Replacing the driveshaft crosspiece in a VAZ 2107 2105 2106 with your own hands.

Today we will learn with our own hands how to quickly and correctly replace the driveshaft crosspiece on VAZ cars of the classic family, such as VAZ 2107, VAZ 2105, VAZ 2106, etc.

We drive into the inspection hole, as in our case, or lift the car on a lift. Unscrew the 4 bolts on the cardan shaft:

We unscrew the two bolts on the suspension bearing (a 12 or 13 wrench, depending on which bolt you have):

We dismantle the cardan. We wrap the splined part with a clean rag to prevent sand and other dirt from getting there. We tap through the mandrel:

We pull it out using pliers:

We select a suitable mandrel and press out the old cups through it:

The last part is knocked out with a hammer. We clean the seats from sand and dirt with a metal brush, carefully clean all the grooves with a screwdriver, and lubricate them. Installing a new driveshaft crosspiece:

We use round-nose pliers to install new locking rings (they come complete with a new cross):

We check the work by rocking it in each direction. The crosspiece should rotate equally left and right, up and down. If one of the sides rotates worse, then when you put the driveshaft on the car you will feel vibration. One of the sides rotates tighter, so we remove the retaining ring from this side and grind it down with sandpaper to make it a little thinner:

After turning and reinstalling, the flange began to move easily in each direction, it can be easily moved with a finger. At the same time, we check the suspension bearing, twist it, make sure there is no noise or play, the rubber band should be intact and not torn.

When replacing the middle crosspiece, mark the cardan with the half-cardan with chalk so as not to confuse it. The removal process is identical to the rear crosspiece:

The video shows the process in full. Before installing the cardan, lubricate its splined part with nigrol.

Which crosspieces to put on the “six”

If you listen to the opinion of service station specialists, they recommend replacing both universal joint crosspieces, even if only one of them fails. But not everything is so simple. The crosspiece located at the front of the driveline travels much longer than the rear one. There are situations when a part in the shank is changed three times, but near the outboard bearing there is no need to replace it. When choosing crosspieces for your car, you should not chase a low price, since repairs will ultimately cost more. Let's look at some hinge manufacturers that you can trust with your choice:

- Trialli. Made of high carbon steel and evenly hardened over the entire surface. The product is able to withstand high impacts of dynamic and static nature. The seal has an improved design, which increases reliability and protection against dust and sand getting inside the bearings.

Before purchasing and installing a universal joint, be sure to consider the size and shape of the cups

Attention should also be paid to the hinge pins. They should not have any burrs, marks or other defects.

For domestic cars, it is better to give preference to crosspieces with a grease fitting, i.e., serviceable ones, which will allow you to periodically renew the lubricant in the bearings. The seals must not have any defects, such as visible tears or manufacturing defects.

Lada 2106 Rubinchik › Logbook › Installing the cardan on the CV joints.

Good day to everyone who reads this. Today we will talk about how to make your car as comfortable as possible by installing just one part. We are talking about the cardan on the CV joints. There are only 2 options for how to do this. 1) buy a ready-made cardan from Sonda for a classic (such a solution costs quite an indecent amount of money, and I personally was able to find it in 1 online store for 9000+ wooden ones, which was not part of my plans) This solution is the simplest, I removed the old cardan and installed a new one , went. 2) make such a cardan yourself, which is what I chose. To do this you will need: - cardan on CV joints from shnivy (4999 RUR)

- gearbox flange VAZ 2101 (350r)

— self-locking nuts (64r)

First, remove the old cardan.

You need to disconnect the back part from it. To do this, remove the crosspiece and put the back part aside (it will no longer be needed). Next, you need to remove the crosspiece fork from the front of the cardan.

We change the suspension bearing if necessary. In my case, the bearing was changed 2 days ago, so I won’t touch it. Next, we take the gearbox flange and assemble the front part of the cardan.

