The vehicle control system is responsible for the direction of its movement, as well as, to a large extent, for the safety of the driver and passengers. One of the most important elements of this system is the steering rack. Its role is to transfer force from the steering wheel to the rods, which, in turn, force the steered wheels to turn in one direction or another.

With the exception of the latest versions in VAZ-2110 cars, the steering rack is not equipped with a power amplifier, but this does not mean that its mechanical design will last forever. Like any other moving mechanism, it sometimes fails. We will talk about what the VAZ-2110 steering rack is and what problems happen with it in this article. In addition, we will figure out how to repair or replace it yourself.

Design and role of the steering rack in the control system

The VAZ-2110 steering rack is a steel form, one side of which has teeth that mesh with the teeth of the drive gear. The latter is driven by the steering wheel through the shaft and its cardan. In VAZ-2110 cars, the steering rack is located in a column, which is mounted on the partition between the engine compartment and the passenger compartment.

Its upper part has a mount for two rods, which are connected to the shock absorber struts through the tips and their fingers.

When you turn the steering wheel, its shaft rotates and transmits force through the cardan to the drive gear. As it rotates, it moves the rack along with the rods in the desired direction. This is how the car is controlled in such a simple way.

Naturally, to ensure normal operation of the rack, the design of the steering mechanism includes a number of other parts:

- column housing (case);

- protective casing (corrugation) with clamps;

- two drive gear bearings (ball and needle);

- support sleeve (fluoroplastic);

- emphasis;

- thrust nut;

- anthers, plugs, washers, etc.

hodovik-razval › Blog › Steering rack diagnostics

We will talk about all the possible causes of knocking (play) in the steering with a rack and pinion steering mechanism. Such mechanisms are now found on the vast majority of passenger cars. People pay a lot of attention to reiki. It is customary to blame a lot of all kinds of malfunction sensations on her. But the rack, according to most automakers, cannot be repaired (manufacturers offer to change this assembly for any reason). It’s really not easy for a rack and pinion steering mechanism in a car to survive in our road conditions. Reika doesn't like bad roads. This is not surprising: such a steering mechanism receives hard blows from all road irregularities over which the steered wheel passes. Previously, there were “upper” racks with long steering rods “mustache”, which were connected to the bipod on the racks (and not on the steering knuckles, as now). The whiskers usually had rubber dampers that softened the shocks transmitted to the rack from the wheel... Now, steering rods (short, straight, with rigid ball joints) transfer all the impacts from the wheels directly to the rack "rasp" of the steering mechanism (which is usually located below between steered wheels). Therefore, rack and pinion steering mechanisms do not last as long in our cars as we would like. Of course, they are “tightened up”, sorted out, restored... But this is troublesome, expensive and not very reliable. I see that many people are interested in the condition of the steering rack on a particular car, and I want to tell you here how to diagnose this mechanism directly on the car and what malfunctions there may be. People associate the steering rack with the entire set of parts (assemblies and mechanisms) included in the rack and pinion steering system. Therefore, the diagnostician needs to go along the entire chain, from the steering wheel to the steering wheels. We will not discuss power steering leaks, jamming and other problems of amplifiers here, we will only talk about knocking and play in the steering. The reasons are in order and how to diagnose them: 1)

The steering wheel is not secured to the steering shaft. It is determined by rocking the steering wheel around the vertical or horizontal chords of the steering wheel.

The feeling is a backlash with a knock. The cause of such play may be a loose steering wheel nut or a damaged steering wheel hub. 2)

Radial play of the steering shaft (shaft play in the steering column on bearings)

Determined by rocking the steering wheel up and down or left and right

The same sensations of malfunction can occur if the steering column is not attached to the car body. 3)

Rotational play of the steering wheel in the steering shaft joints

4)

Rotational play of the steering wheel in the splined joints of the steering shaft.

The spline connections on the steering shaft are movable (adjustment of the steering wheel reach, splines between the body and the frame) and fixed (telescopic mechanism for folding the shaft during an accident, spline connections of parts of the steering shaft with a bolt tie). Movable spline connections may become loose due to wear, and fixed ones may be poorly tightened or damaged in some way. Rotational play in the steering shaft (on crosspieces, dampers, splined joints) is determined by applying both hands to the ends of the shafts being tested. By creating rotational movements with our hands in opposite directions at the ends of the shafts, we try to feel the presence of play in the connections of these shafts (bolt ties can be checked for tightening with a reasonable torque). 5)

Radial (or longitudinal) play of the rack gear shaft in the rack housing (on bearings).

