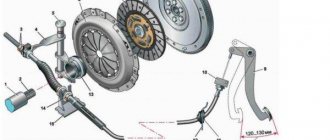

The drive cable in the clutch mechanism of the domestic Lada Kalina model plays a huge connecting role. By means of this element, the driver, when pressing the corresponding pedal, forcibly disconnects the driven disk from the rotating flywheel. A direct “participant” in the process of disengaging the clutch, transmitting the pressing force to the basket, is the release bearing.

Why did the manufacturer prefer a cable drive? In classic car models, the cable gave way to a hydraulic drive, when the clutch is released by acting on the fork by a system of hydraulic cylinders (main and working).

It is not uncommon for the cable to break, after which the car is no longer able to move, since changing gears becomes impossible. Only replacing the clutch cable will return the car to full functionality. The repair procedure itself does not cause difficulties, so it is accessible even to those novice owners who have embarked on the path of a motorist for the first time. And therefore, many people are interested in the question: how to change the cable?

When does the cable need to be replaced?

Of course, after the fact of its breakdown! However, this is not the only case, because experts recommend leaning towards this procedure if several wires are also broken in the tip. Another relevant advice is related to the need for this repair procedure when the plastic braiding of the cable has acquired visible through damage.

Please pay attention! The clutch cable in a Lada Kalina car can not only break, it is also prone to gradual stretching. As a result, there comes a time when it will not be possible to engage the gear. Situations are more rare if the car has been idle for a long time without moving. This can cause acidification of the cable inside the sheath.

Error p0504 Lada Granta

Wiring diagram of Lada Granta norm with description of elements

Granta sport review

Why is lubrication needed on the input shaft?

The lack of lubrication on the input shaft (PS) of the Lada Kalina manual gearbox, as well as other cars, leads to difficulty switching gears. The driver squeezes the clutch, puts the lever in the desired position, but cannot push it further. Or the gearbox starts to crunch the gears, but the clutch kit is fine and doesn’t need replacement.

Some owners of this car think that they will have to disassemble the box. After all, without this it is impossible to fully lubricate either the primary or secondary shaft of the Kalina gearbox. However, there is no need for such complex repairs. It is not the secondary shaft of the Lada Kalina gearbox that is processed, but only the part of the PV protruding from the box.

To understand the causes of the problems, it is necessary to consider the principle of energy transfer from the engine to the wheels. The car's engine works even when the car is not moving, because the car is in neutral gear. Therefore, the input shaft rotates together with the flywheel, and the clutch transmits the maximum torque from the engine to it. To turn on some speed, it is necessary to break the connection between the internal combustion engine. This will reduce the rotation speed of the PV to a safe value, due to which the synchronizers will connect the shafts of the Kalina gearbox through the gears.

Lubrication of input shaft splines

If the rotation speed of the PV is high, then the gear coupling cannot engage with the synchronous gear, which is why a crunching sound appears. The teeth of both parts cling to each other, which leads to tiny pieces of metal being torn off from them. Therefore, to switch on any speed, a complete break in the influence of the internal combustion engine on the input shaft is necessary. After all, even a small influence leads to an increase in the speed of its rotation. Because of this, the secondary shaft of the gearbox on the VAZ Kalina cannot come into contact with the corresponding gear.

This task is performed by the clutch. A normally functioning unit is the key to a comfortable ride and precise activation of the selected speed.

Dismantling the old cable

- First, we find the clutch drive pedal.

- We remove the stop from the cable sheath. The braid itself is attached to the pedal bracket. The manipulation is very simple. Using the “8” wrench, we simply unscrew the nut that secures the shell to the bracket. Having “defeated” the nut, we easily remove the stop from the stud.

- Now there is an approach directly to the finger. A stopper is held on it, which we remove using pliers (or a screwdriver). After dismantling the marked stopper, remove the clutch disc compensation unit (driven).

- We remove the plastic bushing located on the pedal drive finger. A visual inspection of its condition would be useful. If there are visible deformations, we replace it with a new product. Before installing the bushing, lubricate the pin surface with lithol.

- We proceed to removing the seal from the cable sheath.

In the interior of the Lada Kalina, the entire list of manipulations has been completed, so the next step will be dismantling the elements under the hood.

Let's proceed further

- On the transmission unit, pull the end of the cable towards you. It should come out of the landing hook without any effort.

- Now we unscrew the leash, which we remove from the tip.

- The final step is to pull the clutch cable out of the bracket on the transmission.

A special feature of the Lada Kalina model is its one-piece bracket, not a split one. Here you will need to remove the cable from the corresponding hole in the bracket towards the interior. The component we are looking at is now removed.

Cable replacement process

To replace the clutch cable of a Lada Kalina, you will need two things: tools and space. Let's consider each question separately.

