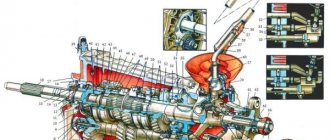

VAZ 2107 is a model considered a classic of the automotive industry in our country. And although the production of 2107 was completely stopped in the early 2000s, many car enthusiasts use this particular car for their personal needs. The popularity of the machine consists of several factors, the first of which can be called the simplicity of the design. However, not all mechanisms are easy to diagnose and repair; One of the most complex components in a car design is the gearbox.

- Box malfunctions

Gear does not engage - Knocks out gear when driving

- Crunching and grinding in the box while driving

- Preparing tools

Video: dismantling instructions

- Operating procedure

- Main shaft bearing

Video: replacement instructions

- Input shaft oil seal

Photo gallery: main stages of work

- Photo gallery: main stages of work

- Video: instructions for removing gears from the shaft

When and how often do you need to repair the gearbox on a VAZ 2107?

(“Volzhsky Automobile Plant”) provides comprehensive information on when and how often the gearbox needs to be repaired. It turns out that this mechanism does not have a service life as such. The only thing AvtoVAZ engineers insist on is the timely replacement of transmission oil:

- After the first 2 thousand kilometers on a new car.

- After 60 thousand kilometers.

- Further, as necessary, depending on the care of the owner and the frequency of use of the car.

Accordingly, the plant does not have any specific wishes or requirements for preventive or repair work. However, in any case, regardless of the mileage, it is necessary to carefully monitor all the nuances in the “behavior” of the box, since repairs will be necessary if the slightest malfunction occurs.

In winter, due to temperature changes, the box experiences additional load

Box faults

The design of the “Seven” gearbox is designed for many years of service. Usually the driver carries out the first and even the second major overhaul of the engine, and only after that does the need to repair the gearbox arise.

In addition, the “seven” itself has acquired a reputation as a “workhorse” throughout its long history. The machine really serves faithfully for many years, but this does not mean that each of its mechanisms will not wear out over time.

If we talk about malfunctions of the VAZ 2107 gearbox, then most often drivers complain about three defects: the inability to engage the desired gear while driving, the gear being knocked out and a strong crunch in the box.

In the early years, the VAZ 2107 was equipped with a four-speed gearbox, and since the early 1990s, a five-speed gearbox

The transmission does not start

It is very difficult to drive a vehicle if the driver cannot change gear. On the one hand, the shift lever moves to the desired position, but, on the other hand, switching as such does not occur. Or the lever cannot be set at all to the desired speed switching position.

In any case, the problem lies precisely in the box:

- Some of the moving (hinge) elements of the shafts are very worn out - it is recommended to carry out a major overhaul of the gearbox;

- wear of the blocking rings on the synchronizer - replace the rings with new ones;

- the synchronizer spring is stretched or broken - replace the spring;

- severe wear of the gear splines - only complete replacement of the gear will help.

The problem is that the lever works, but the gearbox doesn't.

Knocks out gear when driving

Another common problem with the gearbox is the transmission slipping out of gear immediately after turning it on. The lever simply throws back, and the engine begins to experience overloads, since at high speeds it does not receive the required distribution number.

The malfunction may be associated with different elements of the box:

- jamming of the hinge on the gear shift lever - it is necessary to remove the lever skirt, clean all connections and lubricate them;

- breakage of the lever - it is impractical to carry out repairs; it is easier to immediately replace the lever with a new one;

- the clutch does not work correctly - in this case, the entire blame cannot be placed on the box; it is quite possible that after adjusting the main elements of the clutch, the gear will not be knocked out;

- The forks in the box are bent - it is recommended to replace the entire set of forks.

The driver sets the lever in the desired position, but it comes back

Crunching and grinding in the box while driving

The driver may not experience problems with shifting gears, but while driving, hear a loud knocking, crunching and grinding sound in the gearbox cavity:

- the bearings on the shafts are broken - replacement is recommended;

- The gear splines are badly worn - the entire gear needs to be replaced;

- minimum oil level in the cavity of the box - you need to add lubricant and make sure that there is no leak;

- malfunction of the shafts (they began to move along another axis) - replacement of bearings on both shafts.

