The presence of a two-float chamber ensures uninterrupted supply of the mixture regardless of the driving mode. But factory settings are not always accurate and sometimes deviations from operating standards reach 15%.

Therefore, almost every VAZ 21213 carburetor needs adjustment. Another important condition for trouble-free operation of the unit is timely maintenance.

Features of servicing DAAZ-21073 devices

All possible disruptions in the operation of the device directly depend on the quality and frequency of service. Despite the design differences between the VAZ DAAZ-21073 and the DAAZ-4178 carburetor on the UAZ, their maintenance is not much different. The technically required work includes:

- external cleaning;

- washing the float chamber strainer;

- cleaning the float chamber;

- cleaning jets;

- adjustment of the float device;

- adjustment of the starting device;

- stabilization of the XX system.

Washing the external and internal parts of the carburetor unit is carried out using kerosene, white spirit or preparations in aerosol cans. The aerosol composition is injected into the chambers and jets while the engine is running. The cleaned apparatus is blown with compressed air.

Adjusting the Solex 21073 carburetor on Niva

Before starting the adjustment, it is necessary to insert a level in the float chamber so as not to disassemble the carburetor again. To do this, pump fuel using a hand pump and remove the top cover. If you pay attention, there is an inclined plane in the chamber, in the middle of which the fuel level should be located. If it is different, then it is set by bending the antennae of the float.

The next step is to adjust the air damper, starting gap and starting device. There is nothing complicated here. You need to pull out the choke completely and close the damper. In this state the cable is fixed. Now you need to test the operation of the damper: with the handle completely retracted, the damper should be open and vice versa.

Now the carburetor idle speed is adjusted (Solex 21073). To do this, you need to completely tighten the quality and quantity screws, and then unscrew the quality adjusting screw by four turns, and the quantity by three turns. After this, the engine is started and warmed up to operating temperature. After eliminating the interruptions, you can start setting up.

Tighten the quantity screw until the speed drops to 800-900 rpm. Now set the maximum speed by turning the quality screw. Tighten the quantity again to 800 rpm. Now we adjust the quality until the engine begins to shake slightly. This moment will be the most optimal.

There is another method, which involves repeating the first cycle until further adjustment is impossible. Both methods work, so you can adjust them in different ways.

If the carburetor does not work and is not adjustable, you should look for excess air leaking through the gaskets or check the timing belt and ignition. Resolve the problem and try again. To eliminate this problem, check the damper clearances.

The car must be parked on a level surface, and the low beams and main electrical consumers must be turned on. That's the only way to regulate it.

Regulations for adjusting the carburetor on the VAZ 21213

Any work related to the engine or power system on the VAZ 21213 should end with adjusting the carburetor parameters. After carrying out the above procedures, you should sequentially perform a number of settings:

- Throttle valve actuators

- Air damper drive

- Trigger

- Automatic starter

- Idle systems

- Exhaust CO and CH concentrations

Some adjustments can be performed both on the removed device and directly on the machine. In case of sagging or high tension in the throttle valve drive cable, use the adjusting nut to set the desired position, having first unscrewed the lock nut. It is worth checking the distance between the centers of the tie rod ends, it should be within 80 mm. As a result, when the accelerator pedal is fully pressed, the damper is completely open, and when the pedal is released, it is closed.

The air damper drive rod should move freely in the shell, and the lever should rotate around its axis without effort. The handle recessed all the way in the car interior corresponds to a fully open damper (vertical position). When pulling the handle, the area of the chamber inlet must be blocked. Deviations from these requirements are eliminated by adjusting the fastening of the cable sheath or repairing the drive lever.

The next step is setting up the starting device. By forcefully opening the air damper by 1/3 with a screwdriver, you need to set the speed to 3200 - 3300. Then remove the screwdriver and use the adjusting screw to reduce the crankshaft speed to 2800-3100 rpm. At this point, the adjustment of the VAZ 21213 carburetor can be said to be almost complete.

Adjustment of the exhaust gas system and the concentration of hydrocarbons in the exhaust can be done in one step. After starting the engine, you need to use the quality screw to set the maximum possible idle speed. Next, use the quantity screw to reduce the speed so that it is 50-100 units higher than the normal idle speed. After this, use the quality screw to achieve the desired value.

High-quality tuning of the carburetor unit is available to a car enthusiast with basic knowledge of the principles of internal combustion engines and a minimum of tools.

Despite the fact that the VAZ-2121 SUV was developed quite a long time ago, this car is still very popular. In 1994, the model was changed to VAZ-21213. Many people buy these cars because of their high cross-country ability, which can be the envy of some jeeps from famous brands. Others like reliability, unpretentiousness and high maintainability. A simple design and excellent off-road characteristics made this vehicle a vehicle for lovers of travel, hunting, fishing and tourism.

