Clutch disc installation: what to pay attention to

Let's start with the fact that thanks to the clutch, the car is able to move off smoothly, gears are switched smoothly, which contributes to the normal operation of all elements of the transmission and the internal combustion engine itself, preserving the life of components and assemblies.

Taking into account the fact that the load on the clutch is high, the service life of the clutch itself is, on average, about 100 thousand km. Its wear is indicated by loss of traction, slipping of the clutch, incomplete disengagement of the clutch, difficulties when shifting gears, the clutch pedal may become soft or, conversely, too tight, etc.

So, when replacing a clutch disc or the entire assembly, not everyone knows which side to put the clutch disc on. It is important to understand that incorrect installation of the specified disk will lead to the need for repeated disassembly, as well as the rapid appearance of various malfunctions and malfunctions in its operation.

As a rule, replacing the disc is carried out together with replacing the clutch basket, but in some cases only the disc is replaced. Let's move on. For many cars, there are two ways to replace the clutch:

- replacing the clutch with removing the gearbox;

- replacing the clutch without removing the box;

It is not surprising that it is the second method that is more convenient. At the same time, for a car with rear-wheel drive, replacement is easier. It is more difficult to change the clutch on a front-wheel drive car, but it is also possible to do it yourself. Let's look at the main stages.

- To implement the task, you will need a lift, overpass or pit. Before removing the clutch, it is necessary to place wheel chocks under the vehicle wheels.

- First of all, you need to disconnect the cardan from the gearbox and the working cylinder. Next, you will need to disconnect the wiring ends of the reverse light switch;

- Then, using a spanner wrench, you will need to unscrew the mounting bolts that secure the gearbox cushion. Now the pillow needs to be removed;

- Next, you need to move the box away from the engine as far as possible (so that the switch rests on the bottom); The transmission will actually rest on the inlet pipe of the exhaust system. For this reason, the back of the box must be additionally supported with a support or jack;

- Next, retracting the flywheel, you will need to unscrew the 6 mounting bolts on the clutch basket. In order to gain access to the fixing elements, you need to periodically turn the crankshaft;

- Then the disc itself is removed into the groove that appears and by moving the clutch basket. To remove the basket, you need to slide it towards the engine. The last step will require removing the fork and release bearing;

- Replacing the clutch is done in the reverse order. In this case, a special lubricant is first applied to the bearing hole of the gearbox input shaft, and the friction and contact area of the pressure disk is wiped with a rag.

As for installing the clutch disc, it should be installed with the protruding part facing the basket. By the way, marks are applied to the casing and flywheel in advance, which then need to be aligned, which helps to avoid imbalances.

Also, during work, you need to center the driven disk relative to the axis of the crankshaft. To implement the task, you need to use a rule that is an imitation of the splined part of the input shaft. The rule should be easily removed after installation.

The fastening bolts themselves must be tightened alternately with equal force to prevent the casing from moving. Please note that on the side of the casing there are evenly made recesses (shaped like a rectangle).

The indicated recesses fit tightly into the 3 pressure plate hubs. This design solution guarantees effective transmission of torque to the disc at the same time as the possibility of its displacement relative to the axis when the clutch is engaged.

Between the pressure plate and the casing there are 18 springs, which are arranged in pairs. The springs have coils that are made in different directions. This eliminates the risk of possible jamming. Also, so that the working disk does not warp and at the same time a suitable force is achieved, the installed springs must be from the same group.

The springs are protected from excessive heating during clutch slipping by washers made of pressed asbestos material, which is heat resistant and has the ability to dissipate heat.

There are also spherical nuts with conical springs at the ends of the tail forks. This solution can provide a certain rolling of the element, which is necessary in order to level the distance between the axes at the moment the disk is removed.

Replacement steps

The entire installation and dismantling of the clutch disc takes place in several stages:

- The cardan and working cylinder are detached from the gearbox. Then the limit switches of the electrical wiring of the reverse signal switch are turned off.

- Using a spanner, unscrew the bolts holding the KCP cushion. The pillow itself is dismantled.

