Signs that your carburetor needs adjustment

The carburetor design on the VAZ-2101 is quite simple. It may vary slightly depending on the car model. It’s easy to understand that it’s time to configure this node. The main features are the following facts:

- The engine stalls at idle speed.

- The spark plugs are flooded or carbon deposits have formed, which prevents the engine from starting easily.

- Increased fuel consumption or fuel leakage (see fuel consumption table for carbureted vehicles).

In this case, a thorough check of the entire system will be required. In some cases, the malfunctions listed above are associated with other failures in components and mechanisms.

It is recommended to adjust the carburetor before the first signs of malfunction appear. The design of this unit requires adjustment every 8 thousand kilometers. This procedure must be carried out at least once a year, even if the car is rarely used.

Before starting work, if necessary, you need to repair the wiring, distributor and clean the spark plugs. There is a simple technology on how to properly adjust the carburetor on a VAZ 2101.

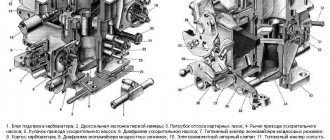

Types of Kopeyka carburetors

Jets for carburetors of VAZ 2101, VAZ 2103, VAZ 2106, VAZ 2107 cars

During the production of the VAZ 2101, several modifications of carburetors were installed in its system. They differ in the size of the jets, as well as the presence or absence of a vacuum corrector. In early Zhiguli models, a carburetor was installed with an ignition system without a vacuum corrector.

The most common carburetor on the VAZ 2101 car is the DAAZ carburetor model 2101-1107010. A vacuum corrector system is already used here. All modifications of carburetors can be adjusted using a similar scheme. But it is impossible to install a model with a vacuum corrector instead of a design without it, or vice versa. Carburetors of well-known brands DAAZ/Weber, Ozone, Solex are also often used; among non-standard carburetors, I would like to highlight Solex 21073 and Solex 21083.

Calibration data for DAAZ carburetors 2101-1107010-01, 2101-1107010-03, 2105-1107010-20, 2105-1107010 10:

| Parameter | Carburetor model and chamber number | |||||

| 2101-1107010-01 | 2101-1107010-03 | 2105-1107010-20, 2105-1107010 10 | ||||

| 1st | 2nd | 1st | 2nd | 1st | 2nd | |

| Diameter, mm: | ||||||

| diffuser | 23 | 23 | 23 | 23 | 21 | 25 |

| main fuel jet | 1.30 | 1.25 | 1.30 | 1,30 | 1.07′ | 1.62 |

| main air jet | 1.50 | 1,90 | 1.50 | 2,00 | 1.70 | 1.70 |

| idle fuel jet and transition system | 0.50 | 0.45 | 0.45 | 0.60 | 0.50 | 0.60 |

| idle air jet and transition system | 1.70 | 0.70 | 1,70 | 0.70 | 1.70 | 0.70 |

| accelerator pump nozzle hole | 0.40 | 0,40 | 0.40 | |||

| accelerator pump bypass jet | 0,40 | — | 0.40 | — | 0.40 | |

| ecomostat fuel jet | — | 1.50 | — | 1.50 | — | 1.50 |

| air jet econoepta | 0.90 | — | 0.90 | 1.20 | ||

| econostat emulsion jet | 1.70 | — | 1.70 | — | 1.50 | |

| starter air jet | 0.70 | — | 0.70 | 0.70 | — | |

| jet of the pneumatic drive of the throttle valve of the second chamber | — | — | — | 1.20 | 1.00 | |

| Spray calibration number | 4 | 4.5 | 4 | 4 | 3.5 | 4.5 |

| Emulsion tube calibration number | FI5 | FI5 | F15 | FI5 | F15 | F15 |

| Accelerator pump flow for 10 full strokes, cm3 | 7±0.25% | 7±0.25% | 7±0.25% | |||

| Distance of the float from the carburetor cover with gasket, mm | 7.5±0.25 | 6.5±0.25 | 6.5±0.25 | |||

| Clearance at the dampers for regulating the starting device, mm: | ||||||

| air damper | 8±0.5 | 7±0.25 | 5 | |||

| throttle valve | 0.75 | 0.85 | 0.75 | 0.85 | 0.7 | 0.8 |

Choosing a carburetor for the “classic”

If you are a fan of drive and want more than what the standard system gives you, then the DAAZ 21053 , manufactured under license from the French company Solex, may be suitable for you. This carburetor is the most economical and provides the best dynamics for classic engines, but it is quite difficult to find it on sale; not all sellers know about its existence. It uses a design that is fundamentally different from the designs of previous DAAZ models. A fuel reverse supply system is used here; there is an outlet through which excess gasoline is returned to the tank, this allows you to save about 500-700 grams of fuel per 100 kilometers.

