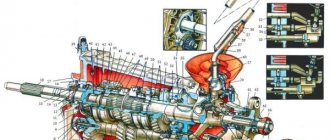

The gearbox is mechanical, two-shaft, with five forward gears. It is structurally combined with the differential and main gear.

The gearbox housing consists of three parts: clutch housing 25, gearbox housing 7 and rear cover of the gearbox housing 1.

When assembling, a gasoline-oil-resistant sealant is applied between them - a gasket.

There is a special magnet in the clutch housing socket that holds metal wear debris.

The input shaft 5 is designed as a block of drive gears, which are in constant mesh with the driven gears of all forward gears.

The secondary shaft 40 is hollow (for supplying oil to the driven gears), up to the removable drive gear of the main gear 17.

It contains driven gears 31, 33, 34, 36, 38 and synchronizers 32, 35, 39 for forward gears.

The front bearings of shafts 18 and 12 are roller, the rear bearings 3 and 37 are ball.

The radial clearance in roller bearings should not exceed 0.04 mm. Under the front bearing 18 of the secondary shaft there is an oil sump 19 that directs the flow of oil into the shaft.

The differential is two-satellite. The preload in the bearings 29 (0.25 mm) is adjusted by selecting the thickness of the ring 28 installed in the gearbox housing housing under the outer ring of the differential bearing.

The driven gear of the main gear 27 is attached to the differential box flange. The gearbox communicates with the atmosphere through the breather 14 located in its upper part.

The gearbox control drive consists of a gear shift lever, a ball joint, a control rod, a gear shift rod and a gear shift mechanism.

To prevent the gears from switching off spontaneously due to the axial movement of the power unit when the vehicle is moving, a reaction rod is introduced into the gearbox control drive, one end of which is connected to the power unit, and the other end is attached to the base of the gear shift lever.

A switch (lever) is attached to the inner end of the rod, which acts on the three-arm lever of the gear shift mechanism.

This mechanism is made as a separate unit and is attached to the clutch housing. The gear shift housing has three axes.

One is equipped with a three-arm gear selection and engagement lever and two locking brackets.

The other axis passes through the holes of the locking brackets, securing them from turning.

The gear selector, mounted on the rod, acts on the arm of the gear selection lever, which in turn engages forward gears with one arm, and reverse gear with the other. A reverse gear fork is installed on a separate axle.

To prevent accidental engagement of reverse gear, a reverse gear lock solenoid is installed in the transmission.

The protruding part of the solenoid core prevents the locking brackets from moving along the axes until the reverse gear is engaged.

A solenoid switch is installed on the gear shift lever.

When the ring under the handle is raised, the switch contacts close and voltage is applied to the solenoid.

The solenoid core retracts and makes it possible to engage reverse gear.

If the solenoid fails or its electrical circuit is broken, it becomes impossible to engage reverse gear.

In order to engage reverse gear and drive to a garage or service station where the fault can be repaired, you should unscrew the solenoid from the gearbox housing and in its place screw in the shift fork rod lock plug, which we recommend taking with you.

Repair, features and technical specifications

Inside a VAZ 21118 car, like any other, there is always a gearbox. For a model such as Kalina 1118, this device is a mechanical type design, which is equipped with one reverse stage, as well as 5 forward stages.

Gearbox from Lada Kalina.

In Lada Kalina, the gearbox is structurally combined with a differential, the main gear. Transmission differential repair should also take this into account.

The mechanism body of the VAZ Kalina car is presented in the form of three aluminum copper crankcases:

Special sealants are applied between them when assembling and repairing the gearbox.

Technical features of the gearbox

The drive gear block is engaged by the input shaft. This is important to consider when repairing a gearbox. As for the input shaft itself, a constant clutch is created for it with the front gear elements that perform similar functions.

When repairing the secondary shaft, we must remember that it has a hollow structure. It is thanks to this that the oil reaches the driven gears without any problems.

Inside the mechanism you can also find driven bearings and synchronizers. When replacing the backstage on your own, this part can also be replaced. This also requires repairing the gearbox driveshaft.

The design of the gearbox is such that repairs cannot be done without the use of special circuits. In this case, the radial clearance on the roller bearings is no more than 0.07 millimeters.

Repairing the gearbox is also a rather complicated process. Especially considering that 0.04 millimeters should not exceed the same figure, but for ball analogues.

Location of the checkpoint backstage on the Lada Kalina.

