What to do if the handbrake (parking brake or handbrake) is stuck or one or both of the rear wheels are stuck? In parking lots, cars are put on the parking brake or, as it is sometimes called, the handbrake (handbrake). This is correct as it ensures safety. If the vehicle is not used for a long time or after a long period of parking, especially when the weather changes, a situation may arise when it is impossible to move away because the handbrake and the rear wheel (one or both) are jammed.

Quite often, the problem with the handbrake jamming and/or occurs on domestic VAZ cars, both front-wheel drive (VAZ 2109, 2110, Granta, Priora) and rear-wheel drive VAZ 2101-2107, this is due both to the design features of the handbrake and to the low the quality of components, and frankly speaking, neglect of regular maintenance of the handbrake.

You can solve the problem with a locked handbrake in one of three ways:

- diagnose and fix the problem yourself;

- Call a tow truck to take the car to the workshop - you will need complex loading with dollies, or even a crane.

- Call a technician to the site of the breakdown.

Our auto technicians can unlock both a mechanical and electronic handbrake anywhere. They have enough experience to do this job efficiently. The cost of a visit to unlock the handbrake is from RUB 3,000*

Why the handbrake on a car might get stuck and how to fix it

Handbrake jamming is not the most common malfunction. But many motorists have encountered it over the years of operation.

There are several main reasons why the handbrake gets stuck. This may be due to weather conditions, or problems with the mechanical component of the unit.

And if the problem of icing is quite easy to solve using available means, then dealing with malfunctions will be much more difficult.

What to do if your electronic handbrake is stuck?

Most often, the electronic handbrake gets stuck due to a malfunction in the brake pad actuators, or due to mechanical damage and dirt in the brake mechanisms themselves, in which case it is better to call a specialist who can try to unlock the brake mechanisms of your car right on the road.

Although on Volkswagen cars (Passat, Tiguan) the error with a jammed electronic handbrake sometimes occurs due to a malfunction of the handbrake button. In such cases, disassembling and cleaning the handbrake button may help.

Some cars provide emergency unlocking of the electronic handbrake mechanically, as described below.

What causes the handbrake to jam?

You should start with the reasons why the handbrake may not raise or lower. What most often happens is that the parking brake does not want to be released after the car has been parked in the cold for quite a long time.

Let's highlight the main reasons why the unit may jam, and the wheel will not want to be blocked or freed from the strong embrace of the brake pads.

- Mechanical problems. The handbrake is activated by pressing the brake pad against the disc or drum. This activates the brake and the car cannot move. If the block gets stuck in this position, the car will not be able to move. As for why this happens, the main reason lies in the block itself, or in the cable. The latter needs to be adjusted or replaced.

- Freezing. The most likely reason why the handbrake does not release completely, or does not want to engage when you try to pull the lever. This freezing is caused by the accumulation of snow or icy water after driving on winter roads. A layer of ice firmly envelops the assembly, which is why the resulting crust does not allow the hand parking brake to be released.

In case of freezing or jamming due to mechanical reasons, do not under any circumstances try to solve the problem with physical force. Do not pull the handbrake sharply towards yourself, do not try to pull it with both hands.

If the brake does not respond with normal pressure, there is a problem. It needs to be found and then eliminated.

Checking and adjusting the hand brake

Adjusting the hand brake

Checking the effectiveness of the hand brake on the VAZ-2109, as on any other car, should be carried out approximately once every 30 thousand kilometers. And it’s not difficult to do it. You can put the car on a downhill or uphill slope, turn off the engine and pull out the handbrake. If the car remains in place and there is no unauthorized movement, then you can continue to operate the car.

Another way to check is to put the car on the platform, turn off the speed and tighten the handbrake. After this, you need to engage first gear and try to move away. If the car moves even a little before the engine stalls, it means that the cable tension needs to be adjusted.

