Lada 2105 Workhorse › Logbook › Carburetor DAAZ 21053-1107010-20 “SOLEKS”

I thought for a long time about the Solex

for the classics, compared prices, there is DAAZ 21053-1107010-20 and PEKAR K178I.21053-1107010-20, I almost bought PEKAR, but DAAZ unexpectedly

dropped in price

from 3990r to 3790r, and then completely to 2990r

so what did I know about carburetors for classics with an engine capacity of 1.5-1.6:

1) for classics (2105, 2107, 2104) with an engine volume of 1.5-, 1.6, a SOLEKS type carburetor is intended 21053-1107010-20

- no options! (no 083 - catch the crap, catch it!)

2) consumption with a SOLEKS carburetor compared to a standard carburetor 2107-1107010 will be MORE!

, the car is more responsive, but you have to pay for everything - on average 0.5 liters more per 100 km

I didn’t install it myself - I installed it without an economizer, I don’t know yet whether it’s better or not

I recommend

to watch on Youtube the blog of carburetor engineer from Dmitrovograd

Nail Poroshin

- very interesting! Video blog of Nail Poroshina (Dmitrovograd)

so that Solex doesn't get dirty

(they have such a disadvantage) you can install a mesh and not have any problems at all, as well as a cut 4th “cam from Nail”

1) the car has become a little faster 2) you need to warm up less to get moving 3) yes, the car is responsive! (smooth ride when changing gears) 4) even the consumption seems to have decreased, even without an economizer - I think the standard carb was a little clogged and ate gasoline very well

and the result: an injection engine is not needed, Solex-a 21053-20 is enough for the ears

I recommend installation!

continuation of a story

I drove for a day, I looked at the idle speed of 1000 somewhere, turned it up to 750, and the next day the idle speed disappeared altogether, as soon as the car stopped at the intersection... I turned it back up... but the idle speed floated 850-1200, so I drive (it was decided - the plug flew out in manifold, plugged it in with a new one and carefully set the speed with the screw - everything was fine)

PLEASE COMMENT on the installation, how should it be done?

Installing a Solex 21053 carburetor on a classic

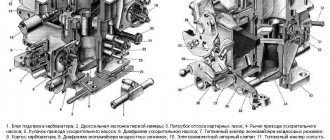

Solex device

Now we can begin the process of replacing the original carburetor of the car with Solex modification 21053 1107010 20. On VAZs, the old carburetor is usually Ozone, produced on the basis of DAAZ. Its main problem is that it is not nearly as reliable as we would like. In addition, its fuel consumption is slightly higher than that of the Solex. That is why one is replaced by another. In addition, in order to simply install Solex 21053 on a classic, it is advisable to configure it correctly.

The procedure for installing the Solex 21053 carburetor on a classic is no different from installing other models of this device on it. Solex 21053 for classics can easily be placed in any rear-wheel drive VAZ engine. So, first you need to eliminate any possibility of foreign particles getting into the intake manifold. We achieve this goal by cleaning the engine compartment from dirt. There is no need to achieve perfect shine. Just wash it.

Now disconnect the ozone carburetor from whatever is holding it in the car. Be careful when disconnecting the hoses from the heating system and fuel hoses. Having done this, you need to remove the cable from the air damper. It is attached to a bracket, which must be removed first. Then you can take out the old carburetor. For the same purpose for which you washed the engine compartment, you should also clean the area where Ozone stood. If during the process you find any cracks, holes or irregularities on the surface, you must cover them with sealant.

Now it’s time to create thermal insulation for Solex 21053 1107010 20. Insulating gaskets will help achieve this. They should be stacked on top of each other, alternating thin and denser ones. Install carburetor 21053 1107010 20 on top. For greater comfort in the future, you should install Solex 21053 on the classic without the top cover. In this case, the throttle valve drive should not be located behind. On the side of the upper part of the cylinder head, you need to place the drive linkage from the primary and secondary chambers. The task of the rocker is to regulate the throttle valve. On the old Ozone you will find simple plastic traction tips; you can remove them and install them instead of the tips on the Solex.

