Brake system VAZ 2101

Any car is equipped with a braking system, and the VAZ “kopek” is no exception. Its main purpose is to slow down or completely stop the vehicle at the right time. Since brakes can fail for various reasons, their performance and the condition of their components must be periodically monitored. Therefore, it is worth dwelling in more detail on the design of the braking system, problems and their elimination.

Brake system design

The Zhiguli brakes of the first model are made of working and parking systems. The first of them consists of the following elements:

- master brake cylinder (GTC);

- brake wheel cylinders (RTC);

- hydraulic drive reservoir;

- hoses and tubes;

- pressure regulator;

- brake pedal;

- brake mechanisms (pads, drums, brake disc).

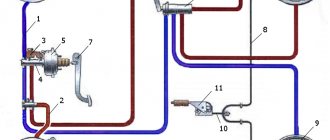

Diagram of the VAZ 2101 brake system: 1 - front brake protective casing; 2, 18 — pipelines connecting two cylinders of the front brake caliper; 3 - caliper; 4 — hydraulic drive reservoir; 5 — brake light switch; 6 — parking brake lever; 7 — adjusting eccentrics of the right rear brake; 8 — fitting for bleeding the hydraulic drive of the rear brakes; 9 — pressure regulator; 10 - brake light; 11 — rear brake wheel cylinder; 12 — lever for manual drive of the pads and expansion bar; 13 — adjusting eccentric of the left rear brake; 14 — brake pad; 15 — rear cable guide; 16 — guide roller; 17 — brake pedal; 19 — fitting for bleeding the hydraulic drive of the front brakes; 20 — brake disc; 21 - main cylinder

The parking brake (handbrake) is a mechanical system that acts on the rear pads. The handbrake is used when parking a car on a slope or on a descent, and also sometimes when starting off on a hill. In extreme situations, when the main braking system has stopped functioning, the handbrake will help stop the car.

Operating principle

The principle of operation of the VAZ 2101 brake system comes down to the following actions:

- When the brake pedal is applied, the pistons in the turbocharger move, which creates fluid pressure.

- The fluid rushes to the RTC located near the wheels.

- Under the influence of liquid pressure, the RTC pistons are set in motion, the pads of the front and rear mechanisms begin to move, as a result of which the discs and drums slow down.

- Slowing down the wheels leads to overall braking of the car.

- Braking stops after the pedal is released and the working fluid returns to the GTZ. This leads to a decrease in system pressure and loss of contact between the brake mechanisms.

The principle of operation of hydraulic brakes on the VAZ 2101

Brake system malfunctions

The VAZ 2101 is far from a new car and owners have to deal with malfunctions of certain systems and troubleshoot problems. The braking system is no exception.

Low brake efficiency

A decrease in the effectiveness of the braking system can be caused by the following reasons:

- violation of the tightness of the front or rear RTCs. In this case, it is necessary to inspect the hydraulic cylinders and replace worn-out parts, clean the brake elements from dirt, and bleed the brakes;

- presence of air in the system. The problem is solved by bleeding the hydraulic drive system;

- The lip seals in the GTZ have become unusable. Requires disassembly of the master cylinder and replacement of rubber rings with subsequent bleeding of the system;

If the sealing elements of the GTZ have become unusable, the cylinder will have to be completely disassembled for repair. - damage to flexible pipes. It is necessary to find the damaged element and replace it.

The wheels do not release the brakes completely

Brake pads may not fully release from the drums or rotors for a number of reasons:

- The compensation hole in the gas turbine engine is clogged. To eliminate the malfunction, it is necessary to clean the hole and bleed the system;

- The lip seals in the GTZ are swollen due to oil or fuel getting into the liquid. In this case, it will be necessary to flush the brake system with brake fluid and replace damaged elements, followed by bleeding the brakes;

- the piston element jams in the GTZ. You should check the functionality of the cylinder and, if necessary, replace it, and then bleed the brakes.