Video: Adjusting the NIVA hand brake. We tighten the Niva hand brake cable ourselves

On the VAZ-2109 it is performed like this:

- the car is driven onto an overpass, a pit, or, in extreme cases, the rear of the car is jacked up and placed on supports, the handbrake lever must be completely lowered down;

- Under the car in the tunnel you need to find a rocker arm from which a central rod with two nuts will protrude - an adjusting nut and a lock nut. Using two keys, the locknut is loosened;

- the adjusting nut is screwed onto the thread of the rod until the cables are stretched. After this, the stroke of the lever is checked until it stops; for a normally adjusted one, it should be 2-4 clicks of the ratchet;

- After this, the adjusting nut is fixed with a locknut and the effectiveness of the parking brake is checked.

The described algorithm for tightening the handbrake is suitable for almost any car that uses a mechanical handbrake. The difference only comes down to some design features.

How to solve a problem

Naturally, motorists are interested in what to do if the handbrake is jammed, and how this could turn out.

There are 2 main situations when there are problems with the parking brake:

- the car does not want to be released from the handbrake;

- The car cannot be put on the handbrake.

It would be fair to call the first situation jamming. We’ll tell you more about it.

Since the handbrake does not release and continues to block the wheels, it is important to first exclude the option of freezing. If it is a warm season and there were no frosts at night or while the machine was idle, the jamming occurred precisely for mechanical reasons. Some kind of breakdown occurred.

There are several potential culprits and solutions to the problem here.

- Handbrake cable jammed or broken. It needs to be inspected and adjusted. If the defect is serious, it will have to be replaced.

- Jamming due to rust formation. Relevant for machines that have been idle for a long time and have not been used. At the same time, the car was stored in a humid environment. Rust has stuck to the pads, caliper or brake disc (drum). This will require dismantling, cleaning or replacing elements.

- The pad linings became soggy, which caused them to stick to the drums. You will probably have to solve the problem by replacing the elements.

Some motorists advise trying to move forward and backward, tap the problem unit with a hammer, insert a pry bar into the gap between the jammed block, and manually try to loosen it.

In reality, such actions can lead to serious consequences. It is better to carefully examine the condition of the handbrake, determine the cause of the jamming, and carefully eliminate it by sequential dismantling, or by contacting a car service.

If the problem is related to the fact that the block is frozen, which can be determined by the presence of an ice crust and indirect signs such as driving through puddles and freezing temperatures, it is much easier to solve.

How to solve the problem of the handbrake jamming in the cold

When your parking brake suddenly jams after a long period of parking in the cold, there is a very high probability that the brake pads will freeze.

This problem can be solved quite quickly in several accessible ways.

- Use of defrosters. These are special liquids, mainly alcohol-based. You can find them in specialized stores in the auto chemicals department. The principle of using funds is extremely simple. You need to spray it on the frozen assembly, wait a while, and then try to unlock the handbrake. If you live in a region with cold and wet winters, having such a can with you will never be a bad idea.

- Using a hair dryer. A very reliable, effective and fast way to remove ice from a handbrake. The only problem is that not every motorist has such a hairdryer at his disposal. Plus, to connect you will need a household outlet or a car inverter. An alternative is a regular household hair dryer, but its power is not enough to quickly resolve the issue. You will have to hold the device aimed at the brakes longer. Here the issue of connecting to the power grid remains relevant too.

- Defrosting with its own exhaust pipe. The meaning is quite simple. You will need a rubber hose that is large enough to fit onto the exhaust pipe. It should also be long enough to extend the other end of the hose to the brakes. Next, start the car and begin to warm up. Hot air comes out of the exhaust pipe, it passes through the hose, and warms up the handbrake.

- Available liquids. Another method involves using suitable liquids. These include antifreeze, alcohol or gasoline. They are applied to the pads and waited for some time. As soon as the ice thaws, the handbrake can be unlocked.

And there are 2 methods that should be abandoned. They should only be used as a last resort. And even in this situation it is better to do without such measures.

Some bad ideas for defrosting a jammed handbrake include the following methods.

- Hot water. There is severe frost outside, due to which the pads froze. The brake system elements themselves are also cold. Now imagine that a large amount of hot water or boiling water suddenly hits the parts. This leads to a sharp temperature drop. As a result, the metal may crack. This will lead to breakdown of expensive components and the need to replace them. Therefore, the idea of boiling water is categorically not welcomed.

