began to be used in 2006. In these car models, the fan operation and other functions are performed by the ECU. On the VAZ 2107 injector, the signal about the antifreeze temperature comes from the coolant temperature sensor, which is located on the right side of the engine cylinder block.

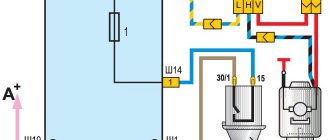

The data is processed by the ECU, which outputs a signal to the control relay to turn on the cooling - circuit diagram. The fan switching sensor is not needed on VAZ 2107 injection systems; it is replaced by a thermistor sensor, and control functions are assigned to the controller.

In any “seven”, to protect the fan from short circuit, there is a fuse F7 located in the mounting block.

Operation of the coolant temperature sensor for the injection system

Usually, turning on the fan on a VAZ 2107 is accompanied by a noise that the driver hears while sitting behind the wheel. A prolonged absence of sound from the device when driving around the city in the summer may indicate a malfunction in the cooling system, which can lead to antifreeze boiling and damage to engine components. The driver must react quickly to such defects so as not to spoil the “heart” of his car.

One of the possible malfunctions in the engine cooling cycle may be a breakdown of the coolant temperature sensor. In addition to the cooling system, it is responsible for the correct supply of the air-fuel mixture to the engine and its inclusion in idle mode.

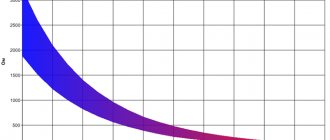

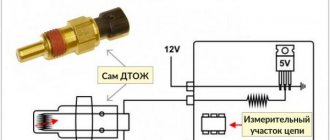

The sensor that affects the operation of the VAZ 2107 injector fan consists of a semiconductor thermistor with two terminals, soldered into a housing with a thread that is screwed into the wall of the cylinder block. A constant voltage of 5 V is supplied to the device. As the temperature of the antifreeze increases, the resistance of the thermistor decreases and vice versa. At the input to the computer, passing through a resistor, the voltage drops as the coolant temperature increases to a certain level, after which the controller gives a signal to turn on the cooling.

How to check and install a new one

Checking the sensor responsible for turning on the fan does not require much effort. The following signs may serve as grounds for verification:

- The “Check Engine” light on the instrument panel is on.

- The fan operates continuously or is turned off.

- Low idle torque.

- Coolant overheating.

The cause of the malfunction may be outdated wiring. To find out for sure, you need to check it, and then move on to the sensor.

For this:

- The negative cable of the battery is disconnected.

- On a cold engine, the antifreeze drains to a level below the temperature sensor socket.

- The protective layer is shifted and the wiring from the temperature sensor is disconnected.

- Use a key to unscrew the sensor from its socket.

Next, check using a multimeter and boiled water. The multimeter is connected to the outputs of the temperature sensor and set to resistance measurement mode. The threaded side is placed in boiling water. If the resistance tends to zero, then the sensor is working. Otherwise, if increased resistance readings appear, the sensor requires replacement.

To replace it, it is better to purchase the same model that was installed when purchasing the car. Installation of a new sensor occurs similarly in the opposite direction.

Types of sensors

Sensors are divided into types. Previously, electromechanical devices were installed, later electronic ones began to be used.

Electromechanical model

They are represented by a large body made of a thick layer of steel. Inside there is a chamber with ceresite, covered with a membrane that reacts to rising temperatures. This design is the sensitive element.

Next to the membrane there is a pusher, which, when heated, moves upward, which provokes the closure of the system of moving contacts. The arrow points to the corresponding indicators.

Electronic view

This temperature sensor for the VAZ 2107 is relevant for new models. Here the thermistor acts as a sensitive element.

When heated, the resistance changes, which is recorded by a certain circuit. From it the signal is sent to the control panel.

Where is the switching temperature located?

The fan switching sensor is located on injection models, on the aluminum outlet pipe of the cylinder head (article - 23.3828, used in VAZ-2107i-2112, 21213, 2123, ALFA ROMEO, DAEWOO, FIAT, LANCIA, OPEL), on carburetor models (TM 108 -02 92/87 C) it is installed on the engine cooling radiator.