It is determined by an attempt to swing this shaft in the rack housing by hand (usually this shaft is accessible in the cabin under the driver’s feet). (such play only occurs in severely damaged racks)) 6)

Rotational play in the “gear-rack” pair. It is usually caused by wear on the rasp and gear teeth. It happens that the gap between the two “middle” teeth of the rack is flared, and it happens that a whole row of teeth in the middle of the rasp is worn out. The rack gear teeth are also worn out.

An increased gap between the gear and the rasp is also due to weak pressure on the rack “stop”. The stop also performs the function of positioning the rasp in the rack body (so that the rasp does not move along the gear axis). Therefore, the stop can be loaded in different directions and can produce a number of unnecessary movements, accompanied by the knocking of the mechanism. The weak clamping force of the stop can be calculated by the fact that the rasp will rotate around its axis in the rack at some noticeable angle (this is especially easy to check when the steering rods are secured not at the ends of the rack, but from the side - you need to grab the rods with your hand - mustache and try to turn the rasp in the rack body). 7)

Play of the stop body in the rack body (the cylindrical hole where the stop is located in the aluminum rack body breaks, the stop seal wears out, and the stop body itself wears out.). This leads to knocking noises during operation of the rack and pinion steering mechanism, since the stop is moved by the rasp in the lateral directions and knocks in the rack body.

Sometimes

It is possible to compensate for knocking noises caused by faults

No. 6

and

No. 7

(and sometimes even

No. 5

)) by

tightening the stop nut

.

This nut must be tightened with the rack removed. Of course, no one will remove the rack to tighten the stop nut, but then you need to somehow control the force of turning the gear shaft (or the force of moving the rasp). I do this on a suspended steer axle. I remember the turning force on the steering wheel (or the turning force around the turning axis of the suspended wheels). While tightening the nut, I constantly monitor the turning force of the steering mechanism. At the slightest sign of the rack biting (at any point of contact between the rasp and the gear), I stop tightening. Play in the area of the plastic rack bushing. The bushing is the second rasp support in the rack body (rack and pinion mechanisms with power steering have a third rasp support - the hydraulic cylinder piston, so in such mechanisms the rack bushing lasts much longer). In the area of the bushing, in the rack body, the lubricant often dries out, and often moisture and dirt get there. Therefore, this plastic bushing is often worn out (the rasp dangles in the bushing, and the bushing dangles in the rack body). All this makes a noticeable knocking sound on bumps when driving and when swaying the steering wheel too.

How to eliminate backlash?

If you identify signs of a malfunction, do not despair; perhaps everything will cost you with minor repairs, especially since the rack itself very rarely fails. First, let's figure out whether there is play in the steering wheel and how to tighten the steering rack on a VAZ-2110 to get rid of it. First of all, open the hood and find the location of the column. We dismantle the engine elements that interfere with free access to it (air filter, air duct). Holding the steering rods with both hands, try to move the rack left and right. If play is detected, we get rid of it by adjusting the thrust nut.

Renovated or new?

Oops, there's a dilemma! Often, a replacement from an official dealer costs a lot of money, it can be 30, 40, or even 50,000 rubles! I know a lot! That’s why many people buy “non-originals” - if you buy a good one, and one that is delivered to the assembly line, then it takes a long time, no less than from the “officials”. However, they often buy cheap or refurbished options; they do not have much of a guarantee, and they often fail after 3–6 months.

You can also buy a repair kit (all seals, boots, bushings, etc.)

They will disassemble the rail for you, replace all the internals and then reassemble it again. But here again there are two aspects:

1) What quality is the repair kit?

2) Who will do the repairs for you, because this requires experience and skills.

To be honest, I personally would buy a normal quality “analogue” (but not China), of which there are a lot now. Or repaired (at a normal station), which is also profitable! You can spend between 10 and 15,000 rubles including the work; also ask for a guarantee.

I’ll probably end here, watch the video I tried to make for you.

Read our AUTOBLOG, there will be many more useful articles.

Similar news

- Seat belt repair

- The stove does not heat, six main reasons. What to do

- Engine overheating

Add a comment Cancel reply

Removing the steering column

If after adjustment the problem with the rack does not disappear, you will have to disassemble and repair it. But to do this it needs to be removed. There are two methods of dismantling: with and without tie rods. The latter method is preferable as it requires much less time. Before removing the steering rack on a VAZ-2110, the front part of the car needs to be jacked up on both sides. This is necessary in order to unload the traction.