Braking of one of the wheel mechanisms when the brake pedal is depressed

Sometimes a malfunction occurs when one of the car’s wheels spontaneously brakes. The reasons for this phenomenon may be the following:

- The tension spring of the rear brake pads has failed. Inspection of the mechanism and elastic element is necessary;

- RTC malfunction due to piston sticking. This is possible when corrosion forms inside the cylinder, which requires disassembling the mechanism, cleaning and replacing worn-out parts. In case of significant damage, it is better to replace the cylinder completely;

- an increase in the size of lip seals due to fuel or lubricant entering the working environment. It is necessary to replace the cuffs and flush the system;

- There is no gap between the brake pads and the drum. The handbrake needs adjustment.

The car skidding or pulling to the side while pressing the brake pedal

If the car skids when you press the brake pedal, this indicates the following malfunctions:

- leakage of one of the RTCs. Replacement of cuffs and bleeding of the system is required;

Fluid leaks on the inside of the wheel indicate a leak in the brake system. - jamming of the piston element in the working cylinder. It is necessary to check the performance of the cylinder, eliminate malfunctions or replace the assembly part;

- a dent in the brake pipe, which led to blockage of the incoming fluid. The tube needs inspection and subsequent repair or replacement;

- The front wheel angles are not set correctly. Angle adjustment required.

Brakes squeal

There are times when the brakes squeak or make a squealing sound when you press the brake pedal. This may occur for the following reasons:

- The brake disc has uneven wear or excessive runout. The disc needs to be sanded, and if the thickness is less than 9 mm, it needs to be replaced;

- oil or liquid getting on the friction elements of the brake pads. It is necessary to clean the pads from dirt and eliminate the cause of leakage of lubricant or liquid;

- Excessive wear of brake pads. Elements that have become unusable need to be replaced.

Front brake repair

Repair of the front brakes should begin with an inspection; first of all, we try to turn the hub by hand; if the cylinders are not jammed, then you will succeed. Next, you can remove the brake pads; to do this, remove the corkscrews and take out the guide pins.

Removing the brake pads

After pulling out the fingers, we try to push the brake cylinder inside using a screwdriver; if you succeed, then the cylinder is in normal working condition and if there are no leaks and the boot is intact, there is no need to go in there. If the cylinders do not yield under the force of a screwdriver, then they need to be repaired or replaced, and I had such a situation.

The boot is torn, the cylinder is jammed

We see how the pads are worn unevenly:

Unevenly worn brake pads

If it is necessary to repair the brake cylinder, then you need to unscrew the hose and remove the caliper by unscrewing the two bolts with a “17” key. Once removed, you must carefully knock the brake cylinder out of the caliper. This must be done carefully, since duralumin cylinder bodies are prone to cracks. I knock the cylinders out of the caliper through a piece of wood.

After the cylinder is removed, it must be cleaned of dirt. Next, you need to remove the piston from the brake cylinder, this can be done using a compressor, pumping pressure into the cylinder (do this very carefully!), I used a wheel wrench.

The cylinder is knocked out of the caliper

Cylinder without boot

We remove the piston from the brake cylinder of the VAZ 2101

Thanks for subscribing!

Piston removed, sea of dirt inside

The pistons were removed, but despite all efforts one cylinder had to be replaced with a new one

After removing the pistons from the cylinders, we wash and clean the brake cylinders from dirt, especially paying attention to the cleanliness of the groove under the sealing ring inside the cylinder; it is often forgotten by oxide from the duralumin cylinder and the piston jams. After everything is cleaned, insert a new o-ring, be sure to lubricate it with clean brake fluid and insert the piston into place. Next, put on a new boot and insert the cylinder into the caliper.

Next, you can put the caliper on the car and secure it by tightening the fasteners well; in the factory version of the caliper mounting, there are locking washers under the mounting screws, which will also not be superfluous. Next, you can install the new pads in place and screw on the brake hose. It is very important that when installing new brake hoses, install new brass O-rings under the hose. If these are included with the hoses, this is very good; if they are not, then be sure to purchase them, since they are practically disposable and new rings contribute to a reliable seal. At this point, the repair of the front brakes of the VAZ 2101 can be considered complete.

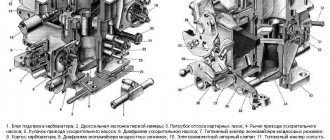

Master brake cylinder

The GTZ of the VAZ “kopek” is a hydraulic type mechanism, consisting of two sections and designed to operate a system with two circuits.