- The PCP is moved a considerable distance from the motor, while the switch is tightly close to the bottom. This is necessary so that the transmission is located on the inlet pipe of the exhaust system. To do this, the gearbox is supported by a jack or a special support.

- The flywheel is dismantled and the 6 bolts holding the clutch basket are unscrewed. The crankshaft must be rotated regularly to ensure easy access to the bolts.

- The clutch basket is moved into the emerging shaft to make it easier to dismantle the part. To remove the basket, it must be moved towards the engine. After which the fork and release bearing are dismantled.

- To install the clutch, all the above steps are carried out in reverse order. The bearing hole of the gearbox input shaft is lubricated. The area with which the clamping part is in contact is wiped with a cloth.

What you need to know when replacing

The question arises: which side should the clutch disc be placed on? The element is installed so that the protruding side and the basket face each other. Before this, marks are applied to the casing and flywheel. In the future, they will be combined - this will ensure correct installation of the clutch.

During installation, the driven disk is centered relative to the axis of the crankshaft. The best rule is that the input shaft is splined. If the installation is carried out correctly, it is quickly and easily pulled out.

The bolts holding the casing are screwed in with equal load, otherwise it will move. On the side of the casing there are rectangular recesses into which 3 pressure plate hubs will fit. This structure will ensure maximum high-quality transmission of torque to the element. Also, it is better to move it relative to the axis when the clutch is disengaged.

18 springs are installed in pairs between the pressure plate and the casing. Each element has coils directed in different directions. This is necessary so that the structure always works smoothly. All springs belong to the same category so that the working disk does not warp under the required force.

Section of a splined shaft and bushing with a straight-sided profile

Washers are installed to prevent the springs from overheating when the clutch slips. The washers are made of compressed asbestos, as it can withstand sudden temperature changes and has good thermal conductivity.

Also, cone-shaped springs and spherical nuts are installed on the ends of the tail forks. All this creates the effect of the mechanism rolling, which is required when leveling the distance between the axles and when retracting the clutch disc.

Spare parts for trucks

How to independently learn to ride a bicycle correctly

Full model range: GAZ-3307, 53, GAZ-3309, GAZ-66, 3308, 33081, 33086, GAZ-33104

Car clutch GAZ-3309, GAZ-3308, GAZ-33081 Sadko for diesel engine

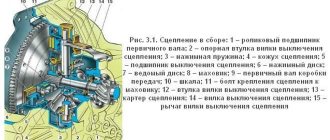

The clutch of the GAZ-3309, GAZ-3308, GAZ-33081 Sadko (diesel engine D-245) is permanently closed, single-disk, dry, with a central pressure diaphragm spring and a damper device on the driven disk. Pressure disk 19 (Fig. 1) is connected to casing 10 by three groups of plates.

The clutch and release mechanism of the GAZ-3309, GAZ-3308, GAZ-33081 Sadko are located in the clutch housing 21, which is attached to the rear sheet of the engine with ten nuts 16 studs and a bolt, under which conical spring washers 15 are installed with the convex side to the nuts and the bolt head.

Centering the clutch housing relative to the axis of the engine crankshaft is carried out using two pins 20 pressed into the clutch housing. On the clutch housing there are 6 brackets for the rear engine mounts, which are secured with 5 bolts.

Rice. 1. Clutch GAZ-3309, GAZ-3308, GAZ-33081 Sadko (diesel engine D-245)

1 flywheel; 2, 5 - bolts; 3 - fork; 4 — rear cushion; 6 — rear engine mount bracket; 7 — protective ring; 8 — clutch; 9 — rivet of the friction lining; 10 - casing; 11 — support ring; 12, 20 — pins; 13 - bearing; 14 — gearbox input shaft; 15 — washer; 16 - nut; 17 — driven disk; 18 — disc pressure spring; 19 — pressure disk; 21 — clutch housing

There is no gap between the pressure spring 18 and the clutch bearing 8, so the inner ring of the bearing rotates at the engine crankshaft speed. During operation, the clutch does not require adjustments.

