The clutch is one of the most important parts of a car; if the clutch fails, it becomes almost impossible to use the car.

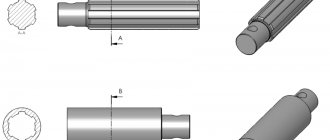

Clutch master cylinder VAZ 2106

A few general points: on all classic VAZ models the clutch is hydraulic, that is, it consists of two cylinders, the main and the working. The master cylinder is installed on top; through the action of the clutch pedal on it, it creates excess pressure, which forces the slave cylinder to move. The slave cylinder is the cylinder in the clutch system that directly moves the clutch fork, is mounted underneath and contains the clutch bleeder.

It is also important to know that from 2101 to 2107 all clutch parts are identical and interchangeable. The working fluid in the clutch system is regular brake fluid.

Role of the master cylinder

The clutch master cylinder (MCC) is responsible for transmitting force from the pedal and further converting this value to a value that will be sufficient to start the clutch fork. This component of modern manual transmission systems is installed internally or externally.

The mechanism of the device is performed in different interpretations, however, the principle of operation of each variation is the same. Among the main details are:

- a pusher connecting the mechanism to the pedal;

- master cylinder;

- piston;

- traffic jams;

- return spring.

Simplicity of design is not a guarantee of uninterrupted operation. The clutch master cylinder can be a serious source of trouble. Then a thorough repair of the clutch master cylinder will be required. The causal factors are as follows:

- lack of working fluid;

- air entering the hydraulic drive system.

The fact is that the likelihood of completely replacing this element is small; most often, a repair kit is needed for the clutch master cylinder, which has the most wearable parts.

Malfunctions and repairs of the clutch master cylinder

If we talk about the GCS, like any other device, this element can also fail. Although the clutch master cylinder is simple in design and reliable, over time individual elements wear out due to constant loads, especially if the car is operated in the city.

As a rule, seals and rubber parts are the first to fail. To put it simply, such sealing elements should be understood as boots that are put on the rod to protect the cylinder from dirt and small abrasives, as well as sealing collars that do not allow the working fluid to leak out.

Another element that can cause problems with the cylinder head is the spring in the cylinder. The spring of the clutch master cylinder constantly experiences loads during vehicle operation, and it is also affected by the brake fluid, which in this case performs the working function. When the metal becomes more brittle, the spring may simply burst.

One way or another, if there is a problem, the cylinder needs to be replaced. At the same time, in a number of cases it is also possible to get by with repairing the main central heating system rather than replacing it. Taking into account the relatively high cost of the part for many cars, this method is optimal. For these purposes, you need to purchase a clutch cylinder repair kit, which includes the necessary spare parts.

This approach usually allows you to sort out the device and completely restore its functionality. The main thing is that the repair kit is of high quality, and that the repair of the clutch master cylinder itself is carried out by experienced specialists.

Clutch assembly

For assembly, use a stand or device used during disassembly.

To maintain the force of the pressure springs of tractor clutches, it is advisable to place washers in the ring grooves of the pressure plate, the thickness of which is equal to the layer of metal removed during turning.

Springs are selected that are equal in length and elasticity. When the clutch is assembled, all ends of the release levers should lie in the same plane, parallel to the base of the housing. The distance from the end of the clutch housing or from the working surface of the pressure plate to the plane in which the ends of the release levers are located is set strictly in accordance with the technical conditions for a given machine. If there is no stand, the correct location of the release levers is installed on the plate using a depth gauge or a special device.

Bleeding the clutch

The assembled and installed cylinders must be filled with working fluid without air pockets. To do this, you will need to properly bleed the clutch. There are several options for performing this operation.

Removing the clutch master cylinder

In the first case , fill the tank with a sufficient amount of working fluid. Next, unscrew the fitting, which is installed specifically for the pumping process, and put the end of the flexible tube on it. We lower the other side into a container under the machine. Now you can press the pedal and thereby release excess air from the hydraulic system. Do not forget to regularly add liquid to the tank during this process. After all the air has come out, screw the fitting on.