Unusual sounds in the gearbox are the first sign that the gearbox needs checking and repair.

It should be emphasized that some types of work with the gearbox are available to the driver himself. It won't be difficult to knock the old bearing out of the shaft and press the new one in. If it comes to major repairs of the box, it is better to turn to professionals.

How to repair a gearbox on a VAZ 2107

A four-speed gearbox was installed on the “old” model VAZ, and a five-speed gearbox on the “new” model VAZ. However, working with both mechanisms is not much different from each other. The essence of the repair work is to perform the following steps:

- Removing the box from the car.

- Disassembling the gearbox into its component parts.

- Replacement of failed elements with new ones.

- Assembling the box.

- Installation of a gearbox on a car.

It should be noted that repairs should only begin if there are clear signs of a faulty box. As a preventive measure, it makes no sense to interfere with the structure of this mechanism again.

With such a defect, the shaft will not be able to work correctly, which will immediately affect the convenience of gear shifting.

Preparing tools

To carry out all of the above work, you will need to prepare in advance:

- heads for 13 and 17;

- extension to the heads;

- Phillips screwdriver;

- flat screwdriver with a thin blade;

- flat screwdriver with a powerful flat blade;

- impact screwdriver;

- tweezers;

- wrenches 13 (2 pcs), 10, 17, 19 and 27;

- circlip puller (or pliers);

- hammer.

How to remove the gearbox

The box can only be repaired after it has been removed from the car, so you will need to be patient and time-consuming. Repairing a gearbox is clearly a difficult and slow task.

To remove the box from a VAZ 2107, you will need to drive the car into a pit or viewing platform. The jacking option will not work, since it will be impossible to complete all stages of the work:

- Remove the wire from the negative terminal of the battery.

- The first stage of work is carried out directly from the salon. For convenience, it is necessary to remove the panel in which the radio is located.

- Press the gear shift lever and insert a flat-head screwdriver into the hole in the gearbox locking sleeve.

- Using a screwdriver, pull the bushing towards you.

- Disconnect the rod from the gear shift lever.

- Use tweezers to hook the edge of the damper insert and remove it.

- Using two flat screwdrivers, press apart the petals of the damper insert and move them apart.

- Then remove the damper and bushings from the gear lever.

- In the cabin, move the foot mat near the gearbox.

- Using a Phillips screwdriver, unscrew the four screws on the box lid.

- Remove the cover from the gear shift lever.

- The second stage of work is carried out directly under the car. The first step is to remove the exhaust manifold pipe from the box.

- Disconnect the clutch mechanism.

- Immediately remove all connections from the gearbox (at the same time, you can check the integrity of the wires).

- Disconnect the cardan drive.

- Remove the flexible shaft mounting mechanism from the speedometer.

- Unscrew the two bolt connections on the side cover of the gearbox.

- Remove the box from the car.

- Place something strong and stable under the body of the box, as it may fall out.

Video: dismantling instructions

Attention! The gearbox on the VAZ 2107 weighs 23 kilograms (including oil), so it is recommended that it be dismantled by two people.

The box body weighs more than 20 kg, so it’s better to ask your friends for help to safely remove it from the car

How to properly disassemble the box

Repair work on the gearbox is possible only after identifying the real cause of the breakdown. Therefore, it will be necessary to disassemble the device correctly and safely for each component of the box and perform troubleshooting.

To ensure the disassembly process goes quickly and without interference, it is recommended to immediately prepare the following tools:

- impact screwdriver;

- wrench 10;

- socket wrench 13;

- three-jaw puller;

- vice;

- tweezers;

- torque wrench.

Of course, as necessary, gaskets, oil seals, and those parts that were discarded during the work will be needed.

There are many large and small parts in the box design

Operating procedure

Disassembling the box yourself in a garage is a completely doable task. However, the work will require maximum concentration and attention:

- After removing the gearbox from the car, it is recommended to wash the housing from dirt. You can even use kerosene or white spirit to ensure the surface of the box is clean.

