Gazelle 406 engine injector does not start reasons

Experienced

Group: Member Messages: 744 Registration: 10/14/2012 From: Berdsk User No.: 211114

Activist

Group: Member Messages: 479 Registration: 06/12/2007 User No.: 49546

Coils can be weird like that. And also the high-voltage wires and tips need to be inspected and ringed, the resistance checked. tips often like to die. Since the spark plugs may be wet if the coils' brains are cut off. and by the way, where did the order 1234 come from when it should be 1342? Where are the cars anyway? Otherwise I can drive up and take a look, maybe I can help.

I looked at the photo on the drome. If the wires are connected in the same way as in the photo in the ad, then the wires of cylinders 1 and 4 need to be swapped on the coil. and then reset the errors (if I remember correctly, on Mikasa it is enough to remove the terminal from the battery for a couple of minutes).

Experienced

Group: Member Messages: 744 Registration: 10/14/2012 From: Berdsk User No.: 211114

Coils can be weird like that. And also the high-voltage wires and tips need to be inspected and ringed, the resistance checked. tips often like to die. Since the spark plugs may be wet if the coils' brains are cut off. and by the way, where did the order 1234 come from when it should be 1342? Where are the cars anyway? Otherwise I can drive up and take a look, maybe I can help.

I looked at the photo on the drome. If the wires are connected in the same way as in the photo in the ad, then the wires of cylinders 1 and 4 need to be swapped on the coil. and then reset the errors (if I remember correctly, on Mikasa it is enough to remove the terminal from the battery for a couple of minutes).

Activist

Group: Member Messages: 479 Registration: 06/12/2007 User No.: 49546

Patriarch

Group: Member Messages: 22547 Registration: 02/19/2007 User No.: 41841

Activist

Group: Member Messages: 479 Registration: 06/12/2007 User No.: 49546

Patriarch

Group: Member Messages: 22547 Registration: 02/19/2007 User No.: 41841

Activist

Group: Member Messages: 479 Registration: 06/12/2007 User No.: 49546

Well, you have to watch it live. and the teeth will be exotic, they are fleshy and the pulley from below should be covered with a shield, in theory, no rubbish from the road should get on it.

By the way, I also remembered one sore that happens in the 406 family. For some time (a long time) the crankshaft pulley was not installed in one piece, but with a rubber damper. and it happens that this damper comes off and the part with the teeth rotates relative to the pulley hub. In this case, the engine will just sneeze, fill the spark plugs, and then an error will appear on the DPKV and will not start. It is easy to check: remove the belts from the pulley and try to turn it by hand by the ring gear. If it turns, the pulley needs to be replaced. I recommend replacing it with a solid one, without a damper.

Carburetor car engine starts and stalls

In this article we will take a closer look at the situation when a carburetor engine of a passenger car (VAZ 2108, 2109, 21099, 2105, 2107 and their modifications) starts and stalls due to a carburetor malfunction. Malfunctions of carburetors 2105, 2107 Ozone, 2108, 21081, 21083 Solex and their modifications will be considered.

Symptoms of a problem

— The engine starts, runs for a few seconds and stalls, repeated starts are unsuccessful

— The engine starts with difficulty, after running for a short time it stalls, after restarting it starts and runs

— The engine starts and immediately stalls, restarts and stalls again, and so on several times, but then it still starts working

Causes of the malfunction “carburetor engine starts and stalls”

— There is no fuel in the float chamber

Pump it up using the manual pump lever on the fuel pump.

The fuel pump or power system may be faulty. Remove the hose from the carburetor fuel supply fitting and press the manual primer lever on the fuel pump several times. A strong pulsating stream of gasoline should come out of the hose hole. If it is missing or weak, check the fuel pump or power system.

Checking the VAZ fuel pump

— The mesh filter at the inlet to the carburetor is clogged

Remove it by unscrewing the cap, clean it (you can use a toothbrush), rinse with acetone or gasoline and blow with compressed air. At the same time, clean the filter seat in the carburetor cover.