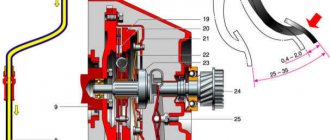

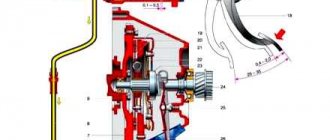

The clutch control drive for GAZ-3309, GAZ-3308, GAZ-33081 Sadko is hydraulic. The clutch master cylinder 15 (Fig. 2), mounted on the front panel of the cab, is actuated by the suspended pedal 20.

The master cylinder of the GAZ-3309, GAZ-3308, GAZ-33081 Sadko clutch is connected by a hose 2 to one of the sections of the three-section supply tank 1, equipped with an alarm sensor for an emergency drop in the brake fluid level (the other two sections of the tank supply the hydraulic drive of the dual-circuit service brake system).

Rice. 2. Clutch drive of GAZ-3309, GAZ-3308, GAZ-33081 Sadko cars

B - compensation hole; G - bypass hole; 1 - supply tank; 2 - supply hose; 3, 18 — fittings; 4, 23 — protective caps; 5, 24 — pushers; 6.33 — bushings; 7.34 - pistons; 8 — piston valve; 9, 14, 35 — cuffs; 10.32, 37 — springs; 11 - coupling; 12 - nut; 13 — thrust washer; 15 — clutch master cylinder; 16 — clutch master cylinder valve; 17 — thrust ring; 19 - pipeline; 20 - pedal; 21 - hose; 22 — clutch slave cylinder; 25 - cover; 26 — fork ring; 27 — fork support axis; 28, 30 — rollers; 29 - coupling pin; 31 — clutch bearing; 36 — spacer sleeve

The working cylinder 22, mounted on the upper part of the clutch housing, is connected to the main cylinder by a pipeline 19 and a hose 21, and is equipped with a valve to remove air from the hydraulic system. When the pedal is not pressed, the cavity under piston 7 of the main cylinder is connected to the reservoir through compensation hole B, which eliminates an increase in pressure in the hydraulic system and clutch slipping.

The bearing 31 of the GAZ-3309, GAZ-3308, GAZ-33081 clutch release clutch is pressed against the pressure spring with a force of 70-100 N (7-10 kgf) using spring 32 through piston 34, pusher 24, fork 3 (see. Fig. 1) and clutch 8. When the clutch linings wear out under the action of the pressure spring, the system takes a new position, compressing spring 32 (Fig. 2).

Excess fluid from the clutch slave cylinder GAZ-3309, GAZ-3308, GAZ-33081 Sadko enters the reservoir through a pipeline into the compensation hole in the master cylinder.

The existing bend in the length of the working cylinder for the movement of the piston provides (without adjustment) the calculated wear of the clutch linings. The position (travel) of the clutch pedal relative to the floor is regulated by changing the length of pusher 5. Repair work on the clutch can be carried out without removing the engine from the car.

Removing the clutch of a GAZ-3309, GAZ-3308, GAZ-33081 Sadko car

To remove the clutch, you must remove the gearbox and clutch housing.

To remove the clutch housing GAZ-3309, GAZ-3308, GAZ-33081 Sadko, you must do the following:

— disconnect the exhaust system pipe from the clutch housing; — Unscrew the fastening bolts and remove the cover of the clutch slave cylinder; — unscrew the nuts of the studs securing the clutch working cylinder, lift up the working cylinder assembled with the pusher, without disconnecting the hose;

Removing the clutch

How to place the clutch disc correctly and which side to use is a question that often arises among novice motorists who do not pay attention to some nuances when performing work, ignoring which can lead to useless repairs and serious problems with the car.

When starting to remove the unit in question, the following requirements must be met:

- Stop the vehicle with special wedges;

Functions and structure of the clutch disc

On the side of the casing there are three evenly spaced recesses in the shape of a rectangle. Three pressure plate hubs fit tightly into them. This structure guarantees the transmission of torque to the working disk and the ability to move it relative to the axis when the clutch is activated.