- Physical impact. Quite often, motorists try to solve the problem of jamming due to freezing or mechanical failures using physical force. Trying to break the handbrake if it is jammed is strongly not recommended. If there is no other way out, you should get behind the wheel, start the engine, and try to rock the car forward and backward with short presses on the gas.

Disrupting the handbrake by physical force can potentially cause serious damage to the suspension and braking system components.

Therefore, these methods are necessarily included in the list of prohibited methods. Only in certain circumstances, when there is no other solution and cannot be, is their use allowed.

It hardly needs saying that lighting an open fire near the car in order to melt frozen pads is the worst idea among all existing ones.

A jammed handbrake is not a rare occurrence. But you can always find a way out of this situation. In some cases, the problem is solved literally in a few minutes, and no expensive repair work has to be carried out. If the jamming is due to a malfunction in the hand parking brake assembly, try to solve the problem yourself, or contact a car service center. If the handbrake sticks, you may need a tow truck to take the car to a service center to fix the problem.

How is the handbrake cable constructed?

There are several types of hand brakes, but each of them contains such an irreplaceable part as a cable; one might even say that it plays the main role in the braking process. The rear cable is located in a multilayer casing, and at both ends there are special tips that are fixed in the socket of the body bracket (front) and in the brake mechanism shield (rear). The braking process using a handbrake is carried out as follows: the force is transmitted from a lever located in the cabin to the brake mechanisms directly through the cable.

Car hand brake - design, principle of operation and maintenance

Each car's braking system is divided into two components - service and parking brakes. The first ensures slowing down and stopping the car while driving. The second excludes the unauthorized movement of the car after it is parked. At the same time, the handbrake must ensure the vehicle's immobility not only on a flat surface, but also on slopes and inclines.

Didn't put the handbrake on

The service brakes on passenger cars usually have a hydraulic drive, the main working element of which is a special fluid. This type of drive ensures rapid transmission of the force that the driver creates on the pedal to the brake mechanisms. Moreover, such a drive allows the use of amplifiers that increase the force in the drive. But it is impossible to use a hydraulic drive as a parking system.

When is a handbrake cable repair required?

This mechanism must be used regularly, and if this is not done, it may become sour, and, accordingly, the entire manual braking system will fail . This is especially true for cars with automatic transmission (automatic transmission), since in this case it is possible not to use the handbrake at all. However, it can also fail due to its service life, especially considering constant loads. This reason, however, is quite predictable and not so fleeting; original parts work for about 10 years without any problems.

The condition of this part is also not reflected in the best way by its location - under the body, where there is always high humidity. And the lack of lubrication contributes to the abrasion of steel threads. Also, a reason for replacement can be elementary damage received during sudden braking, although you have to resort to it extremely rarely, because there is a main brake. You will immediately understand that the handbrake no longer holds your car (at the first parking lot or slope), then you should immediately take action.

In many countries, driving with a faulty hand brake is prohibited and even punishable by a fine; we have not yet strictly introduced such measures, but you will no longer pass a technical inspection without this element.

How does the handbrake system work?

Applying the parking brake activates the rear brakes and ensures that the vehicle does not roll, even on a relatively steep incline. However, if the handbrake does not hold the vehicle, there is a problem that must be corrected to ensure the safety of the driver and others.

Parking brake systems vary greatly from one automaker to another and even between different makes and models of cars. In general, they are divided according to the type of brakes and the method of their use.

It is immediately necessary to understand that in the vast majority of cases in passenger cars, parking brakes use the rear wheels and are divided into two types:

- drum - consisting of two semicircular blocks that are located inside a cylindrical drum. If, on one side, they are rigidly fixed, then on the other there is a special piston mechanism that forces the pads to move when using the handbrake;

- disc brakes - consisting of a special brake disc mounted on the car axle and two pads. When you use the handbrake, the pads compress and prevent the car from moving.