After this, we assemble the entire cardan and install it on the car.

As it turned out, there is nothing complicated. Among the advantages I can note: - relatively inexpensive - easy installation - the elastic coupling remains in its place (when installing the cardan from the sonde, the elastic coupling is removed and the flange is installed). In theory, it should start smoother and softer, but I can’t say how in practice. — absence of vibrations (in comparison with crosspieces there are none at all). — they should go much more than crosses. In theory, consumption should drop slightly, but this is not certain. At the moment I have driven 30 kilometers, I can only say one thing, it has become much better. I don't mind the money given at all.

Source

Replacing the crosspiece of a VAZ 2106 - nothing is easier

So what does the cross do? With its help, it becomes possible to bend the driveshaft

Pay attention to how the rear axle flange and the gearbox shaft are located relative to each other. That's right, the axis of the second one is located higher, therefore, you need to somehow cheat in order to transmit the rotation

The driveshaft must “break” in two places so that movement from the gearbox to the rear axle is transmitted without any problems. In addition, the center of gravity of the entire propeller shaft must be such that axial runout does not occur. Don’t forget about the VAZ 2106 suspension bearing; it is used to attach the shaft to the bottom of the car. If it is destroyed, the axial runout increases, which leads to failure of the crosspieces.

To repair the driveshaft you will need the following tool:

- Open-end and ring wrenches for “12”, “13”, “10”. The latter can also be an end one.

- Pliers.

- Flathead screwdriver if necessary.

- Puller for retaining rings.

- Puller for crosspieces.

- Hammer and wooden spacer.

The procedure is quite simple, it will not take much time:

- Place the car on a flat surface, place stops under the front wheels, and lift the rear with a jack. If there is a hole, overpass or lift, these procedures do not need to be performed.

- Using a 10mm wrench, unscrew the two bolts that secure the suspension bearing to the bottom of the car. You shouldn’t remove them right away; it’s better to do it at the end, just before removing the cardan.

- Hold the head of the bolt that secures the cardan and rear axle flanges to each other with a 12mm wrench. Unscrew the nut with the head to “13”.

- Loosen the bolts securing the outboard bearing and apply several sharp blows to the shaft to knock it out of the rubber coupling.

- Using a puller, remove the rings and apply sharp blows to the driveshaft through the spacer with a hammer. In this case, the crosspiece 2106 should literally fly apart - the glasses will fall out of their seats.

- Before installing a new crosspiece, be sure to clean the seat under it and apply a small amount of lubricant. Do not hit the glass, as this will lead to the destruction of the needle bearing. It is very difficult to collect.

- First, install the VAZ 2106 crosspiece on the driveshaft, then on the flange. Or in reverse order.

The middle cross, located at the outboard bearing, changes in the same way. Before installing the cardan, make sure that the retaining rings are installed correctly and that they will not fall out of their grooves with the slightest force

Please note that the new rings that come with the kit may be thicker than the groove for them, so you will have to use old ones. And most importantly, before starting work, it is advisable to outline the location of the driveshaft relative to the gearbox coupling and the rear axle flange

If an imbalance occurs, an extraneous hum and high vibration will appear.

Replacing the driveshaft crosspiece of a VAZ 2106

Replacing the driveshaft crosspiece of a VAZ 2106

So, let's start, as always, briefly and without unnecessary, unnecessary information! It is better to take the original VAZ crosspiece. My choice fell on a domestic plant, the cost is about 120 UAH ($5). It is also worth buying 4 locking rings. Old ones, as a rule, break and become deformed during dismantling.

Before starting work and removing the cardan, it is necessary to make marks (.) on all parts and joints of the cardan, otherwise, if it is not assembled correctly, it will knock, vibrate, and generally fail.

The cardan is connected with 4 x 13 bolts to the rear axle shank. We unscrew them

Next, unscrew the mounting of the outboard bearing.