Between the pressure disk element and the casing there are 18 springs, placed in pairs, which have versatile curls to prevent the part from jamming. To counteract distortion of the working disk and obtain optimal force, spring elements are placed from the same group. The springs are protected from excessive heating in the event of clutch slipping by washers made of heat-insulating pressed asbestos material.

Spherical nuts with conical springs are attached to the ends of the tail forks of the unit in question, providing some rolling of the element required to dampen the change in the distance between the axles when the disk is retracted. In the grooves of the protrusions of the guide disk element there are three steel levers, which are connected to the disk and support forks by means of needle-type bearings and axles.

Some tricks

Experienced drivers advise, when performing the process of replacing the presented unit, to place evenly small dots of glue (moment or high-quality analogues) on the working surface of the basket. The disk is placed on the basket with the springs facing away from you and aligned along the edges. The glue will help secure the parts while they are attached.

Considering how to place the clutch disc correctly and which side, this method involves a slight continuation. After installing the gearbox, you need to engage the gear and squeeze the clutch and turn the mechanism with the starter. This method is suitable for most machines.

Clutch disc design and purpose

The clutch disc ensures smooth movement of the vehicle, which is achieved by slipping the continuously rotating drive disc. Which is attached to the crankshaft in relation to the driven disk, and is connected to the transmission using a spline. The side of the casing is equipped with three rectangular recesses, spaced evenly. The hubs of the driven disk fit closely into the recesses. Thanks to this design, a torque is applied to the disc, and when the clutch is activated, it moves relative to the axle.

In the space between the clutch housing and the driven disc element, springs are located in pairs (9 pairs in total). In order to protect the spring from overheating (when the car slips), special asbestos friction linings are installed. The entire clutch assembly consists of:

- flywheel;

- clutch driven disc;

- clutch baskets (pressure plate);

- release bearing with clutch

Replacing the clutch slave cylinder

First, we disconnect the cotter pin element, which drives the hydraulic drive mechanism itself, using pliers. We use them to remove the spring. We do not scroll the fitting hose completely.

Do-it-yourself engine repair - major restoration and maintenance of an internal combustion engineDIY bumper: how to make a unique polymer bumper for a car at home (125 photos)

Do-it-yourself car painting - preparation for coating and the main stages of high-quality car painting (100 photos)

Using the 13th key, remove the 2 bolts from the crankcase. And only now we take out the pusher. Access to the cylinders is open. How to further replace the working clutch is shown in more detail in the video.

When to change the clutch

No one can say the exact rules for replacing the clutch. The service life of the unit directly depends on the level of wear of certain elements, driving style, and the quality of the parts.

The difficulty is that it is impossible to directly check the wear of the pressure plate, driven or flywheel without dismantling the gearbox.

The first signs of clutch wear appear no earlier than 30-40 thousand after the previous replacement:

- The clutch does not engage completely. This indicates that the driven disk has worn out, has lost the nominal thickness of the friction linings and cannot engage in frictional engagement with the flywheel. In other words, the clutch is constantly slipping.

- Clutch basket wear manifests itself in a similar way. In this case, you can detect wear on the pressure surface of the basket and destruction of the spring petals.

- Worn release bearing. Accompanied by the same symptoms, but against the background of a strong noise when pressing the pedal or releasing the pedal. Sometimes the noise of the release bearing disappears when you press the clutch pedal, which also indicates wear on the release bearing.

- Flywheel wear. In the most advanced cases, the flywheel can wear out so much that the force of the clamping springs is not enough to press the driven disk to the surface of the flywheel. The symptoms are the same - the clutch slips, the linings overheat with a characteristic odor.

The danger of driving with a worn clutch is not only that the driver cannot fully control the transmitted torque to the gearbox. When the friction linings slip at idle, active wear of the working surfaces of the flywheel and basket occurs, as well as their overheating, which can lead to warping and complete failure of the flywheel .

