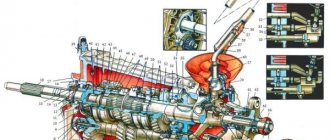

VAZ-2114 gearbox device

To ensure that the engine can operate in optimal modes when driving in various conditions, cars are equipped with gearboxes. This mechanism is capable of changing the amount of torque that is transmitted from the power unit to the drive wheels at the moment of starting from a standstill or at the moment of gaining speed. The mechanism consists of several main elements. This is a set of rotating shafts and gears, transmission links.

The mechanism housing includes a clutch housing, gearbox housing, and rear cover. The main pair is located inside the mechanism. There is a differential and gears, due to which the gear ratios change. This car uses a slightly modified mechanism that was left over from the VAZ-2108. The difference is in the other main pair.

In a gearbox, this is the main gear or the main, input shaft. It is designed to reduce engine speed. The main gear can reduce the number of revolutions in a ratio of 1 to 4. Thus, if the engine speed is 2 thousand, then the speed of rotation of the main pair will be 500 rpm.

On the VAZ-2114, the gearbox in the main pair has a standard rating of 3.7. This figure is stable. But if you change it, you can adjust the dynamic characteristics of the car.

The maximum speed and acceleration capabilities of the car depend on the size of the main pair. It is this element that affects the transmission length. If you change the main pair, you can adjust the length of all gears. Acceleration and top speed also change.

On the VAZ-2109 the main pair is 3.9. Due to this, the maximum speed on this car is lower, but the car accelerates better.

The VAZ-2114 gearbox is a five-speed, mechanical, synchronized gearbox. The main gear is connected to the differential unit. The gears from first to fourth are made in the form of a block and mounted on the input shaft of the box. The fifth block of drive gears is mounted. On the VAZ-2114, the gearbox also has a secondary shaft. Driven gears are installed on it. The shaft itself is connected to the drive gear through the main pair.

Gear ratios

The second, no less important component of this box is the gear ratios. These are gears, each of which is responsible for a specific transmission. What gear ratios does the VAZ-2114 have? Below are the characteristics of each speed:

- First gear - 3.636.

- The second is 1.95.

- Third – 1.357.

- Fourth – 0.941.

- Fifth – 0.784.

- Reverse gear - 3.53.

It is worth considering that the standard gear ratio is far from ideal. The first gear is too short, the second is too long. Because of this, drivers may experience a dynamic dip if they suddenly shift from first to second gear.

And even more - in addition to failure during sharp switching, the synchronizers wear out. Take a look at what the gearbox looks like on a VAZ-2114 - the photo is in our article.

The gearbox is also equipped with a rocker.

This is a special mechanism with which the driver switches from one gear to another. The design of the backstage was developed back in the 80s, so it has a lot of different shortcomings. Most drivers criticize it for its low information content when switching. Gears don't always engage the first time. The link sticks, or the transmission does not engage well.

The switching speed depends on how long the part is. For example, in sports cars the rocker is shortened. This makes it possible to solve a lot of problems with switching and adds dynamics. In order to improve information content and controllability, the rocker has long been replaced with a cable. With it, the gearbox works more clearly. You can easily select the desired gear.

Also, the gearbox control drive is equipped with a shift lever, a rod and a ball joint, a rod for selecting the desired gear, and a speed selection mechanism.

Signs of malfunction and diagnostics of the release bearing of the VAZ 2114 (how the bearing makes noise and hums)

Direct diagnosis consists of checking the functionality and presence of the following signs of failure.

Signs of a malfunction of the VAZ 2114 clutch release bearing, if detected, will require its replacement:

- When you press the clutch pedal, you hear a noise, hum or knocking (rolling, internal vibrations occur due to damage to the tracks with rolling elements, deformation of the cage or the clutch itself).

- A whistle when the clutch is engaged makes it clear that the quantity or quality of lubricant is not enough;

- The speed does not change or the pedal moves hard (occurs when the clutch has fallen apart, as well as if the ear of the release bearing is broken).

- Watch a video example of how the release bearing of a VAZ 2114 makes noise and hums, as well as how the check is carried out. You can also hear the noise of the bearing after disassembling the transmission after removing the VP.

Video: “How to check a release bearing”

Video: “How a faulty release bearing makes noise”

Attention:

In cold weather, a VAZ 2114 car that is not warmed up sometimes experiences noise from the release bearing. This is due to the fact that, unlike ball bearing rings, the coupling is made of a different steel, and also has low hardening, so the thermal expansion of the elements does not occur evenly.

Crunching and crackling noise when shifting

When shifting, the driver will hear a crunching sound when the gearbox synchronizers are badly worn.

If you miss the beginning of this process, then during further operation it will be necessary to replace not only the damaged synchronizer, but also the entire gear unit. If a cracking sound is heard at the moment of switching, this indicates wear of the blocking ring of one of the synchronizers or satellite axes. An urgent diagnosis is necessary.

Good oil means reliable operation of the gearbox

No matter how simple and unpretentious the gearbox on the VAZ-2114 is, you should choose only high-quality oil for it. Experts believe that the best option is mineral gear lubricants. You can also use synthetic products. In the case of synthetic oil, periodic cleaning of the gearbox seals is necessary. Products of the GL-4 category are suitable for boxes of the Samara-2 series. In order for the transmission to operate as reliably and smoothly as possible, it is necessary to constantly check the oil level.

The easiest way is to use a dipstick.

Gearbox for VAZ 2114: faults and repairs

The VAZ 2114 is considered the most picky car, since it consists of 100% domestic spare parts. The main point in its operation is proper maintenance. An important issue is the correct selection of oil, which affects the performance of the gearbox.