Tools

To replace any car part, you need to have a tool. So, to replace the clutch cable you will need:

- Key for 8.

- Ruler and caliper.

- Screwdriver.

- And, of course, a new cable.

When everyone is armed, you can proceed directly to the replacement.

Step-by-step instruction

When everything is ready, you can proceed to step-by-step operations for replacing the cable. They will be performed in two planes - the interior and the engine compartment. Therefore, care should be taken to have good access to both places. So, let's proceed directly to the manipulations:

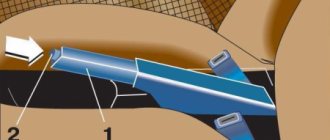

- We remove the stop from the cable.

- Remove the spring clip from the clutch pedal. To do this, you need to pry it off with a flat screwdriver.

Spring clip close up

Unscrew the nut holding the cable on the ratchet mechanism

For convenience, we remove the air filter

The plate to which the cable on the pedal is attached

When everything is assembled, you can check everything and go.

Causes of malfunction

Decoding the Kalina clutch cable elements

There are several reasons that lead to clutch cable failure. Thanks to the ratchet mechanism installed on Kalina, you can adjust the length of the cable, which makes it possible to change the tension when the friction part on the disk wears out. But the cable cannot be tensioned forever, and therefore sooner or later it fails.

Let's look at the main signs of adjusting or replacing the clutch cable on Kalina:

- Insufficient tension.

- Extraneous sounds when disengaging the clutch.

- The clutch does not disengage completely.

- The pedal falls.

- Gear shifts poorly.

Now that we have decided on the causes of the malfunction, we can move on to choosing a cable and the replacement process.

Installation of a new cable

We carry out the installation procedure following this algorithm. We start with manipulations in the salon.

- First of all, we thread the cable into the engine compartment.

- Now we install the body of the compensation mechanism, which serves to level out wear on the disc linings. We install the body itself on the finger and secure it with a locking bracket.

- We return the cable sheath seal to its place.

- In the engine compartment we pass the cable through the bracket, after which we install the guide sleeve.

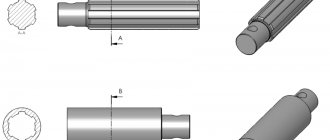

- We screw the leash onto the lower tip of the component. Tightening should be done so as to provide the tip with a protrusion of approximately 1 mm.

- Now we pull the cable all the way. When this manipulation is completely completed, we measure the adjustment distance using a caliper. In optimal condition it should be 27 mm. When the measurements give a different value, we rotate the leash and achieve the specified indicator.

- We place a cable end in the groove on the clutch fork. Under the pressure of the spring, the leash will “climb” into the fork.

- By pressing the pedal several times, we check the unhindered functionality of the unit. We immediately control the adjustment gap (27 mm).

How to lubricate the Kalina clutch fork

Tell me where on the forum there is a topic about lubricating the clutch fork and tuning from a plastic bottle.

My leg is already hurting in traffic jams and the clutch pedal is too tight. Buy a normal cable and adjust it so that it is not tight, otherwise they will adjust the crap that the cable is constantly tense during the ride and the fluoroplastic layer rubs due to vibrations, and then the cable barely moves.

Buy a normal cable and adjust it so that it is not tight, otherwise they will adjust the crap

Everything seems to be regulated there. What is normal?

Where is it regulated? Or are there no adjustment nuts in the Priora?

Where is it regulated? Or are there no adjustment nuts in the Priora?

the fluoroplastic layer is frayed due to vibrations

Everything seems to be regulated there. What is normal?

Where is it regulated? Or are there no adjustment nuts in the Priora?

What layer? The entire bushing is fluoroplastic.

The layer on the cable, look carefully, the cable is also covered with a layer of fluoroplastic.

I replaced the cable with a new one and added oil with a syringe

You can go buy a new cable.

There, the fluoroplastic-fluoroplastic friction pairs will pick up abrasive oil from the box and erase the fluoroplastic again. Look carefully, on high-quality cables, even the cable is lubricated with violet at the factory and a dust cap is always placed at the entrance.

I replaced the cable with a new one and added oil with a syringe

This was not required. There is an opinion that it can kill the cable sheath or otherwise interfere with the design friction and life of the cable. Before you do anything, you need to ask on LOL...

I'll install a new one if necessary.

Look carefully, on high-quality cables, even the cable is lubricated with diol at the factory and a dust cover is always placed at the entrance.

When I changed the cable for the first time on 10, I cursed everything). How inconvenient. The second time was easier. And according to the subject, you most likely won’t change it a second time - you’ll get used to it when you pump up your leg)

Source

Adjusting the pedal position

Having completed replacing the cable in LADA Kalina, it will be useful to adjust the pedal assembly. For this purpose, you will need to place the car on a level area. Now we measure the pedal stroke. We use a ruler. We apply it to the floor and the starting point of the pedal. We press and measure. The stroke should be no more than 150 mm. If the fact of excess is evident, then we adjust the position.