Clutch faults VAZ 2107

The main signs of a faulty VAZ 2107 clutch are:

- it is difficult to change gears;

- the driven disk slips;

- vibration appears;

- The pressure bearing whistles;

- the clutch is hard to disengage;

- The pedal does not return from the lower position.

Destruction of the pressure plate and basket casing can lead to very serious consequences

Almost any malfunction is accompanied by extraneous sounds - noise, knocking, whistling, etc.

Gears won't shift

If the gears are difficult to shift, an experienced driver will immediately tell that the clutch is moving. In other words, the clutch does not disengage completely. As a result, when starting from a stop, it is difficult to engage first gear, and when the pedal is pressed, the car moves slowly. The reasons for this situation may be:

- Increased distance between the thrust bearing support surface and the heel of the basket. It must be set within 4–5 mm, changing the length of the working cylinder rod.

- The spring sectors of the driven disk are warped. The disk needs to be replaced with a new one.

- The thickness of the driven disk has increased due to the stretching of the rivets securing the friction linings. The disk needs to be replaced with a new one.

- Jamming of the driven disk on the splines of the gearbox drive shaft. Both parts are defective and, if necessary, replaced with new ones.

- Lack of brake fluid in the master cylinder reservoir or accumulation of air bubbles in the hydraulic drive system. The working fluid is added to the required level, and the clutch hydraulics are pumped.

The clutch is slipping

The clutch may start to slip for the following reasons:

- there is no gap between the pressure bearing and the fifth basket;

- the clutch drive is not adjusted;

- oil got on the rubbing surfaces;

- the bypass channel in the main cylinder body is clogged;

- The clutch pedal does not return to its original position.

Such malfunctions are eliminated by adjusting the drive, replacing oil seals, cleaning the channel with wire, and identifying and correcting the causes of pedal sticking.

Clutch is jerky

If the clutch starts to jerk, it may be caused by the following:

- the driven disk is jammed on the splines of the gearbox drive shaft;

- oily areas have formed on the friction linings;

- the clutch hydraulic drive is not adjusted;

- the steel disk of the basket is warped, some friction springs have lost their elasticity;

- The driven disk is faulty.

In such situations, a complete clutch replacement is most often required.

Noise when engaging clutch

The appearance of grinding and rattling noises when releasing the clutch pedal may be due to the following:

- the pressure bearing is jammed due to lack of lubrication;

- The gearbox drive shaft bearing is jammed in the flywheel.

In both cases, the problem is solved by replacing the bearing.

Noise when disengaging the clutch

When you press the clutch pedal, you hear a knocking, clanging, rattling sound, and you can feel vibration on the gear lever. The reasons may be the following:

- the damper part of the driven disk (springs, sockets) is faulty;

- The splined connection of the driven disk and the gearbox drive shaft is badly worn;

- the return spring of the clutch fork has become detached, lost its elasticity or broken.

In all cases, worn elements should be replaced with new ones.

The pedal returns but the clutch does not work

Sometimes it happens that the clutch does not work, but the pedal returns to its original position. This may be due to the following situations:

- air entering the hydraulic drive system;

- wear of the sealing rings of the main and working cylinders;

- lack of working fluid in the tank.

In these cases, you should bleed the hydraulic drive, replace the rubber rings with new ones and add working fluid to the reservoir.

Tight grip

The softness of the clutch is determined by the force of pressure on the heel of the basket to retract the pressure plate. The magnitude of the force depends on the elasticity of the damper springs. Baskets from many manufacturers, including foreign ones, are suitable for the VAZ 2107 clutch. A tight pedal signals to the driver that the basket's life is coming to an end.

The pedal disengages the clutch at the beginning/end of its stroke

When you press the pedal, the clutch may disengage at the very beginning or, conversely, at the very end. In such situations, adjustment of the free and working travel of the pedal will be required. The free stroke is regulated by changing the length of the pedal limit screw, and the working stroke is regulated by changing the length of the working cylinder rod. In addition, increased free play may be a consequence of wear on the driven disk linings.

