Crankcase VENTILATION SYSTEM

The power plant of any car is a very complex device, including mechanisms and systems that interact with each other. At the same time, the engine is not a closed hermetically sealed circuit and it also has ventilation. Crankcase ventilation is a scheme that ensures the removal of gases from internal cavities. The fact is that during combustion of the working mixture in the cylinders, exhaust gases are formed, which are under pressure, due to which part of them penetrates into the sub-piston space - the crankcase, where it mixes with oil mist and moisture formed as a result of condensation. This whole mixture is called crankcase gases. If the engine were sealed, with an increase in the amount of gases in the crankcase, the pressure inside it also increased. Because of this, a breakthrough of gases along with oil through the breather, oil seals, seals or the hole in the oil dipstick is possible. Based on this, it follows that the main task of the ventilation system is to maintain pressure inside the engine and prevent it from exceeding the permissible norm by removing crankcase gases.

Operating principle of the crankcase ventilation system

In order to understand why oil is squeezed out of the breather, I propose to briefly consider the principle of operation of the oil system. Not many people know, but for proper operation of the engine, ventilation is necessary, since during its operation gases collect in the crankcase, and now we are not talking about exhaust gases. To ensure the removal of these gases, old cars used a so-called crankcase ventilation system, which after some time became known as a “breather.” With the help of a breather, engineers were able to ventilate the crankcase and thereby relieve the pressure that forms during engine operation. However, the system turned out to be ineffective, since tiny oil particles penetrated the breather along with excess pressure and gases.

The issue of penetration of “oil dust” into the breather was partially resolved by means of a special mesh that traps oil particles and does not let them into the breather. However, despite this, some of the oil vapors still penetrate into the breather, creating certain difficulties for owners. A small amount of oil that has penetrated into the breather is not considered anything terrible, however, if oil flows out of the breather in large quantities, this is a reason to seriously think about the technical condition of the engine.

VENTILATION DESIGN FEATURES, OPERATING PRINCIPLE

The simplest diagram of the crankcase ventilation system used on internal combustion engines previously consisted of only one fitting - a breather installed in the crankcase. This breather connected the internal cavity of the cylinder block with the external environment, and crankcase gases simply escaped through it into the atmosphere. But this scheme had one significant drawback - the exhaust gases contained oil particles, which also entered the external environment. And this is not only loss of lubricant and the need for periodic refilling, but also air pollution. On modern cars the ventilation system is closed. It also has a breather, but a pipe is connected to it, allowing gases to be vented into the intake manifold or air filter housing, from where they enter the cylinders and burn. That is, the atmosphere is not polluted by them. Additionally, the system includes elements that ensure oil separation and return back to the crankcase so that it does not enter the cylinders along with the gases.

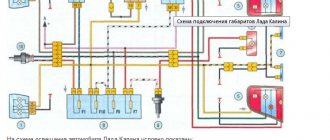

There are several options for oil separators, and on cars from different manufacturers they may differ in design and operating principle. It is worth noting that part of the exhaust gases enters the supra-valve space, and they must also be removed. Therefore, the entire circuit of the engine ventilation system on a modern car consists of a breather, an oil separator and two pipes. Additionally, a special valve can be included in the system to regulate the pressure of gases entering the intake manifold. The configuration of the system can be very different, but this does not change its purpose and operating principle. For example, consider the ventilation design of the VAZ-2110. At the bottom of the cylinder block of this car there is a breather, onto which a pipe is attached; the second end of this hose is connected through a fitting to the cylinder head cover. At the same time, an oil separator is located inside this cover at the inlet of the pipe. On its other side there is another fitting, to which a tube is connected that goes to the air inlet pipe.

The principle of operation of such ventilation is simple - gases enter the cylinder head cover space through the breather and pass through the oil separator, while the separated oil flows to the valve assembly. After this, the gases are mixed with those that have broken into the supra-valve space and are supplied to the air pipe, and then to the manifold. There is no pressure regulating valve in this car. On other machines, the oil separator may be located immediately next to the breather, and a valve is installed behind it.

REASONS FOR OIL EMISSION THROUGH THE BREATH.

But there are many of them, and many of them do not relate to ventilation.

Lubricant may flow through this system due to:

1. Severe wear of the piston rings and the cylinder-piston group as a whole. Because of this, a very large amount of gases break into the crankcase, and the ventilation simply does not have time to remove them all. Therefore, increased pressure is formed inside the engine, which squeezes oil into the breather;

2. Clogged oil separator drain channel. In this case, the separated oil has nowhere to go, and it is mixed into the passing gases;

3. Air filter dirty. The engine sucks in a large amount of air, and if there is not enough air due to a clogged element, the motor will suck it in along with oil from the ventilation system;

4. Increased amount of oil in the system. If there is more lubricant in the engine than normal, then excess lubricant will enter the ventilation;

5. Jamming of the ventilation system valve;

6. Timing belt wear or valve burnout. As a result, crankcase gases enter the above-valve space, then they penetrate into the crankcase, significantly increasing the pressure.