The car's braking system can also be mechanical or hydraulic. If in the first option, braking is carried out using a system of cables and the force of a person who puts pressure on the handbrake, then a special piston is used in hydraulics.

How to replace the handbrake cable - instructions

Repairing a handbrake cable is not a very complicated process, and it is quite possible to do it at home, but it is advisable that two people work, since it will not be very easy to do it yourself. You must proceed as follows. First of all, we remove the vehicle from the handbrake; this is done using a special lever located in the cabin; it must be lowered all the way.

Next, the brake drum of the required wheel is dismantled, you also need to remove the muffler and resonator from the cushions and lower the exhaust pipe down. This way you can get to the equalizer without any obstacles. We find the handbrake adjusting nut, as well as its locknut, they are located under the car body. And, of course, we unscrew them.

We remove the equalizer from the rod, remove the cable tip from the control, and then take out the tip located in the bracket located on the car body. The brackets through which the cable is attached must be bent. On the rear axle beam there are nuts that secure the cable holder; after loosening them, you need to remove the cable itself. Next, it is removed from the grooves of the bracket and brake shield. In order to install a new part, all operations should be done exactly in the reverse order, taking into account that the cables must be installed crosswise in the bracket.

Mechanical hand brake. Design, principle of operation

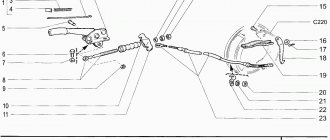

Parts of the VAZ 2105 parking brake drive: 1 - cover; 2 — front cable; 3 - lever; 4 — button; 5 — thrust spring; 6 — latch rod; 7 — bushing; 8 - roller; 9 — rear cable guide; 10 — spacer sleeve; 11 — tension spring; 12 — spacer bar; 13 — lever for manual drive of the pads; 14 — rear cable; 15 — rear cable mounting bracket

The most widespread on passenger cars is a mechanical hand brake, the drive of which is metal cables. The device of this type of brake is quite simple: a lever is inserted into the car interior, which is connected to a drive cable. That, in turn, interacts with the brake mechanisms of the rear wheels of the car, the design of which includes special levers that act on the brake pads.

It all works like this: the driver pulls the lever, and with it the cable. The latter acts on the levers in the brake mechanisms and they unclench the brake pads, pressing them against the brake drum. Due to this, the car's wheels cannot rotate and the car is immobilized.

To prevent the lever from returning to its original position when the handbrake is applied, a ratcheting mechanism is installed on it, consisting of a toothed sector and a lock. When the lever is pulled, the lock fits between the teeth, preventing unauthorized return.

Drive of the parking brake system of VAZ 2108, VAZ 2109, VAZ 21099 cars: 1 - button for fixing the hand brake lever; 2 — parking brake drive lever; 3 — protective cover; 4 - traction; 5 — cable equalizer; 6 — adjusting nut; 7 - lock nut; 8 - cable; 9 — cable sheath

To remove the car from the handbrake, the driver presses a special key on the lever, thereby releasing the lock, and the lever can return to its original position. The cable is pulled into place by springs. At the same time, it acts on the levers in the mechanisms and they stop unclenching the pads.

The mechanical “handbrake” has gained significant popularity due to its simplicity of design and reliability. Even if the service brakes fail, it is always possible to stop the car, since the handbrake has its own drive, and is completely independent of other components of the car’s braking system.

Handbrake cable soured

This concept is used by drivers in colloquial speech. This means that the cable does not move well within the sheath and does not provide easy control of the parking brake. The drive is carried out only on the rear brake pads. The front brakes are not involved in the operation.

Many people say: “My handbrake has gone sour, I don’t understand what’s wrong, I don’t know what to do.” When you start to find out, it turns out that the car is already more than 15 years old, and the cable has never been changed. Moreover, the handbrake was used very rarely. Over time, any materials oxidize and corrosion appears. No matter how high-quality the spare parts and components are, rust takes its toll.

Parking brake device

Before replacing the handbrake cable or tightening it, you need to understand the design of the mechanism. It is designed quite simply and consists of the following main parts:

- Lever with spring-loaded button and latch. Located in the cabin on the right hand of the driver.