- Remove the bell (casing).

- Turn the box over and unscrew the cover bolts.

- Remove the gear block plug from the rear cover.

- Pull out the retaining ring with tweezers.

- Press out the gear block bearing.

- Press out the reverse gear bearing.

- Remove the secondary shaft oil seal.

- Pull out the thrust washer from the rear bearing of the secondary shaft.

- Press out this bearing.

- Remove the speedometer drive gear and pull out the roller ball (clamp) behind it.

- Remove the gear fork mounting bolt.

- Block the shafts by inserting a thick bolt or a powerful screwdriver between them.

- While turning the input shaft, pull it towards you along with the gears and bearings.

- Then pull out the secondary shaft.

- The intermediate shaft comes out easily.

Video: instructions for disassembling the gearbox on a VAZ classic

Signs of failure

All bearings, of which there are quite a few in a car, have approximately the same signs of failure. But since you know the location of the input shaft bearing, it will not be so difficult to determine that the problem arose with it.

There are several characteristic signs of its breakdown.

Sign

Peculiarities

Howling when the clutch is released in a parking lot

The element has failed and needs to be replaced. The howling is usually caused by the formation of chips, cracks, or the destruction of 1-2 rollers

Whistle when driving

The bearing is partially damaged or there is no lubrication. The problem in the absence of lubrication can only be determined by dismantling and visual inspection. To solve the problem, sometimes it is enough to simply lubricate the element and return it to its place

Clutch won't engage or disengage

Most likely the bearing is stuck. If the damage is serious, the input shaft may need to be replaced.

Knock in the area where the element is located

The bearing knocks only when the part is completely destroyed. If you do not replace it in time, the bearing will be welded to the shaft, so you will also have to replace the shaft itself

If you notice the first signs of a malfunction of the input shaft bearing on your gearbox, you should immediately check the condition of the element and, if necessary, replace it.

Replacing bearings

Most often, problems with the gearbox begin with the bearings breaking. Therefore, the bulk of all breakdowns lead to the driver needing to disassemble the gearbox and change the bearings.

Bearings cannot be repaired, since their design does not allow replacement of parts (rollers). Therefore, if the product fails, it is completely replaced.

Main shaft bearing

To change the input shaft bearing, you need to have the same tools as when disassembling the gearbox. The work is not difficult, but it can take a lot of time (depending on the physical fitness of the performer and his skill).

The operating procedure is as follows:

- Clamp the input shaft with a vice. It is better to line the jaws of the vice with a soft cloth so that they do not deform the surface of the shaft.

- Use a puller to clamp the bearing and begin to slowly pull it off the shaft.

- Periodically you need to tap the bearing with a hammer and rotate the shaft between hits, otherwise misalignment may occur in the rollers and it will be very difficult to remove the bearing.

- Gradual knocking out will cause the bearing to jump off the shaft.

- Press a new bearing onto the shaft using the same method.

- It is important to hit only the inner ring of the bearing with a hammer and do it carefully.

The job may take up to 30 minutes

The input shaft bearing can be replaced on an unassembled box using the same method. Only in this case it will be impossible to use a vice.

Video: replacement instructions

Secondary shaft bearing

Replacing the secondary shaft bearing is carried out according to the same principle as the primary one. The only difference is that different types of bearings are used for different shafts.

According to GOST, closed (6–180502K1US9) and open (6–50706AU) type bearings are used to equip the input shaft of the VAZ 2107 gearbox. An open type bearing (2107–1701033) is used to equip the secondary shaft.

Each type is strictly regulated for gearbox mechanisms

Causes and symptoms of bearing failure in manual transmissions

Bearing units in a manual transmission perform the function of rolling bearings, therefore, if the rolling bearing is faulty, there will be difficult rotation of the elements, an imbalance will appear, as well as radial and axial runout, backlash, noise, and knocking.

- The bearing hums, the noise increases when the clutch is disengaged;

- Difficulty switching gears;

- Spontaneous transmission shutdown;

- A knocking noise is heard when pressing the clutch pedal.