The ideal option would be to purchase mineral-based gear oil and gearbox lubricant. But if money is a problem, you can get by with more economical options: semi-synthetic or synthetic.

Of the two options, synthetic will be the best. It does not freeze in winter, and does not overheat in summer. And the gearbox works better on it, only with a little noise. But habit is a great thing.

Changing the gearbox oil

Signs of a malfunction of the input shaft bearing 14 VAZ model

A car uses quite a lot of bearings. Typically signs of failure are:

- whistling while the vehicle is moving;

- knocking in the gearbox.

In fact, the signs of failure of all bearings are almost the same. Considering that the car owner knows the location of the element in question, determining the cause of the malfunction will not be difficult. Let's look at the signs of damage and features in the table.

In case of destruction, jamming, chipping or cracking, replacement must be started immediately.

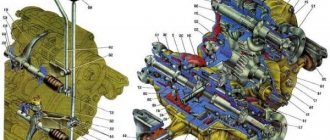

How the box works

It has features that entirely depend on the configuration of the machine. This could be a four- or five-stage vase model. The structure of a four-speed gearbox is as follows:

- 1. Primary shaft;

- 2. Reverse gears, to which the front shaft is attached;

- 3. Synchronizers, 2 pieces;

- 4. Bearings placed on the secondary shaft;

- 5. Driven gear. Attached to the differential flange.

The element is controlled by a drive, rod, rod and ball joint. Only complete interaction of these parts can ensure full operation of the box.

To determine the type of gear, there is an additional lever, which is attached to the inner end of the rod.

There are also axles in the body; a three-arm lever is attached to one of them. Its main purpose is to lock the bracket and bushing, which is necessary to ensure the strength and immobility of the mechanism.

The second axis is designed to fix the locking brackets from their rotation, passing through the center. In addition, there is a lock that prevents the box from loosening. The other axle also has a fork, which is necessary to engage the VAZ 2114 in reverse.

The five-stage type differs in the size of the shaft and the absence of a bushing in the element. Usually this is what is installed in the VAZ 2114, since the other one is not entirely practical to use. Like any spare part, a gearbox can also break down and fail.

The most common problems are:

- Unknown noise: it may be caused by bearing failure or gear wear. In addition, you should play it safe and check the oil level;

The solution to the problem is to completely replace failed spare parts and add oil.

- Difficulty shifting the VAZ 2115 gearbox: the drive rod may have become deformed. It would be a good idea to check how firmly all the screws are screwed on and how the box drive is adjusted correctly. There is a possibility of failure of plastic parts in the drive;

Solution: Strengthen the screws, adjust the drive, replace worn and failed parts, replace or correct the deformation of the rod.

- Turning off the gearbox without the driver's participation: the cause may be damage to the teeth on the synchronizer, an incorrectly adjusted drive, or poor installation of the traction cover, which provokes incomplete engagement of the traction;

Solution: Adjust the drive and replace the covers, replace the failed spare parts.

- Oil leak. The reason is still the same - wear of spare parts, which this time are oil seals, seals and hinge bodies. In addition, you need to pay attention to the strength of the fastening. If it becomes loose, it is necessary to tighten all the bolts and check the seals for damage;

Dismantling

You will need help to complete the next steps. To press out the required part, you need to insert a pry bar between the bearing and the gearbox. One person should hold the pry bar and the other should strike the input shaft. The blows must be precise and strong, and in the process of applying them the shaft must be rotated. It may take more than a quarter of an hour to complete the job.

A special puller will allow you to avoid such a complex procedure. But in order to use this device, you will need to dismantle and completely disassemble the gearbox.

Now you need to prepare a new bearing, thoroughly lubricate it with oil and press it into place. During the installation process, you will also need to apply blows, and they should fall on the inner cage.

After installation, you need to rotate the element and make sure that it fits properly into the seat. At the final stage, the gearbox is assembled.

Bearing repair without replacement

Practice shows that replacing a shaft bearing can be performed at a fairly high level without the involvement of car service specialists. The mistake of many car owners is that in some cases the bearing is in good condition. Lubrication is sufficient to restore its operational parameters. Therefore, the motorist is recommended:

- make sure there is lubrication. If the bearing is dry, then knocking or howling may be caused precisely by a lack of lubricant;

- It is necessary to carefully treat the element with lubricant. To do this, you can use motor oil;

- the bearing is mounted on the seat;

- At the final stage, functionality is checked.

There are two ways to lubricate the bearing. In the first case, a regular syringe is used, into which litol is drawn. The procedure will take a long time, but is highly effective. In the second case, a water bath is used, which involves digestion in lithol.

Each component and unit in the VAZ-2114 car operates almost continuously. Therefore, the wear and tear of certain elements is a completely natural process. To prevent serious damage from occurring, motorists are advised to promptly respond to signs of malfunction and immediately carry out repair work.

Lada 2114 Eva › Logbook › Repair of gearbox 2114.

Vetex last online 11 hours ago

And again, good day!)

Not long ago, or rather 2 weeks ago,

I decided to go through the box

.

I thought that I would come home on the May weekend and take care of it. But it's not that simple. Immediately the next week I had a huge play in the lever. It’s impossible to get to reverse and 5th gears, I’m pushing against the plastic in the cabin... Well, fortunately there are 1,2,3,4. I thought that the clamp on my cardan was just loose and that’s why it was such a problem, but no... Everything was fine there. Well, okay, in 4th gear I drove 80 km/h for 200 km home. This is hell. Already at home it was clear that the problem was inside the box. Well, I just knew that I needed to sort it out) Day 1.

Everything was done in the garage, without a pit, on a jack. This is terribly inconvenient, but there was no choice. They unscrewed everything, removed the box and began to disassemble it. It was scary, the first time after all