In the cabin, in the area of the pedal block, you need to unscrew the steering shaft cardan bolt. After this, we go to the engine compartment and unscrew the 2 bolts securing the rods, having previously bent the locking plate. Then you need to unscrew the 4 bolts securing the steering column to the car body. When this is done, remove the column and remove it through the opening of the left wheel arch.

Removing the rack

Further actions are performed according to this principle:

- Rotate the steering wheel and align the position of the brake discs (the wheels have already been removed).

- The rods from the steering knuckles of the struts do not need to be removed. But it's better to do it. To do this, remove the pins and unscrew the nuts on both rods.

- Install the puller and remove the tip pin from the steering knuckle.

- Then you need to straighten the plate under the bolts that secure the rods to the steering rack housing.

- Use a socket to unscrew the bolts.

- Then unscrew the fastenings of the rail to the partition.

- Inside, you need to loosen the spline connection of the shaft.

What is a do-it-yourself VAZ-2110 steering rack repair?

Take care of your tools in advance. Here you will need two special keys: a 17 octagon and a 24 octagon, as well as bearing pullers. It is worth noting that repairing the VAZ-2110 steering rack involves replacing parts that are most susceptible to wear. These are bearings and a drive gear boot, a stop, retaining rings, a support sleeve, and seals. All these elements can be purchased as a set. There are three types of repair kits on sale:

- minimal, including a support sleeve, boot, retaining rings and seals;

- standard, which in addition to the listed parts includes bearings;

- complete, which also includes a new rack.

It is recommended to buy a repair kit only after you remove the column, write down its markings (different versions of the VAZ-2110 may have different configurations) and disassemble it, identifying the spare parts that need to be replaced.

Repair kit for rack 2110

The whole problem is in the repair kits. Here you need to keep your ears open, since the repair kit may be either incomplete or of poor quality. It is inexpensive, but the very fact of buying a low-quality spare part that you are counting on is unpleasant. Small repair kit includes:

- rack bushing;

- emphasis;

- o-ring, three pieces;

- thrust nut.

This set costs about 300 rubles. But it’s best to pay another 250 and take the full set, which includes boots and bellows. No matter what condition the old ones are in, it is better to replace them, and here's why.

The fact is that on average, at 120 thousand, depending on operating conditions, subtle cracks and breaks may appear on the stockings and corrugations. It is quite difficult to notice them, and water inevitably gets through them. It will not escape from the rack body and will do its wet job - rust cannot be avoided. Any source of corrosion on the rack is a minus to the service life of both the rack itself and the seal. The chain reaction causes the rack to eventually wear too much and repair may not be possible. Don't skimp on a good repair kit.

Disassembling the steering column

We begin disassembling the control unit by removing the protective casing by cutting the plastic clamps. After this, use a special key of 17 to unscrew the thrust nut, take out the retaining ring, the spring and knock out the rack stop. Next, remove the boot and drive gear seal, remove the lock washer, and then use a 24mm wrench to unscrew the nut securing the ball bearing. We remove the gear. Now that there is nothing holding the rail in the case, we remove it through the right side of the case. We remove the needle bearing of the drive gear from its seat. To do this you will need a special puller. Check the drive gear bearings for play. If present, the bearings will have to be replaced.

The support sleeve must also be replaced. It has a cylindrical shape and is located inside the steering housing. The bushing is removed by prying it off with a screwdriver.

How to determine whether a steering rack is faulty

Many, especially novice, car enthusiasts are interested in the question of how to understand a faulty steering rack? In most cases, this can be done directly while driving a car, however, wear of the bushing or wear in the body is diagnosed only during removal or disassembly. You can also identify a malfunction using the symptoms described above.

How to check the steering rack for malfunction and what to do

Diagnosis of a steering rack malfunction must be performed based on the symptoms that appear during operation. To begin with, we will describe the diagnostics of the power steering rack.

Noise when turning

If you hear a hum when the steering wheel is turned to its extreme (or close to it) position, it means that you need to check the condition of the hydraulic or electric booster and the components of its working system. In this case, a hum may occur even if the fluid level is normal. You need to check the condition of the pump blades (often, over time, the pump’s performance decreases), the condition of its bearings, and the tension of the drive belt.