Depending on the model, there may be many auxiliary electronic systems, such as: an idle system controlled by an electro-valve, an automatic choke system and others. But most of them are installed on export models; we mainly have only an idle system with an electric valve. By the way, it can give you a lot of problems, in this carburetor there are very small channels for fuel and air, and they very often become clogged, if they are not cleaned in time, then the first thing that starts to work poorly is the idle system. This carburetor uses about 6-9 liters of fuel during normal driving, while providing the best dynamics of all the units presented above, except for Webers. If you want to get the most out of the engine, but at the same time not bore yourself with unnecessary details of carburetor settings, then feel free to choose it.

Well, I have listed for you all the standard carburetors that are installed on classics without modifications, you just need to remember that if you buy a carburetor, then you need to select it according to the engine size of your car. Even if you get a good carburetor, but it is designed for a different cubic capacity, then with the help of a specialist you can change the jets in it and adjust it to your needs.

But don't think that choosing to install a carburetor ends with this list. If you want to get even more from your car and have a good carburetor technician or can customize them yourself, then you can turn your attention to two more types of carburetors, Solex 21073 and Solex 21083 :

- the first is designed for a volume of 1.7 cubic centimeters (for the Niva engine), it differs from 21053 in that it has larger channels and larger jets. After installing it, you will get even more dynamics, but fuel consumption will be 9-12 liters per 100 km. So if you want a lot of dynamics and at the same time have the money to pay for the extra expense, you can choose it.

- the second (21083) is intended for VAZ 2108-09 cars, and is installed on classic engines only with modifications, because the gas distribution systems of engines 01-07 and 08-09 are different. And if you install the carburetor as is, then at a speed of about 4000 thousand, the speed of the intake air can approach above the sound speed, which is unacceptable, the engine simply will not accelerate any further. If you want to install it, you will have to drill out the diffusers of chambers 1 and 2 to a larger size, and install slightly larger jets. All these alterations are worth doing only if you are a sincere connoisseur of the classics, as they are quite labor-intensive. The price of the alterations is consumption of less than 21,053, increase in dynamics by even more than 21,073.

We can say even more, there are single-chamber and double-chamber carburetors from imported companies, but they are, firstly, expensive, and secondly, they do not always provide better dynamics and economy than those listed above. So it’s up to you to decide what to choose and how to drive.

Common causes of carburetor failure and their solutions

If one of the system elements in the carburetor fails, you may not notice it immediately. Failures appear gradually. Often, unstable idle speed is explained by a failed solenoid valve. Not all carburetors have such a device.

To test the solenoid valve, you will need to disconnect the wire connected to it. A positive contact is supplied to it from the battery. Correct wiring is indicated by a slight click.

You need to check the voltage on the wire that connects to the solenoid valve. If there is no voltage in the line, the wiring has failed. It will be necessary to completely replace the network from the ignition switch to the solenoid valve.

Unstable speed can also be observed when the spark plug electrodes are covered with a large layer of soot. The spark power is insufficient. It cannot ignite the fuel mixture. The poor condition of the spark plugs is due to incorrect carburetor settings. In this case, it supplies too much fuel to the combustion chamber.

The cause of this malfunction may be a burnt-out intake valve. It is responsible for the amount of fuel that is supplied to the combustion chamber of the engine. To ensure this, you need to adjust the carburetor. If this does not help, the inlet valve will need to be replaced.

How to adjust the carburetor on a VAZ 2101

What is needed for adjustment

First you need to prepare the appropriate repair kit for the VAZ 2101 carburetor. You will also need new cuffs, carburetor jets and other spare parts. To adjust the carburetor, you will need a repair kit, which includes the following tools:

- Spanners.

- Rags.

- Screwdrivers (phillips, flat).

- Protective gloves.

- Solvent.

- Toothpicks.

- Compressed air can or pump.

After appropriate preparation of the repair kit, you can begin adjusting the VAZ-2101 carburetor. This does not require much effort. All actions must be careful and precise.

You also need to inspect the components on which the operation of the motor may depend. You need to inspect the spark plugs. By their appearance you can tell in what proportions the fuel is mixed with air.

The carburetor needs to be cleaned. To do this, dismantle its top cover. The float and vacuum valve are removed. The interior of the chambers needs to be cleaned. Soot and dirt accumulate here. Cleaning is carried out using an air can or a pump.

Another mandatory action is to check the gap between the distributor electrodes, as well as the high-voltage coil and wires. The adjustment is carried out only after the engine has warmed up to 90ºС. Cars are put on handbrake.