For the “classic” fan, the operating temperature is 92 degrees and the shutdown temperature is 87 C0, so installing a fan that is suitable in size, but with a different number, is not recommended.

On carburetor models the sensor is located on the radiator

Description of the coolant temperature controller

The temperature sensor is a resistor element that performs the function of transmitting and receiving data about the temperature of the consumable in the cooling system. As the temperature increases, the sensor's resistance changes, causing it to supply voltage to the instrument panel. The latter has an indicator that shows to what temperature the car’s power unit has warmed up. Where is DTOZH located? The device is located on the cylinder head, behind the fourth cylinder.

In injection machines, the DTOZh gives the ECU temperature readings, and the ECU turns on the fan itself, the fan switch on sensor, as a rule, is a power sensor, closes the contacts at a certain temperature - turns on the fan relay and is located mainly on the radiator (in a carburetor car), since the DTOZH is located on the engine.

Principle of operation

The principle of operation of DTOZH is the constant interaction of a magnetic field (constant) with the field of measuring devices. Voltage passes through all windings. The permanent magnet is connected to the indicator located in the dashboard. When the temperature changes, the resistance parameter of the device also changes, which leads to the oscillation of the needle.

Possible problems and methods for eliminating them

What malfunctions can occur in the operation of the device:

- The sensor has failed. This problem can be solved by replacing the controller with a functional one.

- The contact on the connector connecting the device to the on-board network is damaged. Also, the contacts may be oxidized. In case of such a malfunction, you can try to clean the contacts, but if their damage is very severe, then it is better to replace the connector.

- The device may stop working due to a damaged electrical circuit. It is necessary to diagnose the condition of the wiring with a tester; if the circuit is truly damaged, then the faulty section must be repaired or replaced.

Regulator diagnostics

To check functionality, you need to perform the following steps:

- First you need to warm up the power unit so that the temperature of the internal combustion engine increases to 90 degrees. After this, the engine can be turned off.

- Next, the ignition is activated and the car's capo opens.

- You need to disconnect the tip of the wire with the measuring device, and then short it to the motor housing.

- If, as a result of the actions performed, the sensor arrow on the control panel began to deviate to the right, entering the red zone, this indicates a breakdown of the controller. If the arrow does not move, then most likely there is an open circuit in the connection circuit.

The easiest way to check for an open circuit: on a working engine, remove the chip from the DTOZH, if everything is normal and there is no break in any circuit, then the fan will turn on at maximum speed (video shot by Dmitry Makarov).

Fault diagnosis

The indicator on the panel signals you about overheating (boiling) of the engine, but according to external signs, the heating of the engine is quite normal, and there is no sign of boiling, perhaps the sensor (DTOZH) is simply lying. The situation is much worse when the engine “boils”; the indicator on the control panel shows normal temperature, the reason is the same, you just need to wait for the engine to cool down and add fluid (it’s good if you have some in stock). So:

- If you suspect that the controller (DTOZH) on your VAZ 2107 car is giving unreliable readings about the heating of the liquid in the cooling system, then you need to check its operation on a heated engine.

- Turn on the ignition, remove the wire tip from the liquid temperature meter and connect it to the engine body.

- If at the same time the arrow of the heating indicator located on the dashboard deviates to the right, right up to the red zone, this means that the cooling system fluid temperature meter (abbreviated DTOZH) is faulty.

- If the arrow does not move, this means an open circuit.

The temperature (heating) indicator of the cooling system fluid on the instrument panel (Photo below) is located in the lower left part.

- White sector – cold engine;

- Green sector – normal temperature of a running engine;

- Red sector – the engine has boiled (overheating).