Now you need to adjust the length of the cable from the throttle valve drive. If it turns out to be slightly longer than the distance to the carburetor, it needs to be trimmed. Having made these changes, you can close the cover on the carburetor. The old gasket should not be used. Having closed the carburetor with a lid, you should begin connecting it to everything that you disconnected from Ozone. Connect the carburetor tee to the cooling system. Now you need to extend the hoses from the ignition system distributor. Then install a tee at the fine filter. It should be placed on the fuel line. Connect the wire leading to the carburetor float chamber to the tee. This must be done using a check valve. Now all that remains is to attach the return spring back, and for the first time (for safety) you can also install an additional one, attaching it to the top of the block.

Connect the electric valve to the light relay, and then install the air filter base and filter element and connect them to the gas exhaust system. A Solex 21053 carburetor is installed on the classic. 21053 1107010 20 will last a long time if you follow some rules for setting it up and cleaning it from time to time.

Carburetors on the VAZ 2105: solving the main problems

The VAZ 2105 is considered the longest-produced car in the AvtoVAZ line. Indeed, the first models left the factory assembly line in 1979, and the last in 2010. There were many reasons for the popularity of the car: these are the performance characteristics of the “five”, convenient functionality, and ease of maintenance... The largest number of questions about the operation of the VAZ 2105 to this day are related to the carburetors that were installed on the model in different years. It was the carburetor that became a continuous topic of discussion among drivers, as plant engineers periodically changed this device and modified the car, which also affected its performance.

Peculiarities

The engines of this car were equipped with Solex 21053 carburetors. This number must be indicated on the plate, which can be found on the cover of the unit. This two-chamber carburetor is necessary for the correct and rapid process of forming the fuel mixture and supplying it to the combustion chambers.

In order for the engine to function normally in a variety of modes, this carburetor model consists of three main structural elements: the upper part, the middle part, and the lower part - the carburetor.

- The top one is the lid. It has built-in gasoline supply fittings, as well as an air damper, a threaded hole for the idle jet, and a starter housing.

- The middle part is nothing more than the main body of the Solex 21053 carburetor. Large and small diffusers, as well as chambers, are made inside. Solex also has 21053 fuel and air jets.

- At the bottom there is a float chamber for fuel, as well as throttle valves for supplying the fuel mixture to the cylinders and regulating the air flow.

You can briefly describe the operating principle of this unit. Thus, gasoline enters the carburetor float chamber through the needle valve. Then, under the influence of vacuum, gasoline is supplied through nozzles into the first chamber - it is the main one. The second chamber turns on at high loads. Then the fuel mixture is prepared in the first. Passing through atomizers on small diffusers, gasoline is crushed into small particles, resulting in the formation of a fuel mixture. If it is necessary to operate the engine at maximum or full load, the second chamber is also used - the principle of its operation is similar.

Carburetor VAZ 2105

What is a carburetor and what are its functions? Today, carburetor modifications of vehicles are considered to be “outdated”, since they have been replaced by more “tenacious” injection ones.

However, in our country, carburetor versions of cars will be popular for a long time, since most AvtoVAZ cars are designed specifically on the basis of carburetor engines. Including the VAZ 2105 model, popularly called the “five”.

So, the carburetor is the most important mechanism in a car engine. Its main purpose is to prepare the fuel-air mixture and supply it to the engine cylinders. Simply put, a carburetor is needed to ensure that the engine receives fuel in the doses necessary for operation.

Carburetor design

The engines of the VAZ 2105 car are equipped with carburetors of type 2105–1107010. This number must be indicated on a black plate, which is attached to the cover of the carburetor itself.

The device has two chambers so that the processes of formation of the fuel-air mixture and its supply to the cylinders occur quickly and correctly. In fact, structurally, the carburetor has a huge number of small parts interconnected, but technically the device is not considered complex.

In order for the engine to operate in different modes (warm-up, idling, medium load and high speed), the carburetor consists of three main parts:

- The upper one consists of the device cover and fittings for fuel supply.

- The middle one is the carburetor body itself, which houses two internal combustion chambers and diffusers.

- Lower - includes the float chamber and throttle valves.

In the proper operation of the VAZ 2105 carburetor, small parts such as gaskets, springs or jets play a huge role. It is these parts that most often fail, which affects the operation of the engine.

The essence of the operation of the carburetor unit on the VAZ 2105 comes down to the following processes:

- A strictly limited amount of gasoline enters the float chamber through a special valve.

- Fuel is directed through the jets to chamber No. 1.

- Here, gasoline is crushed into tiny pieces and mixed with parts of air.