Niva cars 211213 are equipped with a 1.7 liter engine. It is carburetor, and is based on a VAZ-2106 engine. There is also a five-speed manual transmission and a proximity ignition system. The power system is equipped with a Solex 21073 carburetor for the Niva. Many novice car owners are intimidated by carburetors and everything connected with them. But a carburetor is not a death sentence. You just need to understand its basic structure, how to adjust it, and how to repair it.

We carry out the adjustment ourselves

Niva 21213 can be subject to adjustment of the starting system by the gap at the edges of the valves, if the carburetor is removed, or by the crankshaft speed directly on the car. In the first case, the gap at the location of the lower edge (in the direction of air movement) from the throttle valve is set to a width of 1.1 mm. It is adjusted with a screw that has a 0.7 cm hexagon on the head and a slot from the shank. This operation is carried out with the cam lever turned counterclockwise from the starting system control (all the way). In the same position, the gap at the lower edge of the air damper is set to 3 mm using a screw in the cover from the diaphragm mechanism in the starting system (you need to loosen the lock nut). At the same time, the rod from the diaphragm must be forcibly recessed completely into the adjusting screw. After adjustment, the screw is fixed with a locknut.

The principle of powering a carburetor engine

Adjusting the Niva starting system directly in the car saves time:

If you have a gas analyzer, then the carburetor adjustment in the starting system part can be done based on the amount of CO (carbon monoxide) in the exhaust gases. If, with the choke control lever fully extended, the gas rate is 8%, then everything is in order. If there is less gas than this value, then the screw on the cover of the diaphragm mechanism is tightened; if there is more, it is unscrewed and repeated measurements are taken.

Float mechanism

The Solex 21073 carburetor, installed on the Niva, has a float chamber of two sections. They are located on both sides of the main cameras of the device. The system consists of two ebonite floats, which are mounted on a lever.

The latter swings on an axis pressed into the bosses of the device cover. There is a tongue on the bracket. The element presses the needle valve needle through a special ball. The float mechanism serves to adjust the level of fuel required for normal operation of the carburetor. The needle valve is a non-separable type. It is not being repaired. The valve body is mounted on a thread in the carburetor cap. The ball protects the needle from shock when the machine moves. If the chamber is empty (for example, if the driver is using LPG), then the floats will knock.

Elements of the carburetor on Niva models

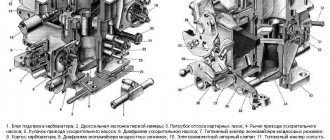

The carburetor circuit also includes: a drive lever from the accelerator pump, a diaphragm, an adjusting screw and an air duct from the starter, a shut-off valve (solenoid), an air damper, a needle valve, a fuel supply fitting, an economizer for power modes, a carburetor heating unit, fittings for crankcase ventilation, for supplying vacuum for the vacuum regulator in the ignition, and other elements.

Niva 2121 has the following sequence of passage of fuel elements through the carburetor chamber. First, fuel moves from the fuel tank to the float chamber in a controlled amount. The float rises or falls as the fuel moves.

Further, the fuel path lies through the nozzle into the atomizer, located in the narrow part of the diffuser, with simultaneous air entering the carburetor through the outer pipe. The throttle valves then deliver varying amounts of fuel into the engine cylinder through an intake manifold cast from aluminum alloys. The manifold is attached to the engine with studs through gaskets that have heat-resistant properties.

Main dosing systems

The first and second chambers are equipped with diffusers. There is one large and one small element. Spray devices are also made together with small diffusers. The latter are connected through channels to the emulsion wells, and they communicate through one channel with the float chamber. To ensure that gasoline flows in certain portions, the main fuel jets are located below in the emulsion wells. These same wells have special tubes. Each of them is equipped with an air jet at the top. Air is supplied to them from the neck of the device.

Scheme and principle of operation

The types and modifications of carburetors for a given car can be very different, but the principle of operation remains the same.

When starting the engine cold, the driver closes the choke to limit the flow of air and increase the amount of gasoline. This makes it easier to start and brings the speed necessary for stable operation.

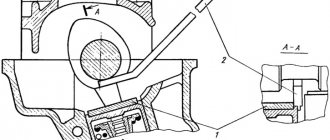

Carburetor 21073 DaAZ device and principle of operation: diagram of the design and operation of the carburetor I - first chamber; II - second chamber; 1 — accelerator pump drive lever; 2 — adjusting screw of the starting device: 3 — diaphragm of the starting device; 4 — air channel of the starting device; 5 - solenoid shut-off valve; 6 — idle fuel jet; 7 — main air jet of the first chamber; 8 — idle air jet; 9 — air damper; 10 — sprayer of the main dosing system of the first chamber; 11 — accelerator pump nozzle; 12 — nozzle of the main dosing system of the second chamber: 13 — econostat nozzle: 14 — main air jet of the second chamber; 15 — air jet of the transition system of the second chamber; 16 — channel for balancing the float chamber; 17 - float chamber; 18 — needle valve; 19 — calibrated hole for fuel bypass into the tank; 20 — carburetor fuel filter; 21 — fuel supply fitting; 22 — power mode economizer diaphragm; 23 - fuel jet of the power mode economizer; 24 — ball valve of the power mode economizer; 25 - float; 26 — econostat fuel jet with tube; 27 — fuel nozzle of the transition system of the second chamber with a tube; 28 — emulsion tube of the second chamber: 29 — main fuel jet of the second chamber; 30 - outlet of the transition system of the second chamber; 31, 33 — throttle valves: 32 — slit of the transition system of the first chamber; 34 — outlet of the idle system; 35 — carburetor heating block; 30 - adjusting screw for the composition {quality} of the idle mixture; 37 — engine crankcase ventilation fitting; 38 - fitting for supplying vacuum to the vacuum ignition regulator; 39 — vacuum selection fittings for the recirculation system; 40 — main fuel jet of the first chamber; 41 — emulsion tube of the first chamber; 42 - ball valve of the accelerator pump; 43 — accelerator pump diaphragm.

During the warm-up process, air intake is increased to reduce speed and eliminate interruptions. Thus, the air damper opens completely and the amount of gasoline is reduced. Other methods of warming up are not provided for by the design.

Gasoline is supplied through the fuel filter to the float chamber, and then to the main metering system of the mixing chamber. The scheme for pumping air and mixing it with gasoline in the diffuser occurs due to the vacuum that occurs during the operation of the valve mechanism and pistons, compressing and pushing out the working mixture.

The second chamber system is designed to increase air flow to the nozzle when the engine is running under heavy load, when the speed is high.

To ensure that the engine runs stably at idle, and at low speeds to prevent it from stalling and eliminate interruptions, an idle system is provided. And to maintain the level of fuel used in the Solex 21073 carburetor, there is a whole scheme for the operation of the float system. Let's consider the operation of each system separately.

Operating principle of the main dosing chamber

Under the influence of vacuum that occurs in the engine cylinders, air is drawn through the filter. Next, oxygen is supplied to the first chamber. It passes through diffusers. Due to the fact that the air flow speed has increased, an even greater vacuum is created in the nozzle area.

Under its action, the fuel rises from the emulsion well from the atomizer. At the same time, air passes through the air nozzle into the emulsion tube and is then mixed with fuel. As a result, an emulsion is formed, which is sucked at high speed into the carburetor channels, where it connects with the air flow. The installed Solex 21073 carburetor on the Niva operates on this principle. Its design may vary depending on the modification. But the principle of operation of the systems is approximately the same for all devices.

How to adjust the carburetor yourself on a VAZ Niva car

Created several decades ago, Niva is still popular among domestic and even foreign motorists. This SUV is in demand due to its unpretentiousness, maintainability and good cross-country ability, which can be the envy of many modern cars of the same class. But proper and uninterrupted operation of even such a durable vehicle can only be ensured with proper and timely maintenance and repair. Therefore, if you are not going to spend money on the services of service station specialists, it is advisable to at least superficially understand the design features of your car. For example, self-adjustment of the carburetor on a VAZ Niva car will allow you to optimize engine performance and reduce consumption at minimal cost.

The VAZ-2121 has become popular due to its cross-country ability, technical reliability and ease of operation and maintenance.

This article will focus on setting up the carburetor on the VAZ-2121 and VAZ-21213 models, as the most prominent representatives of domestic classic SUVs. Niva 21213 replaced its predecessor in 1994, having undergone a number of design changes. First of all, the model acquired a new engine, on which the manufacturer installed a different carburetor. The Niva 2121 used an Ozone carburetor, and owners of the next generation of the SUV were offered a more modern unit called Solex. However, many farmers did not appreciate the innovation due to its increased requirements for the quality of gasoline and often resorted to installing the unit from the previous model themselves. You will learn further about how to set up the carburetor on Niva 21213.

Idle system

The device is equipped with an idle system. It is designed to allow the engine to operate at low speeds. At this moment, the vacuum in the diffusers is very small. Fuel cannot enter the main metering system. At idle speed of the engine, fuel is supplied under the throttle valve of the first chamber of the carburetor. There the vacuum is strong enough to form a stable combustible mixture.

Air is supplied through the main jet and the emulsion well of the first chamber. The fuel will then flow to the idle fuel jet. After this, it is mixed with air supplied from the XX air jet. Oxygen is supplied to this element through a special channel. This operating scheme allows the engine to ensure a smooth transition from load to idle and prevents fuel from leaking out of the float chamber.

How to reduce fuel consumption on a VAZ 2121?

Using a standard carburetor, the Niva consumes a large amount of fuel. Putting a Solex carburetor on the field does not mean that the problem is completely solved. It is important to monitor many other systems and the overall condition of the vehicle.

The following parameters affect fuel consumption:

| Cleanliness of filters . This applies not only to the fuel filter, but also to the air filter. If less oxygen gets into the carburetor, the Niva 2121 will begin to consume more fuel in order to maintain the speed at the desired level. The mixture will become richer and it will begin to pour. |

| Tire pressure . If the pressure is insufficient, then the engine has to do a lot of work to overcome such resistance. This leads to the fact that, while performing unnecessary work, the engine consumes a huge amount of fuel. But you should not overinflate your tires, as this will impair road grip. |

| Excess weight of the car . The effect is the same as with insufficient pressure. If you carry it in the trunk, the carburetor will fill the cylinders with more fuel. Niva 2121 is not designed for transporting goods. |

| Violation of aerodynamics . This applies to luggage racks and cargo installed on the roof of a car. An increase in air resistance causes the motor to consume more energy. The same applies to open windows when driving on the highway. |

| Aggressive driving style . It is known from driving school that a smooth increase in speed and smooth braking helps to save fuel. When driving at higher speeds, the carburetor consumes more gasoline. The VAZ 21213 Niva was designed taking into account driving at speeds no higher than 3000. If you do not exceed these limits, you can save a lot. |

| Driving in neutral gear . This is the biggest mistake many drivers make. When the speed drops below 1100 rpm, the autonomous idle system comes into play, which forces the engine to consume more fuel so that it does not stall, since the throttle is closed at this moment. When approaching intersections, you need to take your foot off the pedal and smoothly shift to lower gears. |

| Use of electronic devices . If you turn on a large number of different devices at a time when they are not needed, the load on the generator, the pulley of which is in mechanical connection with the crankshaft, increases. This leads to excessive consumption of gasoline. |

| Long engine warm-up. Many people take too long to warm up their car. It is most effective to apply warm-up while moving. When the motor has reached 50 degrees Celsius, you can start moving without putting a lot of load on the motor. The temperature will reach 90 degrees much faster, and, accordingly, more fuel will be saved. |

| Driving at maximum speed on the highway . If you go too fast, air resistance increases proportionally, which slows down your movement. The same principle applies here as when aerodynamic characteristics are violated. |

Troubleshooting

Car components do not last forever, and sometimes the installed Solex 21073 carburetor on the Niva fails. Repairing it must begin with diagnostics. It may be possible to get by with a simple adjustment. So, during operation, solid particles can enter the carburetor, which ultimately causes clogging of the jets. Low-quality gasoline leads to the formation of deposits on the walls of the channels in the device. This significantly reduces their cross section. Failure of carburetor systems can be diagnosed by the following symptoms:

- Increased fuel consumption.

- Difficulties in starting the engine. Reduced power and dynamic performance.

- Unstable operation at idle.

In this case, it is necessary to clean the installed Solex 21073 carburetor on the Niva. The adjustments that will be made after this will allow the device to work as it should again.

Do-it-yourself VAZ 2121 carburetor repair

Repair of the carburetor unit on the Niva may be required in different cases. If a car enthusiast has practical skills in servicing his “four-wheeled friend,” then performing repair work independently will not be difficult for him. However, it should be noted that the design of carburetor mechanisms is highly complex, so high-quality work without preparation is unlikely.

Signs and causes of malfunctions of Ozone carburetors

External manifestations of the operation of the engine unit and the driver’s own sensations, as a rule, may indicate the occurrence of any malfunctions in the operation of the carburetor. The most common signs of malfunctions on Ozone are:

unstable operation of the power unit at idle;

the car loses its dynamics;

after reaching a speed of 90 km/h, engine productivity drops sharply;

difficulty starting;

increase in fuel consumption.

Thus, if Ozone shows one or more of these signs of malfunction, this means that repair work is necessary.

Video: carburetor starter repair

The engine receives too much gasoline - the carburetor is flooded / the needle is stuck

If a car owner notices that the carburetor is constantly being filled with excess gasoline, we can conclude that the needle valve is faulty. Over time, it can lose its throughput, which is why at first there are difficulties in starting the engine, fuel drips appear on the carburetor, and then it will be impossible to start the engine at all.

The way out of the situation is to replace the needle valve yourself. To do this you will need:

Remove the cap from the carburetor.

Align the float along its original axis.

Disconnect the needle valve.

Screw a new valve into the vacant space.

Screw the lid into place.

The car cannot maintain idle speed and immediately stalls

In this case, the economizer will need to be replaced. Most likely, the reason lies in this component, since it ensures the supply of fuel to the engine at idle. In rare cases, the idle speed control unit on Niva carburetors may fail.

To determine the cause of the malfunction, it is recommended to disassemble the carburetor and inspect the economizer and idle devices. Their condition will be visually noticeable (adhesion of a large amount of soot and dirt, deformation). If devices fail, the procedure for replacing them is as simple as possible: a new one is installed in place of the old component.

We carry out the adjustment on a warm engine.

By rotating the idle mixture amount adjusting screw (made of black plastic) with your fingers, we set the crankshaft speed to 800±50 rpm (for clarity, the air filter housing has been removed), and by rotating the quality screw with a slotted screwdriver, the content of carbon monoxide in the exhaust gases is not more than 3%.

When you press the gas pedal, the engine should increase the crankshaft speed without interruption, and when you release the pedal, it should not stall.

How to restore carburetor operation?

For repairs, most often you have to remove the device from the engine. First, remove the air filter. Then the fuel lines, air pipes, wires and cables are removed. then unscrew the fastening nuts.

It is best to disassemble the carburetor on a table or other convenient surface. The parts should be laid out in some order. This will help you not lose them. The process of adjusting the needle valve is performed using a special template. To wash the device, you must use special liquids. Replacement jets can be purchased at any auto stores. Often, disassembling and flushing the carburetor helps solve a lot of problems.

Repair and maintenance of the Solex 21073 carburetor in the field

To repair the carburetor, you must remove it from the engine. To do this, first of all, remove the air filter, all hoses going to the device, rods and throttle valve drive, and then it is removed.

Before disassembling, it is recommended to obtain a repair kit to troubleshoot the carburetor, which includes:

- Gaskets;

- Jets;

- Needle valve;

- A set of rods and small fasteners.

It is recommended to disassemble the carb on a large table and lay out the parts in order so as not to lose them during work. Repair of the Solex 21073 carburetor on a Niva car is carried out in the following sequence - disassembly, washing of all parts with a special liquid, installation of parts from the repair kit and assembly. The types of repair kits differ depending on the model of the device.

Selection of jets is one of the most important procedures. The selection is made taking into account the technical data of the device and should be based on the personal choice of the car owner. It should be taken into account that increasing the cross-sectional diameter leads to improved dynamic characteristics and increases fuel consumption. Types of jets can be very different.

Therefore, if you select the jets correctly, you can achieve good performance with minimal gasoline consumption.

After installing the device on the car, the idle speed is adjusted. It will restore normal engine operation and reduce fuel consumption.

Adjustment

If the installed Solex 21073 carburetor on the Niva fails, repairs and adjustments help bring the device back to life. The settings allow you to restore optimal modes in which the motor will operate as efficiently as possible. Fuel consumption is at an average level. First of all, start the engine and warm it up a little. Next, you need to remove the fuel hose and the device cover. It is recommended to remove the latter with extreme caution so as not to damage the float. Next, using a measuring tool, measure the distance in each of the carburetor chambers. Measure from the mating surfaces to the edge of the fuel. This size should be approximately 24 mm. If this distance is less or more, then it is adjusted by bending the float. Then you need to start and warm up the engine again. When the level adjustments are successfully completed, you can proceed to adjusting the idle speed.

The engine is turned off. To set up, you will need a flathead screwdriver and a little time. There is a hole on the base of the device in which there is a screw that regulates the quality of the fuel mixture. It is twisted all the way. Then from the extreme position the same screw is unscrewed by about five turns. Then the engine is started. There is no need to use a suction. If you unscrew the “quality” screw, then the carburetor will change the engine speed. Then it is twisted again. It is required to rotate until the operation of the motor is stable and stable. When the engine starts to run smoothly, then the element is unscrewed no more than one turn. As a result, the idle speed will be set at 900. If the engine starts to stall, it is better to slightly increase the idle speed.

How to adjust Ozone

Self-adjustment of the Ozone carburetor on a VAZ 2121 car allows you to achieve stable operation of the power unit and reduce gasoline consumption.

Typically, adjustment work includes adjusting the starting unit, the idle speed unit and the fuel level in the float chamber tank. To quickly carry out the work, it is recommended to immediately prepare the following set of tools:

multimeter (or tachometer);

flat narrow screwdriver.

The procedure for performing adjustment work:

It is necessary to warm up the engine to its operating temperature.

With the engine running, you will need to fully open the air damper of the carburetor mechanism - fully press the damper drive handle (that is, the choke).

Connect the tachometer (multimeter) to the engine: the minus wire to the vehicle ground, the plus wire to the ignition coil to terminal K.

After connecting, you need to start the engine again, immediately turn on the lighting and the fan to supply heat.

Use a screwdriver to start adjusting the air-fuel mixture supply screw - you need to turn the screw until the power unit begins to idle smoothly. The optimal tachometer indicator is 750–800 rpm.

If it is not possible to achieve the desired performance by normal adjustment, you will need to remove the carburetor and thoroughly rinse it from dirt deposits. Apparently, the mechanism is so clogged with sediment coming from the fuel that its adjustment is impossible.

Video: do-it-yourself carburetor adjustment on a Niva

By adjusting or repairing the carburetor with your own hands, the car owner can be confident in the high quality of the work. In addition, a visual inspection of the internal components of the unit will allow you to draw a conclusion about its resource and thus calculate the frequency of maintenance or routine cleaning. Ozone carburetors have been an invariable attribute of Niva cars for many years, ensuring reliable engine operation and excellent operating characteristics.

How to adjust the carburetor on the field 21213 video Link to the main publication

Source

Checking and adjusting the fuel level in the float chamber of the 21073 Solex carburetor

If malfunctions occur in the operation of a car engine with a Solex 21073-1107010 carburetor: loss of power and throttle response, “dips” and jerks when pressing the gas pedal, “overflow”, it makes sense to check and, if necessary, adjust the fuel level in the float chamber.

Necessary tools and equipment

— Medium Phillips screwdriver

— Slotted mid-size screwdriver

— Drill with a diameter of 1 mm

Preparatory work

— Place the car on a level surface

— Remove the car engine air filter housing

The procedure for checking the fuel level in the float chamber of the carburetor 21073-1107010 Solex

For normal operation of the 21073 carburetor, a certain position of the elements of its float chamber is necessary. Therefore, we check two parameters: the first is the fuel level itself in the float chamber and the second is the position of the floats.

Let's carry out work on checking and adjusting the fuel level in the float chamber using the example of a Solex 21073-1107010 carburetor just removed from the 1.7 liter Niva 21213 engine, the operation of which began to cause small dips when pressing the gas pedal. The carburetor has never been independently adjusted, so all dimensions are original (factory).

— Start the car engine and let it run for 3-5 minutes

In this case, the float chamber will automatically fill with fuel to the verified operating level.

— Remove the top part (cover) of the carburetor

Unscrew the five screws securing the cover using a Phillips screwdriver.

— We measure the distance from the edge of the float chamber to the fuel mirror

(we measure the fuel level)

We use a ruler. The distance from the edge of the float chamber to the fuel “mirror”, if the fuel level is normal, should be 25-26 mm. See photo above.

If the fuel level is normal, further measurements need not be taken. But just in case, let’s check the position of the floats, in case one of them touches the walls of the float chamber.

— We measure the distance between the protrusions on the bottom surface of the floats and the cardboard gasket of the lid

To do this, turn the carburetor cover over with the floats facing up and place it on a horizontal surface. We insert a drill with a diameter of 2 mm between the protrusion on the bottom of the float and the cardboard gasket (it should be pressed tightly against the lid). The drill should go in with a slight pinch. We check for the second float. At a fuel level of 25-26 mm, the distance between the floats and the gasket should be 2 mm. These are interdependent quantities. If the distance is greater or less, then using a slotted screwdriver and pliers we slightly bend the upper tongue on the float levers. Let's check again.

We measure the gap between the gasket and the float using a drill

On our test carburetor 21073 Solex, a 2 mm drill bit fit freely between the gasket and the edge of the float. If you slightly squeeze the cardboard spacer, a drill with a diameter of 2.5 mm will fit in with a slight pinching (I repeat once again that the carburetor has never been adjusted and all its settings and dimensions are “factory”).

— Check the position of the floats relative to the walls of the float chamber

We look from above at the horizontally installed carburetor cover. The floats should be parallel to the print lines on the cardboard lid liner. If not, bend the float arms.

The floats should be parallel to the print on the cardboard “lid” gasket

Place the lid vertically. We look at the stamping line on the side of the float. It should be parallel to the plane of the lid. We check the second float in the same way. In this case, the tongue on the levers should slightly recess the shut-off valve needle ball. If there is no parallelism, bend the float levers and (or) the tongue.

We check the parallelism of the floats relative to the plane of the “cover”

— We adjust the full stroke of the floats

Place the lid horizontally. Using a ruler, measure the distance from the lower corners of each float to the plane of the cardboard lid gasket. Let's remember the number.

Measuring the distance to the bottom corner of the floats

We raise the floats up, simulating their descent to the bottom of the float chamber when the fuel level in it drops. Using a ruler, measure the distance from the bottom corners of the floats to the cardboard spacer. It should be: the first memorized digit plus 15 mm. For example, 3 mm plus 15 mm equals 18 mm. If the distance does not correspond to the required one, then we achieve its compliance by bending the rear tongue on the float levers and checking again.

Set the full stroke of the floats

That’s it, checking and adjusting the level in the float chamber of the carburetor 21073-1107010 Solex is completely done, it’s time to install it on the engine and check whether the “dip” in engine operation has disappeared when you press the gas pedal.

Notes and additions

— If the fuel level in the carburetor float chamber is set correctly, but there are still problems with the engine, it is necessary to check the tightness of the float chamber shut-off valve and the presence of “suction” of foreign air into the carburetor.

TWOKARBURATORS VK -More information on the topic in our VKontakte group

Which carburetor to put on Niva 21213 - setup, adjustment, choice

Owners of the Niva 21213 SUV appreciated all the advantages of this car. This car doesn’t care about anything, and its reliability and simplicity of design delight not only Russian drivers, but also foreign ones. Among the disadvantages of the Niva, one can note its high fuel consumption, which depends on many factors. One of them can be considered a carburetor, which forces owners to choose another unit for their car. Let's look at which carburetor is best installed on the VAZ 21213 (Niva 1700) and how it is configured.

Device

The Solex 21073 carburetor installed on the Niva 1.7 can be classified as an emulsion device.

The mechanism is designed to prepare a working fuel-air mixture. The device consists of two parts - the body and the cover. The device also consists of a float chamber with the ability to balance the level. There is an accelerator pump, an economizer, and an econostat. The design has two fuel chambers and diffusers.

A flammable mixture is prepared in them. The lid has fittings through which gasoline is supplied to the carburetor, and excess fuel goes back into the tank. There are also studs in the lid. They are used to mount the air filter. The lid is also equipped with a needle valve for the float chamber, where the fuel level is directly regulated.

The carburetor has a mechanical air damper. It allows you to start the engine “cold”. In this modification, the Solex 21073 carburetor on the Niva 21213 shows very high efficiency. When properly configured, the device is capable of providing very high technical performance for front-wheel drive vehicles.

Niva carburetor: we set up and repair it ourselves

The carburetor on models 2121, 21213 and other cars has basically the same device. Functionally, it is located in the propulsion system, and with its help the fuel is mixed to the state of a combustible mixture. A carburetor, as a rule, consists of several main elements - a float chamber, a so-called jet (with a spray), a diffuser, and a throttle valve. It can have from one to four cameras on different cars, sequential or simultaneous opening of the throttle valves, horizontal, downward or upward movement of the working mixture.

Carburetor repair for dips and jerks

Carburetor repair may be necessary if the engine idles unstable, and adjusting the quantity and quality screws does not always help. Often the reason lies in over-enrichment of the mixture, which may be a consequence of incorrect adjustment of the float system or malfunctions in the vacuum economizer system for power modes. In the latter case, a torn diaphragm may need to be replaced or the economizer valve through which fuel is leaking may need to be repaired.

Model 2121 may cause jerking, swaying or dips when moving. In this case, there may be several reasons for their occurrence, which may require carburetor repair to eliminate them. Dips that appear when the throttle valve is slowly opened are often associated with clogging of the idle jet. Here it is necessary to adjust the fuel level and check the level of clogging in the main fuel jets.

If the car gives a deep failure when trying to open the first or second throttle chambers, then in addition to clogged nozzles, the reason may be poor installation of small diffusers in the corresponding sockets.

When the Niva 21213 gives slight twitches at low and medium speeds and accelerates sluggishly, it may be due to poor fuel dosage on the shut-off valve side due to its wear. In this case, repairs are needed in terms of replacing the shut-off valve with a shut-off needle made of metal with a valve that has this needle made of a different material.

Cars of the 2121 series sometimes give failures when any sudden opening of the throttle valves, which then disappear within 5 seconds when the engine is running at the same pace. Often such problems are associated with a malfunction of the accelerator pump, which leads to a lack of or an incorrect drop in gasoline flows. A similar situation can result from a diaphragm rupture, a rubber O-ring on the sprayer holder being destroyed, or the lower part of the valve being destroyed.

All-terrain vehicles VAZ 2121 "Niva" already have reliable and durable equipment from the factory. The Niva uses a carburetor engine as its power unit, which allows for uninterrupted loads under any operating conditions. Repairing and adjusting the carburetor on a VAZ 2121 is a much simpler matter than it might seem at first.

How to remove a carburetor from a Niva

To do the job you will need a simple set of tools. Typically, every car enthusiast has all these auxiliary devices:

- head at 8;

- head at 10;

- extension;

- combination key 13;

- flat screwdriver.

The mechanism is located as conveniently as possible for carrying out any work.

When starting to remove the carburetor from the Niva, you need to make sure that the engine has already cooled down, otherwise you can get burned on overheated metal parts . The withdrawal procedure is as follows:

- Remove the air filter box. It will interfere with access to the motor, so it is recommended to immediately unscrew the three nuts securing the box with a screwdriver.

- Next, you will need to use a 8-mm head to disconnect the four bolts that secure the air filter box to the surface of the carburetor.

- After this, the box is moved to the side, and all hoses and lines going to it are disconnected from the carburetor

- The choke cable is disconnected (the clamp is unscrewed with a screwdriver).

- Using a thin blade of a screwdriver, you need to pry the throttle control rod to unhook it from the latch.

- The next step is to dismantle the carburetor itself. The four nuts that secure it to the manifold are unscrewed. After which the knot itself is pulled out from the pins.

It is recommended to place the carburetor on a flat, clean surface.

Cleaning procedure for removing carbon deposits and dirt

Removing the carburetor involves cleaning its components or replacing it in case of severe wear of the rubbing elements. However, most often it is removed in order to rinse and clean it inside and out from carbon deposits and adhering dirt:

- jets require a special approach to maintenance, as they have a fragile structure. To clean them, it is recommended to use toothpicks or thin copper wire. You cannot use any chemical cleaners, as liquid may remain in the nozzle holes and then get into the carburetor. After cleaning manually, it is allowed to blow out the nozzle with a can of compressed air;

- The float chamber is cleaned of carbon deposits with a special cleaner. The use of solvents of the 645–652 series is also allowed. The washing liquid must be poured into the chamber, stirred several times over two hours and drained. After which the internal cavity of the float chamber should be thoroughly dried with a soft, lint-free cloth;

- All throttle valve elements are cleaned of carbon deposits with a standard cleaner or kerosene. The damper, along with other metal parts of the carburetor, can be placed in a container with kerosene and kept there for two hours. After the accumulations of soot and dirt have dissolved, it is recommended to blow out the damper and wipe it dry.

Photo gallery: jets, float chamber and throttle valve

Gasket replacement procedure

The carburetor mechanism is in contact with the intake manifold. The absence of vibration, excess noise, and rapid wear of elements is ensured by the gasket located between this mechanism and the collector.

The gasket has a specific shape, thanks to which the carburetor and manifold successfully “get along” with each other. Replacing the gasket is necessary if additional vibration and extraneous noise are felt while driving. In addition, usually when removing the carburetor for washing, the gasket is also changed so that you do not have to later remove the entire device just to replace it.

The replacement procedure is quite simple: it includes all the steps that were described above (see p. How to remove a carburetor from a Niva). However, immediately after removing and removing the old gasket, a new product is put on the studs. Next you will need to install the carburetor in the reverse order.

The first gasket is new, the second is after a year of use, the third is with the maximum permissible degree of wear.

Adjusting the starter

When turning the choke control lever counterclockwise all the way, the choke should close completely.

If it does not close, eliminate the cause of the jam (or straighten the deformed valve).

With the air damper completely closed, the throttle valve of the first chamber should be slightly open to the starting gap “C”, equal to 1.1 mm.

We measure the gap with a wire of suitable diameter.

This gap is adjusted by turning the screw on the throttle drive lever with an 8" key (or a slotted screwdriver)

With the air damper completely closed, press the trigger rod with your finger until it stops - in this case, the air damper should open slightly to the starting gap “B”, equal to 3.0 ± 0.2 mm.

We measure the gap with a drill

To adjust the gap, use an “8” wrench to loosen the lock nut of the screw located on the starter cover.

Inserting a thin slotted screwdriver into the slot, unscrew (to increase the gap) or tighten (to decrease the gap) the screw, and then tighten the lock nut

Checking the operation of the second camera locking mechanism

Turn the air damper control lever counterclockwise until the damper is completely closed.

Then we turn the throttle valve control lever until the throttle valve of the first chamber is fully open.

The throttle valve of the second chamber must remain closed.