Details of strainer filters for fuel purification of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

— The solenoid valve is faulty or the fuel jet of the idle system is clogged

Check whether the solenoid valve or the idle air system fuel nozzle holder has become loose due to any circumstances. Turn it on. Remove the wire from the valve and then put it back on. You should hear the click of the valve being activated. If it is not there, we connect a piece of wire plus the battery and the valve outlet. There is no click - we change the valve. There is a click - we check the EPH system.

Solenoid valves for carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

Check the serviceability of the valve itself by unscrewing it from the carburetor and removing the fuel jet from it. The jet should be carefully inspected for contamination and deformation. We also check the ease of movement of the valve shut-off needle, the presence and integrity of the rubber O-ring on the valve body.

Carburetor solenoid valve design

Unscrew the idle air system fuel nozzle holder (on carburetors with a holder instead of a solenoid valve), rinse, clean the fuel nozzle and blow with compressed air.

— “Suction” of foreign air into the carburetor

In this case, the fuel mixture is lean. If the engine starts and immediately stalls, it is most likely very lean. The image shows probable places where foreign air is “sucked in” on the 2108 Solex carburetor.

Places of possible “suction” of foreign air into the carburetor 2108, 21081, 21083 Solex

Read more about the “suction” of foreign air in the article “Suction of foreign air into the carburetor.”

— The trigger diaphragm is damaged or it is not adjusted

Disassemble the starter housing and replace the diaphragm with a new one. Adjust the starting device.

Starting devices for carburetors 2108, 21081. 21083 Solex, 2105, 2107 Ozone

— Fuel and air jets, emulsion wells and tubes of the main dosing system are clogged

It is necessary to remove the carburetor cover, unscrew the jets, remove the tubes, rinse and clean them, clean the wells, blow everything out with compressed air and put it back. The image shows what should be cleaned on the carburetor 2105, 2107 Ozone.

On the Solex carburetor, unscrew the air jets and take them out along with the emulsion tubes. At the bottom of the opened wells there are fuel jets. We turn them out with a thin long slotted screwdriver. Clean, rinse with acetone and blow with compressed air.

Fuel and air jets, emulsion tubes and emulsion wells of GDS carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

— Fuel and air jets and channels of the idle system are clogged

Unscrew the jets, rinse and clean them, and blow them with compressed air.

Air and fuel jets for CXX carburetors 2108 Solex and 2105, 2107 Ozone

You can try to clean the idle system without disassembling the carburetor. Here is an article on this topic “Cleaning the idle system of the carburetor 2108, 21081, 21083 Solex.”

— The fuel level in the carburetor float chamber is broken

The fuel mixture is either very lean or very rich due to incorrect adjustment.

Approximate fuel level in the float chambers of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone

Articles on the site about adjusting the fuel level:

— The carburetor air damper drive is not adjusted (“choke”)

A not fully open air damper causes the fuel mixture to become richer in some cases to such an extent that it is difficult to start the engine, especially when it is hot. The spark plugs may become flooded with fuel. Adjust the drive:

With the choke handle fully extended, the air damper should completely cover the cross-section of the first chamber of the carburetor.

The air dampers of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone are completely closed

With the handle fully recessed, the air damper should be strictly vertical.

The air dampers of carburetors 2108, 21081, 21083 Solex, 2105, 2107 Ozone are completely open

Notes and additions

— Before searching for the reasons that a carburetor engine starts and stalls, it is recommended to check the serviceability of the ignition system, since the symptoms of its malfunction are similar to the symptoms of a malfunction of the ignition system and the presence of fuel supply through the power system.

Causes

Not for various reasons. Some of them are related to the time of year, while others are related to wear and tear. This problem can also be caused by the negligence of drivers who are careless about the maintenance of the power unit.

So, if not, there may be several reasons:

- malfunction of fuel system components;

- problem in valves and cylinders;

- malfunctions in the ignition system;

- breakdowns in the starter and battery;

- air supply;

- sensors and control unit.

Malfunctions in the starting system

If there is a malfunction in the starting system, the starter either does not turn at all or rotates the crankshaft of the internal combustion engine too slowly. In the first case, the most likely cause is a breakdown in the electrical connection with the battery. By performing a “diagnosis” of control points, you can detect damage that should be repaired.