- Expiration of product service life;

- Poor quality ball bearing;

- Wear or runout;

- Aggressive driving style and gear shifting;

- Insufficient amount of lubricant on the bearing or its absence;

- Dirt or abrasive particles getting inside the ball bearing;

- Malfunction of adjacent components (releaser, clutch, secondary or intermediate axle).

After removing the axle from the axle, you need to make sure that the part is faulty. To do this, check the ease of rotation of the part, and also do a visual inspection, namely, the presence of damage to the rings, cage, as well as defects in the raceway. If the product is in good condition, it is advisable to take measurements of the axial clearance and radial clearance, as shown in the video.

Video: “How the VAZ 2107 input shaft bearing hums”

Video: “Bearing play in the input shaft of the VAZ 2107 gearbox”

Replacing oil seals

Most often, gaskets and seals are subject to wear. And if the gasket can be changed even by an inexperienced driver, then the replacement of oil seals should be treated with the utmost care.

By its design, the oil seal is a rubber gasket that acts as a sealant. That is, if the oil seal breaks or wears out, the box ceases to be sealed, which, in turn, leads to oil leaks and breakdowns.

The oil seal in the VAZ 2107 gearbox is not made of rubber alloys, as most drivers think. In fact, the product is made of special composite materials, which are much more durable than rubber and less susceptible to tearing. In its working condition (that is, constantly), the oil seal is in the transmission oil, so its elasticity remains for a very long time.

The design of the oil seal allows it to seal all joints between parts on the shaft

In order to restore the tightness of the gearbox, you will need to change this gasket. To work you will need:

- new oil seal from the same manufacturer;

- spanners;

- hammer;

- screwdriver with a flat thin blade;

- knife;

- sealant.

Input shaft oil seal

The VAZ 2107 gearbox input shaft oil seal has the following performance characteristics:

- weight - 0.020 kg;

- dimensions - 28x47x8 mm;

- operating temperature range - from -45 to +130 degrees;

- location - on the input shaft in the clutch housing.

Accordingly, in order to replace the gearbox input shaft oil seal, you will need to remove the gearbox from the car and disassemble the casing:

- Remove the bell (casing) from the box; it is secured with four bolts.

- Remove the fork and release bearing from the box (the fork is secured with screws, the bearing will have to either be knocked out with a hammer or pressed out with a vice).

- Access to the input shaft and its oil seal is provided.

- Using the blade of a knife or screwdriver, pry up the old ring and remove it from the shaft.

- It is good to clean the seal area from dust and dirt.

- Install a new oil seal.

- Reassemble the gearbox in reverse order.

Photo gallery: main stages of work

The bell can be easily removed as it is secured with only 4 bolts

It is important to very carefully pick up the oil seal without scratching adjacent surfaces

Even if the old oil seal does not have cracks or deformations, when disassembling the gearbox it still needs to be replaced with a new one.

The work of replacing the input shaft oil seal is not particularly hassle.

Secondary shaft oil seal

The secondary shaft oil seal differs slightly in its characteristics from the input shaft gasket:

- weight - 0.028 kg;

- dimensions - 55x55x10 mm;

- operating temperature range - from -45 to +130 degrees;

- location - on the secondary shaft at the flange junction.

The oil seal is replaced with the gearbox removed:

- The first step is to firmly fix the flange of the box; you can insert a bolt or a thick screwdriver into it.

- Turn the flange fastening nut with a wrench.

- Using a screwdriver, pry up the centering metal ring and pull it out from the secondary shaft.

- Remove the bolt from the hole.

- Place the puller against the end of the secondary shaft.

- Remove the flange along with the washer.

- Using screwdrivers or pliers, remove the old oil seal from the box.

- Clean the joint and install a new oil seal.

Thus, replacing the secondary shaft oil seal is somewhat more difficult than doing the same job on the input shaft. The difference is due to the location of the seals and their dimensions.

Photo gallery: main stages of work

To work, you need to choose the thickest and most powerful screwdriver or bolt so that they do not bend

The flange can only be removed using a puller

The landing site must be cleared of dust and dirt.