Remove the cardan from the gearbox

Remove the retaining rings from the crosspiece. We didn’t have a special puller, we used ordinary pliers

While the cordan is removed, we get into the car, “accelerate” and take an outrageous photo!))

(don't forget to remove the handbrake)

Next we knock out the cross. If there is a tube of suitable diameter, then this is good. In this case, available materials were used: a socket wrench (for replacing wheels), an adjustable wrench (placed under the crosspiece), and a hammer.

Knock out the old one, insert the new one

We remove the landing cups from the opposite edges of the cross and insert it into the seat. Carefully put the cups back so as not to scatter the needles in them.

We hammer in until you see the groove of the retaining ring.

We put the ring and finish it further.

We perform similar actions with the second part of the cross.

Before planting the crosspiece in the box, we treat the gears with grease. Without sparing, the excess will be squeezed out.

Assembly proceeds in reverse order. Don't forget about the marks on the cardan! Good luck with the repair.

Note:

Special tapered head bolts and fast wearing bald nuts with a nylon ring secure the universal joint flange together with the pinion flange. If the bolt turns, you need to fix it with a screwdriver.

Replacing the VAZ 2106 driveshaft with your own hands

- Using a screwdriver, separate the flanges.

Replacing the VAZ 2106 driveshaft with your own hands

- Unscrew the 2 nuts connecting the cross members of the intermediate support and the body of the VAZ 2106. Remove the washers.

- Remove the cardan drive by moving it in the direction of travel of the vehicle. At this time, the rear shaft should pass above the handbrake cable.

Replacing the VAZ 2106 driveshaft with your own hands

- Install a new cardan drive.

Assembly is performed in reverse order.

Signs of faulty crosspieces

The VAZ 2106 crosspiece, like any other car part, has a certain service life. Theoretically, the service life of the part is quite long, about 500 thousand km, but the real figures are 10 times less. Therefore, replacement has to be carried out after 50–70 thousand kilometers. This is due not only to the quality of the parts, but also to our roads and the intensity of vehicle operation. Lack of periodic maintenance of crosspieces only brings the need for their replacement closer. The following characteristic signs indicate that there is some problem with the hinge:

- blows and knocks;

- chassis vibrations;

- squeaks when driving or accelerating.

Clicks and bumps

Often problems with crosspieces appear when the seals are damaged and dust, sand, dirt and water get inside the bearings. All these factors negatively affect the service life of the product. When the joints wear out, clicks will be heard when changing gears while moving, impacts at a speed of about 90 km/h, and a crunching or rustling sound will also appear. If metallic sounds occur, it is recommended to twist parts of the cardan, for example, by placing the car on an overpass. If large play is detected, the crosspieces will need to be replaced.

When diagnosing the gap in the crosspieces, the gearbox must be in neutral gear.

Video: play of the cardan cross

If clicks appear in the cardan area on my car, but I am sure that the crosspieces are still in good condition and should move, then, most likely, there is simply not enough lubrication in the hinges, for which they need to be injected. If clicks appear, I advise you not to delay maintenance, since the bearings will break and it will no longer be possible to do without replacing the crosspiece.

The cause of squeaks in the area of the driveshaft is usually associated with souring of the crosspieces. The problem is clearly noticeable at the beginning of the movement and when driving at low speed, while the car creaks like an old cart.

The malfunction occurs when the hinges are not maintained, when the bearing simply cannot cope with its task. Sometimes, after removing the cardan, it is discovered that the crosspiece does not move in any direction at all.

Video: how the cardan cross creaks

Malfunctions in the form of vibration with the universal joints can occur when moving forward or in reverse. The problem can be present with both old bearings and new ones. In the first case, the malfunction is caused by jamming of one of the hinges. If the vibration persists after replacing the crosspiece, then a low-quality part may have been installed or the installation was performed incorrectly. The crosspiece, whether old or new, should move in any of the four directions freely and without jamming. If you have to exert little effort when moving the hinge by hand, you can lightly tap the bearing cup; it may not be seated properly.

