What is a PCV valve

Theoretically, without this valve, the forced ventilation system cannot work correctly a priori. After all, it is the PCV valve that doses the supply of crankcase gases to the most important area - the space behind the throttle valve, right in front of the combustion chamber.

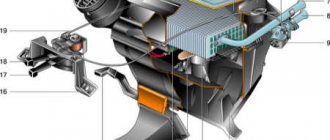

The PCV valve is not a check valve at all, as many people think. Yes, it is not blown in the opposite direction, but it also does not simply have two positions, open and closed. Everything is much more complicated. Inside the PCV valve there is a plunger loaded with a spring, the force of which is calculated depending on the engine volume, or more precisely, on the vacuum created in the manifold.

PCV Valve Design

The valve has four operating positions:

- The engine is switched off. The valve is completely closed, gases do not enter the manifold, and now they have nothing to do there.

- The engine is running at idle speed. In this mode, the vacuum in the manifold is the highest, the valve is completely open (100%) to ensure the supply of gases (essentially air) into the throttle space. Moreover, the amount of gases is strictly regulated and clearly controlled by the ECU, and the ECU already controls the idle speed controller depending on the amount of air supplied and a number of other factors.

- The engine operates in normal mode at medium speed and medium load. The PCV valve is approximately 50% open. The flow of crankcase gases is average, they burn efficiently in the cylinders.

- Maximum load and high speed mode. The PCV valve is open by 20-25%, the maximum amount of crankcase gases is burned, thereby the pressure in the crankcase is not dangerous for oil seals and gaskets, since it is completely controlled due to the vacuum in the manifold.

Algorithm for the operation of the crankcase ventilation valve

On the Lada Vesta, the ventilation system is designed in such a way that in fact it always works the way a normal system works in the fourth mode. The flow of gases is limited only by a 1.7 mm jet built into the throttle pipe. In theory, the expectation was that the system would operate as a dual-circuit one.

This is how the ventilation scheme is implemented on 8 and 16-valve VAZ engines

The first circuit operates in the speed zone from idle to 1500 rpm. The pipe behind the throttle and the same 1.7 mm jet are involved here. The second circuit is connected to the ventilation already at high speeds, and gases begin to flow into the intake manifold up to the throttle through a hose with a diameter of 18 mm.

Schemes for upgrading the crankcase ventilation system

Schemes for modifying the crankcase ventilation system, as well as a description, are provided by IgorRV.

For LADA cars with manual transmission and AMT (“robot”), scheme No. 1 “Crankcase ventilation scheme with PCV valve for E-GAS and cable throttle” is suitable:

It is necessary to install a PCV valve (article 94580183, price about 400 rubles) from a foreign car into the small crankcase ventilation circuit. When connecting the PCV valve to a small circuit on an E-GAS, use a new hose (petrol-oil-resistant 8 mm without fabric reinforcement). On a cable choke, connect to the receiver, not to the choke.

As a result, the valve will shut off the circuits in transient modes, which will allow:

- Accept the load without jerking or dropping engine speed (for example, when the compressor is running, heated windows, seats, etc.).

- Reduce vibration load at idle

- Increase traction from the bottom (noted by owners of automatic transmission with VAZ-21126 engine, manual transmission with VAZ-21227, 21126 and 11186 and AMT with VAZ-21127).

- Get a sharper response to the gas pedal and faster shifts (on AMT). Perhaps due to the fact that the valve does not allow the engine to slow down, maintaining a more optimal switching algorithm.

- Reduce oil consumption through ventilation.

The valve replacement period is 40,000 km.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 2 is suitable:

Description of scheme No. 2: The pressure reducing valve is connected in series to a large ventilation circle. Thus, it regulates the flow of crankcase gases at high speeds and during transient processes. This allows:

- Exercise full control over the flow of crankcase gases between the small and large circuits.

- Improve engine operating mode.

- Reduce vibration load.

- Reduce oil release into ventilation.

For LADA cars with automatic transmission (Jatco) and AMT (“robot”), scheme No. 3 is suitable:

Description of scheme No. 3: To improve the operation of the braking system and facilitate the process of holding the car on the brakes in mode “D”, an “Ejection Pump” was used. Due to the flow of crankcase gases from the small circuit, the vacuum in the tube leading to the vacuum booster increases. This happens at low speeds, which is very helpful when driving in traffic jams. Keeping your foot on the brake all the time is not very easy, but this pump makes the task easier.