Consequences of using cheap products

The extensive range of clutch master cylinders on the market is characterized by a wide range of prices for similar products. As practice shows, a low price is achieved due to reduced quality indicators of the finished product. Cheap clutch master cylinders fail due to poor-quality piston seals, fluid leaks due to low precision manufacturing of parts and poor assembly quality. It makes sense to repair such products; a low-quality cylinder is completely replaced.

Repair kit for repairing the clutch master cylinder - what does it consist of?

At its core, a repair kit is a set of parts that are most necessary for repairing a specific component of a car unit.

Most often, a repair kit for repairing the clutch master cylinder consists of 4 parts. The set contains 1 protective cap, 2 pcs. sealing heads of the rear brake pressure regulator piston, one cap of the fitting for the clutch release cylinder bleeding hose. By purchasing such a set, each car owner will be able not only to save a certain amount of personal funds for the purchase of a new cylinder, but also to restore the functionality of this part of the car.

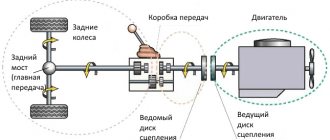

Clutch drive and its types

The drive is designed for remote control of the clutch directly by the driver from the passenger compartment. Pressing the clutch pedal directly affects the pressure plate.

The following types of drive are known:

- mechanical;

- hydraulic;

- electrohydraulic;

- pneumohydraulic.

The first two types are most widespread. Trucks and buses use a pneumatic-hydraulic drive. Electrohydraulic is installed in cars with a robotic gearbox.

Some cars use a pneumatic or vacuum drive booster to make driving easier.

Mechanical drive

A mechanical or cable drive has a simple design and low price. It is unpretentious in maintenance and consists of a minimum number of elements. The mechanical drive is installed in passenger cars and light trucks.

Mechanical clutch drive

Mechanical drive elements include:

- clutch cable;

- clutch pedal;

- clutch release fork;

- release bearing;

- adjustment mechanism.

The clutch cable, enclosed in a sheath, is the main element of the drive. The clutch cable is attached to the fork, as well as to the pedal located inside the car. When the driver presses the pedal, the action is transmitted through the cable to the fork and release bearing. As a result, the engine flywheel is disconnected from the transmission and, accordingly, the clutch is disengaged.

The connection between the cable and the lever drive has an adjustment mechanism that ensures free movement of the clutch pedal.

The clutch pedal travel is free movement until the drive is activated. The distance covered by the pedal without much effort from the driver when pressed is free play.

If gear shifting is accompanied by noise, and at the beginning of the movement there are slight jerks of the car, then adjustment of the pedal travel is necessary.

The clearance in the clutch should be within 35-50 mm of pedal free play. The standards for these indicators are indicated in the technical documentation of the car. Adjustment of the pedal stroke is carried out by changing the length of the rod using an adjusting nut.

Trucks use a lever mechanical drive rather than a cable drive.

The advantages of a mechanical drive include:

- simplicity of the device;

- low cost;

- reliability in operation.

The main disadvantage is considered to be lower efficiency compared to a hydraulic drive.

Hydraulic clutch drive

The hydraulic drive has a more complex design. Its elements, in addition to the release bearing, fork and pedal, also include a hydraulic line, which replaces the clutch cable.

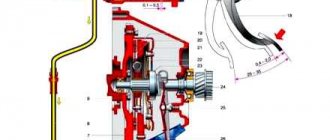

Hydraulic clutch diagram

In essence, this line is similar to the hydraulic drive of the brake system and consists of the following elements:

- clutch master cylinder;

- clutch slave cylinder;

- reservoir and pipeline with brake fluid.

The clutch master cylinder is similar to the brake master cylinder. The clutch master cylinder consists of a piston and a pusher located alone in the housing. Its elements also include a fluid reservoir and sealing collars.

The clutch slave cylinder, which has a similar design to the master cylinder, is additionally equipped with a valve to remove air from the system.

