Carburetor DAAZ 21073 - device

The device of the Dimitrovgrad Automotive Aggregate Plant is designed for mixing fuel and air and consists of two main components:

- Frame;

- Top cover.

The device is also based on a float chamber for balancing the level of fuel supplied to the diffuser, an accelerator pump, a forced idle economizer and an econostat. The top cover contains: an emulsion tube or emulsion wells, fittings designed for atomizing fuel in the diffuser, as well as an air damper necessary for cold starting of the power unit. The Solex 21073 carburetor on the Niva is installed and configured from the factory, and its design and calibration data provide good dynamic performance with minimal fuel consumption.

Calibration data

| Name | 21073 stock | 21073 mine | 21053-*** | 21053- | ***-20 | |||

| 1st camera | 2nd camera | 1st camera | 2nd camera | 1st camera | 2nd camera | 1st camera | 2nd camera | |

| Engine capacity | 1700 | 1500 | 1500 | 1600 | ||||

| Main diffuser | 24 | 24 | 24 | 24 | 23 | 24 | 23 | 24 |

| gtzh | 107,5 | 115 | 115 | 115 | 102,5 | 115 | 107,5 | 110 |

| GVZh | 150 | 135 | 150 | 135 | 150 | 135 | 140 | 165 |

| TJ XX and move on. System 1 | 39 | — | 42 | — | 39 | — | 40 | — |

| TJUN | 45 | — | 35 | 40 | 35 | 40 | 45 | 40 |

| Kulachek UN | 4 | 7 | 4 | 5 | ||||

| TJ EMR | 40 | — | 40 | — | 40 | — | 40 | — |

| Choke cam | 6 | — | 6 | — | 7 | — | 3 | — |

| T/W ratio | 0,717 | 0,852 | 0,767 | 0,852 | 0,683 | 0,852 | 0,768 | 0,667 |

| Total t/v ratio | 0,781 | 0,807 | 0,763 | 0,713 | ||||

Carburetor calibration data 21073-1107010 | ||

| Options | first camera | second camera |

| Mixing chamber diameter, mm | 32 | 32 |

| Diffuser diameter, mm | 24 | 24 |

| Main dosing system: fuel jet marking air jet marking | 107,5 117,5 | 150 135 |

| Emulsion tube type | ZD | ZC |

| Idle system and transition system of the first chamber: fuel jet marking air jet marking | 39 140 | |

| Second chamber transition system: fuel jet marking air jet marking | — — | 70 140 |

| Power mode economizer: | — | 70 |

| Econostat: conditional fuel jet flow rate fuel jet marking spring compression force at a length of 9.5 mm, N | — 40 1,5±10% | — |

| Accelerator pump: nozzle marking, fuel supply in 10 cycles. sm3 cam marking | 14 — 4 | — — |

| Starting clearances: air damper, mm throttle, mm | 3,0 | — |

| Marking of the choke control lever | 6 | — |

| Hole diameter for vacuum corrector, mm | 1,2 | 1,2 |

| Needle valve hole diameter, mm | 1,8 | 1,8 |

| Diameter of the fuel bypass hole into the tank, mm | 0,70 | 0,70 |

| Engine crankcase ventilation hole diameter, mm | 1,5 | — |

Features of the Niva 2121 carburetor

If we are talking about a carburetor, then you should know that this part is so named because its main functional purpose is carburetion or mixing. Indeed, fuel liquid and air are mixed in the carburetor. In addition, the supply of the resulting mixture to the engine cylinders is regulated.

The carburetion mechanism depends on the design of the carburetor device itself. Thus, the “native” carburetor on the Niva 2121 consists of:

- float chamber (the optimal functioning of the idle system and transition systems of all chambers depends on the level of fuel liquid in this device);

- jet (the main metering part through which fuel liquid and air enter the carburetor in metered quantities, they are also called nozzles or plugs);

- diffusers (they are narrowings in the carburetor pipes of both chambers; they are needed to increase the speed of air passage to the mixing chambers);

- throttle valve (mechanical type channel flow regulator, which is intended to change the amount of fuel liquid or gas passing through this channel).

The fuel supply mechanism through the carburetor device on the Niva 2121 has the following diagram:

- From the fuel tank, fuel liquid in optimal quantities enters the float chamber.

- Under the weight of the fuel liquid, the float chamber lowers.

- As the fuel liquid moves, the float chamber rises.

- After the fuel liquid passes through the float chamber, it enters the nozzle.