VAZ-2107 input shaft bearing: number, price, which one is better to buy, size (5 mortar, 4 mortar)

In the “Classics” manual transmission, the designers provide a radial open single-row ball bearing of class 6 accuracy, which absorbs 90% of radial loads. To select this spare part, you need to pay attention to the radial and axial clearance, ease of rotation, appearance of the product (no corrosion, cracks, nicks, cavities).

Before you buy a gearbox input shaft bearing for the “seven”, check out the list of recommended manufacturers. The listed manufacturers produce high-quality products at reasonable prices with exact dimensions in accordance with GOST 520-211.

How to replace gears and synchronizers

The gearbox on the VAZ 2107 is a complex device. Therefore, if you do not have confidence in your abilities, it is better not to start replacing gears, but to turn to specialists for this service.

The work of replacing shaft elements is considered the most difficult and time-consuming

However, if you decide to replace worn out gears and synchronizers yourself, you will need to prepare the necessary tools in advance and buy a repair kit for replacement.

The standard repair kit for gearbox shafts 2107 usually includes gears, synchronizers, washers, a pin, nuts and bolts.

To work you will need:

- vice;

- puller;

- screwdriver with a thin flat blade;

Replacing gears and synchronizers on the primary, secondary or intermediate shafts is generally carried out according to the same scheme:

- Remove the shaft from the box.

- Clamp the shaft in a vice (it is important to wrap the jaws of the vice with a soft cloth so that they do not damage the surface of the shaft during operation).

- Use a screwdriver to pry up the shaft retaining ring and remove it.

- Press out all bearings.

- Unclench the vice and rest the first gear on two supports.

- Compress the gear by gently hitting it with a hammer.

- Perform the same actions for all subsequent gears and synchronizers.

Video: instructions for removing gears from the shaft

During operation, it is necessary to carefully inspect the shaft. Between the gears there may be clamps, retaining rings and other small parts. They must be removed without fail, otherwise it will be impossible to remove the gear.

Between each moving element there is one or another part

Accordingly, the installation of new elements occurs in the reverse order.

Thus, repairing a gearbox on a VAZ 2107 cannot be called a simple task. The driver needs not only to exert maximum physical effort, but also to act extremely carefully so as not to damage the shaft and its elements. If you are unsure of your abilities, it is better to contact a car service specialist.

Repair process

When starting to repair or tune the gearbox, try to wash all accessible surfaces with kerosene as thoroughly as possible.

Next, you should carefully unscrew all the fastening bolts, sequentially releasing the parts.

Each gear is disassembled separately, and it is important to carefully check not only the gaskets, but also the seals. Correcting and diagnosing breakdowns includes replacing gaskets, this is a prerequisite; oil seals are usually changed if they are very worn.

The disassembled VAZ 5 mortar box must be washed again, after which all parts are checked again for faults and, if necessary, replaced with new ones. Most often you have to replace a worn gear or bearing.

To replace parts, you can buy a ready-made gearbox repair kit, designed taking into account the most frequently occurring faults in five-speed gearboxes. Also, before disassembling the transmission, prepare the necessary tools: an impact driver, a three-jaw puller, wrenches of different diameters and a torque wrench. Also for maintenance you will need fixing glue, a set of gaskets and seals, preferably a repair kit.

It should be noted that, like any gearbox, the VAZ 2107 5 mortar requires periodic maintenance to prevent malfunctions while driving.

After all the parts have been checked and replaced, you can begin assembling the gearbox, carrying out all the steps in the reverse order. If the parts have undergone too much wear and replacement of individual components no longer helps, a complete replacement of the gearbox on a VAZ 2107 may be necessary.

Thus, it is quite possible to carry out maintenance and repair of the VAZ 2107 gearbox yourself, the main thing is to follow all the requirements of the dismantling instructions and follow the drawings during assembly.

The VAZ 2107 is equipped with two types of gearboxes, one of which is four-speed and the other five-speed. Sooner or later, these devices begin to malfunction, as a result of which it becomes almost impossible to drive a car. In this material, we will find out what the repair of both types of gearboxes on a VAZ 2107 is, what are the differences between these two mechanisms, and when repair work is required.