The mechanism of action of a hydraulic drive is the same as that of a mechanical one, only the force is transmitted using the liquid in the pipeline, and not through a cable.

When the driver presses the pedal, the force is transmitted through the rod to the clutch master cylinder. Then, due to the incompressible properties of the fluid, the clutch slave cylinder and the release bearing drive lever are activated.

The advantages of the hydraulic drive include the following features:

- hydraulic clutch allows you to transmit force over a considerable distance with high efficiency;

- resistance to fluid flow in the hydraulic drive elements contributes to smooth engagement of the clutch.

The main disadvantage of a hydraulic drive is that it is more difficult to repair compared to a mechanical one. Leakage of working fluid and entry of air into the hydraulic drive system are, perhaps, the most common breakdowns that the clutch master and slave cylinders can boast of.

The hydraulic drive is used in passenger cars, as well as on trucks with a tilting cab.

Installing the clutch master cylinder repair kit

It is not difficult to determine when it is necessary to repair the master cylinder; the main signs of its malfunction are:

- Insufficient clutch release (clutch drives)

- Any type of leakage, whether from under the nuts securing the hose and tubes, or from the end from under the rubber seals

- Master cylinder stuck in pressed position

In my situation, the main leak was due to a worn out sealing ring, in other words, fluid flowed down the clutch pedal into the passenger compartment.

I started the repair by dismantling the reservoir hose, unscrewed the clamp on the main cylinder and quickly removed it from the main cylinder, turned it up and pinched it behind the reservoir cap so that the liquid did not flow out of the reservoir. Next, I unscrewed the tube that goes to the working cylinder, I did this with a special key, it’s a pity there is no photo, but you can buy one without any problems at any auto store. All that remains is to unscrew the main one itself, it is secured with two 13 nuts and remove it from under the hood.

Main removed

The boot was removed and it was noticeable that fluid was flowing from here.

Having picked up the boot with a screwdriver, I saw exactly where the liquid was flowing from; the assumption was absolutely correct.

Next, you need to wipe the cylinder, remove dirt and rust.

Attention!!! Do not use gasoline or similar liquids for washing, as they will very quickly ruin the new rubber bands. To flush the clutch and brake elements, use clean brake fluid.

After cleaning the dirt, you can begin disassembling. To do this you will need an awl or similar object.

Corkscrew ring

Corkscrew ring

We take out the ring

Next, you need to carefully remove the insides, keeping in mind that the piston is under the action of a spring.

This is what it looks like

Next, you need to clean the master cylinder body, you cannot scrape the parts with a screwdriver, sandpaper, etc., this is just in case, I use a rag with brake fluid. In repair manuals, I often came across such expressions that if rips, scratches, etc. appeared on the parts, then it is unusable. But despite all this, practice shows that despite all the risks, provided that a high-quality repair kit is installed, the master cylinder works without problems. I used this kit:

Repair kit for clutch master cylinder VAZ

We remove the old rings, clean all the grooves and holes. There should be no dust or debris there.

The ring is removed, clean the piston, install a new one

Product location

The master cylinder on a VAZ 2107 is located under the hood, directly on the wall separating the interior from the hood, near the driver’s feet. Directly above it is the expansion tank, and next to it are the vacuum booster and the brake master cylinder. Usually, simply looking at the product is enough to determine the problem. The presence of a leak indicates that the part is faulty and requires repair or replacement.

We change it ourselves

Replacing the VAZ 2107 clutch master cylinder begins with the need to pump out the brake fluid from the hydraulic reservoir. This can be done using a syringe or a rubber bulb. Together with this socket or a 10mm wrench, unscrew the bracket securing the expansion tank and move it to the side to gain access to the cylinder.

The next step involves removing the clutch expansion tank hose. To do this, you need to loosen the hose clamp, then disconnect the hose and position it so that it does not interfere with further work. If you want to remove the tank completely, this is done very simply.