Tools

- A 21mm socket wrench or a 21mm deep socket, a spark plug wrench will also work

- Container for draining liquid from the cooling system

- New meter

Temperature sensor malfunctions

There are two reasons why the sensor may not transmit a signal to the dashboard. Here they are:

- The fuse responsible for the temperature sensor has blown (the sensor itself may be working properly). To understand that the problem is in the fuse, the driver will have to look under the steering column, into the fuse block of the car. A burnt fuse will be immediately visible: it usually melts slightly and turns black;

Sometimes the sensor does not work due to a blown VAZ 2107 fuse - The temperature sensor itself has burned out. As a rule, this occurs due to a sharp voltage drop in the vehicle's on-board electrical network. The cause of such a jump may be a short circuit in the electrical wiring. The fact is that the insulation of wires on the VAZ 2107 has never been of high quality. Over time, it becomes unusable and begins to crack, which ultimately leads to a short circuit.

Important nuances

There are several important points that cannot be left out. Here they are:

- The above sequence of replacing the sensor with completely draining the antifreeze is not always used. Experienced car enthusiasts do it simpler: they unscrew the faulty sensor, then clamp the drain hole with their finger. This action requires a fair amount of skill. But even if you do everything very quickly, some of the antifreeze will inevitably spill out and you will still have to top it up;

Sometimes car enthusiasts do not drain the antifreeze from the VAZ 2107 when replacing the sensor

- When going to the store to buy a new temperature sensor, you should remember: you can now find both electromechanical and electronic temperature sensors on sale. It is better to choose electronic ones, despite the fact that they are more expensive than electromechanical ones (a good electronic sensor costs 500 rubles, and an electromechanical one - 300). The logic of choice is simple: the fewer moving parts there are in the sensor, the longer it will last.

So, replacing a temperature sensor is not a very difficult task. Even a novice car enthusiast can handle it if he has held a wrench in his hands at least once in his life. By precisely following the steps outlined in this instruction, the car owner can save about 700 rubles. This is how much it costs to replace a temperature sensor at a car service center.

Copywriter with five years of experience.

Cost of sensors

VAZ 2107 temperature sensors have an attractive price. Their low price is due to the simplicity of the design, inexpensive production process and the absence of the need to use expensive materials. Therefore, if any meter does not work, you need to check it and, if necessary, replace it. The table below shows approximate prices for sensors.

Table - Cost of temperature sensors VAZ 2107

| Sensor | Cost, ruble |

| Fan switch sensor | 300-450 |

| DTOZH | 370-500 |

| Outdoor temperature sensor | 340-700 |

| DTS | 240-500 |

| Fuel temperature sensor | 450-800 |

Cooling fan sensor

Sensor (controller) for turning on the fan

If the arrow of the indicator indicating the heating of the coolant, located on the dashboard, is in the red sector of the scale, and the electric fan does not turn on for additional cooling of the engine, then you need to check the serviceability of the fan sensor. So:

- To check it, turn on the car's ignition and short-circuit the ends of the wires that go to the fan switch control.

- If the forced cooling electric fan does not turn on, this means that the fan motor itself is faulty.

- If the fan turns on, this indicates a malfunction of the fan switch controller.

We wait until the engine cools down, and only then can we go for a new indicator or fan.

Removing the Fan Controller

All you need from a tool is a 30mm wrench and a container to collect coolant from the system:

- We drive the car onto an overpass or inspection hole

- Removing the terminals from the battery

- Draining the coolant from the radiator

- Disconnect the wire ends from the fan controller.

Remove the wire ends from the fan controller

Using a 30 key, unscrew the fan switch. We take out the fan controller.

Attention: there is a copper sealing ring on the fan switch, be careful not to lose it.

We take out the fan switch controller along with the sealing copper ring

- To check the serviceability of the new fan switching controller, connect the tester probes to its contacts, lower the threaded part of the controller into a container filled with water

- We heat the water and, using a thermometer, check the temperature of the opening and closing contacts of the fan switch controller

- The working controller temperature corresponds to 87 and 92° Celsius

Install the fan switch sensor:

- Install the fan switch in the reverse order of removal

- We pour the coolant we drained through the radiator

That's all, as you can see, the procedure is very simple, you don't even need a training video.

Checking the temperature sensor of the VAZ 2107

To carry out the test we will need the following tools:

- household multimeter;

- container with water;

- household boiler;

- thermometer;

- temperature sensor removed from the car.

Test sequence

- The sensor is lowered into the prepared container so that its threaded part is completely under water.