Drives oil through the breather: diesel and gasoline internal combustion engines

Let's start with the fact that during engine operation, so-called crankcase gases accumulate in the crankcase. To prevent excess pressure from being created, there is a special valve for ventilation. This solution allows the closed crankcase to communicate with the atmosphere. This valve is the breather. In simple words, a breather on an internal combustion engine is actually needed to equalize the pressure inside the engine.

It should be noted that in the crankcase gases mix with oil mist. As a result, lubricant particles enter the breather. Although there is a special oil trap inside the device, a certain part of the oil may escape out. Given this information, minor contamination of the system is acceptable, which is normal. In cases where a lot of lubricant leaks, you should look separately for why oil is leaking from the breather.

On injection engines, traces of oil getting into the throttle area are noticeable, the power unit also loses its throttle response and power, and fuel consumption increases noticeably. It turns out that to check it is necessary not only to inspect the outer surfaces under the hood, but also to remove the air filter, throttle assembly, etc.

If oil appears from the breather, there may be several reasons. Given the various features, before self-diagnosis, you need to pay attention to additional symptoms.

- First of all, the oil presses as a result of significant wear of the piston rings. This means that gases from the combustion chamber penetrate through the seal into the crankcase, after which too high pressure is created there. Excess pressure causes oil to flow out through the breather.

- Another possible cause could be a clogged oil deflector drain. In this case, gases and oil particles that are no longer able to pass through normally exit through the breather rather than through the cleaner.

- Also on the list is a significant reduction in air filter capacity. In this case, the engine simply does not have enough air at the inlet. The result is the appearance of oil in the filter housing and on the filter itself.

- Possible problems with the breather itself should not be ruled out. As a rule, the valve fails, the passage hole in the breather becomes clogged, etc. Normal ventilation is disrupted, exhaust gases enter the internal combustion engine crankcase and increase the pressure.

- In some cases, overfilling engine oil much higher than the recommended level causes the excess to leak out through the breather. It turns out that excess oil simply presses out of the engine. In such a situation, you should check the lubricant level and adjust it if problems are detected.

Engine diagnostics for oil leaks through the breather requires an integrated approach. There is no need to disassemble the power unit to check. It becomes clear that at the initial stage you should assess the condition of the breather, make sure it is working and clean the device if necessary.

After making sure that the breather is working properly and ventilation is at an acceptable level, you will need to make a series of measurements and assess the condition of the CPG. As already mentioned, the cause may be failed rings, that is, you will need to measure the compression in the engine.

Also, the color of the exhaust gases can additionally indicate the need to measure compression. To check, just start the engine and then evaluate the exhaust. If the engine smokes blue or gray smoke, then this may be a sign of engine oil getting into the cylinders due to worn piston rings.

When checking compression, you need to take readings in each individual cylinder. In the normal state of the CPG, compression should be at 11 MPa and above (it is recommended to consult the technical literature in relation to a specific type of internal combustion engine). If a run-up is detected according to the readings in the cylinders, the differences should not exceed 1 MPa.

Failure to reduce compression will indicate that further checks will be related to the ventilation system. The method for testing this system will be considered using the example of the domestic VAZ 2110 model. Other cars may have some individual features, but the general principle will be similar.

- At the very beginning, you need to disconnect the tubes from the valve covers, breather and air duct pipe. Then the degree of contamination should be assessed. If the tubes are clogged or dirty, then they can be cleaned with carburetor cleaner or gasoline. Afterwards you will need to blow them with compressed air or dry them naturally.

- Next you need to get to the oil separator by unscrewing the fixing bolts and removing its cover. After this, the oil separator itself is removed. This device is made of special plates. It is necessary to disassemble the element and wash it. Washing can be done in gasoline and then dried.

- At the same time, it is recommended to inspect and flush the valve, and also check the stroke of the rod. This is possible after removing the device. Valve jamming can also be eliminated by washing. The entire list of actions described allows you to keep the crankcase ventilation system clean and maintain its functionality.

DIAGNOSING THE CAUSE OF OIL RUSSIAN

Since there are a large number of reasons for oil leaking through the breather, a comprehensive check of the engine is necessary to determine exactly why the problem arose. At the same time, to carry it out, you don’t even need to disassemble the power plant, it’s just enough to take measurements of some parameters, as well as visually assess the condition of the ventilation. For example, let's take the already mentioned VAZ-2110. Let's assume that in the engine of this car, plaque and oil deposits were noticed in the intake manifold, which indicates oil leakage through the breather.