- From the nozzle, fuel is supplied to the atomizer (it is located in a narrow place in the diffuser).

- Air enters the carburetor device through the outer pipe.

- Through the intake manifold, a certain amount of fuel fluid is supplied by the throttle valves directly into the engine.

If the old carburetor on the Niva 2121 fails, experts advise replacing it with a more modern model.

Scheme and principle of operation

The types and modifications of carburetors for a given car can be very different, but the principle of operation remains the same.

When starting the engine cold, the driver closes the choke to limit the flow of air and increase the amount of gasoline. This makes it easier to start and brings the speed necessary for stable operation.

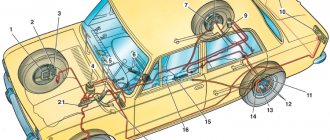

Carburetor 21073 DaAZ device and principle of operation: diagram of the design and operation of the carburetor I - first chamber; II - second chamber; 1 — accelerator pump drive lever; 2 — adjusting screw of the starting device: 3 — diaphragm of the starting device; 4 — air channel of the starting device; 5 - solenoid shut-off valve; 6 — idle fuel jet; 7 — main air jet of the first chamber; 8 — idle air jet; 9 — air damper; 10 — sprayer of the main dosing system of the first chamber; 11 — accelerator pump nozzle; 12 — nozzle of the main dosing system of the second chamber: 13 — econostat nozzle: 14 — main air jet of the second chamber; 15 — air jet of the transition system of the second chamber; 16 — channel for balancing the float chamber; 17 - float chamber; 18 — needle valve; 19 — calibrated hole for fuel bypass into the tank; 20 — carburetor fuel filter; 21 — fuel supply fitting; 22 — power mode economizer diaphragm; 23 - fuel jet of the power mode economizer; 24 — ball valve of the power mode economizer; 25 - float; 26 — econostat fuel jet with tube; 27 — fuel nozzle of the transition system of the second chamber with a tube; 28 — emulsion tube of the second chamber: 29 — main fuel jet of the second chamber; 30 - outlet of the transition system of the second chamber; 31, 33 — throttle valves: 32 — slit of the transition system of the first chamber; 34 — outlet of the idle system; 35 — carburetor heating block; 30 - adjusting screw for the composition {quality} of the idle mixture; 37 — engine crankcase ventilation fitting; 38 - fitting for supplying vacuum to the vacuum ignition regulator; 39 — vacuum selection fittings for the recirculation system; 40 — main fuel jet of the first chamber; 41 — emulsion tube of the first chamber; 42 - ball valve of the accelerator pump; 43 — accelerator pump diaphragm.

During the warm-up process, air intake is increased to reduce speed and eliminate interruptions. Thus, the air damper opens completely and the amount of gasoline is reduced. Other methods of warming up are not provided for by the design.

Gasoline is supplied through the fuel filter to the float chamber, and then to the main metering system of the mixing chamber. The scheme for pumping air and mixing it with gasoline in the diffuser occurs due to the vacuum that occurs during the operation of the valve mechanism and pistons, compressing and pushing out the working mixture.

The second chamber system is designed to increase air flow to the nozzle when the engine is running under heavy load, when the speed is high.

To ensure that the engine runs stably at idle, and at low speeds to prevent it from stalling and eliminate interruptions, an idle system is provided. And to maintain the level of fuel used in the Solex 21073 carburetor, there is a whole scheme for the operation of the float system. Let's consider the operation of each system separately.

Design features of the Ozone carburetor for Niva 2121

The Ozone carburetor device, suitable for the Niva 2121 all-terrain vehicle, can be of two types:

- With serial number 2107-110-7010-10, it is distinguished by the fact that this carburetor:

- equipped with an old style breaker;

- not equipped with a vacuum corrector.

- With serial number 2107-110-7010-20, the difference is that this device:

- does not have a microswitch from the economizer (it affects fuel consumption and environmental friendliness of emissions).

Common features of the Ozone design of both models include:

- Durable, massive body (thanks to this, the carburetor device is practically not deformed).

- Fuel jets with a large diameter (this involves the use of Ozone for low quality fuel fluid).

- The idle system is equipped with a solenoid-type shut-off valve.

- The second chamber with a throttle valve is pneumatically driven.

- Diaphragm trigger.

- The mechanical control system is equipped with a cable drive, which leads to the air damper of the first chamber.

- Accelerator pump with ball valves.

Although the absence of an economizer with powerful modes reduces the dynamic characteristics of the vehicle and does not save fuel consumption.