- A thermometer and a boiler are lowered into the same container (you need to make sure that these tools do not come into contact with each other).

- The multimeter contacts are connected to the sensor contacts, and the multimeter itself is configured to measure resistance.

- The boiler is plugged in and the water starts heating.

- When the water reaches a temperature of 95 degrees, the sensor resistance shown by the multimeter should disappear. If this happens, the sensor is working. If at the above temperature the resistance on the multimeter does not disappear, the sensor is faulty and needs to be replaced.

Video: checking the antifreeze sensor

coolant temperature sensor (dtozh) of a VAZ 2107 car - check - replacement

To perform the work of checking the VAZ 2107 coolant temperature sensor, you will need: a multimeter, a thermometer (with a measurement limit of at least 100 °C), a small heat-resistant container with a volume of about 0.5 liters for water and about 0.2 liters of water heated to boiling point.

The sequence of work to check the coolant temperature sensor of the VAZ 2107

1. We prepare the VAZ 2107 car for the operation (see “Preparing the VAZ 2107 car for maintenance and repair”).

2. Release the clamp of the wiring harness block and disconnect it from the coolant temperature sensor.

3. Connect the negative voltage probe of the VAZ 2107 engine.

4. Having turned on the ignition of the VAZ 2107 car, use a voltmeter to measure the voltage at terminal “A” of the coolant temperature sensor wiring harness block. The voltage at the coolant temperature block terminal must be at least 12 V. If voltage is not supplied to the block, this indicates a malfunction in the power circuit or the computer.

5. Turn off the ignition on the VAZ 2107 car.

6. Using a 19 mm wrench, unscrew the coolant temperature sensor and remove it together with the sealing washer from the engine cooling system pipe housing.

7. Connect an ohmmeter to the terminals of the coolant temperature sensor.

8. Fill the container with hot water and immerse the working part of the coolant temperature sensor into it. We record the readings of the device at a temperature of about 90 “C. As the water cools, we measure the resistance of the coolant sensor at temperatures of 80, 60, 40, 30 and 20 °C.

The resistance of a working coolant sensor should approximately correspond to the data shown in the table:

Coolant temperature, °C Coolant temperature sensor resistance, Ohm

90 80 60 40 30 20

250 340 670 1500 2250 3500

If there are large discrepancies in the data, replace the coolant temperature sensor.

Installing a coolant temperature sensor on a VAZ 2107 car

1. Installation of the coolant temperature sensor on a VAZ 2107 car is performed in the reverse order.

2. We start the engine of the VAZ 2107 car and make sure that there is no coolant leakage from under the sensor. If necessary, additionally tighten the sensor. If it was not possible to eliminate the leak in this way, reinstall the coolant temperature sensor by applying a heat-resistant sealant to its threaded part.

portalvaz.ru

Temperature sensor location

On the VAZ 2107, the coolant temperature sensor is covered with a protective cover that prevents the ingress of dirt and water. It is located in the engine head just above the spark plugs. The sensor is threaded into the mounting hole; you can see its exact location in the photo.

Air temperature sensor VAZ 2107 injector

The engine starts after a long period of oiling. There was an error 113 - high level of DTVV signal. How to check for wine in the sensor or something else? Thank you in advance.

In general, this sensor is located together with the mass air flow sensor at the intake. But usually its glitches appear when traveling, and it should not affect startup. But if the error writes about the temperature sensor, then it is quite possible that the startup is not going well because of it. Try disabling the feature and run it. This has already been tested and will not harm anything. Perhaps there will be increased idle speed, when connected, they will be normal again (it’s better to turn the switch off and on with the engine off). You can ask your neighbor for this mass air flow sensor unit and try it on your car (the article number must match).

Well, if the DTVV lies, then the DMRV will give incorrect readings about air flow, accordingly the ECU will make the mixture lean or rich, and that’s a bad start for you.

This is all understandable, but the question is, what could be the problem of poor starting of a cold engine? I changed the IAC and throttle valve, as well as the fluid temperature.

You can try to wash it with carb cleaner, it is possible that oil vapors have settled on it, see if there is any oil in the corrugation.