Slow starter rotation indicates poor electrical contact. It may appear due to:

- brush wear or getting stuck;

- contamination, burning or abrasion of the working surface of the collector;

- oxidation or damage to the contact plates of the traction relay.

Elimination of the above problems can be done by dismantling the starter assembly and disassembling it.

Fuel cells

It is worth understanding that almost all elements affect the starting of the motor. For example, since the Gazelle was produced both with carburetor and injection, the injection elements will be different. This means that the reasons for possible breakdowns will not be the same.

The Gazelle-406 engine is an injection version of the vehicle. It has injectors installed, which can be the source of the problem. If cleaning has not been carried out, then most likely the injectors are dirty. To fix this, you need to remove the parts from the machine and send them for cleaning. If, during the process of restoring the functionality of the injectors, it turns out that the product cannot be repaired, then it must be replaced.

A fuel pump malfunction may be due to a breakdown inside the module. To check whether the pump is pumping, you need to get behind the wheel of the car and turn the ignition key to the second position. In this case, a characteristic noise should begin from behind, which will mean that the pump is in working condition.

Particular attention should be paid to the condition of the fuel filter. According to the service manuals and recommendations of the manufacturer, the fuel filter element must be changed every 40,000 km. If this is not done, the filter becomes clogged and does not allow fuel to pass through properly, which results in a lean mixture in the cylinders, or gasoline does not get in for ignition at all.

Battery problems

If the Gazelle does not start, then you should start searching for the impossibility of starting the engine with the battery. If it is insufficiently charged, the starter does not have enough energy to turn the crankshaft. In this case, a significant drop in the on-board network voltage occurs. The traction relay starts to click, but the engine cannot start.

Read more: Shell oil ultra 5 30

The situation with starting the engine with a discharged or old battery is aggravated in cold weather. There are two reasons for this:

- engine oil thickens in the cold and it becomes more difficult for the starter to crank the crankshaft, which causes increased starting current and greater battery energy consumption;

- When it's cold, the chemical reactions of the battery slow down and the battery becomes able to deliver less charge.

In winter, both of the above reasons overlap each other. Starting becomes especially difficult when cold. Under unfavorable conditions, the car may completely refuse to start.

With a discharged battery, many car owners start their Gazelle only with a pusher, but there are other ways, the main ones being:

- start using ROM;

- “lighting up” from another vehicle;

- charging the original battery with a nominal or increased current and then starting the power unit.

A situation with a discharged battery does not require special attention from the car owner if it occurs only once. It is enough to recharge the battery and you can continue to operate the machine as before. If the battery dies often, then it is necessary to diagnose it. Based on its results, a decision is made on the method and feasibility of restoration work. In some cases, it is more rational to purchase a new battery.

If the battery shows full serviceability, but dies in a short period of time, then the on-board network must be checked. It may contain short circuits and high leakage currents. If they are identified, you should not delay troubleshooting. Prompt resolution of problems will eliminate the risk of a car fire.

The integrity of the battery case directly affects the success of starting the power unit.

The presence of through cracks and other similar defects leads to the loss of part of the electrolyte. The battery's ability to deliver starting current and energy is significantly reduced. To diagnose the problem, just carefully inspect the case. If any damage is detected, the car owner is faced with a choice between carrying out repairs or purchasing a new power source.

Valves and cylinders

Quite a few motorists monitor the condition of the power unit. As you know, wear and tear does not spare anyone or anything, and accordingly, burnout of valves and pistons can lead to the fact that at first the engine begins to start poorly, and then stops altogether.

The second nuance is the high degree of wear of the valves, which is why they do not fit tightly to the seats. Gasoline drips through the cracks into the cylinders. It turns out that there is an overflow of fuel, and since the spark plugs are filled, the power plant does not start due to the lack of a spark.

Gazelle

Model ZMZ 40524.10 is a gazelle carburetor known to everyone. The car brand “Gazelle” is one of the most popular and affordable trucks in Russia, which were originally intended for transporting not very large loads. Due to the huge number of such machines, we will consider several nuances of different gazelle systems. For example, a microprocessor ignition system, which is installed on the 406 model.