- Getting rid of vibrations, failures, transmission shocks.

- The engine begins to operate more calmly and softly.

- The force on the brake pedal becomes less.

- The air conditioner turns on almost imperceptibly.

Required:

- ejection pump (article 10793 VIKA, price 546 rubles);

- pressure reducing valve (article 1117701500 JP GROUP, 422 rubles);

- PCV valve (article 94580183 GENERAL MOTORS, 400 rubles);

- clamps (about 10 pieces, 600 rubles);

- thin, petrol-resistant 8 mm hose 50 cm (100 rubles);

- standard ventilation pipe.

Installation example on video:

By the way, there are other ways to modify the crankcase ventilation system. Are you ready for such modernizations? Let us remind you that modification of the ignition system (installation of capacitor ignition coils in the harness) is also common among owners of LADA cars.

Keywords: lada xray engine | Lada Vesta engine | Lada Largus engine | Lada Granta engine | Lada Kalina engine | Lada Priora engine | Niva engine | universal article

14

1

Found an error? Select it and press Ctrl+Enter..

The Lada Largus subframe was modified at the factory

Installing a rear view camera on Lada Granta, Priora and Kalina

What to do if the stove does not heat well on the Lada Vesta and XRAY

Correct sound insulation of car wheel arches with your own hands

Video

—Before reading the post and deciding to implement it, think about whether you need it. If there are problems described in the recording, contact those who have already installed the valves, ask whether they work or not.

—Due to the weak design and small engine volume, everyone who installed a General Motors valve 94580183 in a small circuit without a pressure reducing valve in a large circuit, monitor the oil level and jerking from the engine. — If oil burns, strong jerking and vibrations appear, remove the General Motors valve 94580183. Instead, it is better to choose the PSV-PCV valve 2674021314. Sankei KP125 or 2674032804 for eight-valve engines. — You can also choose the PSV valve yourself. The main criterion when choosing a valve is the volume and power of the engine on which it is installed, which should be no less, but preferably a little more.

Next, carry out the following work: - check the entire intake system for leaks. — crankcase ventilation large and small circuits, tubes pressed into the valve cover, oil dipstick seal, breather. — intake control hoses for leaks on engines with variable intake length. — update the ECU firmware to the latest factory firmware. — replace the vacuum booster valve with MW400017 MITSUBISHI, if you hear a rattling sound when you press the brake pedal, or you have no news and crap, they have it like that from the factory. - check the efficiency of the adsorber valve, before starting the engine, turn off its pipe to prevent it from working - check the timing marks - on cars with E-GAS, check the correct operation of the clutch sensor, it may not work and not give errors.

Some more advice, I will add to it: - never install filters or oil sumps in the low ventilation circuit if there is a PCV valve. Never. - make the small circuit line as short as possible, so that on the 16 valve the valve lies above the throttle, and on the 8 valve the valve is above the receiver fitting or valve cover. — if you operate the machine in areas with a cold climate, you can insulate the small circuit line with a valve. — in case of maintenance, do not blow with compressed air, do not shake the valve. Simply rinse with carb cleaner and dry.

The second method of upgrading crankcase ventilation

The meaning of the following is to transfer the small ventilation circuit from the throttle part to the receiver, which helps reduce differences when switching modes. To complete this design, you will need to perform the following manipulations:

- The thin crankcase ventilation hose is disconnected from the throttle;

- The free end is connected to the free inlet fitting on the receiver, with preliminary removal of the plug;

- The free opening of the remote control is blocked by installing a plug;

- As a result, the flow of air mass increases, eliminating the possibility of a sharp response of the throttle valve to a jerk of the engine;

- In addition, crankcase ventilation increases and additional draft appears in the lower part of the mechanism.

How to clean the crankcase ventilation system on a VAZ 2110-VAZ 2112?

Note! Before you start work, remove the air filter housing, as it will interfere greatly; if you do not know how to do this, then read the article entitled: “Replacing the air filter housing on dozens”!