To determine what caused this problem, you will need little - a set of open-end wrenches, a screwdriver, a compression gauge. We'll start the test by assessing the exhaust gases. To do this, just start the engine and look at their color shade. If it is gray or black in color, this indicates oil getting into the cylinders due to wear or sticking of the CPG rings or problems with the timing belt. Only this can help determine the cause; read more here - the causes of smoke from the exhaust pipe. It is also necessary to check the compression in all cylinders. In the normal state of the cylinder-piston group, it should be in the range of 11-13 MPa. The difference between the readings in the cylinders is allowed to be no more than 1 MPa.

If the compression in one cylinder is significantly lower, it can cause oil leakage. But why exactly this is happening - rings or valves - can be determined by the spark plug that was installed on this cylinder. Heavy carbon deposits on it will indicate a problem with the CPG.

Troubleshooting

- The first thing you need to pay attention to is the color of the exhaust, blue or black smoke, a sign of burnt valves or problems with rings.

- Next, you should check the compression in all cylinders. The value on gasoline internal combustion engines should be within 11-13 MPa.

- Disconnect the pipes from the valve covers, air vent and breather. Assess the degree of contamination. If the pipes are very dirty or clogged with oil deposits, use gasoline to clean them or a special carburetor cleaner.

- Check the condition of the oil separator. Unscrew the required bolts to get to this unit. Remove the oil separator and assess its condition. If necessary, clean or rinse followed by drying.

- Inspect and, if necessary, flush the breather valve. There are situations when the valve gets stuck, resulting in exhaust gases entering the crankcase and creating excess pressure. Remove the part and wash it; in most cases, this will resolve the issue of squeezing oil out of the breather.

Helpful advice! To distinguish stuck rings from a burnt-out valve, it is enough to perform several manipulations. After checking the compression in the cylinders, determine the cylinder with the lowest value. Then inspect the spark plug of this cylinder; if the rings are lodged in this cylinder, the spark plug will be covered with a thick oil layer. If the valve is burnt out, the spark plug will appear normal without any major abnormalities.

Finally…

The problem of oil escaping through the breather worries many motorists and causes a lot of trouble, but if the problem is detected in a timely manner and the right approach is taken, serious consequences can be avoided. It is important to ensure that the oil level is normal; as soon as you find that the engine is taking oil, monitor its level and constantly monitor it so that it does not fall below the permissible level. Also pay attention to the breather and filter; oil on the air filter in large quantities also does not bode well. Regularly monitor the condition of the engine and all systems, and also promptly correct any malfunction. This will save you from engine overhauls and unnecessary waste.

INSPECTION AND CLEANING OF THE VENTILATION SYSTEM

On the VAZ-2110 this is done like this:

1. Disconnect the pipes from the breather, valve cover, air pipe and check the degree of clogging. If necessary, they can be washed in gasoline or kerosene and then dried;

2. Unscrew the nuts securing the valve cover and remove it. On the inside there are two bolts securing the oil separator roof, which must be unscrewed;

Source

How to clean the crankcase ventilation system on a VAZ 2108-VAZ 21099?

— Cleaning the breather

The engine crankcase ventilation system of the VAZ 2108 2109 21099 is designed to ventilate the engine crankcase from gases that have broken into it from the cylinders. From the engine crankcase, gases are supplied through a hose to the valve cover, where they pass through an oil separating mesh and are sucked into the carburetor air filter.

If the oil separating mesh becomes dirty and oil no longer deposits on them, the oil will enter the carburetor air filter. If the air filter is filled with oil, then it is necessary to clean the crankcase ventilation system. But as a rule, many people often do not do this, but disconnect the hose between the valve cover and the air filter and direct it to the side.

The hole in the air filter is plugged with a champagne cork - and all is well. It seems that the air filter is clean and the oil is no longer spitting out as much. However, this is for the time being. Sooner or later, the crankcase ventilation system will become completely clogged, and then the VAZ 2108 2109 21099 engine will begin to press oil. As a rule, it goes into the distributor through the camshaft oil seal.

Presses oil into the VAZ 2109 distributor

In general, the prerequisites for cleaning the crankcase ventilation system (breather) are as follows: — The air filter is in oil; — Distributor in oil. The procedure for cleaning the breather of a VAZ 2108 2109 21099: 1) First, you need to disconnect all the tubes from the engine valve cover and remove the carburetor air filter.

Disconnect the tubes from the cover

2) Unscrew the gas pedal cable from the engine cover.

Unscrew the fastening of the gas pedal cable

3) Unscrew the two nuts securing the valve cover to the engine and remove it.

Removing the valve cover of the VAZ 2109

4) The lid will be covered in dirty oil all over the inside.