Vibrations in the driveshaft may be due to imbalance. The reason may lie in the impact on the cardan with something hard, for example, when hitting a stone. The balancing plate could also fall off the shaft. In such situations, you will have to visit a car service to eliminate the imbalance, and possibly replace the shaft itself.

Cardan vibrations are caused not only by the failure of the crosspiece. From personal experience I can say that the problem also manifests itself when the outboard bearing breaks, when the rubber in which it is held breaks off. The vibration is heard especially clearly when reversing and when starting to move in first gear. Therefore, before you start replacing the crosspiece, it would be useful to check the driveshaft support.

Replacing the VAZ 2106 universal joint

The cardan crosspieces must only be replaced, since the bearing needles and the outer and inner parts of the race wear out, which leads to the formation of play. This indicates the impossibility and inappropriateness of restoring the part. If characteristic signs indicate that the cardan joints need to be replaced, you will need to dismantle the shaft itself, and then begin repairs. For the upcoming work you will need the following tools and materials:

- open-end wrench 13;

- head 13 with a knob or ratchet;

- copper or aluminum extension;

- hammer;

- compression pliers with thin jaws;

- universal puller;

- chisel;

- new crosspiece;

- lubricant “Fiol-1” or “CV joint-4”;

- large screwdriver.

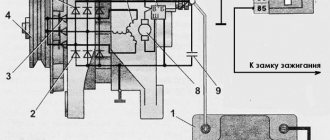

Removing the cardan

On the VAZ “Six” the driveshaft is mounted to the rear axle gearbox, and closer to the gearbox the driveshaft is held by an outboard bearing. Removing the shaft from the car is carried out as follows:

- Unscrew the cardan mount with a 13 key.

Removing the cross

After dismantling the driveshaft, you can immediately begin disassembling the crosspiece:

- We mark the universal joint forks to avoid disturbing the factory balancing during assembly. To apply marks, you can use paint (pictured below) or hit it lightly with a chisel.

- We remove the retaining rings using special pliers.

We install the hinge and shaft in the following order:

- We remove the cups from the new cross and insert it into the eyes.

Video: replacing the cardan cross on a VAZ 2101–07

The cardan crosspieces are filled with lubricant from the factory. However, when replacing a product, I always syringe the hinge after the repair. There will be no excess lubrication, and its lack will lead to increased wear. For crosspieces, it is recommended to use “Fiol-2U” or “No. 158”, but in extreme cases “Litol-24” will also do. Although I know car owners who use Litol for both crosspieces and spline joints. When injecting, I pump the lubricant until it begins to come out from under the seals. According to the regulations, the hinges must be serviced every 10 thousand kilometers.

You don't have to be an experienced auto mechanic to replace universal joints. The desire of the car owner and step-by-step instructions will help identify the malfunction and carry out repairs in a garage without making mistakes.

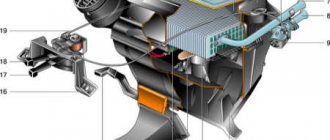

Cardan transmission VAZ 2106 Zhiguli

Cardan transmission elements

1 – elastic coupling; 2 – flange of the secondary shaft of the gearbox; 3 – dirt deflector; 4 – secondary shaft of the gearbox; 5 – nut; 6 – centering ring seal; 7 – centering ring; 8 – elastic coupling liners; 9 – bolt; 10 – plug; 11 – front propeller shaft flange; 12 – cuff;

13 – splined end of the front propeller shaft; 14 – front driveshaft; 15 – intermediate support; 16 – rear propeller shaft; 17 – flange fork; 18 – retaining ring; 19 – universal joint bearing; 20 – cuff; 21 – crosspiece; 22 – fork; 23 – elastic cushion; 24 – intermediate support bearing.

