setting the ignition timing on a VAZ 2108, VAZ 2109, VAZ 21099

The ignition timing (aka ignition timing) is checked and set at engine idle (at a crankshaft speed of 820-900 min).

The ignition timing should be within 0±1° before TDC (top dead center). If the ignition timing on a VAZ 2108, VAZ 2109, VAZ 21099 is incorrectly set, the engine overheats, the engine does not develop full power, the car consumes excess fuel, and detonation occurs. The ignition timing is checked by the mark on the flywheel and the scale in the clutch housing hatch (the rubber plug is removed). When combining the marks on the flywheel with the middle division (notch) on the scale, the pistons of the 1st and 4th cylinders are installed at TDC. One division on the scale corresponds to 1° of crankshaft rotation.

To adjust and set the ignition timing on a VAZ 2108, VAZ 2109, VAZ 21099 car, do the following:

1. Disconnect the vacuum hose from the vacuum corrector.

2. To check the ignition timing, connect the “+” terminal of the strobe to the “+” terminal of the battery.

3. Connect the ground clamp of the strobe to the “-” terminal of the battery.

4. Remove the tip of the high-voltage wire from the socket of the 1st cylinder of the distributor cap, insert the strobe sensor into the vacated socket and connect the high-voltage wire from the 1st cylinder to the sensor.

5. Remove the rubber plug from the clutch housing hatch.

6. Start the engine of a VAZ 2108, VAZ 2109, VAZ 21099 car and direct the flashing stream of strobe light into the clutch housing hatch.

7. In the flashing light of a strobe light, the mark on the flywheel visually appears motionless. https://avtotel.com/acura-mdx-2010-2013/ When the ignition timing is correctly set, mark 1 on the flywheel should be between the middle division (notch) 2 and the previous division 3 of the scale. Otherwise, adjust the ignition timing.

8. To set the ignition timing, loosen the three nuts securing the ignition distributor.

9. To increase the ignition timing angle, turn the distributor housing clockwise (the “+” mark on the flange of the distributor housing to the protrusion on the auxiliary drive housing). In this case, one division on the flange corresponds to 8° of rotation of the crankshaft. To reduce the ignition timing angle, turn the distributor housing counterclockwise (the “-” mark to the protrusion on the auxiliary drive housing).

Setting the ignition timing (ignition timing) on VAZ-2108, 2109, 21099 cars

Setting the ignition timing

(ignition timing)

on VAZ-2108, 2109, 21099 cars

(second slide)

Setting the ignition timing is one of the main settings of a car engine. Incorrectly set ignition (both in the direction of increasing the advance angle and in the direction of decreasing) immediately affects its operation for the worse.

Signs of incorrectly set ignition timing

overheating, detonation, shots into the muffler or carburetor, this is not a complete list of such malfunctions.

It should be borne in mind that similar symptoms occur with an incorrectly adjusted or faulty carburetor, faulty valve mechanism, etc.

Purpose of setting ignition timing

Set the optimal ignition timing at which the main characteristics of the car engine - power, throttle response, idle speed, fuel consumption - will be normal.

Tools for work

— Tachometer

(you can use the built-in one in the instrument panel, you can connect an external one (for example, an auto tester, a multimeter in tachometer mode), you can use your ear, if you have experience).

strobe and autotester

- Socket or open-end wrench.

Either a matching ratchet socket or an L-shaped wrench. Size 10.

— We warm up the car engine to operating temperature (85-90

)

.

— Set the minimum idle speed (750-800 rpm)

. To do this, turn the “amount” screw of the fuel mixture on the carburetor. You can set the minimum speed using the tachometer or by ear. If they correspond to the norm, then we skip this point.

location of the adjusting screw for the “amount” of the fuel mixture on the carburetor 2108, 21081, 21083 Solex

- Remove from the fitting on the housing of the vacuum ignition timing regulator

,

on the distributor-distributor, a silicone vacuum supply tube coming from the carburetor.

— We check by placing a finger on its hole to see if there is a vacuum in it.

It shouldn’t be there, since in theory it should start working at speeds above 800. If it is, slightly reduce the idle speed (by rotating the “amount” screw of the fuel mixture on the carburetor) until it disappears.

— We plug the hole in the silicone tube with a small bolt or simply bend it in half (tie it in a knot).

— Using a 10mm wrench, loosen the three nuts securing the breaker-distributor housing.

— We are looking for a hatch on the gearbox housing with a scale and a visible part of the flywheel. It is usually closed with a rubber stopper.

We remove the plug.

location of the inspection hatch in the clutch housing on VAZ 2108, 2109, 21099 cars

- Wipe the scale in the hatch with a rag so that the installation marks are clearly visible on it.

— Using a screwdriver, turn the flywheel by the teeth of its crown and find a long transverse alignment mark on it.

When it stands opposite the triangular cutout on the scale in the hatch, it means that the ignition timing is 0 0, and the pistons of the first and fourth cylinders have risen to top dead center. If it is poorly visible due to oiling or contamination, we wipe the edge of the flywheel through the hatch until we find it. You can highlight the mark with chalk.

mark for setting the ignition timing on the flywheel and a scale with degrees

— We check whether this is a risk (what if your flywheel is installed incorrectly).

We check using the following marks - the long mark on the flywheel should be opposite the triangular cutout on the scale, the mark on the camshaft pulley should be opposite the protrusion on the rear timing belt cover (to see them, remove the plastic timing belt cover).

Methods for adjusting the ignition

There are two ways to set the ignition correctly, both using special equipment and improvised means:

- using a strobe light;

- using a regular light bulb.

Of course, using a strobe, it will be much easier to adjust the ignition angle; the cost of this equipment is low.

In any case, regardless of the chosen adjustment method, it is necessary to carry out preparatory work, namely, warm up the car to operating temperature (80-90 degrees) and set the speed to 800 per minute using the fuel regulator on the carburetor body.

How to set the ignition on a VAZ 2109 with a strobe light

- The first thing to do is make sure the flywheel is visible. To do this, you will need to remove the protective rubber from the gearbox housing;

- Instead of the high-voltage wire of the first cylinder on the camshaft cover, we connect a strobe sensor;

- Connect the strobe to the battery;

- Start the engine.

Next, you need to unscrew the distributor mount.

The strobe light must be directed through the window at the flywheel; a mark on the flywheel should appear in time with the strobe light. We change its position by smoothly turning the distributor.

As soon as the mark is equal to the mark, this means that the ignition is set correctly.

How to set the ignition without a strobe with a light bulb

Without a strobe, you can set the ignition correctly using a light bulb; consider the algorithm of actions:

- We disconnect the wire going to the ignition coil from the distributor. You need to connect a wire from a light bulb (for example, a carrier) to it. The other wire from the lamp must be connected to the ground of the car (body);

- similar to the adjustment with a strobe light, unscrew the distributor mount;

- turn on the ignition - the light should light up. Next, you need to smoothly rotate the distributor until the lamp goes out. After the lamp has gone out, we also smoothly turn the distributor in the opposite direction and as soon as the lamp lights up again, you can tighten the distributor fastening.

Of course, this method will not allow you to adjust the ignition with great precision, as with a strobe, but you can still achieve good and correct engine operation.

Share the link with your friends on social networks:

We also have interesting e-mail newsletters, subscribe ! (once a week)

Incendiary physics - advance, distributor and UOZ

How to set the ignition? What is UOZ? Where did the runners rotate in domestic cars? What does the expression “set by spark” mean? - there are many interesting questions to which owners of modern cars may not give the correct answers.

What is ignition timing - also known as ignition timing? Is this some kind of attribute of ancient cars or something unshakable, akin to universal gravity? Most modern car owners are unaware of this. All car systems are controlled by numerous controllers, and therefore timely sparking in the engine cylinders is entirely their responsibility. Meanwhile, a huge number of ancient machines are running around the country, unfamiliar with processors and other chips. Therefore, questions like “How to regulate the SOP?” still sound today.

It's always a pleasure to answer technical questions. But first you have to remember some “incendiary” terms.

How to check the ignition module of an injector with 8 valves?

Before setting up the ignition of an injection engine, you will need to prepare:

- laptop with ID diagnostic program;

- tester;

- keys, screwdriver.

Before checking the VAZ 21099 ignition module, it is necessary to monitor the components of the control system. Everything must be connected and working properly; if necessary, the required parameters must be adjusted. Turn on the ground and ignition, while gasoline is pumped. When a red light appears, diagnose problems on the car’s on-board computer and the PC connected to it.

Check the throttle device: turn on the ignition, use a tester to check the voltage values for the on-board network and the sensor. Reference diagram of indications: BS voltage - more than 12 volts, sensor voltage - approximately 0.5 volts, opening degree - up to 1%.

Terminology

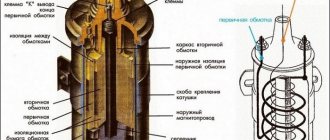

Ignition distributor

- an electromechanical device that ensures timely supply of high voltage pulses to the spark plugs.

It is often called a distributor

.

Ignition advance

- ignition of the working mixture in the cylinder before the compression stroke ends.

Ignition timing (IDA)

— the angle of rotation of the engine crankshaft from the position corresponding to the appearance of a spark on the spark plug until the piston reaches top dead center.

Contact ignition system

- a system in which switching of the ignition coil is provided by a mechanical interrupter.

Contactless ignition system

- a system in which switching of the ignition coil is provided by an electronic module controlled by an electronic crankshaft position sensor - for example, a Hall sensor (VAZ-2108) or magnetoelectric (GAZ-2410).

Breaker

ignition system - a mechanical switch in the distributor, directly connected to the primary circuit of the ignition coil.

Runner

- a distributor element that alternately transmits high voltage from the ignition coil to high-voltage wires connected to the engine spark plugs.

Angle of closed state of contacts (UZSK)

- a value indicating how long the contacts of a mechanical breaker should remain closed. For classic Zhiguli cars, the UZSK is approximately 55 degrees. A correctly selected UZSK gives the ignition coil the opportunity to gain the necessary energy and completely transfer it to the spark plugs.

Ignition system in the “nine” and its modifications

The ignition system in the VAZ-2109, 21099 and 2108 models is electronic. It is a set of components and parts with the help of which a spark appears in the spark plugs and the fuel mixture ignites.

How to set up and regulate the ignition

It consists of the following elements:

- distributor or main distributor of ignition impulses;

- a coil producing high voltage, which creates a spark;

- wires and connectors for connecting components;

- switches;

- high voltage wires with reinforced insulation;

- spark plug.

In carburetor and injection engines, the ignition circuits have significant differences.

Ignition circuit for a carburetor internal combustion engine

All elements of this unit are connected to each other by a special high-voltage or low-voltage wire. One of the main design elements is the ignition distributor. It serves to select the moment of ignition of the spark and supply it to the cylinders. At the same time, it constantly monitors the engine speed in order to regulate the spark supply depending on the need.

If these parts are correctly configured, the timing of the feed is clearly selected and the required feed is set, then the car serves perfectly. If something starts to go wrong, then repairs are required. Incorrect setting of the feed timing can cause many malfunctions in the operation of the motor and reduce its service life.

Ignition circuit for an injection engine

When and why do you need to adjust the ignition?

First, a little theory. If the working mixture in the cylinders burned instantly, then there would be no problems with advance in principle. Set it on fire at top dead center and everything is fine. But the mixture does not burn instantly: it takes milliseconds. In this case, the actual rotation speed of the crankshaft is, of course, not constant. Therefore, you cannot stupidly ignite the mixture at the same time under different engine operating modes: it will burn either too early or too late. The result will always be disappointing - the engine pulls poorly, overheats, runs unstably, detonates, etc.

How to regulate OZ?

Aurally? By spark? By a light bulb? By strobe? Let's figure it out now.

Let’s say right away that we won’t talk about the strobe light. Firstly, the average driver simply does not have it at hand. And, secondly, it’s better not to mess with him. The fact is that the strobe light shows the ignition timing only when the engine is running, but at the same time, due to the centrifugal regulator, the OZ is shifted towards advance even at minimum idle speed. Therefore, generally speaking, there is no point in waiting for precise adjustment.

The correct adjustment recommendations are always contained in the specialized literature for a specific car model - they should be followed. Let's take for example the AZLK-2141 car with a UZAM engine and a contact ignition system. Please note that the slider on Ufa engines rotates COUNTERclockwise.

The sequence of operations for a Moskvich engine should be as follows.

- Loosen the distributor fastening.

- We determine the beginning of the compression stroke in the first cylinder. To do this, we turn out the spark plug of this cylinder, plug the hole with a suitable plug (even from crumpled paper) and turn the crankshaft with the starting handle until the plug pops out.

- We continue to turn the crankshaft until the first mark on its pulley aligns with the tip of the ignition installation pin pressed into the lower crankcase cover.

- We make sure that the slider is looking with its current-carrying plate at the contact of the distributor cover, corresponding to the wire of the first cylinder.

- We connect any low-power light bulb (for example, in a test screwdriver) with one end to ground and the other to the low voltage terminal of the coil connected to the breaker.

- Turn on the ignition and turn the distributor body counterclockwise until the breaker contacts close. The lamp shorted by the breaker should go out.

- Holding the slider, apply a small force clockwise to eliminate gaps in the drive mechanism, then slowly turn the distributor clockwise until the light comes on.

- Tighten the distributor fastening. Don't forget to return the candle to its place!

On cars like the VAZ-2108, which switched to electronic ignition, but at the same time retained both centrifugal and vacuum regulators, the procedure is completely similar - up to a different location of the standard marks. The slider rotates counterclockwise. However, the probe lamp must be connected between the switch and the ignition coil, and in no case to the Hall sensor.

What does the expression “set by spark” mean? Roughly speaking, the same as with a light bulb. In this case, instead of a light bulb, use a spark plug that has been unscrewed in advance, the threaded part of which must be connected to the engine ground. Instead of the light bulb lighting up, we catch the moment the spark jumps - that’s all.

What about adjustment by ear? It is carried out like this: when driving on a warm engine at a speed of approximately 50 km/h in 4th gear, sharply press the right pedal. If the OZ is set correctly, then a short-term disappearing detonation should be heard. If the detonation is too strong, you should turn the distributor in the direction of rotation of the slider. If there is no detonation at all - against the rotation of the runner. You still remember that in the domestic automobile industry the runners rotated both back and forth?

How to set the ignition of a VAZ 2108

Step-by-step installation of ignition VAZ-2109 carburetor

Not all car enthusiasts can answer the question “How is the ignition installed on a VAZ model such as 2109 (carburetor)?” This process, of course, is quite painstaking, but in general even inexperienced drivers can carry it out.

As practice shows, VAZ-2109 owners sometimes encounter improper operation of the power unit, caused precisely by problems with the ignition being set incorrectly.

The most common symptom here is the engine starting easily when it is not functioning correctly at idle.

According to experts, in 9 out of 10 cases, repairs, replacements and adjustments can be made directly on site. That is, having dealt with the nuances, any car owner will save a lot of money by refusing to visit a car service center.

VESKO-TRANS.RU

AutoNews / Reviews / Tests

How to set the ignition on a VAZ 21099 Injector

Tuning VAZ 2109

Many car owners who own a VAZ- 21099 most likely have encountered difficulties associated with the correct operation of the engine. A common problem. Returning the engine key starts it, but the engine does not respond properly to idle ignition . Let's try to find out the cause of this problem, which is most likely due to improper inflammation.

Basic technical concepts

The ignition system consists of various interconnected devices and devices that ensure the occurrence of an electrical discharge, which in turn ignites the mixture of fuel and air in the internal combustion engine system. This system plays a huge role in automotive and electrical equipment.

We are not interested in the entire ignition system, but only when a spark occurs, which determines the correct operation of the entire system. This point is called ignition timing because it determines the time at which the working mixture is compressed. Incorrect ignition timing causes many problems with your car. Use this article to learn how to identify the problem, how to fix it, and how to fix it.

VAZ-21099: under the hood

What are the ignition problems?

Starting problems, hot exhaust gases, and other problems that can occur with your vehicle are often the result of improper ignition timing without carburetor problems. Ignorance of this simple fact forces drivers to delve into the details of the car for a long time. However, if the spark doesn't appear or doesn't fill the plugs at all, you should look elsewhere for the fault.

VAZ-21099 with a carburetor engine requires precise adjustment of the ignition timing. This can be done without special equipment, but it is easier to use a gate. This tool will make it much easier for you to set the ignition timing, which will likely be done more than once.

The problems described in this article can occur for many reasons, but it is easier to check the first problem that comes to your mind. The ignition angle is incorrectly set. So, the most common engine system failures are:

- Excessive explosion in the piston system. Characteristic features: when you press the gas, a characteristic ringing sound sounds. This problem is typical for inattentive motorists who do not pay enough attention to their car. The cause of early detonation is premature ignition, which threatens not only inconvenient operation of the car, but also further deformation of the piston rings. It should be noted that the repair of the piston system. not the cheapest “pleasure”;

- When the engine starts, strong black smoke comes out of the exhaust pipe. This problem may also indicate that the ignition is too fast;

- engine power is significantly reduced; using a larger volume of fuel compared to the normal displacement; the engine cannot quickly change operating mode and reduce throttle response. All of the above problems are related to the opposite problem. ignition too late. The reason is that the mixture does not completely burn out at the highest point of the piston position. This high point is still called dead. Thus, even when the piston is inverted, the mixture continues to burn. A possible second reason is that the exhaust system temperature is too high;

- If the problem is diagnosed by pressing the accelerator pedal, then the most likely cause is inflammation that is too late. In this case, the engine operates with significant interruptions, and when gas is compressed, so-called “failures” are diagnosed, during which the engine does not work. This problem can cause erratic driving;

- Idle speed does not work smoothly.

Therefore, if you see one of the problems listed in your VAZ-21099, look at the angle set in the ignition system. There may be a problem with this.

Injector ignition marks. Replacing the timing belt on 8 cl. Gap between DPKV and ignition pulley.

Tag ignition

to the injector.

We change the time on the 8 cl engine. Gap between DPKV and ignition

.

How does an ignition malfunction manifest itself?

If the unit in question is adjusted incorrectly, the following alarming symptoms are almost always observed:

- starting difficulties;

- black or gray exhaust color;

- instability of the engine at idle.

Meanwhile, the vast majority of car owners spend energy on carburetor prevention, mistakenly believing that this is where the cause lies.

Naturally, their work is wasted.

If the angle adjustment was made incorrectly, then the following are observed:

- too strong detonation of the fuel-air mixture;

- thick smoke from the exhaust pipe;

- loss of power;

- high fuel consumption;

- uneven work at XX.

All this leads to rapid wear of the engine as a whole.

Signs of incorrect ignition operation 21099

The VAZ 21099 engine, like the engine of any car, is a closed system in which everything is interconnected. Sometimes it is very difficult to distinguish between malfunctions of the power supply system and the ignition system if they do not manifest themselves in external signs. Incorrect operation of the ignition system can lead not only to deterioration in vehicle dynamics. Here are just a few basic examples of what an incorrect installation or failure of settings in the ignition system of the VAZ 21099 can do:

- increased fuel consumption;

- failures in transient speed regimes;

- unstable idle speed;

- Difficulty starting the engine, regardless of the engine and air temperature.

Popping noises in the carburetor or muffler may indicate early or late ignition. It is almost impossible not to notice them. In addition to external manifestations, a failure in the ignition installation often leads to burnout of the exhaust system, breakdown of gaskets, burnout of valves and pistons, breakdown of the cylinder head gasket; in general, you need to have a very rich imagination to list all the troubles that an incorrect ignition installation angle brings.

Before you set the ignition on the VAZ 21099, you should make sure that it is the ignition system that is to blame, since similar symptoms can occur with:

- incorrectly set fuel level in the carburetor float chamber;

- clogged air or fuel jets;

- incorrectly set thermal clearances of valves in the timing belt;

- broken valve timing;

- malfunctions of ignition system elements - coils, distributors, breakdowns of high-voltage wires, etc.

How to regulate

Practice shows that most often problems with the ignition system are observed in older models with a carburetor type of power plant.

To perform the setup you will need the following tools:

- Screwdriver Set;

- strobe light (you can basically do without it, but with its help you can set the angle more accurately);

- 10mm wrench (suitable for both socket and socket wrenches);

- tachometer (it is available in almost any car multimeter).

On to the road. Ignition installation (VAZ 2109)

In this video, Nail Poroshin once again shows and tells how to install the ignition

on the…

2109. Ignition in minus, do it as it should, and not according to the strobe

Carburetor mechanics on the Map - - near you! — Buy from Nail...

Preparation

As previously noted, you can do without such a device as a strobe light, but if you want to set up the ignition yourself, then there is still a reason to purchase it.

Before you start setting the angle, do the following:

- start the engine;

- heat it up to 90 degrees;

- increase the speed to 800;

- remove the pipe used to discharge the fitting;

- the dismantled tube is clamped with a finger - this will allow you to find out whether vacuum is actually occurring;

- if it is present, the speed is increased until it disappears;

- then the engine is turned off and the pipe is bent so that there is no gap left in it;

- use a wrench to unscrew the nuts securing the distributor;

- clean the inspection hole from dirt (it is located in the crater of the gearbox and is closed with a plug).

There is a special scale with which the set angle is determined. This should be discussed in more detail, since you need to set the ignition according to the marks. For this:

- Use a flat screwdriver to turn the flywheel until a long strip appears;

- in the future, during adjustment, you need to ensure that it remains clearly in the triangular cutout (this is the zero angle, that is, the starting point of adjustment).

If everything is done correctly, then cylinders 1 and 4 move to the TDC position.

When the scale is poorly visible and you are not sure that you have found the necessary feature, then you can verify the correctness of the position in another way.

There are pulleys on the camshaft gears. They must coincide with the mark on the wall of the timing belt protective housing.

Setting the ignition using a strobe

Checking and subsequent adjustment of the VAZ-2109 ignition (carburetor) can be considered correct only if the engine is warmed up to its operating temperature (in the range from 80 to 90 degrees). All further actions must be performed in accordance with the instructions below:

- Start the engine and set the crankshaft speed to 800–900 rpm.

- Remove the vacuum hose from the ignition timing vacuum corrector fitting and, turning off the engine, close the gap in the hose.

- Using a “10” wrench, unscrew the three nuts that secure the breaker-distributor.

- There is an inspection window on the gearbox housing, closed with a plug, after removing which the flywheel ring gear is revealed. Rotate the flywheel until you see the alignment mark, which, when placed opposite the center mark on the scale located at the edge of the inspection window, will place the first and fourth pistons at top dead center. It would be useful to check the correct location of this mark - to do this, find the same mark on the crankshaft pulley and make sure that it is aligned with the mark on the timing cover.

Settings

The strobe is used like this:

- the red wire is applied to the “plus” on the coil;

- black – to the body;

- the clamp is connected to the veins installed on cylinder number 4.

After this, the actual adjustment begins.

The work is carried out in the following order:

- start the engine, bring its speed up to 800 and no more (measurements are made with a tachometer);

- the beam from the strobe is aimed at the inspection hatch;

- the long line is placed in the zero position (scale in degrees).

The angle is adjusted by rotating to the right - this increases the angle, respectively, movement in the opposite direction decreases it.

It is not difficult to find out the exact direction - it is indicated by the scale marked on the distributor (there is an o and a “plus” there). Each division corresponds to 8 degrees. For this reason, adjustment is slow. After finding the desired position, the distributor is secured.

Checking with a light bulb

It will simplify your work when using a strobe.

The lamp requires a 12-volt lamp. The procedure is as follows:

- one contact from the light bulb is connected to the wire running from the coil to the distributor;

- the second is applied to the mass;

- the central (high-voltage) short-circuit cable is installed there;

- start the engine and loosen the bolts on the distributor;

- the housing must be rotated to the right until the lamp goes out;

- then it is turned slowly to the left - when the light flashes, the distributor is fixed.

To better understand how torque is set, we suggest watching this video:

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.