- If the maximum amount of fuel is required (for example, during acceleration), then chamber No. 2 begins to work in the same way.

- After the fuel-air mixture is formed, the accelerator pump directs the fuel to the diffusers and then directly to the cylinders.

Carburetor calibration data

The main dosing systems include the diameter of the mixing chamber: the size of the first chamber is 28 mm, and the second is 32 mm, the diameter of the narrow part of the large diffuser with the size of the first chamber is 21 mm and the second is 25. This also includes the marking of the small diffuser with the corresponding chamber size 3 .5 and 4.5 mm, the diameter of the main fuel jet of the GDS with chamber sizes of 1.07 and 1.62 mm.

The acceleration pump has a diametral nozzle opening of 0.4 mm and a capacity with 10 presses equal to 7 ± 1.75 cm3. Econostats have fuel jets with a diameter of 1.5 mm, air jets with a diameter of 1.2 mm, and emulsion jets with a diameter of 1.5 mm. Characteristics of the pneumatic drive of the second chamber.

Carburetor 2105-1107010 has a remote pneumatic valve, but 2105-1107010-20 does not. In addition, carburetors 2105-1107010 and 2105-1107010-20 have a vacuum tap to the vacuum ignition timing regulator. Carburetor 21053 has slightly different parameters.

What carburetors are installed on the VAZ 2105

All carburetor installations equipped with the VAZ 2105 are focused, first of all, on minimizing fuel consumption. Of course, AvtoVAZ engineers throughout the history of the “five” experimented with the equipment of the car in order to identify the most effective mechanisms.

Over the years, various modifications of carburetors were installed on the VAZ 2105. All of them had both their advantages and disadvantages, which the drivers themselves often had to identify while driving.

Modification of DAAZ

The Dimitrovgrad Automobile Unit Plant (DAAZ) has launched the production of carburetor units under license from Weber. The main quality of DAAZ products is ease of operation and repair. The production of all parts necessary for repair and replacement was established, so if necessary, the driver could easily buy the necessary components and independently carry out the work of adjusting the carburetor.

DAAZ carburetors provided the car with increased speed characteristics, since the new nozzle system made it possible to react as quickly as possible to an increase in speed and supply the required amount of fuel to the engine.

Types of carburetors used

For classic VAZ cars, only three types of carburetors have been developed:

| Weber | Solex | Ozone |

All these models of components are successfully used on classic cars of domestic production. As an exception, there is a carburetor model called Weber. The history of this device originates from Italy. Its creator was Eduard Weber, who improved the dynamics of cars and allowed them to spend less fuel. And since Russian-made cars begin their history from the same country, this carburetor fully works with them.

The second carburetor used is called OZONE. When developing this device, the designers had a goal - to reduce fuel consumption, which, in the end, they succeeded in doing. This carburetor is still found on classic cars today and produces good indicators of efficiency and dynamics. But due to the low reliability of the unit and frequent failures, it is increasingly being replaced with more successful modifications.

The third type of carburetor and the most popular is the Solex fifth modification 21053 1107010 20. The founder of the product was a French company that has long ceased to exist, but has made an enormous contribution to the global automotive industry. Today, under the manufacturer’s license, this carburetor is produced by the Dimitrov Automobile Unit Plant (DAAZ). The main difference between Solex and Ozone is that the former does not fail. At the same time, it is possible to change the performance characteristics of Solex by calibrating it. The model is maximally adjusted from the factory and only correct installation is required from the user.

Installing two carburetors

Experienced VAZ 2105 drivers sometimes resort to such a drastic measure as installing two carburetors at once on the standard car engine. Why is this necessary? Two carburetors can solve the main problems with engine operation:

- uniform fuel supply;

- uniform supply of air to the mixture;

- At high speeds, the fuel-air mixture will form faster, which will significantly facilitate engine operation.

Accordingly, the operation of two carburetor units will minimize engine wear, which will extend the life of the car for many years.

The easiest way to install a pair of carburetors is in a car repair shop, but if you wish, you can do this work in a garage. For this you will need:

- set of wrenches;

- pliers;

- drill;

- vice;

- two carburetors of the same model;

- two collectors of the same type;

- coolant;

- rags;

- hoses according to the diameter of the carburetor inlets.