The oil sump is responsible for supplying oil. It is located in the area of the front bearing, fixed behind the output shaft. Major repairs often affect such details. If you select the desired thickness of the rings, it will be possible to adjust the tension indicator. The dimensions of the seals are easy to find in the instructions; these parts can be replaced without problems, even at home.

When repairing the gearshift knob, you must remember that the driven gear of the gearbox on this machine is attached to the differential flange. Through the saloon, the atmosphere is combined with the box itself, located at the top of the structure we are considering.

Lever repair is not the only operation that needs to be carried out from time to time. Sometimes it is necessary to replace bearings; this is done when extraneous noise appears. A gearbox repair kit must be purchased if excess noise becomes noticeable when pressing or releasing the clutch pedal.

All control drive elements of the Lada Kalina gearbox.

The repair manual says that the box is controlled using a drive, which consists of several elements:

- Switch rod.

- Spherical bearing.

- Lever arm.

According to the manual, cable structures are always equipped with jet traction, then the gears do not turn off on their own. One of the ends of the rod is connected to the lever, and the other to the motor. If the seals of the internal joints are faulty, it is necessary to carry out independent repair of the gearbox. But before replacing them, you need to completely change the oil. The front wheel drive is completely disconnected.

Servicing the gearbox involves using a screwdriver to remove the necessary parts. But you will need to purchase a mandrel with the necessary parameters in order to carry out the pressing.

Three axes are present on the shift system. One axis is equipped with a three-arm lever for selecting and disengaging gears. There is no gearbox on the second axle, but there are brackets that block rotation. After every 75 thousand kilometers, this design is completely changed. Gearbox lever play should also alert you, as should failure of other parts.

Manual Transmission

Lada "Kalina" cars are installed combined with a two-satellite differential of the main gear. They have four forward gears, only one reverse. All forward gears with installed synchronizers. They are the ones that give the box a characteristic creaking sound when switching, for which the car is often criticized. But it is quite simple to eliminate this defect of the device; you need to adjust the synchronizers if you need to replace them. Kalinas are equipped with mechanical boxes, the power of which depends on the number of valves in the engine. Recently I improved them for these cars; this affected the copies with eight- and sixteen-valve engines; they were replaced. For these Lada Kalina models, reinforced secondary shafts are now installed on the devices, which make them more reliable and powerful.

Device composition

The mechanical gearbox itself consists of three metal housings:

- Clutch housing;

- Gearbox housing;

- Rear gearbox housing cover.

A special feature of this device model is the fact that there is a special magnet in its core. It is designed to hold small metal debris so that it does not end up in the box, replacing parts allows it to be removed. The bearings installed in the system are divided into rear type - ball and front type - roller. In the space below the front bearing of the secondary shaft, a special oil collector is installed, which will torsionally direct the mass of oil inside the secondary shaft.

Change of oil

The manufacturer has supplied the box with special gear oil; it requires regular replacement. On Kalina, the oil is changed after about 75 thousand kilometers, but the level must be constantly monitored. To do this, the car is equipped with a special oil dipstick, which must be carefully lowered into a funnel on one of the crankcases. There are special marks on the dipstick; you should follow them; they will show the oil level. If the oil level is insufficient, then it must be added, this must be done slowly in small portions. The used oil must be drained through a special hole located at the bottom and closed with a valve.

Locks

Another feature of the Lada Kalina gearbox is a specially installed locking solenoid, which prevents accidentally engaging reverse gear. If such a solenoid fails or its electrical network is interrupted, it becomes impossible to engage reverse gear. If such a malfunction is detected, in order to get to a repair shop, you should unscrew the solenoid from the box. Its place should be taken by the plug of the rod lock of the shift fork. It should be in the repair kit, you need to take it with you. You need to drive to the workshop slowly and carefully, making sure that you do not accidentally change from first gear to reverse.

Removal and installation of the gearbox

Servicing the gearbox assumes that the mechanism will have to be removed and its position changed. Before doing this, you need to install the vehicle itself on the lift. The ignition must be turned off completely and the parking brake must be used.

How to repair a gearbox? To do this, disconnect the minus terminal from the battery. The hood must be opened completely. Any manual on gearbox repairs writes about this.

The oil filler cap is also removed. It is necessary to install the previous item after the screen is removed. The gearbox requires loosening the clamp responsible for fixing it. The inlet pipe hose must be disconnected from the corresponding sensor. Gearbox lever play requires the same actions in practice. Then you need to unscrew the air intake nut.