Removal: 1) The hardest thing is to remove the cylinder head cover, but the remaining parts that relate to the ventilation system (And these are mainly hoses), removing is as easy as shelling pears, in general, let's start, first you will need to disconnect the wires from each other, namely the upper connectors (see photo 1 ) and lower connectors (Indicated by a red arrow), once this is done, remove the connectors, to do this, squeeze the two latches on one connector with your fingers and remove it (see photo 2) and do the same with the other connector, just without removing it, they will interfere, and in general you won’t be able to remove the cylinder head cover without removing these connectors, because the wires simply won’t allow you to do this, both connectors were sitting on brackets, so unscrew the bolts securing them and remove both brackets from the cylinder head cover, in more detail how to do this , look at photos 3 and 4 below.

2) Now remove the exhaust manifold from the cylinder head cover, it is bolted on and by the way, when you remove it, replace all the O-rings, firstly they are not expensive and secondly, after replacement, you will be 100% sure that the collector will not let air through anywhere, since the rings will be new; you can read in more detail how to do this in the article entitled: “Replacing the receiver on a 16-valve car.”

3) Then start removing the hoses, they are held in place by clamps, the clamps are loosened using a screwdriver or wrenches, if it is not convenient to work with a screwdriver, all the clamps that you will need to loosen and all the hoses that you will need to remove, you can see in the photographs a little below:

Note! Rinse the removed hoses with gasoline or kerosene, then dry them in the sun and, if possible, also blow them with compressed air (for example, a compressor), before installation, make sure that the hoses are dry, if necessary, wipe them dry with a rag and by the way, Carefully clean all those places where the hoses are connected with a cloth and remove all dirt from them!

4) When everything is finished, remove the cover from the Cylinder Head, it is secured with fifteen bolts, these bolts are unscrewed with a socket wrench or a socket head and an “8” wrench, then the cover is separated from the cylinder head with a screwdriver and removed from the car, it is most convenient to separate it from the cylinder head in those places where there are special protrusions for this, one of such protrusions is indicated by a blue arrow.

5) After you have the cylinder head cover in your hands, using a wrench or a socket wrench, unscrew the six bolts that secure the separator to it (Several bolts are indicated in the large photo) and disconnect it from the cover (see small photo).

Note! This separator is an integral part of the crankcase ventilation system, it has such a part as an oil deflector, to pull it out, you will need to compress the side clamps using pliers (see photos 1,2), a rubber o-ring will be installed on the oil deflectors, picking it up with a screwdriver , you also need to remove it (see photo 3,4) and replace it with a new one, if such a ring is difficult to find in car shops, then you are allowed not to change it if it is in good condition, namely: It should not be too compressed, the rubber is not should become rough and lose its elasticity, and there should be no cracks or other types of damage on the ring!

Installation: Installation of all parts is carried out in the reverse order of removal, but before installation, wash everything thoroughly with gasoline or kerosene, this also applies to the cylinder head cover itself, there should be no dirt on it, and also remove old sealant (with a screwdriver or fine-grained sandpaper) the surface where the cylinder head cover is installed, after cleaning, degrease it and apply a new sealant, as it is shown in the small photo below:

Additional video: An interesting video that will give you a little additional information on the crankcase ventilation system is located just below:

Source

Over time, tarry deposits from crankcase gases accumulate in the engine crankcase ventilation system, making it difficult to remove these gases into the engine cylinders for combustion

Because of this, the gas pressure inside the engine increases, and oil leaks through the seals appear.

To avoid this, periodically clean and flush the system.

The engine crankcase ventilation system must be cleaned every 60 thousand kilometers.

Clean the crankcase ventilation system before each oil change.

In order to clean the ventilation system, you need to remove the air intake manifold and cylinder head cover.

For this:

We prepare the car for the job. Open the hood and disconnect the negative terminal of the battery.

Remove the engine protective screen.

Disconnect and move the throttle cable to the side.

Disconnect the wire blocks from the ignition coils.

We take the wiring harness to the side.

Cut or unfasten the clamp securing the wiring harnesses of the engine management system

Unfasten the wire block from the phase sensor.

We remove the throttle assembly without disconnecting the hoses from it.