The most common mistakes when installing the clutch

For the average auto mechanic, replacing the clutch is a common routine procedure associated with dismantling the gearbox. Therefore, most conscientious craftsmen try to replace the clutch so that they do not have to remove the box and waste time after a thousand kilometers.

However, not all mechanics are equally competent, and even more so, not all drivers who change the unit with their own hands. Here are the typical mistakes when replacing a clutch:

- Installing a clutch on a worn flywheel. The easiest and fastest way is to replace the clutch disc, plug in the box and move on. But before installing a new disk, it won’t hurt to take a closer look at the condition of the flywheel. There should be no burrs, scratches, traces of oil or corrosion on its working surface. If wear of more than 2-3 mm is detected, the flywheel must be ground or replaced with a new one. Otherwise, even the highest quality clutch disc will wear out in 500-700 km and the clutch will simply disappear, it will slip, further wearing out the basket, disc and the flywheel itself.

- Installing the clutch into an oily crankcase. Where did the oil come from in the gearbox housing? Of course, it leaked through the crankshaft seal or the transmission input shaft seal. Do not install the clutch without ensuring the integrity of the seals, as well as the hydraulic drive system, if any.

- Installing the clutch with backlash on the gearbox shaft or support bearing play. Distortions and uneven frictional contact will lead to the clutch failing again after 1000 km and the input shaft bearing wearing out even more. The same applies to the crankshaft support bearing.

- Installing a clutch without a centering mandrel. A serious mistake that leads not only to an imbalance of the basket and disk, but also to immediate failure of the crankshaft bearings and the gearbox input shaft with all the ensuing consequences.

- Application of shock loads when installing the clutch basket. This can cause the appearance of microcracks in the spring petals, bending of the basket body, tearing out the rivets of the tangential plates, breakage of the clutch basket body, and breakage of the release bearing.

- Uneven or too loose tightening of basket bolts. This leads to imbalance of the basket, driven disk and flywheel. The consequence can be all of the problems listed above.

Cleaning is required

Before installing a new kit or disk (depending on the degree of wear of the flywheel and basket), it is necessary to thoroughly clean the gearbox housing, input shaft, and release bearing guide sleeve. Only in this way can a thorough inspection be carried out and defects identified in time.

What you need to know

The release bearing is not the weakest link in the clutch system, but for some reason it is the one that causes problems and troubles.

coupling

Some car owners have gotten used to the whistle and simply ignore it. But this cannot continue for long, since untimely solution to the problem can lead to even more complex and expensive repairs. If the situation gets worse, then a simple replacement will not be enough for you.

The clutch serves to act on the leaf spring of the clutch basket. It is also called diaphragm, so don't be confused if you hear this designation. Due to this impact, the driven disk is disconnected from the flywheel and the pressure plate of the basket. This disengages the clutch.

If the squeezer is faulty, this can lead to various consequences:

- The clutch fork will be damaged;

- The integrity of the clutch spring petals will be compromised;

- The guide bushings are deformed.

In order not to pay twice, or even three times, promptly react to the appearance of a whistle in the clutch and try to quickly take action.

How to choose a side?

We figured out how to install the clutch disc , but it is also important not to make mistakes when choosing the side of the disc. The following methods will help you figure out which side needs to be installed:

- Certain manufacturers indicate which direction the disc should face on the damper spring housing. The letters are written in different languages, based on who and where the car part was made;

- You can apply the disk first with one side and then with the other side to the flywheel in order to check which of them will easily lie on the surface and will not touch anything. True, this method is often ineffective, since many disks fit equally on either side:

- If there are no markings, it is worth performing an independent inspection of the mechanism using a caliper. It should be taken into account that on the engine side the disc should protrude a quarter less than on the gearbox side.

How to center the clutch disc? (solved) - 1 answer

to center the clutch disc :

- Expose it to the eye. If you take your time and look carefully and thoughtfully, everything will work out. Accuracy is quite enough.

- If the eye is deceiving, then loosen the fastening of the basket so that the driven disk dangles freely in it. And when putting on the box, first we catch the driven disk with the input shaft, and then the KV bearing. Lastly, tighten the clutch basket bolts.