Power steering fluid leak

Regular leakage is a reason to check the power steering system and its seals. In particular, if the car owner is forced to frequently add fluid to the system’s expansion tank. In this case, a concomitant symptom of a faulty steering rack will be a fluid leak from the line. It can drain directly onto the ground under the car (usually right under the expansion tank) or streaks can be seen on the steering linkage boots.

Often, when a liquid leaks, air enters the system (the system is “aired”). It can be seen by the bubbling liquid in the expansion tank. As stated above, the cause of the leak may be rust on the rack. To get rid of it in the future, it is advisable to use non-standard plastic clamps to tighten the anthers, and their metal counterparts, which provide a higher level of tightness.

Knock when driving in the front axle

In fact, such a knock may also indicate a malfunction in the vehicle’s chassis, so additional diagnostics must be performed. The knock can be either in the center or on the left or right side. In the best case, a knock may indicate a torn traction boot; in the worst case, it can indicate problems with the rods, levers or other elements.

To understand exactly why such a malfunction occurred, it is better to remove and disassemble the rack. After all, the most harmless thing may be a loose adjusting nut or wear of the bushing (when there is a knock on the right), but a more serious problem is wear of the worm pair.

Torn boot on traction

When checking the performance of the rack, it is necessary to pay attention to the integrity of the traction boot. Ideally, it should be intact and the rubber should be elastic. If it is torn and dirt has gotten inside, it must be replaced, lubricant must be added after removing dirt, moisture, and debris from the mechanisms.

Electric power steering rack

To localize faults in the electric steering rack, it is necessary to check the following elements.

Broken bushings

Most often, the cause of a hum and/or rattling of the steering wheel when turning (and even without it) is broken bushings. Accordingly, it is necessary to carry out dismantling work and check their condition. Usually they cannot be restored. Therefore, you can do it in two ways - change the electric amplifier along with the rack assembly, or buy and use a repair kit, including bushings.

At the same time, it makes sense to check the condition of the worm gear (gear). It fails much less frequently, however, if the car has a high mileage, it is definitely worth checking it.

Turn sensors

The operation of torque sensors is checked using computer diagnostics. Here it is advisable to seek help from a car service center. But, as a rule, sensors are quite reliable devices, so they rarely fail. such a sensor begins to “fail” if the boot that is installed above it is damaged and moisture gets inside.

Electric steering

In modern VAZs with electric power steering, with significant mileage, problems with the electric motor may occur. This can be felt by the increasing force on the steering wheel. Accordingly, in this case it is advisable to check the condition of the brushes, bearings and windings of the electric motor.

Similarly, as when checking a hydraulic rack, you need to pay attention to the condition of the boot, tips, and rods.

Replacing the steering rack of a VAZ-2110

It is rare, but it happens that replacing consumables is not enough. The steering rack, although made of steel, is still subject to wear. Most often, the reason for this is the negligence of car owners who do not monitor the condition of the steering mechanism. In addition, the rack may also be damaged as a result of a traffic accident. But there is no need to despair here either. The VAZ-2110 steering rack is replaced according to the scheme described above. The only thing you need is to purchase a complete repair kit, which costs on average about 1,500 rubles.

Repair Tips

If characteristic knocking noises occur, you need to carry out some specific procedures. That is, to manually determine the level of connection between the column and the rack, whether the needle bearing needs to be replaced, whether lubrication is required or not.

When bitches appear, you need to make sure how well the fastenings are adjusted. If you tighten them, dismantling is not required. Experienced drivers usually give some very useful advice regarding troubleshooting and problems with the VAZ 2110 steering rack.

First of all, this is the purchase of a new part. Restoring such an important component at a car service center with the help of specialists is no less effective. For beginners without some experience, the most unsuitable option would be to carry out independent repairs.

Take care of your life, do not take unnecessary risks. And traveling along the roads behind the wheel of a VAZ 2110 should be nothing but pleasure, full of new impressions and emotions.

| 1. Inflate tires to normal pressure |

| Increased steering wheel play |

| 1. There is a large gap in the gearing of the steering mechanism |

| 1. Adjust the gap in the steering gear gear |

| Clicks and noises when turning the car |

| 1. Wear of wheel bearings |

| 1. Replace wheel bearings |

| Moving the vehicle away from straight-line motion |

| 1. Different tire pressures on the front wheels or different levels of wear |

Useful tips

Finally, here are some useful tips that will extend the life of the steering rack and other elements included in the control unit:

- At least once a quarter, check the condition of the steering at a service station or yourself.