The throttle body connection is sealed with a rubber gasket

Loosen the clamp on the vacuum supply hose

Despite the fact that the intake manifold and throttle assembly differ from the same components used on other modifications of the car, removing the throttle assembly is performed in the same way.

Disconnect the vacuum supply hose.

Loosen the crankcase ventilation hose clamp

Disconnect the crankcase ventilation hose from the pipe on the cylinder head cover

Loosen the self-tapping screw securing the oil level dipstick guide pipe

Using a 10mm socket, unscrew the two cap nuts of the upper fastening of the intake manifold to the cylinder head cover

Using a 13mm socket, unscrew the two bolts and three nuts of the lower fastening of the intake manifold

The attachment points of the intake manifold to the cylinder head (Figure 14, studs B and bolt holes A) are shown by arrows (the intake manifold, fuel rail and injectors have been removed for clarity)

Remove the ignition coils of the first, second and third cylinders.

Removing the intake pipe from behind the wiring harness

Remove the intake manifold along with the oil level dipstick guide tube.

After this, remove the cylinder head cover.

Use a Phillips screwdriver to loosen the clamp on the small crankcase ventilation hose.

Disconnect the hose

Use a Phillips screwdriver to loosen the hose clamp of the large crankcase ventilation hose.

Remove the hose

Using a 10mm wrench, unscrew the bolt securing the wiring harness bracket

Using a 10mm wrench, unscrew the bolt securing the injector wiring harness block bracket

Using a 8mm socket, unscrew the 14 bolts securing the bolt head cover

Use a screwdriver to pry the cover off by the protrusion

Removing the cylinder head cover

Rinse the hoses with gasoline or kerosene, blow with compressed air and dry.

Clean the holes in the fittings and pipes for connecting hoses

We unscrew the six bolts securing the separator from the inside of the cylinder head cover.

Remove the separator

Squeeze the separator oil deflector clamps with pliers and remove the oil deflector from the oil separator.

Using a screwdriver, carefully pry up the rubber O-ring and remove it

Replace a ring that is severely compressed or has lost its elasticity with a new one.

Before installing the cylinder head cover, clean (remove old sealant) and degrease the mating surfaces of the cylinder head and cylinder head cover.

Apply a thin layer of sealant to the mating surface of the cylinder head.

Install hoses and parts in the reverse order of removal.

Design and principle of operation

As was said at the very beginning, the ventilation system removes crankcase gases from the VAZ 2114 back into the engine, preventing unburned fuel oil mixture from entering the atmosphere. It includes a pair of pipes through which gases are removed, and a filter that traps solid particles and clots.

The principle of operation of the crankcase ventilation system of the VAZ 2114

The whole system functions as follows:

- the fuel mixture entering the engine burns and forms exhaust gases, most of which are discharged from the engine into the exhaust line;

- a small part of the gases leaks through the piston rings and enters the lower pipe of the ventilation system;

- From the lower pipe, gases enter the filter (made in the form of a multilayer mesh), after which, already purified, they return to the engine, where they burn out.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

Engine crankcase ventilation system

It would seem that the operation of the internal combustion engine itself serves as a source of severe air pollution, and we are trying to talk about ventilation here. However, not everything is so simple; the engine, like everyone else, also needs fresh air. It is also provided by the crankcase ventilation system.

About the purpose of the ventilation system

All problems, as always, are hidden in the little things. In this case, this concerns the existing gaps between the piston and the engine cylinder block. It would seem that the design provides special elements that minimize these gaps. And yet, despite the sealing rings, fuel combustion products, its unburned particles, and water vapor enter the engine crankcase volume. The consequence of this is a deterioration in the quality of the oil and loss of its lubricating properties. A similar effect manifests itself in the fact that ordinary oil becomes a water-oil emulsion, and it also liquefies.

It is to prevent such phenomena described above that the crankcase ventilation system is designed. It allows you to remove escaped exhaust gases from it, ensure normal pressure, thereby increasing the reliability and durability of the engine.

How does crankcase ventilation occur?

As always in such cases, there is a choice.

The implementation of this system can be of two types:

- open;

- closed.