Solex carburetor float chamber

The float mechanism is located in the top cover of the carburetor and serves to maintain the required level of fuel, which is supplied to the metering chamber.

He is:

- Small cavity;

- Ebonite float;

- Needle valve.

The calibration data for the Solex DAAZ 21073 carburetor provides for the following operating principle of the float chamber. When the fuel level decreases, the float lowers and with its lever opens the needle valve at the top of the cover. Through the resulting hole, gasoline enters the chamber and fills it, raising the float up. As soon as the float rises completely, the valve closes and the cycle repeats throughout engine operation.

Adjusting and adjusting the level of the float chamber affects the dynamic performance of the motor. If the level is insufficient, the power plant does not operate stably, and if it is too high, fuel consumption increases and the spark plugs fail.

Which carburetor is best for Niva 2121

Experienced auto mechanics offer two modern carburetor models for the Niva 2121 to choose from:

According to experts, these carburetor models are almost identical. But there are still differences:

- Ozone is not equipped with a vacuum corrector.

- Solex operates without an economizer.

What is the importance of each of these carburetor devices? Let's consider their functional features:

- the vacuum corrector is designed to rotate a table located inside the toggle switch, as a result of which the ignition timing changes;

- The economizer is a heat exchanger that must preheat the water that is supplied to the steam boiler.

Although both models of carburetor devices are suitable, many experts are inclined to think that Ozone is much more finicky than Solex. This is due to individual differences in their designs.

Main dosing chamber - operating principle

During engine operation, the cylinders create a vacuum, which draws air from the air filter and supplies it to the diffusers - these are the main metering systems. After this, all the oxygen leaves through the cross-section of the damper of the first chamber and the jets of the Solex 21073 carburetor. Thanks to the throttle jets of the second chamber and the reduced diameter of the diffuser of the first chamber, the air flow speed increases, and in the spray zone it reaches maximum values.

Subsequently, after passing through the air jet of the throttle valve of the first chamber, the air is mixed with fuel and sucked into the channels of the intake manifold, which distributes the mass of the fuel mixture among the engine cylinders. To increase efficiency, distribution occurs in those cylinders where the intake valve is open and there is the required vacuum. This principle of operation ensures a reduction in fuel consumption and the elimination of contamination of the timing belt.

Idle system

In some situations, engine operation must be ensured even when the car is in neutral, when the speed is too low. At such a moment, the vacuum is insufficient and fuel will not be able to pass through the main metering chamber. A forced idle system is provided specifically for this purpose.

To do this, air is supplied through the main idle fuel jet into the first chamber. The fuel will then flow to the idle fuel jet. The air also passes through a special jet through a separate channel. This design allows the engine to operate even at low speeds, and when the throttle valve is opened, the power mode economizer begins working, which is considered as a transition system.

However, the system has a number of disadvantages when coasting:

- When the speed decreases by releasing the gas, fuel consumption continues;

- When switching to neutral gear, it increases completely.

Especially for this purpose, the calibration data also includes an EPHH, which turns off the fuel supply when coasting. Its operation continues until the speed drops to 1200 rpm and turns off when the throttle is opened. But when the car is stationary, it does not work.

Troubleshooting - Solex carburetor 21073

The Solex carburetor 21073 was installed on the Niva 21213 for quite a long time, after which repairs and adjustments are quite common.

Therefore, the following malfunctions cannot be excluded:

- Higher fuel consumption;

- Poor starting qualities;

- Power reduction;

- Unstable engine operation at idle.

The main malfunctions during carburetor operation originate from low-quality fuel, which has foreign particles. They are the main reasons that clog the jets and channels, leading to malfunction of the device. The installed carburetor 21073 1107010 DAAZ on Niva has a device in which the jets are most susceptible to contamination. Therefore, diagnosis must begin with them.

Which carburetor is better to install on a VAZ 21213 Niva with a 1700 engine?

The best option for reducing fuel consumption on a Niva is to install a DAAZ 21083 carburetor. The “eight” carburetor has all the necessary characteristics that a 1.7 engine may require. If you are looking for an answer to the question of which carburetor to install on Niva 21213, then this is exactly what you need.

Carburetor DAAZ 21083

The only negative that may follow after such an installation is a decrease in throttle response of a carburetor engine due to a smaller throttle valve diameter of several mm. Also on carburetors 21083 the float has a small stroke. Installation can be done by yourself without outside help. Adjusting a new carb is also not difficult. The cost of this carburetor is not small - 6,290 rubles, but the quality of the parts and service life deserves respect.