- A metal rod with a pin at the end and a rocker arm for installing the cable is located under the bottom of the car and attached to the lever. This is the “handbrake” tensioning device.

- The ends of the cable (or two cables), installed on the rocker arm, are attached to the brake levers of the rear wheels - disc or drum.

The parking brake works like this: when the driver lifts the lever in the passenger compartment, the rocker moves forward and acts on the pads through a cable drive. In drum mechanisms, the brake pads move apart, and in disc mechanisms, they converge. The “handbrake” holds only the rear wheels and functions independently of the main brake system, which is activated when the pedal is pressed.

The handle is fixed in several positions thanks to the latch. To unlock it and lower it to its original position, a special button is installed at the end of the handle. If the pads “grab” the wheels on the second click, and after the fourth click they hold the car securely, then the drive is considered to be working well.

How to remove the handbrake button and make repairs using the example of a VAZ

If the button on the handbrake of a car of the “tenth” family does not work (the latch does not work), and the lever itself is not bent and the teeth on the ratchet are not worn out, then the following operation should be performed:

- Remove the handbrake button. This is very easy to do without using any tool, since it simply unscrews counterclockwise;

- Remove the spring. It is simply removed from the rod;

- Straighten the spring and stretch it slightly (about 3-5 centimeters);

- Return the spring to its place;

- Screw the button. This will be somewhat more difficult to do, but the latch will work accurately.

Is it possible to restore without changing

If the cable has soured, but is not torn, but simply rusted, then it can be developed and partially restored. Of course, this is the wrong approach and can only serve as a temporary solution.

Try the following procedures:

- Sit behind the wheel, press the button on the handbrake handle and pull it up and down many times. If, apart from corrosion, there is no damage to the cable, then the functionality of the mechanism should be restored. You will have to pull for a long time for the rusty cables to start working.

- Another, more complex and time-consuming method is to remove the cables from the machine and lubricate them. Few people do this, but it also helps. The process of removing the handbrake cables from the car differs on different models. This will require an overpass or a hole in the garage. After removing the cables, you also need to pull them in different directions, and then try to lubricate them with engine oil. To do this, lubricant must be dripped inside the braid. It's a lot of work, but it often helps and extends the service life by several years.

Why does the handbrake fail quickly?

On many (even not too old) cars, the handbrake no longer works. But why is this happening so quickly? In normal condition, the handbrake cables will not rust in a short time. The reason lies in the penetration of moisture into the cable sheath. Water enters the internal cavity due to cracks that form on the braid. She just breaks down.

This occurs due to the design features of the mechanism. The fact is that the rear wheels move up and down when driving on uneven roads. And the handbrake cables are also forced to bend following the wheels and brake mechanisms to which they are attached.

Imagine how many bends the cable braid makes when driving on an uneven road? No metal can withstand such a load and will break. As a result, at the point where the braid is broken, water easily penetrates into it, and hence rust will not appear for long.

Other types of parking brake

There are several other types of hand brakes.

- The first, the so-called central one, is used on cars equipped with automatic transmissions. The principle of operation of such a brake is that when the gearbox selector is moved to the “Parking” position, the drive shafts of the wheels are blocked. But it is worth noting that the central brake is only auxiliary; the mechanism that ensures wheel locking has not been abandoned and is present in the design of the braking system.

- The second type of machine brake is electromechanical. Unlike a cable type, this type does not have a drive as such for the wheel locking mechanism, but it does have electric motors that act on the levers in the brake mechanisms. That is, the driver simply presses a button and the electric motors block the wheels. It's simple, but not as reliable as a cable.

Since the mechanical handbrake is the most common, we will consider it further. And let's start directly with the drive itself. And we will look at it using the example of the VAZ-2109.

Most often, on a car, the handbrake drive consists of a central cable, an equalizer, or, as it is also called, a rocker arm, and two side cables. The central one is connected at one end to the lever in the cabin, and at the other to the rocker arm. But on the VAZ-2109, instead of a central cable, a rod is used, at the end of which there is a thread for adjusting the tension. At the ends of the side cables there are limit switches, with which they engage the rocker arm on one side, and the wheel locking levers on the other.