They kill him with carb cleaner. For this platinum sensor, a special liquid molly product is sold. But for the author of the question, it was not the mass air flow sensor that died, but the temperature sensor, which is located right next to it and does not change separately. And there is nowhere for oil vapors to come from, only if there is dust, which is washed off with alcohol (but, in principle, the air filter should also trap dust). And the corrugation comes later, after the mass air flow sensor housing. The oil will not fly towards the wind if it suddenly appears there.

Oil could have been spit on him due to a clogged oil trap in the crater gas ventilation system.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

How to replace the fuel level sensor on a VAZ 21074, injector?

Which fuel level sensor should I install on a 2107 carburetor?

Sensor (meter, controller hereinafter) showing the heating of the engine coolant (DTOZH)

To prevent the VAZ 2107 engine from boiling, sensors are built into its cooling system. The first shows the heating of the liquid, the second turns on the fan for additional cooling of the engine. If the temperature controller gives incorrect readings, then the coolant temperature sensor of the VAZ 2107 is replaced. Replacing it is such a simple procedure that you should not even think about going to the service station. Do-it-yourself checking and replacement will take 5-7 minutes and will save you a lot of time and money.

Oil pressure sensor

The oil pressure sensor is necessary to indicate to the driver that there is no pressure in the internal combustion engine. The oil necessary to lubricate the engine's rubbing parts is located in the crankcase, but some rubbing parts that need lubrication are located much higher than the crankcase. To provide them with lubrication, the engine has an oil pump that pumps oil into the cylinder head and lubricates the camshaft, crankshaft and much more.

Installed on the cylinder head.

Signs of malfunction:

- The oil pressure lamp does not light up when the ignition is turned on;

- The lamp is constantly on;

DIY replacement instructions

To replace the sensor, do the following:

- First, open the hood and disconnect the battery.

- Remove the coolant expansion tank cap and unscrew the cap from the radiator unit. This will prevent the formation of high pressure in the system.

- Next, place a container under the radiator assembly - the antifreeze will pour into it after removal. Turn off the tap and wait until the liquid drains.

- When these steps are completed, you will need to disconnect the wiring connector from the device. Next, using a 30mm wrench, you will need to unscrew the sensor and remove it from its seat. When dismantling, do not lose the steel seal, and before further installation it will be necessary to treat the installation site with sealant. It is important that the sealant itself is high-temperature - treating the seat with it will prevent leakage of consumables.

- When the device is installed, it is necessary to reinstall the plug on the radiator assembly. Further assembly is carried out in the reverse order - first you need to fill in the coolant, then connect the battery terminal.

- To diagnose the performance of the device, you need to start the power unit and warm it up to operating temperature so that the fan turns on.

How to independently check and replace the DTOZH on a VAZ 2107

The internal combustion engine requires constant cooling, regardless of the season. Impaired coolant circulation threatens to overheat the power unit, which can lead to interruptions in its operation and even damage it. To control the coolant temperature, a special sensor is used - DTOZH. Sometimes it breaks, so you need to be able to diagnose it and replace it if it fails.

Purpose and design of the device

The sensor is designed to measure coolant temperature and display readings on the instrument panel, on which the indicator is located at the bottom left.

If the value is close to 95 degrees, this indicates that the cooling system is not coping with its functions and the engine may overheat.

Types of devices

Different VAZ 2107 models are equipped with either electromechanical or electronic sensors. The first ones were installed on the first models, then they were replaced by more modern ones - electronic ones.

The electromechanical device is a steel case. Its walls are made thick, so the sensor heats up evenly. Inside there is a chamber with a mixture of ceresite and copper powder, which sensitively reacts to temperature fluctuations. The chamber is closed by a sensitive bimetallic plate, which is connected to a pusher. When the body of the device is heated by coolant, the ceresite inside expands and puts pressure on the plate, which in turn moves the pusher to the upper position. The circuit is closed and the signal is transmitted to the instrument panel.

The latest VAZ 2107 models are equipped with electronic devices. Their main element is a thermal resistor with high sensitivity. The resistance in it changes in inverse proportion to changes in temperature. Through a special circuit, the signal is sent to the instrument panel.