When selecting carbs, there are several points to consider:

- The DAAZ 21083 carburetor is not designed to fit the Niva manifold - it will have to be bored;

- A new throttle control system is needed;

- You will need a set of larger diameter fuel jets;

↑

Repair and maintenance of the Solex 21073 carburetor in the field

To repair the carburetor, you must remove it from the engine. To do this, first of all, remove the air filter, all hoses going to the device, rods and throttle valve drive, and then it is removed.

Before disassembling, it is recommended to obtain a repair kit to troubleshoot the carburetor, which includes:

- Gaskets;

- Jets;

- Needle valve;

- A set of rods and small fasteners.

It is recommended to disassemble the carb on a large table and lay out the parts in order so as not to lose them during work. Repair of the Solex 21073 carburetor on a Niva car is carried out in the following sequence - disassembly, washing of all parts with a special liquid, installation of parts from the repair kit and assembly. The types of repair kits differ depending on the model of the device.

Selection of jets is one of the most important procedures. The selection is made taking into account the technical data of the device and should be based on the personal choice of the car owner. It should be taken into account that increasing the cross-sectional diameter leads to improved dynamic characteristics and increases fuel consumption. Types of jets can be very different.

Therefore, if you select the jets correctly, you can achieve good performance with minimal gasoline consumption.

After installing the device on the car, the idle speed is adjusted. It will restore normal engine operation and reduce fuel consumption.

Causes of malfunctions of carburetors on the VAZ 2121 Niva and self-repair

All-terrain vehicles VAZ 2121 "Niva" already have reliable and durable equipment from the factory. The Niva uses a carburetor engine as its power unit, which allows for uninterrupted loads under any operating conditions. Repairing and adjusting the carburetor on a VAZ 2121 is a much simpler matter than it might seem at first.

Models of carburetors on VAZ 2121 Niva cars

The 2121 is equipped with Ozone carburetors. These mechanisms are divided into only two types:

- 2107–110–7010–10 (equipped with an old-style breaker, does not have a vacuum corrector);

- 2107–110–7010–20 (a more modern model, however, due to the absence of a microswitch from the economizer, it has increased fuel consumption).

“Ozones” have a structure and operating principle that is traditional for carburetor units.

The equipment unit for VAZ 2121 cars has a design traditional for carburetors

Do-it-yourself VAZ 2121 carburetor repair

Repair of the carburetor unit on the Niva may be required in different cases.

If a car enthusiast has practical skills in servicing his “four-wheeled friend,” then performing repair work independently will not be difficult for him.

However, it should be noted that the design of carburetor mechanisms is highly complex, so high-quality work without preparation is unlikely.

Signs and causes of malfunctions of Ozone carburetors

External manifestations of the operation of the engine unit and the driver’s own sensations, as a rule, may indicate the occurrence of any malfunctions in the operation of the carburetor. The most common signs of malfunctions on Ozone are:

- unstable operation of the power unit at idle;

- the car loses its dynamics;

- after reaching a speed of 90 km/h, engine productivity drops sharply;

- difficulty starting;

- increase in fuel consumption.

Thus, if Ozone shows one or more of these signs of malfunction, this means that repair work is necessary.

Video: carburetor starter repair

The engine receives too much gasoline - the carburetor is flooded / the needle is stuck

If a car owner notices that the carburetor is constantly being filled with excess gasoline, we can conclude that the needle valve is faulty. Over time, it can lose its throughput, which is why at first there are difficulties in starting the engine, fuel drips appear on the carburetor, and then it will be impossible to start the engine at all.

The way out of the situation is to replace the needle valve yourself. To do this you will need:

- Remove the cap from the carburetor.

- Align the float along its original axis.

- Disconnect the needle valve.

- Screw a new valve into the vacant space.

- Screw the lid into place.

The car cannot maintain idle speed and immediately stalls

In this case, the economizer will need to be replaced. Most likely, the reason lies in this component, since it ensures the supply of fuel to the engine at idle. In rare cases, the idle speed control unit on Niva carburetors may fail.

To determine the cause of the malfunction, it is recommended to disassemble the carburetor and inspect the economizer and idle devices. Their condition will be visually noticeable (adhesion of a large amount of soot and dirt, deformation). If devices fail, the procedure for replacing them is as simple as possible: a new one is installed in place of the old component.