Further actions are performed in the following sequence:

- Using a “10” wrench, you need to unscrew the pipeline securing nut to the device. Once the nut is unscrewed, the tube can be moved to the side.

- There is a hose nearby near the steel pipeline, which also needs to be disconnected from the main device. This can be done by loosening the fixing clamp.

- The GCS is fixed to the body using two fastening nuts. To unscrew them, you will need to use a wrench with an extension and a “13” socket. After unscrewing the two nuts, you can remove the product and drain the remaining brake fluid from it. If it is not possible to dismantle the unit, you can press the clutch pedal, as a result of which it will move.

- But repairs are usually not rational, so after removing the old one, a new unit is installed in its place. Installation is carried out in the reverse order of removal. After installation, it is necessary to carry out the process of pumping the hydraulic drive, first pouring fuel fluid into the tank. You can find out how the system is pumped from the relevant material on the website.

READ How much oil is needed for a VAZ 2107 gearbox

After the work is completed, you can test the operating features of the new GVC. If necessary, the RCS (working cylinder) should also be replaced, but you can find out more about this in the corresponding material.

Cars of the Volzhsky plant models 01-07 have a hydraulic clutch drive. The main actuator of this mechanism of the VAZ 2107 is replaced in the event of its breakdown or failure. The cylinder is secured to the engine compartment shield on the driver's side with two studs and nuts, and a reservoir with brake fluid is installed in the upper part. A pipeline is laid from it to the working unit.

The role of the working cylinder

The clutch slave cylinder (CLC) is an element of the hydraulic clutch system without which the car cannot operate. It is assigned one of the most basic functions: receiving forces that come from the master cylinder, thus moving the clutch release fork.

Clutch slave cylinder

Located on the crankcase, the clutch slave cylinder is practically the same in all models and brands of cars. Based on this, the fundamental features of its replacement are identical and do not depend on the brand of your vehicle.

Replacement work

Replacing the clutch slave cylinder involves the following manipulations:

- First, pump out the hydraulic fluid using a syringe.

- We remove the expansion tank for convenient further dismantling.

- Unscrew the nuts securing the barrel (from where the liquid was drained) using a 10mm socket and remove the hose.

- The aluminum tube coming from the GCS is unscrewed.

- Using a 13mm socket, unscrew a couple of nuts holding the main center joint together and pull it towards you.

- Unscrew the hose from the RCS using a 17mm wrench.

- Using the 13mm head, unscrew the last nuts holding the control center together and remove it.

The cylinder has been dismantled and we begin to inspect it for possible damage. If there are none, repairs are possible. A repair kit will help with this, which has three different cuffs and a boot. Upon completion of disassembly, the old cuffs should be replaced with new analogues and the boot should be installed. If repair work cannot be performed, it is necessary to purchase a new device.

Important: the nut is screwed on at the same distance as it was on the old cylinder.

Assembling the clutch system involves performing the above steps in reverse order. At the same time, do not forget to replace old aluminum tubes. At the very end, brake fluid is added and bleeding is performed.

We recommend: Spare parts for MAZ-206 bus

Do-it-yourself replacement of the VAZ 2107-2101 clutch slave cylinder

Carrying out independent repairs of this drive will require the owner not only to have a certain set of tools in the form of various keys with different head sizes and repair kits, but also certain repair skills. Self-repair is quite within the capabilities of an experienced owner of a VAZ classic. Also, the owner will definitely need a lift or MA in the garage, since the part is located in the lower part of the engine compartment, in close proximity to the gearbox.

For beginners, in most cases you will need an assistant. In total, there are two main types of work with this part - removing and installing a new device into the system, which will not require additional time, and repairing the original part with complete or partial disassembly, which will require a sufficient amount of time, this directly depends on the experience of the owner.

How to remove the clutch slave cylinder VAZ 2107-2101

The procedure for removing the unit as a whole takes place in several main stages:

- All fluid must be removed from the clutch reservoir. To do this, you will need a regular small volume syringe. This tank is located in the upper part of the engine compartment. This is necessary to prevent the substance from spilling onto the owner or outside the system.