Throttle valve adjustment

Adjusting the VAZ-2101 carburetor begins with adjusting the throttle valve. This is a simple procedure. It can be done in three stages. Manually turn the damper control lever counterclockwise. It opens completely.

The distance to the primary chamber is measured. The carburetor design suggests that this figure is 12.5-13.5 mm. If the result is different, you need to bend the rod antennae. Throttle adjustment involves determining the opening value of the throttle valve. It should be 14.5-15.5 mm. Otherwise, you will need to tighten the pneumatic drive rod.

Starter battery correction

At the second stage, you will need to adjust the operation of the starting device. The throttle lever on the secondary chamber is manually turned counterclockwise. It will close. The tip of the thrust lever should fit snugly against the axis of the primary chamber throttle valve.

At the very end there should be a starter rod. Otherwise, you will need to adjust its position. To do this, the rod is bent. This device in carburetor engines is fragile. If you apply too much force to it, the rod will break off.

Checking the pump accelerator and repairing it

You need to start checking by testing the functionality of the system. You need to collect in a beaker the fuel that will be generated during 10 cycles of operation of the throttle lever. From 5.2 to 8.7 cm³ of fuel should accumulate. If this is not the case, you need to clean the VAZ 2101 carburetor jets. To do this, bleed the pump. This will help clear clogged injectors. This procedure is performed about 10 times. Then the fuel is measured again.

If the purging procedure does not give the desired result, the accelerator will need to be completely replaced.

If the engine malfunctions at high speeds, you need to check the pump diaphragm. It could wear out. The fuel pump rod often wears out.

Idle speed adjustment

Adjusting the fuel system involves adjusting the idle speed at the final stage. You will need to warm up the engine for 15 minutes. Then the engine must be turned off. The quantity and quality screws are tightened until they stop. The first of them needs to be released 3 turns. The quality screw is unscrewed 5 turns.

The motor starts. The quantity screw sets the speed, which is about 800 per minute. Then the quality screw is slowly tightened. This way you can reduce the enrichment of the fuel mixture. This procedure is carried out until the speed begins to drop. After this, the quality screw must be unscrewed another half turn and fixed in this position.

Knowing how the carburetor adjustment procedure is carried out, you can do the job well yourself. The engine will operate stably, and the VAZ 2101 will operate in normal mode.

Carburetor VAZ 2102 adjustment

To ensure that your VAZ 2102 does not experience problems with the engine, you need to correctly adjust the carburetor. Today we will talk about adjusting the VAZ 2102 carburetor with our own hands.

Before you begin adjusting the carburetor, you must first adjust the position of the carburetor throttle flaps.

1. In order to adjust the carburetor, the throttle valves must be fully open; the position of the valves can be checked by turning the lever and the drive all the way.

2. The maximum opening value of the throttle valve of the primary chamber (13±0.5 mm); the opening is regulated by bending the lower tendril.

3. The maximum opening value of the secondary chamber damper is (15±0.5 mm), it is adjusted by tightening or unscrewing the pneumatic drive rod.

4. When the primary chamber damper is not fully opened, the upper tendril of the third lever should come into contact with lever 2, distance 6±0.1 mm. This size should be adjusted when bending the upper antenna of the third lever.

Starting device:

5. If you turn lever 1 all the way counterclockwise, the air damper will be completely closed. You need to know that in this position of the lever, the end of the rod 3 will have to be at the end of the rod 4 of the starting device, and the rod should not be moved. This is done by bending rod 3.

6. If the air damper is closed, then the primary chamber damper will be open by 0.70–0.80 mm.

7. If the air damper is completely closed, it will be opened by the trigger rod 4 by 5 0.5 mm, if you move it manually all the way to the right. This value should be adjusted with screw 5.

Adjusting the accelerator pump performance

8. Pump performance is always checked over ten full strokes of throttle valve control lever 4. The fuel coming out of the atomizer in ten strokes must be collected in a beaker. Its volume should be 5.25–8.75 cm3.

9. Before starting the test, it is advisable to make ten test moves with lever 4, this is done in order to fill the channels of the accelerator pump.

Checking the tightness of the needle valve

10. The tightness of the needle valve can be checked on a stand, the task of which is to ensure the supply of fuel to the carburetor under pressure. After the level in the test tube of the stand is established, it should not drop; in the next 10–15 s, if the level drops, then there is a leak through the needle valve.

Video. How to clean and adjust a carburetor with your own hands

All is ready! Now you can enjoy the trip. If your friend has a Lada Kalina and his window regulator does not work, we will tell you how you can repair it yourself.