To make adjustments, move to the engine compartment. Here, at the junction of the fork and the cable, there are two adjusting nuts. We twist the first one (the locking one), after which we rotate the second one until the required stroke is achieved. Typically this value is 120-130 mm. Continuing to loosen the nut, we increase the free play, and do the opposite - we decrease it.

How does the clutch work?

This system works as follows:

- The clutch basket, which includes the drive disc, is rigidly attached to the flywheel of the power unit. Therefore, it constantly rotates with it.

- When the driver presses the appropriate pedal, the cable is tensioned. It forces the fork to press the release bearing against the elastic petals of the basket.

- The harder the release bearing presses on the petals, the further the drive disk moves away from the driven one. The driven one presses weaker against the flywheel.

- The driven disc is equipped with friction pads on both sides to ensure maximum torque transmission when the pedal is released.

- As the release bearing moves, the pressure on the drive disc decreases. It begins to slip along the surface of the drive disk and flywheel.

- Approximately in the middle of the last quarter of the clutch pedal travel, the pressure weakens so much that it no longer affects its rotation speed. The input shaft of the gearbox on Kalina 2 or 1 also slows down.

- When the PV speed is low enough, the selected speed is easily switched on. After all, to do this, the clutch needs to connect a freely rotating gear on needle bearings to the secondary shaft.

- Then the driver smoothly releases the pedal, due to which the pressure on the driven disk also gradually increases. This leads to an increase in the torque transmission coefficient from the engine, first to the manual transmission, and then to the wheels.

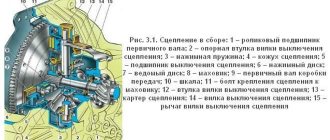

Replacing the clutch on LADA Kalina

But, as with any other car, there are certain components that require inevitable replacement after a certain mileage. Such components include the clutch, without which every car simply cannot exist.

It is quite difficult to independently replace the clutch on a LADA Kalina, although it is doable. Below, in our article, we will carefully tell you how to carry out such work from beginning to end without making mistakes.

Preparatory work

It is no secret that work on replacing the clutch is carried out by dismantling the gearbox; however, you need to take care in advance of the presence of an inspection hole or overpass. We will also need the following tools and materials:

- New clutch set.

- Set with tools.

- Hex key.

- Jack.

- Rags.

- Screwdriver.

- Container for draining oil.

- New gear oil (as needed).

- Lamp for illuminating inaccessible places.

READ What Antifreeze to Pour into a Gazelle

Clutch types on Kalina

VAZ 1117, 1118 and 1119 cars are equipped with two different types of clutches: 190 and 220 mm. Finding your own diameter is painfully simple, you just need to pay attention to the number of starter mounting bolts. At 190 mm there are 3 of them, and at 200 mm there are 2 of them. Regardless of the manufacturer’s office, in the assembly you will almost always find the clutch disc itself, the basket and the release bearing.

If problems with the clutch occur on the road, then you need to have the car towed by a tow truck, because the upcoming movement may damage the gearbox.

Step-by-step clutch replacement process

First, work must be carried out under the hood of the car.

- Disconnect the power and negative cables from the battery and then remove it.

- Then we remove the air filter housing together with the corrugation.

- Remove all wires from the starter.

- We dismantle all the wires coming from the gearbox and the unit.

Let's move on to working under the car

- If there is crankcase protection, unscrew all the bolts and remove it.

To dismantle the protection, you need to unscrew 4 bolts

We remove the gearbox and move on to working with the clutch.

- First we need to unscrew the release plate housing, which is attached to the flywheel with 6 bolts. When performing this work, the flywheel must not be allowed to rotate and it is necessary to hold it in place with a screwdriver prepared in advance. Unscrew the bolts slowly, one at a time, allowing one turn per circle for each bolt.

The driven disc is covered in oil - one of the reasons why the clutch

If you are not confident in your own abilities, then you should not proceed with this type of repair and should contact a car service center for more professional assistance.

Additional Information on Clutch Cable Compensating Mechanism

The compensation mechanism on the LADA Kalina clutch cable is designed to ensure that cable is always in a tense state. A slight deviation of 1-2 mm is either “selected” or added to the length by the compensating mechanism.

The clutch cable of the Lada Kalina, as on any car, is one of the irreplaceable and fundamental parts that performs the function of turning the clutch on and off at the time of gear shifting. A malfunction of this unit can affect the operation of the unit, and untimely replacement will lead to excessive wear on other parts of the structure.

READ Changing the Oil in an Automatic Transmission Peugeot 308

Clutch cable, LADA Kalina, replacement.

Replacing the LADA Kalina clutch cable,