If the driver claims that his car makes some popping noises, jerking noises and loses its power. In this case, the power system, engine and ignition system should be checked. We checked the carburetor with a gas analyzer not during the operation of the 1st and 2nd chambers, cutoff, enrichment and during idling and did not find any violations. Next they check the engine. When checking the compression, no problems were identified, but the next time deviations from the norm were detected. It was concluded that the jerks and pops that the driver did not like were due to the jumping of the teeth of the upper chain.

Carburetor ZMZ 406 series

What to do if a gazelle loses power?

From the very beginning, you need to check how the diagnostic circuit and the on-board diagnostic system function, because when the travel image mode is activated, you should receive a malfunction code - 12. To read the code, the 10th and 12th contacts of the diagnostic block must be closed. Using a diagnostic toaster, engine sensor parameters are measured and then compared with typical values for average engines. The most common reason for a decrease in car power is contamination of the tube that connects the intake manifold and the pressure sensor.

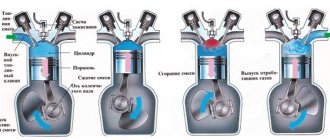

Gazelle ignition system

The microprocessor ignition system ignites the working fluid in the cylinders and sets the required vehicle ignition timing for all engine modes. The ignition system performs the function of regulating the operation of the forced idle economizer. Thanks to the ignition system, engine operation becomes more economical, compliance with all exhaust gas toxicity standards is monitored, detonation is eliminated and the vehicle's power is increased. If we compare the classic system with this one, then this ignition system is much more reliable and durable. Here only the spark plugs can wear out.

How does diagnostic mode work?

When the ignition system is turned on, the indicator light begins to light. At that very moment, the diagnostic system begins to work. If the system is working properly, the light stops lighting, but otherwise it continues to light. That is, an extinguished warning light indicates that the ignition system is absolutely working.

Carburetor ZMZ 406 series

Why does the 406 engine sometimes not start during a freeze?

The most common reasons why the 406 engine does not start:

Ignition system

Spark plugs and high-voltage wires directly affect engine starting. Accordingly, breakdowns in the elements will cause a failure of the entire system. To check spark plugs, a special stand is used, although you can check it the old fashioned way:

- We unscrew the candle from the well.

- We connect the armored wire.

- Connect the spark plug body to ground.

- We try to start the engine.

If everything is in order with the spark plugs, then there will be a spark between the contacts. If the part is faulty, then there will be no spark, and accordingly, the element must be replaced. Checking armored wires is quite simple. All elements are removed from the car and measured by a tester. The resistance on each high voltage wire should be 5 ohms.

Recommendations

Comments 60

And how did the epic end? I have similar syndromes =(

remove the chip from the mass air flow sensor and start it! If it doesn’t help, then put it back on and take it off. Even if the pump dies, then at xx it will create the necessary pressure, but in power mode it will not work! pull the chips and look!

So, I’ll check with the MAF tomorrow morning, but if I reset the MAF, it generally stalls immediately after starting, but sometimes it lasts for 5-20 seconds, but then it dies immediately. What else to watch? I installed the new phases, for some reason they are shorter than the old one, by 0.2 cm somewhere, +- 0.1. Rxx seems to be working, I checked it as a direct plus, according to the book it was written to check the central socket and the side ones (in turn), it closes, I check the two outer ones, it also closes, although nothing is written about the outer sockets... The mass air flow sensor is also intact, it seems like it gives out 2.80 ohms and not the norm of 2.6 as it should be...what is the reason?

according to IAC - everything depends on the ECU firmware! DPRV - question to the manufacturer DMRV - it is still a sensor and it also has brains!

filter, there’s nothing else, and maybe a fuel filter, but then it won’t work

Advertisements on NN.RU - Auto

Wide selection of hydraulic pumps and hydraulic motors of all series. Axial piston hydraulic motor. Splined shaft, reverse rotation. Analogs - (many. Price: 1,000 rub.

Manufacturing of a broken-type platform with retractable ramps on the GAZ-33023 Gazelle-farmer chassis. Technical characteristics of the tow truck.