Valve cover VAZ 2109

It will be necessary to remove the cover covering the oil separating nets and clean them from adhering dirty oil.

Remove the cover of the oil separating mesh

To clean, you need to disassemble the nets and bathe them in kerosene or gasoline until they are clear of adhering oil.

Oil separating mesh for breather VAZ 2109

Some people pour gasoline on the meshes and set them on fire - the oil burns out and then just wipe the meshes a little with gasoline and that’s it.

Burning the oil out of the mesh

5) You also need to be patient and try to clean the valve cover itself of the VAZ 2108 2109 21099 from adhering oil, especially the place where the oil separating mesh is installed.

6) There is also a small outlet on the valve cover, which is connected through a tube to the throttle body of the carburetor. In my case, it was also completely clogged with hardened oil and I had to clean the outlet with a thin steel wire for about half an hour. 7) Then, you need to put the cleaned oil separating mesh of the VAZ 2108 2109 21099 breather in place and close it with a lid.

The oil separating mesh is cleaned

Before replacing the valve cover, it is necessary to clean the surface of the engine from old sealant and dirt. It is also necessary to wipe the rubber gasket of the valve cover itself. 9) Then apply a thin layer of sealant along the edges of the valve cover to improve sealing. We put the cover in place and tighten the nuts securing it.

Before replacing the valve cover, it is necessary to clean the surface of the engine from old sealant and dirt. It is also necessary to wipe the rubber gasket of the valve cover itself. 9) Then apply a thin layer of sealant along the edges of the valve cover to improve sealing. We put the cover in place and tighten the nuts securing it.

10) We connect all the tubes back, fasten the gas pedal cable and put the air filter in place. 11) For better sealing, it is better to give the sealant a couple of hours to dry before driving the car. The work on cleaning the breather of the VAZ 2108 2109 21099 is now completed. You will immediately notice that the engine will consume less oil during operation and will need to be topped up less.

The VAZ 2108 breather is the same as other front-wheel drive VAZs, since the eight-valve engine differs little, the difference is in engine cubic capacity and crankshaft stroke, and the valve cover with the breather device is the same.

The breather is not cleaned often; usually they start cleaning it when oil starts flying out of the breather. But the breather is not always to blame; oil can fly out from the breather and due to broken piston baffles.

It is very easy to clean the breather yourself.

— Cleaning the breather

What is an engine breather and why is it even needed? Here's the question"

What is an engine breather and why is it even needed? Here's the question

This can save you from more expensive repairs. In fact, the breather, although it seems like an insignificant detail, in practice is of great importance for the health of the power unit.

What is an engine breather?

Before answering this question, it is important to understand what it is intended for. This is directly related to the principle of its operation. The main task of this device is to reduce the pressure in the engine crankcase. When the power unit operates, various gases collect in the crankcase. Gradually they accumulate and create quite a lot of pressure. If you do not bleed them, the engine may stop, the pressure will back up the pistons. In this case, the gas will seek an exit through any available hole. To prevent this from happening, a breather is installed.

This also happens with the help of this device. Unnecessary gases are removed from it. Thus, the temperature inside the engine is slightly reduced. The engine breather has two tasks: ventilation and releasing excess pressure. In some cases, the operation of the breather can indicate the presence of problems in the engine. or damage to the piston, gray smoke characteristic of the exhaust will fly out of the hose. This way you can diagnose these faults without disassembling the engine. In normal condition, a slightly noticeable transparent smoke comes out of the breather.

The breather is essentially a valve that bleeds air from the engine. As the pressure increases, it begins to allow a certain amount of gases to pass through it. The greater the pressure, the more air can pass through it. To prevent atmospheric air from entering inside, the valve is capable of flowing only in one direction. But on some cars this process is reciprocal. In such versions, a filter is installed in the valve to prevent dust from getting inside the motor.

Most often, the breather is located next to the oil filler neck. Much less often you can find options with its location on the side of the cylinder block. From the outlet pipe there is a hose connected to the air filter housing. This arrangement is typical for all cars. It may differ only in small nuances due to the characteristics of the body. Sometimes there are 2 pipes, in which case the second hose is connected to the injector.

When the pressure increases, it “shoots off” with a characteristic pop. The impact may be so severe that it leaves a mark on the hood. If any of these signs appear, you need to clean the breather valve.

To clean it, you need to remove the breather. Then they clean it. This work is done in several steps:

- Preparatory work is being carried out - the hoses are removed. Some models will require removal of the air filter;

The breather cap is unscrewed. It can be mounted with 2 or 4 bolts. After removal, it should be inspected for damage;

The nut located on the oil sump mounting stud is unscrewed. On some models it is not recommended to remove it entirely; various structural elements will interfere with putting it back on;