- Pay attention to the condition of the steering column protective cover.

- Try to limit driving on uneven surfaces, especially at high speeds.

- Do not test the strength of the steering rack and the entire mechanism by moving away with the steering wheel turned all the way to the side.

- If play or other signs of steering rack malfunction are detected, repair or replace it.

The steering mechanism of dozens has undergone several ongoing improvements throughout the entire production period of the car, but in general, the steering system is not far removed in design from the VAZ 2108-09 design. Perhaps that is why almost everyone who operates a ten repairs and adjusts the steering rack with their own hands. There is nothing complicated about this and now we will see it.

Under what circumstances does it fail?

As is clear, the rack is connected to the wheels, and you can “kill” it by carelessly moving over uneven terrain. Or in simple words, if you fly over tram rails, deep holes, bad roads, or drive sharply onto curbs, it will fail very quickly. Also, almost any “steering wheel” does not like sudden “starts” from a standstill, especially if your wheels are turned all the way in one direction or another.

Remember, before an obstacle you need to slow down and slowly overcome it, such as rails or a hole. Then the service life of this element increases significantly.

The design of the steering rack on the VAZ-2110

First, let's decide what we will regulate. The design of the rack is extremely simple. The hydraulic booster is not provided, so even with dismantling (which is not at all necessary), all the work will take an hour or an hour and a half.

Scheme and design.

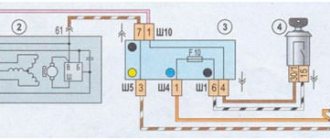

The steering mechanism of the VAZ-2110 is a rack and pinion gearbox that converts the rotation of the steering shaft 27 into the movement of the rack 16 itself. Steering rods 5 and 7 are attached to the rack with bolts 6, which turn the racks with the steering knuckle. The contact point between the drive gear 21 and the rack 16 is most subject to load and, accordingly, wear .

When adjustment is necessary

between these parts , which leads to the appearance of symptoms indicating the need for adjustment:

- knocking in the steering rack when driving over bumps;

- increased steering wheel play;

- the steering wheel is too tight, the wheels do not align after turning;

- the rack “bites” periodically, this indicates critical wear of the rack or drive gear 21.

Clearances and adjustment

In these cases, it makes sense to try to adjust the gap between the rack and pinion in order to delay a major overhaul of the entire mechanism. And we will adjust the gap by pressing the adjusting nut 33 through the spring 32 and the rack stop 31, the rack to the gear.

Symptoms of a problem

Without proper care, such as lubricating bearings and checking play, the steering rack can quickly fail. Signs of malfunction that indicate that the mechanism should already be changed:

- A noticeable knock when driving over bumps, which is transmitted to the steering wheel. If a knocking noise is heard when turning the steering wheel, it is unsafe to drive such a car; it is necessary to urgently diagnose the mechanism.

- Strong play in the steering wheel indicates loose fasteners or wear of the rack-and-pinion joint.

- The effort when turning the wheels has increased.

- You can hear noise from the hydraulic booster (if equipped).

- The cause of the knocking noise may be an insufficiently lubricated bearing or wear of the gear-rack pair. If, when rocking the steering shaft, there is noticeable play at the junction with the rack, repair is necessary. If not, just check and tighten the joints between the bushing and the steering shaft gear.

A powerful vice is used to fasten the rail

We tighten the rail ourselves

We will carry out the work from under the car, so it is advisable to use an inspection hole or overpass. You can tighten the nut from under the hood, but this is extremely inconvenient and will take more time, we checked.

We install the car and secure it with the handbrake; just in case, we put wheel chocks under the rear wheels. Next we do this:

- Remove the engine protection.

We extend the carrier so that it can be seen better.

This is the same nut.

This is what the plastic plug looks like.

You will have to try a little to get the wrench into the nut.

Checking the steering play

To perform a play test, place the front wheels of your vehicle in a straight-ahead (straight-ahead) position. Take a long-blade slotted screwdriver and tape it to the dashboard with the blade facing the steering wheel. Now carefully turn the steering wheel in one direction and the other until the wheels begin to turn. When the wheels begin to turn, use chalk or thread to mark the limits of its free play on the steering wheel rim. Measure the distance between the marks and determine the free play of the steering wheel, which should not exceed 15 mm. If the free play of the steering wheel exceeds 15 mm, you need to check the condition of the steering rack, tie rods and ends, front wheel hub bearings and strut swing arms. After this, sharply jerk the steering wheel from side to side at a small angle. Make sure there is no knocking noise in the steering column universal joints or steering gear. If necessary, tighten loose fasteners or replace faulty parts with new ones.