The master cylinder creates fluid pressure throughout the entire brake system.

If problems arise with one of the circuits, the second, although not as effective, will ensure that the car stops. The GTZ is mounted to the pedal assembly bracket.

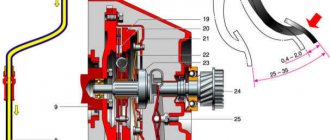

Design of the GTZ VAZ 2101: 1 - plug; 2 — cylinder body; 3 — rear brake drive piston; 4 — washer; 5 — front brake drive piston; 6 - sealing ring; 7 — locking screws; 8 — piston return springs; 9 — spring plate; 10 — pressure spring of the sealing ring; 11 — spacer ring; 12 — inlet; A - compensation hole (gaps between sealing ring 6, spacer ring 11 and piston 5)

Pistons 3 and 5 are responsible for the performance of different circuits. The initial position of the piston elements is ensured by springs 8, by means of which the pistons are pressed into screws 7. The hydraulic cylinder is sealed with the corresponding cuffs 6. In the front part of the housing is plugged with a plug 1.

The main problems with the GTZ are wear of the lip seals, the piston or the cylinder itself. If rubber products can be replaced with new ones from the repair kit, then if the cylinder or piston is damaged, the device will have to be completely replaced. Since the product is located under the hood near the clutch master cylinder, replacing it does not cause any difficulties.

Video: replacing the GTZ with a “classic”

Rear brake repair

With rear brakes on a penny, everything is not so simple, and the reason for this is the wear of the brake drum. This defect occurs often and it may happen that you install new pads and there are no brakes anyway, because even despite the new pads their thickness is not enough for braking. Accordingly, the handbrake does not hold either.

But the reason for the rear wheels not braking can also be the “sorcerer”, so you need to make sure that it is working.

If the brake cylinder is leaking, then it is necessary to replace the rubber seals; this is not difficult to do; it is not even necessary to remove the cylinder from the car.

Rear brake cylinder

So what should you do with worn brake drums? Another option, and I use it quite often, is to make brake pads with my own hands, namely, rivet pads from a UAZ car onto the VAZ 2101 pads; they are somewhat longer, but the bending fits, and most importantly, they are somewhat thicker than the standard Zhiguli ones.

Tubes and hoses

Brake pipes and hoses of the braking system of the VAZ “kopek” are used both front and rear. Their purpose is to connect the GTZ and RTC to each other and supply brake fluid to them. Sometimes connecting elements become unusable, especially hoses, due to aging rubber.

Damage to the hose leads to fluid leakage and depressurization of the brake system.

The parts in question are attached using a threaded connection. There are no difficulties in replacing them. You just need to unscrew the fasteners on both sides, remove the worn element and install a new one in its place.

Video: replacing brake pipes and hoses on a “classic”

How to properly bleed the brakes on a VAZ 2101-VAZ 2107?

Note! Before we begin, let’s say a few words, namely, in classic cars, the braking system is divided into two circuits, in which both front wheels are the first circuit, and both rear wheels are the second circuit, so if you have air in any of the circuits, then you need will bleed this particular circuit and it is not necessary to bleed the second one, it will simply be pointless, let's give an example, let's say you replaced the brake caliper on the right front wheel, when replacing you had to disconnect the brake hose from it (the hose must be disconnected, without disconnecting it you have nothing won’t work), so when you installed a new caliper in place of the old one, you first need to bleed the brakes, and why bother with the rear circuit if you only had the front one depressurized, then you will need to bleed exactly the two front wheels and this will get rid of from air in the system!

Brake pedal

The main control element of the VAZ 2101 braking system is the brake pedal, located in the cabin under the steering column between the clutch and accelerator pedals. The pedal transmits the muscular force from the driver's legs to the GTZ. If the brake pedal is adjusted correctly, the free play will be 4–6 cm. When you press it and travel the specified distance, the vehicle begins to smoothly slow down.

Free play of the brake pedal: 1 — master cylinder; 2 - pusher; 3 — brake pedal; 4 — brake light switch buffer; 5 — switch nut; 6 — brake light switch; 7 — pedal release spring