- After this, it is necessary to loosen the fastenings of the tank itself and, if necessary, dismantle it. At the same time, use a 13-mm wrench to loosen the rubber pipe leading from the tank to the master cylinder, thereby freeing up free access to the system.

- After this, also use a 13 key to disconnect the part from the other clamps of the clutch system and unscrew the 2 mounting fasteners using a regular screwdriver, which hold the body in the seat. After this, the part can be completely removed.

Repair of clutch slave cylinder VAZ 2107-2101

Repair work also takes place in several stages and is carried out immediately after dismantling the device itself:

- Using a 22mm socket wrench, unscrew the plug and remove the boot along with the locking ring.

- Then move the VAZ 2106 clutch slave cylinder rod all the way and then remove the fitting from the seat. This opens access to all internal parts of the device.

- These parts are located inside the housing and are arranged in a certain sequence.

Installation of the clutch slave cylinder VAZ 2107-2101

Reinstallation of a repaired part or installation of a new device occurs in the reverse order:

- The tank and cylinder linkage assembly must be secured in the standard mounting points in the engine compartment using keys.

- After this, it is necessary to connect the main part with the branch pipes of the vehicle systems, while choosing the correct tightening torque for the clamps.

- After this, connect the tank to the general hydraulic drive system and fill the liquid in accordance with the level.

Causes and symptoms of GCS malfunction

As mentioned above, wear and tear of individual cylinder elements is inevitable over time. Also, premature failure of a part can be caused by untimely replacement of brake fluid, ruptures of seals, errors in assembling/installing individual spare parts from the repair kit, etc.

As a rule, the most serious damage can be considered when the mirror of the cylinder itself is heavily worn, scuffs, abrasions and other defects appear on the metal surface, and pockets of corrosion are visible. In such a situation, a conventional overhaul using a repair kit is often not possible. The only solution is to completely replace the clutch master cylinder.

Article on the topic: HBO: gas instead of gasoline

The fact is that one of the properties of brake fluid is high penetrating ability. This means that fluid seeps through even the smallest scratches on the cylinder bore and/or piston. Replacing only the rubber seals does not help in this case.

We also recommend reading the article about whether there is a clutch in an automatic transmission. From this article you will learn what devices and mechanisms in an automatic transmission perform the clutch function, as well as how the clutch works in an automatic transmission.

Often, a high-quality GCS repair kit usually has both cuffs and a new piston. However, if there are scratches on the cylinder mirror, in this case the entire part needs to be replaced. For this reason, it is important to prevent critical wear and tear by paying attention to the slightest signs of failure of the main circulation system. As soon as a problem occurs in the cylinder, fluid can leak out of the system and its level decreases.

Also, the clutch pedal may work worse; while driving, the driver notices that the gear shifting process is disrupted as a result of clutch malfunctions. If there are problems with the cylinder, the clutch pedal may fall to the lower position (fall, stick), the pedal travel becomes tight, etc.

In this case, a visual inspection must be carried out immediately. First of all, you should check the level and condition of the brake fluid. You also need to inspect the cylinder itself. If there are obvious stains on the cylinder or the seals (cuffs) are wet, then a leak is obvious.

We also note that a common problem with the clutch master cylinder is active clogging of the holes in the reservoir cap. In order for the device to work properly, it is assumed that the fluid level in the cylinder reservoir constantly rises and then decreases.

In order for the level to rise and fall normally, there are special ventilation holes in the tank lid. In cases where the holes are clogged with dirt, the entire hydraulic drive malfunctions, the clutch pedal moves hard, the clutch pedal slowly returns to its original position, etc.

The principle of operation of the clutch slave cylinder VAZ 2107-2101

The operating principle of this part is quite simple, however, despite its small dimensions, the function of pushing fluid into the system is very important in the operation of the entire clutch. The principle of operation of this unit is to briefly disconnect the gearbox and the motor itself during gear shifting. When you press the clutch pedal, fluid enters the master cylinder under the influence of a piston, which also presses on the clutch fork. This, in turn, acts on the gear selection clutch through a bearing, which also presses on the driven disk, disengaging the clutch.