The repair progress further depends on the specific malfunction.

Gearbox Lada Kalina after dismantling and disassembly.

The gearbox can be installed in its original place after the 1st speed repair is completed. SHRUS-4 lubricant is applied to the outer surface of the corresponding bushing in the clutch in a very thin layer. This will also help if the gearbox is loose. The pin fixing bolts are removed from the steering knuckles.

Sports gearbox

There is also a special gearbox for the Lada Kalina, which belongs to the sports class. The Kalina sports gearbox is distinguished by carefully adjusted synchronizers and gears. The production of such devices has been discontinued by the manufacturer, but they remain in operation, and passionate owners dream of acquiring them. Therefore, many companies today offer conversion of the Lada Kalina box and bring it to a sporty state, changing the device beyond recognition. To do this, companies use refurbished spare parts, which are tested and are often not inferior in quality to new ones.

Gearbox lever jammed

In any case, it is necessary to remove the last fastener after the bolt nut securing the left suspension arm has been unscrewed to the body bracket.

Repairing a box cushion is not complete without many of the steps described above.

After this, all that remains is to remove the lever. Another rather important element is the gearbox fork; its condition must also be monitored.

You will need to drain all the remaining oil into the container. A complete gearbox repair also involves removing such parts as the wheel drive from the gears of the differential axle shafts. The plugs are placed in the place where the gears used to be. After the gearbox adjustment is completed, they usually proceed to installing the left suspension support and brackets for the rear of the car.

Any such work, including repair of the secondary shaft, must take into account the general design of the gearbox and the basic principle of its operation. It contains a book on repairing the box. The same applies to the functionality of the component elements, otherwise the gearshift lever support cannot be replaced, like other parts.

Dismantling of the Lada Kalina gearbox at a specialized service station.

The features of the repair are fully familiar only to real professionals. It is better to entrust the work to them if you do not have the proper experience or some practical skills.

It is necessary to completely rinse the mechanism with water before disassembling it to identify a gearbox malfunction. Problems during repair may arise if the part itself is not installed on a special stand. The bracket, which is responsible for fixing the clutch cable and engine suspension, is completely dismantled.

Many people give useful advice on replacing a VAZ gearbox. According to them, in any case you will need to remove the rear cover of the crankcase.

How to remove the gearbox

The fork fixing bolt and nut must be unscrewed after the input shaft stopper has been removed. The same thing will have to be done if it is necessary to replace the short-throw gearshift link.

The spline must be removed from the secondary shaft. The box assembly diagram assumes the reverse procedure.

One of the popular domestic cars is the Lada Kalina. The second generation became available in 2013. The car has improved its technical qualities. Also, the exterior has improved.

Design features

The optimal level of acceleration is ensured by the transmission system. In particular, on the version of the car that develops 87 horsepower, the car accelerates to 100 km/h in approximately 12.5 seconds (manual transmission). This indicator is higher only on a car where an automatic transmission is installed. As for fuel consumption, the basic configuration consumes approximately 8 liters per 100 km. This indicator is optimal for cars of this class.

The Kalina 2 gearbox includes a block of drive gears, driven bearings and synchronizers are installed. There is an oil sump near the front bearing. This element is responsible for supplying oil. The mechanical housing on the Lada includes, in addition to the clutch housing, the rear crankcase cover. They are cast from aluminum alloy.

A distinctive feature of the Kalina gearbox is that there is a magnet in the existing drain plug. The need for this is explained by the fact that it directly attracts metal debris that can get into the system.

The solenoid is effective. It is necessary to block accidental reverse gear. The solenoid is located in the gearbox housing. If the solenoid breaks down, reverse gear will no longer engage. However, the occurrence of this malfunction may be due to an electrical circuit break.

Thus, Lada Kalina can be equipped with a manual or automatic transmission. The service life of the machine depends on how often the device can be serviced. It is recommended to periodically check the oil level in the Lada Kalina box.

Gearbox Maintenance

Lada Kalina automatic, gearbox Lada Kalina automatic transmission, fuel consumption, acceleration

To maintain normal operation of the gearbox, it is necessary to systematically monitor the oil level. The procedures should be performed on a cold box. The desired oil level indicator is located between two control marks marked on the indicator.