The broken-type towing platform produced in our company has a highly reliable design, which is confirmed by many years of use.

A wide selection of hydraulic pumps and hydraulic motors of all series: spline hydraulic pump of right rotation. It is used in road construction and... Price: 1,000 rub.

More and more often you can hear complaints from parents of schoolchildren: “How is it possible: our eyesight is good, but the child was prescribed glasses?!” Alas, they are.

Signs

If the principles of preparing the fuel mixture in the carburetor towards enrichment are violated, then problems with starting the engine are observed. A hot engine starts especially hard. If the engine does start, the speed is unstable (often increased in idle mode). It is impossible to adjust or somehow stabilize the speed using conventional methods.

If the fuel mixture is too rich, black smoke will come out of the exhaust pipe - the mixture burns directly in the exhaust pipe. When you press the accelerator pedal, failures are possible - the rich mixture burns very poorly. There will be a thick layer of black carbon on the spark plugs.

Video: Carburetor overflows

Video: CARBURETOR K 151 ADJUSTING FUEL LEVEL

Poor starting on cold Gazelle 406 injector

Today -14, started only with the gas pedal. When hot, it starts without the gas pedal, but it turns several revolutions longer compared to a serviceable Volga 406i. Otherwise the engine runs like a clock. I understand from reading the conference archives that the temperature sensor is to blame, I want to try transferring it from the Volga.

Which temperature sensor needs to be replaced? The one in the receiver that measures the air temperature? Or is it a sensor in the thermostat housing?

Thanks in advance, Alexander (Gazelle 406i and Volga 406i).

PS Forgot to indicate: Gazelle, engine 4062, Mikas 7.1 film, 590 firmware.

It’s not a fact that the sensors.. It could be spark plugs (BB) or problems with freezing of the IAC (DZ). And when you operate the pedal, you simply control the speed yourself, and not MIKAS in XX mode

nope.. Look. If so, then there is NO heating of the DZ yet (the antifreeze is still COLD). And when it starts up, does the “air flow” “suck out” EVERYTHING with black smoke? Wow. If there is LOW oxygen (for example, the IAC is malfunctioning). That is what will happen - RE-ENRICHMENT.

Briefly speaking. I would still look at the “IAC steps” during startup and during operation. Another option is injector glitches

| Time zone: UTC + 3 hours | Current time: Mon Aug 05, 2021 19:50 |

The engine starts and stalls at idle

One of the reasons for the engine stopping after starting may be a false “triggering” of the installed anti-theft system. It happens that the immobilizer did not receive the deactivation command. Perceives an attempt to start as a hijacking.

A clogged idle air valve can damage the engine. The resulting sediment on the element parts leads to unstable operation of the throttle valve. Therefore, it (the damper) jams or does not work smoothly: in jerks. A dirty sensor transmits a command (incorrect data) as a result of which, immediately after starting the engine, it stalls. In addition, the problem may be:

- Poor quality fuel.

- Technical fluids. In particular, engine oil, which should be changed as soon as possible to avoid serious problems.

- The formation of an air lock in the main fuel line will lead to engine malfunctions.

- Exhaust gas circulation sensor malfunction. A clogged EGR is a direct path to blocking the power unit.

- Dirt accumulated in the air or fuel filter indicates problems with the engine. Timely maintenance will help avoid such problems.

- The stumbling block may be a faulty oxygen sensor.

The stable operation of the engine can be affected by a malfunction of the crankshaft sensor; the car starts and stalls literally after a minute of operation. At idle speed, the power unit stalls if the engine idle speed adjustment is disturbed. Adjustment will be required.

The car started and stalled. The reason for this strange behavior may be the drainage tube through which air is sucked in. It needs to be changed. The problem may be the carburetor idle economizer control unit, as well as the connecting hoses.

The car started and stalled: the pneumatic valve may have been damaged or failed. Also, stopping the engine after starting is caused by a faulty carburetor: clogged jets, water, diaphragm tightness, problems with the ignition system.

A running car may stall if there is no contact or the battery terminals are oxidized. On diesel engines, the pre-heating system of the power unit has failed.