Subsequently, when the pedal is released, the cylinder is returned to its original position by means of a spring, and the liquid flows back into the tank. The clutch also returns to its original position regardless of whether a particular gear is engaged or the vehicle is in neutral. Thus, this part is an important link during switching and acts as the main part of the hydraulic drive system. The advantage of this system is the simplicity of the design with the presence of a small number of mechanical parts, thereby limiting the friction process and increasing the overall resource. It is also worth noting the ease of repair and low cost of spare parts.

Clutch cylinder repair

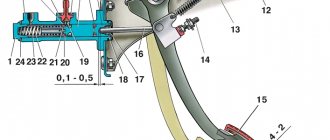

Rice. Hydraulic clutch drive device VAZ-2101-07: 1 - main cylinder; 2 - compensation hole; 3 — fitting gasket; 4 - fitting; 5 — lock spring washer; 6 — piston of the main cylinder; 7 - sealing ring; 8 — pusher piston; 9 - hook; 10 — axis of the clutch and brake pedals; 11 — bracket for clutch and brake pedals; 12 — clutch pedal reinforcing spring (Servo spring); 13 — clutch pedal release spring; 14 — clutch pedal travel limiter; 15 — clutch pedal; 16 — pusher; 17 — protective cap; 18 — retaining ring; 19 — bypass hole; 20 — sealing ring (ring valve); 21 — piston bypass hole; 22 - working cylinder; 23 - spring; 24 - gasket; 25 - plug; 26 — inner pedal bushing; 27 — outer pedal bushing; 28 — spacer sleeve; 29 — brake pedal

To carry out the work, it is necessary to dismantle the entire assembly, first disconnecting all pipes and draining the liquid from the system. You should also prepare in advance a repair kit for the clutch master cylinder, which includes all parts subject to wear. Despite the fact that the design of the clutch master cylinder is not complicated, it is advisable to carry out the work by persons who have at least minimal experience in plumbing work. If the question of how to remove the clutch master cylinder is completely unclear, it is better to abandon repairs yourself and simply replace the cylinder with a new one.

To eliminate errors during dismantling and subsequent reassembly of this unit, you should remember all the stages of disassembly, and reassemble it in the reverse order. If there is clearly not enough experience in such actions, the stages can be written down - this is guaranteed to protect you from mistakes.

After dismantling, the cylinder should be disassembled and its parts should be thoroughly washed with brake fluid (the use of solvents or gasoline is prohibited). It is also advisable to wash all parts from the repair kit that are planned to be used before installation.

After dismantling and completely disassembling the master cylinder into its component elements, you can begin to assess the technical condition of all parts. First of all, carefully inspect the piston, mirrors and sealing elements. Quite often, pockets of corrosion can be found on internal surfaces; they can be eliminated by careful treatment with fine-grained sandpaper. Multiple, extensive and accompanied by the presence of scuffing foci of corrosion indicate a violation of the gap between the piston and the cylinder walls.

It is recommended to replace all sealing elements with new ones, since when working under pressure, even minor defects inevitably lead to fluid leaks from the cylinder. It is not permissible to treat rubber seals with oils to facilitate assembly - this will lead to their swelling and the impossibility of normal functioning.

After all faults have been eliminated, the device can be reassembled in reverse disassembly sequence.

After replacing the clutch master cylinder or repairing it, the clutch system must be bled. This is a necessary measure to eliminate accumulated air bubbles, the presence of which is not allowed in the hydraulic drive system.

For bleeding, it is necessary to provide free access to the master cylinder, and for this it will be more convenient to drive some vehicle models into a pit or lift them on a hydraulic lift. New brake fluid is poured into the reservoir, a transparent tube is put on the fitting, the end of which is lowered into a container with the same working fluid. By rhythmically operating the clutch pedal, the hydraulic drive is pumped until the release of air through the fitting stops completely. After this, the fitting is tightened and the car is ready for use.

