Crankcase ventilation system for engines 2108, 21081, 21083 with Solex carburetor

Purpose of the crankcase ventilation system for VAZ 2108, 2109, 231099 cars The crankcase ventilation system for engines 2108, 21081, 21083 with a carburetor 2108, 21081, 21083 Solex and its modifications is intended for the forced removal of accumulations of various types of gases resulting from engine operation from its crankcase

Design of the engine crankcase ventilation system 2108, 21081, 21083

1. Cavity of the air filter housing. 2. Carburetor. 3. Hose for removing crankcase gases into the cavity of the air filter housing. 4. Connection for the hose for removing crankcase gases into the throttle body. 5. Hose for removing crankcase gases into the throttle space. 6. Oil separator. 7. Crankcase gas exhaust hose. 8. Calibrated hole.

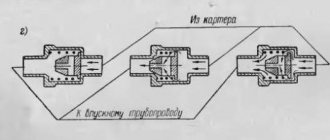

Diagram of the crankcase ventilation system for VAZ 2108, 2109, 21099 cars

Operating principle

Exhaust gases that have broken into the engine crankcase, water vapor, and other toxic substances are removed from the crankcase through the ventilation system. At idle, when the throttle valve is closed, they are sucked into the rear throttle space of the carburetor, thanks to the strong vacuum present there, through the exhaust hose of crankcase gases (7), the oil separator (6) under the valve cover, the exhaust hose for discharging crankcase gases into the rear throttle space (5) .

In the fitting of the crankcase gas exhaust channel of the Solex carburetor 2108, 21081, 21083, a calibrated hole of 1.5 mm (8) is made to reduce the vacuum in the throttle space as a result of crankcase gases entering there and reducing its effect on the operation of the car engine at idle.

When the gas pedal is pressed and the vacuum in the carburetor chambers increases, crankcase gases are extracted through the crankcase exhaust hose into the air filter housing and then through the carburetor chambers into the engine cylinders.

Repair

It is necessary to periodically inspect the elements of the crankcase ventilation system for contamination. Since, due to their complete or partial contamination, the gases accumulated in the crankcase cannot be removed and the increasing pressure there will begin to drive oil through the engine seals and into the air filter housing.

Therefore, we remove the hoses, remove the valve cover and the oil separator installed in it, wash everything with gasoline, and blow it with compressed air.

We blow the fitting on the carburetor, together with the gas exhaust channel, with compressed air and, if necessary, clean it with copper wire. For more details, see “Cleaning the crankcase ventilation system of engines 2108, 21081, 21083.”

Source

Cleaning and washing parts of the crankcase ventilation system of the VAZ 2109

- torque wrench

- screwdriver

- new head cover gasket

- kerosene

- clean rags

- container for washing parts

- keys for “8” and “10”

Flush every 60,000 km or when the ventilation system is clogged.

If the ventilation system is clogged, the pressure in the engine crankcase increases, which can cause oil to leak through the seals and gaskets.

1.

Open the hood. Unscrew the nut securing the air filter cover and remove the washer.

2.

Unfasten the four spring clips.

3.

Remove the air filter cover.

4.

Remove the filter element from the housing.

5.

Loosen the clamps and remove the hoses from the pipes on the cylinder head cover.

6.

Remove the four nuts.

7.

Remove the filter housing from the studs and pull the warm air intake hose off the pipe. Remove the hose from the filter housing, first loosening the clamp.

8.

Disconnect the plastic holder from the hose, loosen the clamp and remove the hose from the pipe on the cylinder head cover.

9.

Unscrew the nut and remove the accelerator cable bracket, leaving the bracket hanging on the cable. Unscrew the two nuts securing the cylinder head cover.

10.

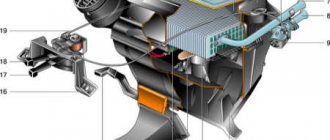

Remove the cylinder head cover.

11.

Remove the two bolts from the inside of the cover.

12.

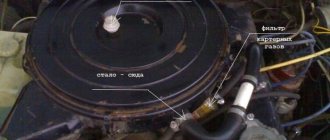

Remove the oil separator housing.

13.

Remove the screen from the cylinder head cover.

14.

Wash all parts thoroughly in kerosene.

15.

Install all parts in reverse order. Before installing the head cover, be sure to replace the gasket. The nuts securing the cylinder head cover must be tightened to a torque of 2.0-4.5 N m (0.20-0.45 kgf m).

Video about “Cleaning and flushing parts of the crankcase ventilation system” for VAZ 2109

How to clean the valve cover (breather mesh) of a VAZ Cleaning the breather of a VAZ Crankcase ventilation hose, the fitting is loose. VAZ 2110-2112, Lada Priora, Kalina, Granta, VAZ 2114-15

Engine crankcase ventilation VAZ 2109 carburetor

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Dear experts, please enlighten me.

I recently discovered that there was smoke coming from the valve cover. I determined that there should be a hose connecting the cover to the carburetor. However, this fitting is plugged on the carb. I want to plug the hole in the lid, but I have doubts. Question: why is this compound needed in the carb and how does its absence affect the operation of the carb?

excess pressure of crankcase gases by the carb and is drawn out

Quote: “In order to prevent the emission of very toxic (more than tens of times compared to exhaust gases) crankcase gases into the atmosphere, a forced crankcase ventilation system is used on modern engines. To do this, crankcase gases are supplied under vacuum into the air filter cavity after the filter element and, mixed with air, enter the cylinders. However, at low load conditions, the vacuum in the air filter is small, and such a system does not provide satisfactory removal of crankcase gases. To increase the efficiency of the crankcase ventilation system, it is supplemented with a so-called small branch connecting the gas exhaust fitting from the engine to the throttle space. The cross-section of this additional channel does not exceed 2-3 mm in diameter. The fitting for connecting the small branch of the crankcase ventilation system is located on the carburetor in its lower part, in the throttle valve area of the primary chamber under the accelerator pump. Next, the gases enter through the channel into recess 6 on the lower flange and exit directly into the throttle space under the throttle valve of the primary chamber.”

The filter in the saucepan becomes clogged. after 200, but it is not oily. But smoke comes through the hole in the small branch in the valve cover. I do not like it. If this smoke is blown into the engine, it can affect the spark plugs, etc. And if you turn it off, will the pressure from under the cover push through the gasket?

The filter in the saucepan becomes clogged. after 200, but it is not oily. But smoke comes through the hole in the small branch in the valve cover. I do not like it. If this smoke is blown into the engine, it can affect the spark plugs, etc. And if you turn it off, will the pressure from under the cover push through the gasket?

To clean it, you need to drill and remove the aluminum plug in the carb. Channel diameter 1.6 mm. Therefore, pick with a needle or a thin drill. Next, use a short M4 screw as a plug, cutting a thread in the hole. You may not find a standard hose. But you can use the gas hose as on the return line. Everything described was done on our own pepelats, i.e. verified.

No need to look for difficult ways! Buy a Carb Cleaner, blow into this nipple on the carb a couple of times, wait a couple of minutes and blow again - everything will be cleaned. In an extreme case, remove the Nuna carb and blow on both sides, but this happened to me on a 10-year-old carb - everything is cleaned “without the use of brute force.” Again, finding a new hose is not a problem. The problem is finding the right sellers. IMHO the fuel hose is not the best option, because... and the lid gets hot, and the carb, and the gases passing through the hose. But the regulated hose is designed for all this and must be replaced after 3-4 years, because... it becomes tanned at the edges and begins to leak, or cracks. However, maybe the fuel one will behave exactly the same