How to solve a problem

Naturally, motorists are interested in what to do if the handbrake is jammed, and how this could turn out.

There are 2 main situations when there are problems with the parking brake:

- the car does not want to be released from the handbrake;

- The car cannot be put on the handbrake.

It would be fair to call the first situation jamming. We’ll tell you more about it.

Since the handbrake does not release and continues to block the wheels, it is important to first exclude the option of freezing. If it is a warm season and there were no frosts at night or while the machine was idle, the jamming occurred precisely for mechanical reasons. Some kind of breakdown occurred.

There are several potential culprits and solutions to the problem here.

- Handbrake cable jammed or broken. It needs to be inspected and adjusted. If the defect is serious, it will have to be replaced.

- Jamming due to rust formation. Relevant for machines that have been idle for a long time and have not been used. At the same time, the car was stored in a humid environment. Rust has stuck to the pads, caliper or brake disc (drum). This will require dismantling, cleaning or replacing elements.

- The pad linings became soggy, which caused them to stick to the drums. You will probably have to solve the problem by replacing the elements.

Some motorists advise trying to move forward and backward, tap the problem unit with a hammer, insert a pry bar into the gap between the jammed block, and manually try to loosen it.

How to replace the parking brake

If after adjustment the parking brake does not work, it barely holds, and the cable is tightened to the maximum until it stops, then it’s time to make a replacement.

To replace the main cable or those extending to the wheels, you must also put the car in an inspection hole.

From the interior, remove the decorative trim at the base of the handbrake and unscrew the nut with which the adjustment was made. For auxiliary cables, the equalizers must be disconnected by turning 90 degrees.

Remove the brake drum, brake pads, and use a screwdriver to pull the cable tip out of the groove on the release lever. Using pliers (pliers), we open the spring retainer and remove it from the shield.

We recommend: What is a carburetor: device and purpose

Lubricant for hand brake cable

It is better to lubricate the cable with a grease that has good performance characteristics: a high maximum melting point and resistant to oxidation.

Litol 24 cable lubricant is excellent. You can also use its foreign analogues.

What can be done

I'll give you an example of what I did in my car. I haven’t seen this method anywhere, maybe it’s on the Internet, I don’t know. I just found a piece of thick hose in the garage and cut it lengthwise so that I could put it on the handbrake cable. You need to put it on exactly the place where the braid burst due to bending. The hose was put on with the longitudinal slot down.

Thus, this protects against water getting into the cable sheath when driving through water, through puddles, and extends the service life of the hand brake.

When is it better not to use the handbrake?

Oddly enough, there are cases when it is better not to use the handbrake. This time occurs during the winter cold, especially in wet weather, or in the spring. When heat turns to cold, and vice versa. And if you drove through puddles and then frost hit, you need to dry the brakes urgently. This can be done by intensively braking on the road 5-6 times, or drying it in the garage.

Otherwise, if you then park the car and apply the handbrake, you may not be able to drive home. The brake pads will simply freeze to the drums and you will not move. Such cases occur quite often in practice. As a result, you have to knock on the wheels, remove them, and even warm the drums with a blowtorch.

In other cases, it is advisable to always use the handbrake so that it does not go sour, and most importantly for your safety. If you do not agree with our opinion, share it in the comments.

HOLD, HANDBRAKE

Why does the parking brake fail, how does it affect the working braking system of the car and how to achieve its reliable and long-term operation?

It is difficult to find another car system that has undergone so few changes throughout its history. The design of the hand brake is simple and almost the same for the “penny” of the 70s and many modern foreign cars: the lever (or pedal, as in a Mercedes) pulls the system of cables (Fig. 1), and those, through other levers, lead to action of brake pads. It would seem that there is nothing to break. However, there are plenty of defects. The main one is the loss of mobility of cables due to corrosion caused by salt, dirt, and water.

But there are factors that sharply accelerate the corrosion itself - we will talk about them today. Let's take the Zhiguli as an example, although I hope our recommendations will be useful to owners of other cars.