Work process

Before installing the second carburetor, it is necessary to drain the antifreeze from the system and remove the standard manifold. After this, you can proceed directly to the installation:

- Place carburetors on each manifold.

- When installing, it is important to ensure that the edges of the collectors do not protrude, as otherwise they may cause the chambers to jam.

- If there are any objects (such as studs) in the manifold passages, they must be removed so that there is no resistance to fuel flow. The studs can be cut with a drill.

- After this, each carburetor on the manifold is “fitted” to the cylinder head. To properly install each of the two devices, you will need to remove the cylinder head.

- Fasteners need to be cut from a 3–4 mm steel plate. These products will hold the collectors using nuts.

- Connect the manifold heating using gasoline tees, as well as a vacuum brake booster. If the amplifier is not provided in this configuration, then the places for it must be plugged in any convenient way.

- Next, install the carburetors on the cylinder head, adjust their operation with the quality and quantity screws.

- Connect the gas drive and gasoline hoses to the device connectors.

Video: performing work on installing two carburetors on a VAZ 2105

There is an opinion that when installing two carburetors on a VAZ 2105, fuel consumption immediately increases by 2 or 3 times. However, it is not. Consumption can be reduced by up to 1.5 times, since the operation of two devices at once significantly facilitates the functionality of the motor.

Idle speed adjustment

The idle system in the carburetor is the most unstable. Therefore, it needs to be adjusted from time to time. The idle speed control elements are 2 screws, one of which determines the composition of the mixture, and the second regulates its quantity.

Step by step steps:

- Using screw 1, you need to set the crankshaft speed to 820-900 min -1 using the stand tachometer.

- Using screw 2, it is necessary to achieve the CO concentration in the exhaust gases without going beyond 0.5-1.2%.

- Using screw 1, restore the shaft speed to 820-900 min -1.

- Screw 2 needs to restore the CO concentration to 0.5-1.2%.

- To complete, press limit marks (plastic bushings) onto these screws and orient the slots of these bushings relative to the mounting lugs.

Problems that may arise when setting idle speed:

- There is no reaction from the engine to tightening the propeller (during tightening, the engine should gradually slow down and eventually stall). This sometimes happens if there is an excess of gasoline in the idle speed indicator. The reasons may be:

- very large jet XX;

- the solenoid valve or plug is not screwed in properly;

- The seat of the XX jet has a deformation in its structure or the jet itself is damaged.

Ways out of the situation are presented below. So, with the engine running smoothly at idle, remove the wire from the solenoid valve. When this action is performed, the engine will stop immediately. If this is exactly what happened, then most likely the XX jet is too large and does not suit you. The solution here is very easy - purchase and install a smaller one.

- If the engine continues to run, then most likely gasoline does not enter the XX nozzle, but goes by. You need to carry out the following manipulations, namely, unscrew the plug (solenoid valve) and examine your XX jet to see if it is damaged. If deformations are detected, there is no other way but to buy a new carburetor cover. If no deformations were found during your examination, put the jet on the valve, lubricate the O-ring with oil and tighten it with a wrench (tighten without much effort, it is advisable to tighten with a wrench using only one finger).

Signs of a carburetor malfunction

Carburetors produced by DAAZ of any type and year of manufacture must ensure continuous operation of the engine in any operating mode: be it idling or high speed at speed. However, it is precisely when changing these modes (for example, after warming up in winter, a quick start from a place) that errors in the operation of the device can be detected. So, the carburetor clearly has some kind of malfunction if:

- the engine, when idling, experiences failures;

- the driver began to notice gaps in the time between pressing the gas pedal and accelerating the car;

- the engine runs jerkily (this is especially noticeable at high speeds);

- fuel consumption gradually increases;

- It is difficult to start the engine the first time after a long period of parking.

Settings

The unit requires setup

After you have installed Solex 21053 on the classic, you need to configure it. This is done in order to obtain better performance in the car's driving speed and reduce its fuel consumption. So, the first thing to start with is adjusting the fuel level in the float chamber. You can customize it using a special template. However, since gas pumps on cars are not always the same, you shouldn’t do this.

You need to adjust the level in the following way:

- Start the engine for five minutes and let it idle. I must say that it will start, even if the Solex is very weak and it’s high time to change the jets.

- After allowing the specified time to work, turn off the engine.

- Remove the fuel line hose. If this is not done, gasoline may flow over it and change the readings. Unscrew the screws securing the Solex cover and pull out the choke cable.