How to remove a carburetor from a Niva

To do the job you will need a simple set of tools. Typically, every car enthusiast has all these auxiliary devices:

- head at 8;

- head at 10;

- extension;

- combination key 13;

- flat screwdriver.

The mechanism is located as conveniently as possible for any work

When starting to remove the carburetor from the Niva, you need to make sure that the engine has already cooled down, otherwise you can get burned on overheated metal parts . The withdrawal procedure is as follows:

- Remove the air filter box. It will interfere with access to the motor, so it is recommended to immediately unscrew the three nuts securing the box with a screwdriver.

- Next, you will need to use a 8-mm head to disconnect the four bolts that secure the air filter box to the surface of the carburetor.

- After this, the box is moved to the side, and all hoses and lines going to it are disconnected from the carburetor

- The choke cable is disconnected (the clamp is unscrewed with a screwdriver).

- Using a thin blade of a screwdriver, you need to pry the throttle control rod to unhook it from the latch.

- The next step is to dismantle the carburetor itself. The four nuts that secure it to the manifold are unscrewed. After which the knot itself is pulled out from the pins.

It is recommended to place the carburetor on a flat, clean surface.

Cleaning procedure for removing carbon deposits and dirt

Removing the carburetor involves cleaning its components or replacing it in case of severe wear of the rubbing elements. However, most often it is removed in order to rinse and clean it inside and out from carbon deposits and adhering dirt:

- jets require a special approach to maintenance, as they have a fragile structure. To clean them, it is recommended to use toothpicks or thin copper wire. You cannot use any chemical cleaners, as liquid may remain in the nozzle holes and then get into the carburetor. After cleaning manually, it is allowed to blow out the nozzle with a can of compressed air;

- The float chamber is cleaned of carbon deposits with a special cleaner. The use of solvents of the 645–652 series is also allowed. The washing liquid must be poured into the chamber, stirred several times over two hours and drained. After which the internal cavity of the float chamber should be thoroughly dried with a soft, lint-free cloth;

- All throttle valve elements are cleaned of carbon deposits with a standard cleaner or kerosene. The damper, along with other metal parts of the carburetor, can be placed in a container with kerosene and kept there for two hours. After the accumulations of soot and dirt have dissolved, it is recommended to blow out the damper and wipe it dry.

Photo gallery: jets, float chamber and throttle valve

The fuel nozzle is one of the smallest elements that must be very carefully cleaned of carbon deposits. The float tank must be thoroughly washed with special means. The throttle valve is a small element that requires washing and purging.

Gasket replacement procedure

The carburetor mechanism is in contact with the intake manifold. The absence of vibration, excess noise, and rapid wear of elements is ensured by the gasket located between this mechanism and the collector.

The gasket has a specific shape, thanks to which the carburetor and manifold successfully “get along” with each other. Replacing the gasket is necessary if additional vibration and extraneous noise are felt while driving. In addition, usually when removing the carburetor for washing, the gasket is also changed so that you do not have to later remove the entire device just to replace it.

Adjusting the Solex 21073 carburetor on Niva

Before starting the adjustment, it is necessary to insert a level in the float chamber so as not to disassemble the carburetor again. To do this, pump fuel using a hand pump and remove the top cover. If you pay attention, there is an inclined plane in the chamber, in the middle of which the fuel level should be located. If it is different, then it is set by bending the antennae of the float.

The next step is to adjust the air damper, starting gap and starting device. There is nothing complicated here. You need to pull out the choke completely and close the damper. In this state the cable is fixed. Now you need to test the operation of the damper: with the handle completely retracted, the damper should be open and vice versa.

Now the carburetor idle speed is adjusted (Solex 21073). To do this, you need to completely tighten the quality and quantity screws, and then unscrew the quality adjusting screw by four turns, and the quantity by three turns. After this, the engine is started and warmed up to operating temperature. After eliminating the interruptions, you can start setting up.

Tighten the quantity screw until the speed drops to 800-900 rpm. Now set the maximum speed by turning the quality screw. Tighten the quantity again to 800 rpm. Now we adjust the quality until the engine begins to shake slightly. This moment will be the most optimal.

There is another method, which involves repeating the first cycle until further adjustment is impossible. Both methods work, so you can adjust them in different ways.

If the carburetor does not work and is not adjustable, you should look for excess air leaking through the gaskets or check the timing belt and ignition. Resolve the problem and try again. To eliminate this problem, check the damper clearances.

The car must be parked on a level surface, and the low beams and main electrical consumers must be turned on. That's the only way to regulate it.