The sensor is located on the cooling radiator of the VAZ 2107, which allows it to quickly respond to fluctuations in coolant temperature. In the first "sevens" it not only controls the temperature of the liquid, but also serves as a plug for the neck through which the coolant is drained.

In new modifications, the drain hole has its own plug. A special seat is provided for the sensor.

Self-check and DTOZh malfunctions

If your instrument panel displays incorrect temperature readings, there may be two reasons for this:

- The fuse responsible for the temperature sensor has blown, but the device is working properly. To make sure of this you need to look into the mounting block under the steering column. A blown fuse can be identified by its appearance: black and melted.

- The DTOZH is out of order. It can burn out if there is a sudden surge in voltage in the car's electrical network. This occurs due to damage to the wire insulation, which wears out greatly during operation, which leads to a short circuit.

Depending on the cause of the problem, either the fuse or the temperature sensor is changed.

To check the VAZ 2107 DTOZH you will need a multimeter, a boiler, a heat-resistant container with a volume of approximately 500 ml, a thermometer with a measuring limit of at least 100 degrees. Pour a glass of water into the container.

Further steps to check the sensor:

- Disconnect the negative terminal from the battery.

- We press the latch holding the block with the wires and disconnect the cables from the DTOZH.

- Set the multimeter to voltmeter mode. We connect the negative probe of the device to the ground of the power unit.

- Turn on the ignition and check the voltage at terminal “A” of the connector with wires. It should be at least 12 V. If there is no voltage, this indicates a problem with the computer or electrical wiring.

- Turn off the ignition.

- At the next stage, unscrew the DTOZH and remove it along with the sealing rubber.

- We connect the probes of the multimeter, set in ohmmeter mode, to the terminals of the dismantled sensor.

- We immerse the threaded part of the device in a container of water.

- Then turn on the boiler and heat the water.

- When the water temperature reaches 95 degrees, the resistance reading on the tester should disappear. If they remain, the sensor has failed and requires replacement.

There is another simple way to check the sensor. It is used in operating mode. A working sensor should turn on the fan if a critical temperature is reached. If this does not happen, remove the wires from the sensor and connect them to each other. If the fan starts working, then the sensor is faulty. If it does not start to rotate, this indicates a malfunction.

Checking the temperature sensor.

Instructions for replacing the sensor

Faulty DTOZH cannot be repaired, since they do not have parts that can be replaced independently. In addition, their body cannot be disassembled. Therefore, they are simply replaced with new ones. To carry out the replacement, you need to buy a new DTOZH for the VAZ 2107, prepare a “30” head with an extension, a spark plug wrench and a container into which the coolant will be drained will do.

The replacement process consists of a sequence of steps:

- We drive the car onto any lifting device or inspection hole.

- We place a prepared empty container under the radiator into which we will drain the coolant.

- Sliding the cap, pull the wires towards you, disconnect the contacts from the sensor.

- To unscrew the sensor, use a socket head set to “30”. When removing the device, you should not forget about the O-ring under the sensor so as not to lose it.

- Drain all coolant.

- We screw the new device into the regular place of the old sensor. When tightening the sensor, you should not be too zealous, as you can accidentally break the thread in the socket.

- Next, we put the plug with wires on the new sensor. Unscrew the cap on the expansion tank and fill in new coolant to the required level. You can add coolant through the radiator.

- To ensure there are no air pockets in the system, start the engine and press on the tubes going to the radiator.

An option is possible when you do not need to drain the antifreeze. Experienced drivers unscrew the non-working sensor, clamp the drain hole with their finger and screw in a new product.

But despite the quick replacement, some of the liquid still spills out, so you will have to add it to the expansion tank.

When purchasing a new DTOZh, preference should be given to the electronic version, although it is more expensive. They have no moving parts, so they last longer.

To replace the DTOZH on a VAZ 2107, no special knowledge is required, so even a novice driver can do it, following the instructions. This saves time and money on visiting a service station. An additional advantage is gaining experience.

Checking and replacing DTOZH VAZ 2107.

Did you like the article? Share with friends: