string(10) “error stat”

Any internal combustion engine must have an effective cooling system. Without it, the motor will overheat and all its moving parts may fail. Modern cars are equipped with a cooling system in which coolant circulates. Circulation is carried out using a special pump - a pump. Any coolant that is heated for a long time begins to boil. To prevent this, a radiator is provided in the cooling system. The engine cooling radiator consists of many thin tubes to which special lamellas are attached to increase the cooling area. When the car moves, air passes through the radiator fins and cools the metal, thereby reducing the temperature of the coolant. But at low speeds or when standing in a traffic jam, the radiator is not able to withstand engine overheating alone. In such a situation, an electric fan comes to the rescue, which is activated automatically at a certain coolant temperature. If the cooling fan fails, the engine will overheat. Next, we will look at why the radiator fan does not turn on, as well as possible causes and malfunctions that lead to this and methods for eliminating them.

What is an electric radiator fan?

A car cooling system fan is a regular electric motor that is powered by the car’s on-board power supply. An impeller is attached to its shaft, which directs a strong air flow to the radiator, to the front of which it is attached using a special frame. For more efficient operation, the cooling system is equipped with a fan diffuser. Most cars have one fan, but there are cars with two independent electric motors with an impeller that turn on simultaneously. Two fans are installed to cool the motor faster.

Modernization

If you want to improve the operation of your radiator fan on the VAZ 2109, we offer the appropriate instructions.

To upgrade, you will need to install a second sensor and modify the system somewhat.

- The standard power sensor will be responsible for the operation of the fan at maximum speed.

- An additional sensor will include a reduced speed. It is installed at the top of the cooling system.

Now let’s talk more specifically about how to organize all this.

- Take a temperature sensor whose response temperature is similar to the standard regulator.

- Install it in the upper pipe fitting to the radiator.

- To mount the element, you will need a pair of washers and a nut. Be sure to lubricate the washer with sealant to prevent leakage from the installation hole.

- Buy a resistor to install on the stove fan. It has several outputs, so if desired, you can make several operating speeds.

- It is necessary to make an additional control circuit. Through it, less voltage will be supplied to the motor winding.

- The temperature sensor located in the upper part of the cooling system is responsible for turning it on.

- It is better to do control not by plus, but by weight.

- The system will work through a button in the cabin. To the left of the dashboard there is a grille with two plugs. Cut out one of them and set it to turn off on two modes. You can take the heater switch from a VAZ 2107.

- In the first position the low frequency will be switched on, and in the second – the maximum speed.

- One common wire is fed to the minus.

Such modernization is not provided for by the design of the VAZ 2109. These are modifications made by car enthusiasts. Therefore, installing a second sensor is entirely your personal responsibility.

The fan is an important component of the cooling system of VAZ 2109 injection and carburetor engines. If you wish and have time, you can easily replace or repair it yourself.

The combustion of fuel in the cylinders of an internal combustion engine is accompanied by the release of a significant amount of heat, only part of which is used by the engine and converted into mechanical energy. The rest is uselessly lost, and special devices have to be used to neutralize its excess. These include, the ability of which to operate in any conditions is provided by the radiator cooling fan.

How does the fan turn on?

The device starts differently in different car models. A carburetor engine has a fan switch on sensor, which sends a signal to the relay after the liquid heats up to the set temperature (100-105 ۫). The fan relay then operates and supplies voltage to the motor. In an injection engine, control occurs using an electronic unit, which first analyzes the information received by the controller and then transmits it to the relay.

Examination

On VAZ 2109 engines, the operating temperature is 90 degrees.

If the indicator needle crosses the 100 degree mark, the car should be stopped immediately, the engine should be turned off and the power unit should cool down. Without doing this, you risk major, expensive engine repairs.

The motor can overheat for various reasons:

- The thermostat has failed;

- The radiator is clogged;

- The radiator fan has failed;

- The fan switch sensor is broken;

- The coolant level in the system has dropped;

- The pump has failed;

- The integrity of the wiring in the fan circuit has been compromised.

All these reasons can and should be checked before purchasing new parts.

Here is an example of checking a fan and sensor.

| Object to be checked | Method |

| Fan | Take one wire about a meter long. Preferably with two crocodiles at the ends. The mass goes to the fan. Your task is to supply voltage directly from the battery to the fan. Apply 12 volts to the second contact of the fan. If he's spinning, he's fine. If not, you'll have to change it |

| Fan sensor | Turning on the ignition, close the sensor contacts with a screwdriver. Normally, when it is closed, the fan should start spinning, and if it is open, it should stop. Please note that different types of sensors have a certain response temperature - from 87 to 90 degrees or more |

Don't rush to change the fan right away. Often the problem was a sensor, relay, fuses, or simply broken wiring. First of all, we will check the sensor and also tell you about the features of replacing it.

Signs of a faulty sensor may include failure to turn on when the coolant temperature is high or turning on when the engine is cold.

The fan switch sensor is located at the bottom of the radiator. A couple of wires come off it.

Accurate check

In order not to rush to conclusions, experts first advise checking the sensor for functionality.

- If the fan does not want to turn on according to the standard circuit, try shorting the wires that go to the sensor. If the fan is running and the sensor is hot, the problem lies there. If the radiator is hot during testing, the sensor housing may be warm. This suggests that you should check the condition of the thermostat and the coolant level in the tank. You may need to change and top up accordingly.

- If, after closing the wires, the fan does not turn on, the sound of the relay being activated is not observed, check the condition of the relay and fuse. It is number 4 in the mounting block.

- By shorting the wires, the fan did not start, but the relay worked. Here you should check fuse number 8.

- If the fan starts randomly on a cold engine, it does not turn off for a long time, try disconnecting one wire from the sensor. If the fan stops, the sensor contacts are stuck. If the fan continues to turn, sticking has occurred on the contacts of the control relay.

Having discovered that the regulator has failed, there is nothing left to do but change the radiator fan activation sensor.

Replacing the sensor

Changing the sensor is quite simple:

- Turn off the ignition;

- Drain the coolant from the expansion tank;

- Disconnect a pair of wires from the sensor terminal block;

- Using a 30 mm wrench, unscrew the regulator from its seat. You shouldn’t apply a lot of force; you risk breaking the seat;

- Following the reverse sequence, install the new sensor.

You can change the sensor without draining the coolant. To do this, you need to quickly unscrew the old regulator and screw in a new one in its place. A small part of the coolant will spill out, but you won’t have to drain it for a long time and then pour it back in.

Possible malfunctions in the operation of the electric fan

When the coolant temperature is within critically high limits and the radiator cooling fan does not turn on, it means that there is a problem somewhere. The task before us is to identify it and correct it. Here are some common reasons for fan failure:

- Electric motor failure;

- Broken fan power supply or power sensor;

- The sensor or motor connection contacts have oxidized;

- The electric fan fuse has blown;

- The fan switch-off relay is broken;

- The power sensor has failed;

- The expansion tank valve is faulty.

What's the result?

Having examined the operating features of the radiator fan, it becomes obvious that the internal combustion engine cooling system as a whole and the engine cooling fan itself make it possible to maintain the required temperature regime of the internal combustion engine.

It is also important to understand that the uninterrupted operation of the cooling system depends on the coordinated operation of all components. For example, the fan normally turns on when the engine temperature rises above 90°C to cool the engine, and then should turn off.

However, in practice, you can often independently diagnose a problematic device, identify the cause of the breakdown and, if possible, fix the problem. Finally, we note that most problems associated with engine overheating can be avoided through preventative checks, as well as regular cleaning of the cooling fan terminals and contacts.

There is air in the engine cooling system: symptoms of airing, reasons for the formation of an air lock. How to bleed the engine cooling system.

The engine cooling fan turns on when the engine is cold or after the ignition is turned on: the main causes and solutions to the problem.

Design and principle of operation of a radiator cooling fan. Common faults, troubleshooting and repairs. Tips for use.

Common engine cooling system failures: water pump, thermostat, radiator, cooling fan and others. How to determine the reasons yourself.

Why does the engine overheat or boil while the cooling radiator is cold? Signs of engine overheating, how to prevent serious consequences.

Radiator in the cooling system, design and principle of operation, thermoregulation of the coolant. Troubleshooting and self-repair

Source

How to check a radiator fan

The very first thing to do if the cooling fan fails is to check the fan drive motor. To do this, you need to take two wires and connect them directly from the battery to the electric motor. If it works, then the problem should be looked for somewhere else. You can immediately check the quality of the contacts connecting the electric motor. Sometimes it happens that they oxidize or dirt and dust get into them. If the electric motor does not start after connecting it directly, most likely it has failed. The cause of the malfunction may be worn out motor brushes, replacing which will solve the problem. There are breakdowns, and more serious ones, for example, breakage of the winding, destruction of the commutator. In such a situation, repairing the radiator fan will not help; the radiator fan must be replaced.

Electrical circuit malfunctions

If everything is fine with the tank cap and there are no problems with pressure, then the causes of the radiator cooling malfunction should be sought in its electrical circuit.

- The search begins with checking the functionality of the fuse marked F7. To do this, you have to get to the mounting block. Check the quality of the contacts and the presence of traces of oxidation. If everything is good here, we move on. If the contacts are broken, simply clean them, or simply change the fuse. This is a small financial cost.

- The next place to check will be the VAZ 2110 fan switch sensor. You do not have to go to a specialized service station to check the efficiency of the sensor. This is done in a garage:

- Warm up your car's engine to above 100 degrees Celsius;

- Turn off the engine, then start the engine again;

- Lift the hood and remove the terminal from the VAZ 2110 fan sensor;

- If after removing the element the fan begins to spin, then the unit is working properly, but there are problems with the sensor;

- When on a VAZ 2110 the cooling system fan does not turn on after disconnecting the terminal, the situation is the opposite - the fan does not work, but the sensor is in good condition.

- Electric motor. It is possible that the radiator fan stopped working precisely because of a faulty electric motor. If all previous manipulations did not produce results, you will have to remove the electric motor. It may have several characteristic failures:

- The commutator brushes are worn out;

- The commutator brushes are stuck;

- A short circuit has occurred in the armature winding (this can be determined by the characteristic unpleasant odor).

- Relay. Maybe the button to turn on the cooling radiator fan on your VAZ 2110 has simply failed. In such a situation:

- The trim on the right side of the console inside the cabin is removed by unscrewing two screws;

- There are three relays under the panel;

- The relay we are looking for is usually located on the edge of the row in relation to the front of the car;

- To play it safe, arm yourself with the instruction manual and check the wiring that goes to our turn-on relay;

- To resolve the problem, install a new, functioning and good quality relay.

Checking the electrical wiring

Electrical wiring fault is another of the most common reasons why the engine cooling fan may not work. There can be either an open circuit or a short to ground in the wiring. The integrity of the wiring is checked using a tester, which is switched to detector mode. It is necessary to “ring” the entire circuit, from the engine to the relay, from the relay to the fuses, from the fuses to the controller, from the controller to the sensor. If everything is in order with the wiring, we move on to the next stage of testing.

Removing and replacing the fan resistor

To understand whether they work or not, you need to disconnect the connector from their motors, and connect a lamp to the wires through which voltage is supplied; we do the same with the sensor; if both lamps light up, then the problem is in the fans.

To remove them you need to do the following:

After removal, it is recommended to immediately replace both with new ones, since there is a possibility that a little time will pass and the second element will fail and all replacement work will need to be done again. You can do this procedure from below, but you will need special equipment, and you will need to move the engine ten centimeters back, which is very labor-intensive.

If the fan motors do not start when the wires from the battery are connected directly to the power terminals, the devices must be replaced.

Also interesting: Where is the Niva Chevrolet knock sensor located, its installation and malfunctions

To do this, you will need a set of wrenches ranging in size from 10 to 17 mm and a Phillips screwdriver.

Before starting work, you need to drive the car onto an inspection ditch or a lift and turn off the power to the on-board network by removing the negative terminal of the battery.

Fans are dismantled as follows:

This method is probably suitable for restyled Niva Chevrolet models. On older cars, you will have to remove the radiator grille and bumper, unscrew the fasteners and move the air conditioning and cooling radiators forward. After this, access to the electric fans will be open.

During dismantling, you should carefully remember the procedure. Assembly is carried out in reverse order.

Before starting work, you must go to the inspection hole and remove the terminal from the battery. For repairs you will need 10-13 wrenches, a screwdriver and a new resistor. The part is installed in the beam below the radiator. The removal procedure is as follows:

Assembly is performed in reverse order.

Checking the serviceability of the electric fan start relay and fuses

First, check the electric fan fuse. It is usually located in a block under the hood of the car. You can find the right fuse using the car's owner's manual, although there are often markings on the cover of the mounting block with the location of the fuses. We check using a tester. If no problem is identified, move on. We find the electric fan switch relay. It will not be possible to check it with a tester; to check it, you will need to replace this relay with a working one.

Fan relay

Tell me how to check the functionality of the cooling fan relay. Yesterday it suddenly got warmer, but I forgot to remove the blanket from the engine on the highway, and for some reason it ended up boiling, and the fans didn’t turn on. The fuse appears to be intact.

Does the air conditioner not work when you turn it on? Why are you sinning on the relay, the sensor (next to the thermostat) may also die, this can be checked by simply closing the contacts.

Yes, according to the diagram there are three fuses: one common for both fans No. 17 (7.5a), No. 57 (20a) for the radiator fan, No. 56 (20a) for the condenser fan, as well as one relay for each motor.

I forgot to say RD-1 1996. According to the manual, the fuse is in the main fuse block (No. 15 is labeled as an engine cooling fan), the relay is also nearby - second from the right from the top. I didn’t find any others.

Under the hood in the relay block there are two fuses No. 11 and 12 of 20 A each for the radiator fans and one in the passenger compartment for 7.5 A under No. 17, although the information differs in different sources.

The relevant fuses under the hood are No. 41 (well, this is a common 100A), then No. 42 (40A, but this is also common for a bunch of everything), No. 57 (20A - this is the main one for the engine cooling fan), and fuse under the steering wheel No. 17 (7.5A on the fan relay). Actually, the relay itself is located in a block under the hood, called RADIATOR FAN RELAY. I would start the check something like this: if the car has air conditioning, then turn it on - both fans should spin. If there is no air conditioner, then we short-circuit the temperature sensor responsible for the fan to the housing (two similar ones, it seems to be located under the distributor and closer to the radiator, you need to find the one to which the green and black wires go, short the green one to the housing or just the wires to each other). If the propeller does not spin, listen to see if the relay clicks. If the relay clicks, but the propeller does not spin, then feel for fuse No. 57. If it is intact, the relay clicks but does not spin, then check the voltage at the fan terminals. If not, then the wiring and the relay itself (you can pull it out and check it with a jumper or install it temporarily from another socket). If voltage is supplied but does not spin, disassemble the fan and look at the brushes, etc.

Yes, by the way, the numbering of the fuses may differ - correctly noted. I take it from the service manual for the American one, but it matches my European one.

Last edited by Advik_78; 03/08/2011 at 10:34 am.

I checked. When you press the air conditioner button, there is no reaction (but it doesn’t seem like it should be at negative temperatures). There seems to be one wire coming to the temperature sensor, and not two (or am I thinking about the wrong sensor - it seems to be under the distributor, closest to the radiator, similar to the picture in the manual?). I didn’t shorten it because... The engine temperature on the panel shows correctly (or are there different sensors?). Both fuses in the cabin (F17) and under the hood are intact, I pulled out the relay, checked it - it works.

The sensor on the thermostat housing is 2-pin, look for it in the lower pipe from the radiator, where it connects to the engine and there is a thermostat with a sensor.

Checking the electric fan switch sensor

One of the reasons for the failure of the electric fan may be a breakdown of the sensor. It is possible to establish with certainty that it is the fan switching sensor that has failed only on an injection engine. When we disconnect the sensor from the power supply, the control unit starts the electric fan in emergency mode. To check, you should warm up the engine to a temperature of about 100۫С, then turn off the engine, lift the hood and disconnect the sensor from the network. Then we turn on the ignition and if the fan starts, it means there is a breakdown in the electric fan switch sensor. On a carburetor engine, you can check the serviceability of the sensor only by replacing it with a new one. After which, it is also necessary to warm up the engine until the radiator cooling electric motor starts.

Cooling fan VAZ 2107

In the power plants of the first "sevens" the radiator fan was installed directly on the water pump shaft. Like the pump, it was driven by a belt drive from the crankshaft pulley. This design was also used on other cars at that time. It almost never failed, and it was impossible to overheat the engine with it. However, she had one drawback. The constantly cooled power unit warmed up very slowly. That is why AvtoVAZ designers changed the principle of forced airflow, replacing the mechanical fan with an electric one, and with automatic activation.

Early modifications of the VAZ 2107 had a mechanically driven fan

Why do you need an electric fan?

The fan is designed for forced airflow of the cooling radiator. During operation of the power plant, liquid coolant enters the radiator through the opened thermostat. Passing through its tubes equipped with thin plates (lamellas), the refrigerant cools due to the heat exchange process.

Later modifications of the Sevens were equipped with electric cooling fans

When a car moves at speed, heat transfer is facilitated by the oncoming air flow, but if the car sits for a long time or drives slowly, the coolant does not have time to cool. At such moments, it is the electric fan that saves the engine from overheating.

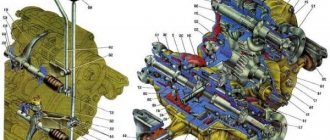

Device design

The radiator fan consists of three main elements:

- DC motor;

- impellers;

- framework.

The fan consists of an electric motor, impeller and frame

The electric motor rotor is equipped with a plastic impeller. It is she who, rotating, creates a directed air flow. The engine of the device is installed in a metal frame, with which it is attached to the radiator housing.