In the first case, when the engine crankcase ventilation system is open, the exhaust gases that have broken through are removed outside the power unit. The simplicity and low cost of this method is compensated by environmental pollution.

In addition, you should know that open ventilation:

- does not work at low speed and at idle;

- does not cope with its duties at high speeds;

- through it it is possible to suck in atmospheric unfiltered air when the engine cools down;

- may be one of the reasons for increased oil consumption, as well as a reason for oiling of the engine.

Closed or forced crankcase ventilation is carried out when trying to reduce the degree of pollution caused by the car. For this purpose, a special valve is installed, thanks to which, during forced crankcase ventilation, the exhaust gases that enter there are discharged into the engine intake manifold.

increased contamination of the carburetor and inlet air ducts; strong draft at high speeds in the exhaust gas suction system, which can serve as an additional reason for oil oxidation.

The advantages include:

- reduced oil consumption;

- stable operation in winter due to heating of the inlet air by crankcase gases;

- they also increase the engine’s knock resistance by diluting the fuel-air mixture.

Options for creating forced crankcase gas cleaning

The truth is that not everything is as simple as it seems at first glance. There are two approaches by which forced crankcase ventilation can be performed. Exhaust gases can be removed from the crankcase, and perhaps the opposite effect is the flow of air from outside.

An indispensable attribute of a modern internal combustion engine is crankcase ventilation, most often designed as a closed system. It allows you to increase the reliability of the engine and reduce the negative impact of vehicle exhaust on the atmosphere.

How does crankcase ventilation work in an engine?

It should be noted, friends, that crankcase ventilation has different designs for different engines, and even more so for different manufacturers, although some elements of this system are indispensable for almost all versions.

More precisely, this is:

- oil separator;

- crankcase ventilation valve;

- various air tubes and pipes.

Let's look at these nodes in more detail.

Oil separator

Needed to separate flies and cutlets, or more precisely, crankcase gases from lubricant.

As a rule, modern cars are equipped with a combined oil separator, which combines the best features of labyrinth and centrifugal types. It is a device into which oil saturated with crankcase gases is supplied from the crankcase - we need to separate them.

First of all, the incoming mixture is spun, as a result of which the heavier lubricant settles on the walls of the separator, thanks to centrifugal forces, and flows into the crankcase.

The gases, in turn, enter the outlet labyrinth of the damper, where their final filtration occurs.

The path of gases does not end there.

Ventilation valve.

This unit is regulated by negative pressure in the intake manifold. If the vacuum is small, the path is open for gases and they enter the intake valves, and then into the cylinders, where they burn safely.

If the vacuum is high, then the ventilation valve is closed. This is the algorithm for how the system works.

SVKG device in Lada Priora

In all brands of cars, the SVKG is built on a similar principle. Only small details differ. On the upper side of the crankcase there is an oil separator, which looks like a hollow plug. An oil deflector is placed under the plug, which is designed to clean the gases from the crankcase as much as possible from oil particles. The oil separator has an outlet for the crankcase ventilation hose.

In order for the gases to return to the cylinder chamber, a ventilation valve is placed along their path. The valve has three modes, which allows you to maintain a certain level of gas rarefaction in the crankcase.

While the engine is idling, gases move through a small circuit hose through a special passage hole in the throttle assembly. At this time, a high vacuum is created in the intake hose, which allows crankcase gases to be effectively sucked out of the throttle block. The passage hole in the throttle regulates the amount of gases that are sucked out.

This allows you to stabilize the engine in idle mode. When the car begins to move, the throttle valve opens, causing gases from the crankcase to enter the cylinder through a large circuit hose for combustion.

Options for creating forced crankcase gas cleaning

The truth is that not everything is as simple as it seems at first glance. There are two approaches by which forced crankcase ventilation can be performed. Exhaust gases can be removed from the crankcase, and perhaps the opposite effect is the flow of air from outside.

An example of how a forced crankcase ventilation system based on exhaust gas removal is constructed is given above. In this case, the exhaust gases that have broken through are under the influence of vacuum in the intake manifold and enter through the oil separator (1), valve (2) and through hoses, having been cleared of oil particles, they again enter the engine cylinders.