- When removing the cover, be extremely careful; if done incorrectly, you can damage the floats.

- Using any distance measuring device, determine the number of centimeters from the fuel level to the place where the cap used to be.

Both chambers will have different distances, but you need values from 23 to 25 cm. You can level the fuel level by bending the floats and draining all excess. Now you can put back everything that you removed from the carburetor in the process. Start the engine and watch both Solex cameras. If gasoline drips from them, then you need to reduce the amount of fuel a little more.

If the motor is acting up, it means you need to increase it. Then check the liquid level in the fuel drum again. Most likely, you will make 3-4 attempts before success. You can reduce the amount of time you spend at work by pumping gas by hand.

Adjusting the carburetor VAZ 2105

During operation, all DAAZ carburetors will need adjustment. Some drivers adjust the device when the seasons change, some when certain defects appear.

In any case, adjusting the VAZ 2105 carburetor is a process that will optimize engine performance and extend its life. In addition, even a standard carburetor setting significantly improves the basic performance indicators of the engine: for example, it increases speed data and reduces fuel consumption.

It is recommended to adjust the carburetor setting at a car service center. Carrying out the procedure independently is only recommended for those car enthusiasts who are well versed in car systems.

For high-quality, full adjustment you will need:

- Prepare your workplace. To adjust the device’s systems, it will need to be removed from the machine, washed, blown out and installed in a flat and clean place.

- Prepare the tool. In the case of the VAZ 2105, this is a set of wrenches, a Phillips and flat-head screwdriver. A rag will also be a good idea, as fuel leaks are possible.

- Find a service book for the VAZ 2105. In this manual, the manufacturer indicated all the operating parameters of a particular model; it is these parameters that will need to be checked during the work process.

Main adjustment steps

Once the carburetor has been fully prepared for operation, you can begin adjusting it:

- First of all, specialists usually adjust the amount by turning the crankshaft. The optimal number is between 750 and 800 rpm. To set this parameter, you will need to tighten the adjusting screw all the way, and then carefully open it three turns back.

- Next, you will need to adjust the volume of CO2 gas in the vehicle exhaust. To do this, you need to tighten the quality screw all the way and unscrew it back 4 or 5 turns.

- The idle speed is adjusted using the idle speed screw. To do this, you need to slightly tighten the screw in the opposite direction from the carburetor.

- The float in the float chamber must be strictly in the center, so to achieve the desired value, you can lightly press the latches.

Photo gallery: do-it-yourself adjustment

Cleaning the jets

Car owners have many questions about cleaning jets. Does it make sense to clean these devices or is it better to immediately replace them with new ones? In fact, it all depends on the driver’s financial condition - of course, it’s faster and easier to remove the old jets and install new ones in their place.

However, if the holes in the tubes are not blown apart, you can simply wash the nozzles in acetone or a special liquid, then blow them out with compressed air from a can and install them back. They will work exactly as long as new ones.

source

Operation and repair of the device

The carburetor serves to form a combustible mixture by combining injected fuel and air, in order to ensure the operation of the internal combustion engine. In this case, the correct proportions must be observed to ensure normal combustion. If the proportions are not observed, an over-enriched mixture is formed due to an excess amount of fuel or lack of air, which leads to breakdowns.

In addition, you need to adjust the gaps on the gas distribution mechanisms and open the air damper. Special attention should be paid to the correct setting of the ignition timing. When adjusting carburetor 2105, first of all, set the crankshaft rotation frequency to 700-800.

When installing a carburetor on a classic VAZ 21053, you should remember that, unlike the VAZ 2105, 21053 20 has a somewhat poor second chamber. This is explained by the fact that the first has a fairly rich adjustment. It can be made poorer by installing 102-150 jets, but then there will be a need to enrich the second chamber by installing 115-135 jets.

What cars were equipped with ICE 2105?

This modernization could not satisfy users of the domestic automobile industry. The main drawback was the regular breakage of the timing belt, AvtoAZ management reduced production volumes, then removed the 2105 engine from production, so only three modifications of the Zhiguli were equipped with the engine:

- 2105 sedan;

- 2104 station wagon;

- 21072 sedan.

Four with engine 2105

Currently, tuning for the engine of this series is not difficult, but among the operating fleet of Zhiguli “fives” with the “native” engine there are very few left.