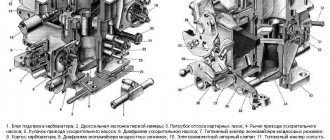

How does an electric fan turn on and work?

The process of turning on the fan for carburetor and injection “sevens” is different. For the former, its activation is controlled by a mechanical temperature sensor mounted in the lower part of the right cooling radiator tank. When the engine is cold, the sensor contacts are open. When the temperature of the refrigerant rises to a certain level, its contacts close and voltage begins to be supplied to the brushes of the electric motor. The fan will continue to operate until the coolant cools down and the sensor contacts open.

The device circuit is closed via a sensor that responds to changes in refrigerant temperature

In injection “sevens” the electric fan switching circuit is different. Everything here is controlled by an electronic control unit. The initial signal for the ECU is information coming from a sensor installed in the pipe leaving the engine (near the thermostat). Having received such a signal, the electronic unit processes it and sends a command to the relay responsible for turning on the fan motor. It completes the circuit and supplies electricity to the electric motor. The device will continue to operate until the refrigerant temperature drops.

In injection "sevens" the fan is turned on by command from the ECU

In both carburetor and injection "sevens", the electric fan circuit is protected using a separate fuse.

Continuous operation of electric cooling fan

One of the problems that a car enthusiast may encounter is the continuous operation of the cooling fan. If the fan starts very early, when the liquid temperature has not reached the operating temperature, or does not turn off at all, you should find the cause of the breakdown and remove it. Here are some reasons why the fan is constantly running:

- Relay contacts sticking. In this case, the fan electric motor will start as soon as the ignition is turned on;

- Sensor problems. If the fan begins to start earlier than expected, the fan switch sensor is often faulty. It needs to be changed;

- The thermostat does not open. In this situation, the coolant does not enter the radiator and quickly overheats, which causes the electric fan to turn on. And since the liquid does not reach the radiator, its temperature will not drop and the fan will operate in constant mode.

However, continuous operation of the electric fan is not as dangerous as its failure completely, but not in the third case, when the thermostat is jammed.

Regularly check the proper operation of all components of the engine cooling system. Monitor the coolant temperature readings on the dashboard and listen to see if the electric fan starts. Check that the coolant level is correct. Replace the coolant as scheduled. Keep the expansion tank cap clean and rinse it under running water at least once every six months. This will help extend the life of the safety valve.

If there is any malfunction in the engine cooling system, it is necessary to stop and take measures to eliminate it. If the radiator fan thermal switch, electric fan relay or fuses fail, to continue driving, you can connect the radiator cooling electric motor directly to the battery, in the case of a carburetor engine, and on an injection engine, you must disconnect the power supply to the electric fan sensor from the on-board network. This way, you can get to the service station without overheating the engine.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

Useful tips

Finally, check out these useful tips that will allow you, if not to avoid problems with turning on the cooling fan in a timely manner, then at least to correct the situation a little.

- Systematically check the operation of all elements of the cooling system. Pay attention to the coolant temperature indicators on the instrument panel, and also listen to whether the fan turns on.

- Monitor the coolant level in the system. Replace it in a timely manner.

- At least once a year, wash the expansion tank cap under running water. This solution will extend the life of the safety valve.

- If there is the slightest malfunction in the cooling system, stop driving and take corrective action.

- If the cooling fan does not work due to a sensor, fuse or relay failure, and this malfunction caught you on the road, disconnect the sensor (for an injector) or connect the electric drive directly to the on-board network (for a carburetor). This way you can drive to the nearest service station without the risk of engine overheating.

Cooling fan diagnostics - trying to find the problem

There will be two temperature sensors: one, which is on the thermostat, is connected to the ECU. It is necessary to turn it off - leave the second one as it is.

DTOZH on engine 11183

We disconnect the connector, but do not remove the sensor itself. Then we turn the key to position 1, and so on.

Electrically, things look complicated: the fan relay is in one box, and the fuse is in another. We need fuse F5 (20A). By the way, both a fan and a horn are connected to it.

Mounting block 2114-3722010-60 and 2114-3722010-10

The main mounting block is installed under the hood, and the additional one is located at the left foot of the front passenger.

Additional mounting block (option 1)

In the additional block we see three relays. The "main relay" is located at the bottom. And then there are possible options:

- The fan relay is mounted in the middle;

- This relay can also be installed at the top.

We recommend: Checking and repairing the xenon ignition unit: 4 signs of a device malfunction

The second option is shown below.

Additional mounting block (option 2)

By the way, there is always a fuse located near the relay we need. It is part of the fan circuit.