- Carve the wooden mandrel. Measure the inner diameter of the bearing in HF and the inner diameter of the spline in the driven disk and make a mandrel based on these dimensions.

For example, on a Ford Focus, alignment is done this way:

A “12” head is used (50 mm long and 17/15 mm in diameter).

The driven disk is centered along its splined hole and the hole in the crankshaft flange (under the shank of the gearbox input shaft).

When installed, the “basket” is centered on three pins pressed into the flywheel.

How to center a clutch disc without an input shaft

A little about clutch disc alignment. And a popular myth:

Myth.

If you do not center the disc, the clutch will “beat”. Is it true.

If you do not center the disk, you will not be able to install the gearbox in place, because the centers of the holes in the basket, disk, seat on the flywheel must coincide, otherwise the shaft will not go all the way.

In general, there are 2 official methods for centering a disk.

1) Centering the disk on the seat of the input shaft.

This method is routinely used in service centers for opulent cars, incl. and Lanos. A mandrel according to the dimensions of the input shaft is used. For Lanos like this

2) Centering the disc on the basket.

This type of tool is used

There are many unofficial methods - using a shovel handle, a finger, other parts of the body and any other crap that comes to hand.

But I will describe 2, which are very simple, do not require investment, and can be made from scrap materials in 5 minutes

1 Method. Bolt and blue electrical tape.

In general, blue electrical tape is a unique thing. She can repair anything. And not only to repair.

We will need an M10 bolt or a 10 or 11 mm drill. — a roll of blue electrical tape First, wrap a certain amount of electrical tape around the end (of the bolt) and try it on so that it (the end of the bolt) fits into the seat of the input shaft on the flywheel with a slight interference. Then, we measure the distance at which the clutch disc will be located and wrap the required amount of electrical tape so that the disc can fit with a slight interference fit. Those. we get an analogue of the device from the official 1st method.

2 Method. Using 2-sided tape.

We will need - double-sided tape - scissors. The idea is simple, we must fix the clutch disc to the basket by aligning it in the center. To do this, cut 3-4 small pieces of 2-sided tape, 5x5 mm in size. No more. Paste on the basket as in the photo

The name is so long because it is difficult to find information on this particular model. Thanks to everyone who answered the questions, special thanks to Dima trilian for the tips. I’m writing but I haven’t finished it yet - I haven’t pumped the clutch. I hope for some advice. The symptoms for replacement were as follows. In 4.5 gears, if you give the gas sharply, the revolutions first increase, then the car accelerates. The mileage is about 250. The clutch was most likely original Valeo. I only changed the disk without the basket. Only stellox 0700094sx could find the disc separately. I don’t trust this company, but I couldn’t find any other analogues. If you know, write. Okay, at least this one fits. Now the price according to the autodoc is 1370 rubles, and in winter I took 1000 rubles from the party committee. Assembled Valeo costs 6-7 thousand and the release one costs about 5. This is if you do it wisely. And don't forget the gearbox oil.

The slave disk found only this one, okay, at least it stood up

Let's move on to replacement

Now let's move on to the most important thing in this article, that is, the replacement itself. Before you begin the process, you need to arm yourself with the necessary tools

In particular, you need to prepare:

- a pry bar or a long thick screwdriver;

- tenth size wrench or socket;

- a special mandrel that will help straighten the driven disk. By the way, such a mandrel is sold in a specialized store, or you can use the gearbox input shaft instead, removing the gears from it.

First of all, before installing the clutch disc, you need to dismantle the gearbox. But again, we must not forget that replacing a disk can be done in different ways. For example, replacing the clutch on front-wheel drive cars is much more difficult than on rear-wheel drive cars. And besides this, each make or model of car may have its own nuances when replacing this part.

Video on how to replace the clutch:

https://youtube.com/watch?v=jhpohw9qgJE

What does it mean? And the fact is that, before starting the replacement process, you should read the clutch replacement instructions provided by the manufacturer. You can also use special forums for information, where those who have independently changed the clutch disc of a car of a certain make or model give useful advice.