We recommend: Replacing a ball joint with your own hands: instructions with photos

Replacing the clutch master cylinder VAZ 2107

The simplest way to repair a VAZ 2107 clutch is to change the worn cylinders (main and slave). Their price is low, and the labor intensity of the operation is much lower than when carrying out repairs. Therefore, car owners often prefer to replace rather than repair clutches.

Let's start by replacing the master cylinder. The order of operations is as follows:

- Drain the brake fluid from the clutch reservoir into another container. This can be conveniently done using a syringe.

- Loosen the clamp and remove the hose from the master cylinder fitting.

- Unscrew the fitting of the metal tube going from the master cylinder to the slave cylinder and disconnect the tube.

- Using a 13mm wrench or a socket with an extension, unscrew the two nuts securing the master cylinder to the body bulkhead and remove the master cylinder.

The new clutch master cylinder can now be installed. Before doing this, you should check the condition of the flexible hose of the clutch reservoir. If it cracks at the end, it needs to be trimmed slightly or replaced with a new one.

When installing a new cylinder, it is necessary to ensure that the clutch pedal drive rod fits inside the cylinder. For convenience, you can ask your partner to slightly press the clutch pedal and hold it. Then follows:

- Install the master cylinder onto the studs and tighten the nuts.

- Attach and tighten the metal tube fitting.

- Place the pipe from the clutch reservoir and tighten the clamp.

- Fill the reservoir with brake fluid, following the level marks.

The clutch master cylinder has been replaced.

Dismantling process

First, the tank is turned off. Next, release the clamp on the main body and turn it so that excess liquid does not drain. We unscrew the pipe going to the DC. This is done using a special key, which can be bought at any auto store.

Step 1. Remove the protective cap Step 2. Remove the lock washer Step 3. Remove the fitting Step 4. Unscrew the plug Step 5. Use a puller to remove the washer Step 6. Remove the contents of the cylinder

After this, unscrew the two nuts to 13. They secure the GC. Now the GC can be removed outside. We clean the cylinder of dirt so that we can continue working with a clean part. To do this, it must be washed.

You need to know that it is prohibited to use gasoline to wash the master cylinder. This leads to corrosion of the rubber elements. New brake fluid must be used.

To see the design of the clutch master cylinder, you need to release the retaining ring. This can be done using an awl or a special puller. The internal contents must be removed carefully, since the mechanism contains a spring.

You should not scratch the case with metal objects, including a screwdriver, as the surface may be damaged. Clean only with a rag and brake fluid.

Old rings must be replaced, even if they look slightly worn out. It is also necessary to carefully clean all grooves from possible dirt. The assembly process consists of the reverse of disassembly operations. The last step is to install a new retaining ring.

Clutch master cylinder malfunctions

Despite the simplicity of the device, the clutch master cylinder may have the following breakdowns that make its normal operation difficult or impossible:

- Lack of process fluid. The liquid level in the tank must be periodically monitored and, if necessary, topped up to the set level. It appears when the cuff on the cylinder is damaged or broken or the system connections lose their tightness. Eliminated by identifying the location of the leak and ensuring its tightness.

- The entry of air into the system, leading to failure of operation, which is manifested by “under-depressing” of the clutch with a characteristic crunch or vibration of the lever when changing gears. The cause of the malfunction is cracks in the tubes, wear of moving parts or leakage of the system at the connections. The malfunction can be resolved by identifying and eliminating such areas and bleeding the entire system to remove any air trapped there.

- Pumping liquid through oneself. The malfunction occurs when the cuffs fail or there is wear on the piston itself. Eliminated by replacing damaged parts.

The first signs of a malfunction should serve as a reason to diagnose the clutch master cylinder and the entire system as a whole. Timely measures taken will allow you to avoid replacing the entire assembly by eliminating the malfunction by replacing worn parts.