A running car with a gasoline power plant may stall if the fuel injection system is damaged.

If we talk about the problems of the 307 model, then a faulty flow meter or fuel pump (dirty filter) causes the engine to stop after starting.

The Peugeot 307 model may stall at idle if the fuel supply from the tank is cut off. It is necessary to clean the mesh in the tank with ultrasound. Perhaps it is clogged.

FakeHeader

Comments 11

Try pumping it up three times and starting it! 1 temperature sensor 2 pump is dying!

Try starting it with the gas pedal depressed. To be honest, there can be many reasons: injectors (flow), pump (pressure), jot (new, it’s not a fact that it’s working or not for your brain www.drive2.ru/l/5303392/), ignition angle, quality of gasoline, rxx ( try flushing), voltage on board (try to throw a wire on the coil with the + battery when it’s cold and start it like that, when you connect the ignition will turn on, that’s how it should be!), spark plugs (gap of spark plugs), air filter (unlikely, but still) , timing belt (stretched chain), try wiping the headlights before starting))) (HUMOR), maybe I missed something else, someone will add!

Thank you for your response, everything that you listed this year, everything was installed new, you understand, the mileage is 356,000 km... it starts but not the first time, the second or even the third... on a warm engine with half a turn... by the way, what kind of OZ should Mikasa 11 have? The ZMZ 405 won't start at all with the pedal depressed! If the forces were flowing when the ignition was turned on, popping noises would be made in the combustion chambers! this is not the case. Idle speed is perfect 800 rpm. Most likely the DTOZh stuck the wrong one!

On Mikasa I can’t say, it seems to be programmed there from the factory because it doesn’t change the advance angle from the onboard one. But on Soate it changes for me. Try to play around with the camshaft sensor, it also sometimes gets weird and there is no way to check it and it won’t give an error until it shorts out, it was like seven years ago, at idle there seemed to be little shaking and every other time it started normally, who knows? . you can check its integrity through resistance with a cartoon just like a jot, but I don’t remember the parameters ((, a guy suggested it a long time ago, since they are not exchangeable, he checked it right away from the cash register, out of 10 only 5-6 are normal .

Thank you for your response, everything that you listed this year, everything was installed new, you understand, the mileage is 356,000 km... it starts but not the first time, the second or even the third... on a warm engine with half a turn... by the way, what kind of OZ should Mikasa 11 have? The ZMZ 405 won't start at all with the pedal depressed! If the forces were flowing when the ignition was turned on, popping noises would be made in the combustion chambers! this is not the case. Idle speed is perfect 800 rpm. Most likely the DTOZh stuck the wrong one!

jot Sensor resistance: 24…27 kOhm just in case

First group

Determines that the “4062.10” engine belongs to the modern trend in engine building - distributed fuel injection with electronic control. This is a microprocessor control unit (CU), electromagnetic injectors, numerous active sensors, relays, electric fuel pump and others. From the moment the ignition key is turned, the driver can only read information from the instruments.

The microprocessor engine control system today is quite mature and reliable. In the practice of our station, there were 2-3 cases when the car arrived on a “strap” - the control unit or the fuel pump failed. There were significantly more cars equipped with a “402” engine with a faulty transistor switch.

The new engine and its control circuit contain self-diagnosis and self-healing functions. Any car enthusiast, having studied the instructions, can independently and confidently communicate with electronics, find out about any malfunctions that have arisen, get to their destination, and then get repaired.

At this point in our lesson, I ask S. N. Vershinin to show how to do this in practice. We open the hood of the Volga GAZ-3102, sit down in the front seats, and turn on the ignition. The indicator lamp flashes and goes out. This means that the diagnostic system confirms that the vehicle is in good working order. Then we “make” the problem ourselves: remove the terminals from the coolant temperature sensor. We turn on the ignition - the lamp lights up and does not go out. We pretend that we didn’t notice the fault and turn on the self-diagnosis system. To do this, disconnect the battery for 10-15 seconds and connect it again. We find the self-diagnosis system block under the hood on the right side of the cab front panel and close the contacts with a regular paper clip (Fig. 1).