Main menu. Services. Diagnostics in Kyiv ➧ Steering Center Power Steering + Power Steering

An important step in repairing a steering rack is diagnosing the hydraulic system as a whole and the system units individually. We offer diagnostics of power steering on a car in Kyiv.

Specialists of the Steering Control Center "GUR+EUR" (CRU "GUR+EUR"), using special equipment without dismantling the units, can accurately identify a problem in the power steering system on cars and trucks, which will help avoid additional costs if the power steering problem is incorrectly installed .

Our equipment allows you to check the power steering hydraulic system directly on the vehicle without any disassembly of components. Until now, the only method for diagnosing power steering actuators and power steering pumps was inspection on a test bench and visual inspection of fluid leaks.

Removing power steering components for testing on a test bench and then reassembling them takes 2 to 6 hours, which is a big waste of time. Also, the traditional method cannot guarantee 100% success, because when dismantling the unit from the hydraulic system, the opportunity to see the operation of the unit in the environment where it is constantly operating is lost.

By using testing equipment, all these inconveniences can be avoided and the test can be performed in a much better way. We can check directly at our service station the operation of steering racks, steering gears, and power steering pumps without dismantling them from the vehicle.

Connecting the test equipment will take 10-15 minutes and after starting the engine, any problems can be easily identified by simply reading the following parameters from the sensors:

- Pressure in the steering system at extreme right and left steering positions.

- The maximum pressure produced by the power steering pump.

- Nominal fluid flow (liters per minute).

- Measuring small internal leaks in a system.

- Detection of any iron impurities (contaminants) that are in the liquid.

This service depends on the complexity of the location of the connecting points.

Stand for washing and testing the hydraulic steering system of a vehicle's power steering.

It is characterized by its small overall dimensions and mobility. Flushes the system under pressure.

Allows you to carry out the following types of diagnostics:

- Check the tightness of the seals on the steering rack being tested.

- Check the functionality of the distributor and identify any bypasses in the cavities of the steering rack hydraulic cylinder.

- Check pump characteristics (pressure, fluid flow).

Diagnostics of a removed steering rack with power steering.

Main parameters when checking the steering rack on a stand:

- Checking for steering rack leaks.

- Serviceability of the distribution mechanism.

- The presence of backlash in the worm pair.

- and other necessary parameters.

Also, diagnostics of a steering rack with power steering is necessary if the rack was purchased at a disassembly facility or repairs were made independently. This diagnostic will cost 100 UAH. If it becomes necessary to adjust the steering rack, we will make additional adjustments.

Stand for checking and testing power steering rack.

A distinctive feature is the use of high-quality materials and components in the production of the stand.

Allows you to carry out the following types of diagnostics:

- Check the tightness of the seals of the steering rack being tested (leak test).

- Check the performance of the distributor and identify bypasses in the cavities of the steering rack hydraulic cylinder (load test)

A stand for checking and testing the power steering pump of a car.

A distinctive feature is the use of high-quality materials and components in the production of the stand.

Allows you to carry out the following types of diagnostics:

- Check the operating parameters created by a single-circuit mechanical pump.

- Check the operating parameters created by a double-circuit mechanical pump.

- Check the operating parameters created by some types of electric drive pumps.

Steering Center "GUR+EUR" (CRU "GUR+EUR") - Professional repair of steering racks with power steering. Quality guarantee, minimal repair time, low prices and free shipping!

☎(096)99-11-911″,”word_count”:499,”direction”:”ltr”,”total_pages”:1,”rendered_pages”:1}

Source: https://gureur.com.ua/diagnostika

Checking the condition of the tie rod ends

You will need an assistant to perform this test. Take 2 jacks and lift the front of the car. Secure the machine to support stands. If you have a lift at your disposal, use it. Ask an assistant to grab the wheel and jerk it sharply in a horizontal plane, i.e. pull the rear part of the wheel toward you and the front part away from you. During this, you place your hand on the body of the ball joint of the steering tip and the swing arm and evaluate their mutual movement relative to each other. If you feel the ball joint move freely, replace the tie rod end immediately. In addition, change the steering tip if, during the inspection, you notice that the ball joint boot is torn.