Using the dipstick you can determine how much fluid needs to be added. It is better to pour the substance in small doses through the hole closed with the dipstick.

The Kalina operating manual defines the filling volume of the box as 3.1 liters. But practical advice on how much to fill with transmission fluid differs slightly from the normative ones. It is more often said that a complete fluid change requires 3.3 liters.

For the Kalina gearbox, clear parameters have been defined according to which the planned replacement of the transmission substance is carried out. High-quality oil lasts 75,000 km or 5 years of vehicle operation. Depending on what comes first, the transmission substance is replaced.

Identifying and eliminating gearbox problems

Servicing the gearbox involves removing this device from its original location. Especially for this, the car needs to be placed in an inspection hole or use a lift. To remove the box, you need to remove the air filter, starter, mudguard, crankcase protection, wheel drive, suspension mounts, disconnect the jet rod, front wheel drives, mounting bolts and nuts. Transmission repair may also involve replacing the rocker.

During diagnostic work, all components of the gearbox control drive are checked, from the shift lever to the control rod. Attention must be paid to the gearbox fork. This component of the gear shift mechanism is made of durable material. The fork has two branched tines and an axle. If it becomes deformed, the part should be replaced.

Lada Kalina can be repaired with your own hands. In particular, one of the ways to restore the performance of the gearbox is to change the gearbox oil. It is possible to independently determine the oil level using the control marks that are placed on a special indicator. As for the use of transmission fluid, you should choose a fuel that does not lose its properties over a wide temperature range. In particular, it can be 75W-90, 80W-85 oil.

When repairing the Kalina gearbox, special schemes are used. This allows you to get an accurate and complete picture of the vehicle system. Increasing noise and howling may also be a consequence of worn-out gear teeth. In rare cases, this is due to the fact that there is not enough oil in the box.

It is possible to eliminate noise from the gearbox if you replace the bearings. Repairing the Kalina gearbox can involve replacing the internal joint seals. If the seals are worn out, then because of this the owner of the Lada will be faced with such a manifestation as an oil leak.

Choosing the best oil

KAMAZ gearbox diagram and design

When choosing oil for the gearbox, and for other units of the Lada Kalina, you must take only the original fluid. Since, recently, the market has a significant share of fakes, it is necessary to approach the issue carefully.

Thus, Kalinovody chooses to fill with TNK TRANS KP Super oil. As practice shows, the gearbox on it begins to operate more quietly, and the speed shifts smoothly. Monitor the oil level in the gearbox.

And in an 8-valve engine they prefer to pour what is recommended by the factory, just like in a 16-valve engine. A 16-valve engine is more capricious, so you need to be very strict when choosing oil.

A table of recommended oils for Kalina, as well as their coding, was found in the factory service manual.

It is worth remembering that only transmission oil is poured into the gearbox. After a major overhaul, at the time of break-in, you can use the simplest thing - TAD-17.

Consequences of untimely replacement

Since, over time, gearbox oil loses its properties, both physical and chemical, this can cause the following consequences:

- Wear of shafts and gears. This is due to the fact that after 150,000 km the oil loses its physical properties, namely its cooling effect. Thus, rotation of shafts and friction of gears leads to heating and increased wear.

- The loss of chemical properties will also lead to wear and accumulation of metal shavings in the oil, which will affect not only the gears, but also the bearings.

All these reasons can lead to increased wear, which will lead to premature overhaul of the gearbox.

On Lada Kalina 70w-90!

Replacement process (briefly)

Read more about changing the oil in the material: changing the oil in the gearbox on a Lada Kalina.

Changing the oil in a Lada Kalina gearbox is, on the one hand, simple, but on the other, not so easy. To do this, you will need tools, namely: a jack, flushing oil, a 17 mm wrench and a container for working off.

Now that everything is ready, let's begin the work process itself:

- We place the car on a lift or pit.

- Remove the air filter.

- Using a dipstick, check the amount of oil.

- We remove the lower engine protection.

- Unscrew the drain plug on the gearbox.

- Draining the oil can take up to 40 minutes.

- We tighten the drain plug, while not forgetting to replace the O-ring.

- Now, insert a watering can with an extended tube into the dipstick.

- Fill in about 3 liters of oil.

- We wipe the dipstick and insert it, and then remove it. We look at the level, it should be between the maximum and minimum indicators.

That's all, the oil in the box has been replaced. We drive 10-15 kilometers and look at the level indicator. If necessary, add oil.