Turn on the ignition. The control lamp repeats the code “1-2” to us three times (one short light on for 0.5 s, a pause of about 1.5 s and two short lights). The diagnostic system signaled with this code that it was working, and then “blinked” us with the code “2-2”, repeating it three times. According to the fault code map, this signal precisely means a malfunction of the sensor from which we removed the terminals.

Starts up poorly (takes a long time), the ZMZ 406 injector fails

Thanked:

0 times. Thanked:

0 times.

Car:

Gazelle

I'll tell you right away. DTV and DTOZh are new, the mass air flow sensor is working (I removed the chip), the DPKV is working (because it wouldn’t start, I cleaned it), the ECU (brains) is working

The spark plugs are new and the coils are in good working order. No air leak

Starting is equally bad on both gasoline and gas.

The car runs fine on gasoline, everything is fine here.

On gas everything is worse, from 1000 to 2500-3000 thousand revolutions the car shakes, but sometimes it’s normal.

I've already tried everything, nothing helps. Everything worked fine before, but suddenly such problems appeared. HELP

Gazelle SOATE 302 40522 stalls when you press the gas

#1 Leksandrych

The car runs at idle, but as soon as you press the gas pedal it stalls. It works fine on gas.

I installed a replacement controller, it didn’t help.

I tried pouring gasoline into the receiver at the moment of stalling, but it didn’t help.

#2 -Alexander-

Is everything normal according to the parameters when the gas is muffled?

#3 Leksandrych

Yes, all parameters are adequate. During deafness, all the pros and cons are present. It stalls abruptly, “like it’s cutting off.”

This doesn't happen on gas.

#4 -Alexander-

I would log the parameters at the moment the engine stops, if the connection does not break

#5 Greek M

Gas injection? The air flow sensor is alive and original?

#6 BLACK1520

HBO, presumably, a firecracker? what's up with the dpdz?

Causes of poor engine starting "hot"

For a novice car enthusiast, a difficult start when hot looks like something supernatural. Why is the engine difficult to start? Just half an hour ago I started the car with half a click, a hot engine is guaranteed, but now the car won’t start! Miracles, and that's all. No magic - banal mechanics and physics. If the car does not start when hot, the reason may be a malfunction of some sensor. Incorrect operation of one sensor can cause engine failure as a whole.

When carrying out maintenance, it is necessary to check the functionality and condition of the sensors. Their incorrect operation is often a problem that makes the engine difficult to start when hot. When carrying out the replacement procedure, use tools for installing electrical contacts; they reduce the risk of failure.

You can use Electronic-Spray for electrical wiring.

Low quality gasoline

There is no common method for assessing fuel quality. You have to use indirect signs, for example, a bad factory after refueling at an untested gas station. At the same time, while your car does not start, there is a high chance of the battery dying, “killing the spark plugs,” clogging the injector, and even destroying the engine in case of improper detonation.

If the engine does not start well when the engine is hot, the reason is probably due to unsuccessful refueling. The solution to this problem is the use of additives in the gas tank that improve the basic characteristics of gasoline.

To protect yourself from the consequences of refueling with low-quality fuel and keep the injector in good condition, we recommend that you always keep on hand the long-term injector cleaner Langzeit Injection Reiniger for gasoline engines and the long-term diesel additive Langzeit Diesel Additiv for diesel engines.

It is recommended to use these fuel additives when refueling at untested gas stations, as well as on highways.

Air filter problems

In winter, when there is a large temperature difference, a possible cause of problems such as icing of the air filter. Lack of air is also a reason that prevents the car from starting. In this case, it is recommended to immediately replace the air filter at the first sign of trouble. The procedure is quite simple and does not require special skills.

IMPORTANT! One of the key factors causing a vehicle to start poorly when cold may be incorrectly selected engine oil. If you fill in oil with a viscosity of 10W-XX and higher, and there is severe frost, the oil thickens and its pumpability in a cold system drops sharply, which leads to significant wear on the engine at start-up; As a result, the car will not start.

In winter, it is important to choose only high-quality oils from trusted manufacturers, as this guarantees that the oils comply with the declared parameters of “behavior” in the cold.