Replacing the clutch slave cylinder VAZ 2107

Removal of the working cylinder should be done from the inspection hole or using a lift. The order of operations is as follows:

- Remove the return spring from the slave cylinder bracket.

- Unscrew the fitting of the tube coming from the master cylinder. To prevent brake fluid from leaking from it, you can put a cap on it, removed from the cylinder bleeder fitting, or direct it into a container prepared in advance.

- Unscrew the two bolts connecting the slave cylinder to the gearbox and remove them together with the plate.

- Remove the clutch slave cylinder.

The new working cylinder is installed in the reverse order of removing the old one.

After replacing any of the cylinders, the hydraulic drive system must be pumped. The work must be carried out together with a partner. This is done like this:

- Place a hose on the fitting of the working cylinder and immerse its end in a prepared container for brake fluid.

- Depress the clutch.

- Unscrew the fitting on the working cylinder 1 turn.

- Wait until air bubbles stop coming out and tighten the fitting.

- Repeat the operation until air stops coming out of the fitting. At the same time, monitor the fluid level in the clutch reservoir.

- Tighten the fitting and put on the cap.

There are several ways to bleed the clutch on a VAZ 2107, here is a video about the most popular ones

How to purchase a high-quality clutch cylinder, what to look for

The first thing you should pay attention to when choosing a quality clutch cylinder is its cost. Unfortunately, today in the automotive market it is quite difficult to choose high-quality spare parts for a car, the cost of which will be significantly lower than the average selling price. Before you go to a car store for a new part, it is recommended to study the market and all possible offers. Only after this, guided by the suggestions, feel free to go to a more convenient car store for the required clutch cylinder.

In fact, purchasing a high-quality clutch cylinder is quite a difficult task, since it can be fully checked only after installation in the car, bleeding and testing. However, the selection of a cylinder must begin with a visual inspection for visible damage. You should inspect the cuffs that prevent the release of brake fluid from the system. They should be tightly seated and not have any visible damage.

Next, you can close it, press the rod as hard as possible and see how quickly it returns to the reverse position after the impact on it is completed. The rod should immediately return to its place, thereby confirming the normal operation of the return spring.

You can also independently check the tightness of the system at low pressure. To do this, close the outlet and inlet fittings with your fingers, through which the brake fluid passes through the system. By pressing the rod again, air should not escape from the joints of the structure and the sealed cuff.

There should also be no visible damage on the case itself - chips, impacts, cracks, dents. Since this part of the car is quite often under the influence of internal pressure when pressing the clutch pedal.

VAZ 2107 clutch: device

The “Seven” has a dry single-disc clutch. The clutch hydraulic master cylinder is located directly under the pedal, when pressed, the pusher moves, acting on the master cylinder piston, creating pressure. The brake fluid that fills the hydraulic drive is squeezed out and flows into the working cylinder.

The piston of the working cylinder is connected to the clutch fork by a pusher. When you press the pedal, the latter moves the fork, it displaces the release bearing and separates the support and pressure discs. As a result, the torque from the crankshaft flywheel is no longer transmitted to the gearbox and it becomes possible to change gear.

If the clutch unit malfunctions, when you press the pedal, the gearbox shaft continues to rotate and changing gears becomes difficult or even impossible. If the clutch is adjusted incorrectly, the discs may slip, which is accompanied by accelerated wear.

You cannot continue to drive a car with a faulty clutch - both the clutch discs and the gearbox may be damaged. Therefore, at the first sign of a malfunction, you should start repairing and adjusting it.

Selection of GVC for VAZ 2107

The best option for replacement is to purchase a GCS designed specifically for classic VAZ models. Clutch master cylinders from UAZ, GAZ and AZLK vehicles are not suitable. The same applies to foreign analogues - foreign cars with rear-wheel drive are equipped with GVCs, which only highly qualified specialists can adapt to the VAZ 2107 (different sizes, different threads for pipelines, different pipe configurations). However, you can easily replace the original cylinder with a GCS from a VAZ 2121 and from a Niva-Chevrolet.