How to diagnose wear on crosspieces

Replacing the crosspiece in a VAZ 2106 is carried out after diagnostics:

When, during rapid acceleration or braking of a car, when changing gears, a knocking sound from the cardan transmission or vibration of the axle is heard, all this indicates wear of the crosspiece and its bearings

There is an urgent need to replace the VAZ 2106 crosspiece, which has become unusable.

If you don’t pay attention to these signs in time, then the result will be destruction of the bearing and the cardan falling out directly onto the road. The axle gearbox and the underbody of your car can also be damaged.

Buy a “VAZ” crosspiece, do not forget to purchase spare retaining rings (if they are not included in the kit), because old rings, as a rule, become deformed or break.

Tool required for replacement

Replacing the driveshaft crosspiece of a VAZ 2106 requires the following tools:

- Two open-end wrenches 13 and 12

- Socket wrenches 27 and 13

- Copper or aluminum extension

- Hammer

- Compression pliers with thin jaws to remove circlips

- Two mandrels for pressing out the cardan cross bearings.

- Universal puller

- Ticks

- Chisel

- Large screwdriver

We remove the cardan

Replacing the VAZ 2106 crosspiece with your own hands is not possible without removing the cardan from the car. So:

- We remove the cardan on a lift or inspection hole. Unhook the handbrake cable spring.

- Using a chisel, we apply marks at the junction of the cardan and the gearbox flange. Using a 13mm wrench, unscrew the nuts (there are four of them). Use a large screwdriver to secure the cardan shaft from rotating.

- Remove the rear end of the cardan.

Disconnect the cardan from the bridge

Use a chisel to mark the position of the cardan and flange of the rubber coupling

Mark the position of the cardan and flange with a chisel

- Then we bend the locking tendrils of the seal ring near the rubber coupling

- We move the cage with the seal together towards the propeller shaft

Move the clip to the side

- Using a 13mm socket, unscrew the nuts and take out the safety bar

- Supporting the cardan, unscrew the nuts using a 13mm wrench and remove the plate securing the outboard bearing from the studs. It is attached to the body using rubber washers.

Unscrew the nuts securing the outboard bearing

We pull the cardan out of the slots inside the rubber coupling flange and take it out

It is first recommended to watch how to replace the crosspiece of a VAZ 2106 video.

Recommendations:

When working with a lift, it is necessary to hang the rear wheel so that the cardan drive rotates more conveniently; if the car is parked on a viewing hole, secure the wheels with wheel chocks.

- Lower the parking brake lever and leave the shift knob in the neutral position.

Replacing the VAZ 2106 driveshaft with your own hands

- Remove the nuts that secure the safety bracket to the body, remove the lock washers and flat washers, and remove the bracket.

Replacing the VAZ 2106 driveshaft with your own hands

- Remove the 3 mounting nuts from the bolts securing the flexible coupling to the gearbox flange.

Replacing the VAZ 2106 driveshaft with your own hands

- While rotating the propeller shaft, remove the flange and coupling bolts (this can only be done when the bolt is located in the upper left corner in relation to the coupling axis). If they are tight, you can use a beard.

Replacing the VAZ 2106 driveshaft with your own hands

- Use a screwdriver to remove the coupling from the flange and lower it.

Replacing the VAZ 2106 driveshaft with your own hands

Replacing the VAZ 2101 driveshaft crosspiece - installation

- You need to remove both cups from the cross.

- Install the cross into the eyes.

- Slowly, moving it to the side, put on the cup, while making sure that the needles do not fall out of the cup.

- It is necessary to squeeze the cup until it forms a groove for the retaining ring, to do this, use a soft metal attachment.

- Install the locking ring, turn the cardan very carefully, while moving the cross forward towards the cup, and put it on. Squeeze the cup and install the retaining ring.

Replacement of the cross - completed! I think you have succeeded, if I missed anything, I hope you will find the answers in the informative photos

Thank you for your attention, try it and you will definitely succeed!