An option when the ventilation system is built on the influx of fresh air is shown in the figure below. In this case, outside air enters the engine crankcase, mixes with crankcase gases, and flows back into the engine cylinders through a special PCV valve. A ventilation system constructed in this way avoids the release of internal combustion engine products into the atmosphere. This is exactly the approach used by modern automakers when designing and manufacturing cars.

To maintain normal engine operation at idle, the PCV valve blocks the exit of gases from the crankcase when there is a deep vacuum in the pipeline.

An indispensable attribute of a modern internal combustion engine is crankcase ventilation, most often designed as a closed system. It allows you to increase the reliability of the engine and reduce the negative impact of vehicle exhaust on the atmosphere. » alt=»»>

How often should cleaning be performed?

If the ventilation system is clogged and its filter is unable to clean the mixture passing through it, then not only unburned gases, but also oil particles and other pollutants will enter the engine. All this will ultimately have a negative impact on both the operation of the engine and its remaining service life.

The frequency with which the crankcase ventilation of the VAZ 2114 should be cleaned directly depends on the condition of the engine. So, if the car just recently came off the assembly line, and its engine has not clocked up 50,000 km, you shouldn’t even think about cleaning it, since the piston rings are still new, and there is practically no leakage of gases through them.

Valve cover of VAZ 2114 engine

The first cleaning (as recommended by AvtoVAZ itself) should be performed after the car has covered 60,000 km. And all subsequent cleanings should also be performed after every 60,000 km.

Crankcase ventilation system Kalina 8kl

Today we’ll talk about the crankcase ventilation system on Kalina with an 8-valve engine. And to be more precise, about cleaning this system. Crankcase gases straight from the crankcase (hence the name) are sent mixed with air to the intake manifold for re-burning, thus saving a certain percentage of fuel. So, along with the gases, oil particles enter the system and clog it.

It is this oil that needs to be cleaned from the crankcase ventilation system. Over time, plaque forms on the walls of the hoses, which impedes the passage of gases.

In the Kalinovsky engine, in the valve cover, there is a special separator that separates crankcase gases from the oil. It gets clogged the most. So, let's get started. The entire ventilation system consists of 3 pipes. We need to unscrew them.

Then remove the valve cover. There are two bolts on the back side, unscrew them and get to the separator.

- The easiest way to clean it from oil and deposits is in a bath of gasoline or solvent.

While the separator is acidifying, you can work on the pipes. In general, if they are heavily soiled, it is advisable to replace them with new ones. In my case, I replaced only one - coming from the valve cover to the air filter pipe. The rest were washed with carburetor cleaning fluid (great stuff, it corrodes absolutely everything). The separator itself can also be washed a second time with this thing.

We wipe everything with a clean cloth and put it back together as it was.

Pay attention to the condition of the valve cover gasket. It is considered disposable and it is better to replace it with a new one each time you remove it in order to avoid oil leaks.

Modification of the crankcase ventilation system Kalina 8 valves

This system could be improved a little. One of the 3 pipes supplies crankcase gases directly to the throttle valve assembly next to the IAC. If they contain oil, it will definitely settle there. This is how the IAC becomes clogged. So, to avoid this, you can embed a regular fuel filter right in the middle of this pipe.

It will trap oil particles contained in crankcase gases. After a few hundred kilometers, you will see for yourself. Monitor the condition of this filter and promptly change it to a new one. On average, as practice shows, it needs to be changed every 1000 kilometers.

VKG (crankcase ventilation)

Crankcase ventilation

This term is abbreviated as VKG.

During the operation of a car engine, some of the gases enter the crankcase during processing, which leads to an increase in pressure and provokes breakdowns and disruption of proper operation. The crankcase ventilation system is responsible for cleaning ill-fated gases.

Advantages of VKG:

- regulation of the pressure of crankcase gases that enter the manifold;

- increased performance;

- reduced wear of spare parts.

In order for the crankcase to work correctly, two main aspects need to be taken into account:

- supply of “new” air;

- separation of unnecessary gases.

VKG systems can be divided into two types: closed type systems

and

open systems

. The operating principle of open VKG systems is that they use fresh air from outside. Another type of ventilation systems, KG, absorbs it with the help of batteries. It should also be noted that there are several methods for removing crankcase gases: ejection and forced.