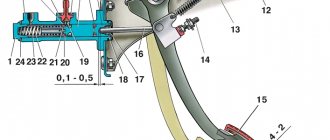

The workshop adjusted your handbrake. Wonderful. Now, slowly pulling the lever all the way, count how many clicks there will be. Many mechanics tend to tighten the cable to almost two or three clicks. They say that the handbrake will hold better, and the traffic cop won’t find fault, and when the cable stretches and the pads wear out, then the four or five clicks mentioned in the repair manual are just a stone’s throw away. But the trouble is that the stroke of cables 3 and 11 (see Fig. 1), as well as the pads, is very small, and this is what is favorable. corrosion: the low-moving cable is not lubricated even by the remaining lubricant that, we assume, was added during assembly, and is not cleaned of rust. As a result, lever 1 will have to be pulled with both hands. But the work of corrosion is not limited to this! By tightening the handbrake cable, you get a reduced stroke of the pads (small gaps between them and the drum) and at the same time - the brake pedal. Disinhibited pads seem to hang on the handbrake levers, and not on their main limiters. Remember: in the first VAZ 2101 cars, these were special eccentrics, with the help of which the pads, as they wore out, had to be brought to the drum. The VAZ 2103 already had a (though not very perfect) automatic machine in the form of a friction clutch in the block itself, which solved this problem. Today, the gaps between the pads and the drum are set by an automatic machine built directly into the working brake cylinder: the free play of the pistons is 1.25–1.65 mm.

Instructions for tensioning and replacing the drive

Since the parking brake system mechanism is located under the bottom of the car, an inspection ditch, overpass or lift is needed to perform the work. In extreme cases, you can do without them, but then you will have to hang out the back of the car and lie under it, which is not only inconvenient, but also dangerous. Before tightening the cable, securely secure the front wheels of the vehicle with wheel chocks.

Then act in the following sequence:

- Set the handbrake lever to the down position.

- Jack up any of the rear wheels.

- Armed with two open-end wrenches that fit the tensioner nuts, go down into the inspection hole.

- While holding the main nut located on the stud near the rocker arm, loosen the locknut.

- Tighten the tension nut, periodically checking the rotation of the suspended wheel by hand. To prevent the pin from spinning, it must also be held with pliers or a wrench.

- Stop tightening the cable as soon as the pads begin to grip the wheel. Make 1-2 turns of the nut back and check the operation of the handbrake. It should fire after the second click.

- Tighten the locknut, lower the jack and test the handbrake on a slope.

Replacing the cable drive will require more time, especially to disassemble the drum brake system. To hang both rear wheels, prepare wooden blocks, and to replace them, use a standard set of tools; no special devices are required. The algorithm of actions is as follows:

- Place the car on the pit and loosen the cable completely, as described above. Unscrew both nuts and remove it from the rocker arm.

- Lift the rear of the car, place it on blocks and remove the wheels.

- Remove the drums and unscrew the bolts securing the cable to the rear casing.

- Remove the brake pads and spacer bar. When you reach the lever, remove the cable loop from it. Remove it from the casing and repeat the operation on the other side.

Install the new cable drive in the reverse order, starting with the wheel mechanisms. At the end, tighten it and check the operation of the handbrake.

https://carnovato.ru/remont-zamenit-tros-ruchnogo-tormoza/https://vipwash.ru/tormoznaya-sistema/tros-stoyanochnogo-tormoza-nepoladki-i-zamena-svoimi-rukamihttps://mikrob. ru/viewtopic.php?t=54173https://autochainik.ru/tros-ruchnogo-tormoza.html

The wheel is stuck. Handbrake jams

The wheel is stuck. Handbrake jams

Post by krenkel » 18 Dec 2009 08:49

Re: Wheel stuck

Post by worodew » Dec 18, 2009 12:57 pm

Post by krenkel » 18 Dec 2009 18:25

prone to diagnosis - handbrake. Diagnostics will tell. The specialist did not defrost the wheel. I'm afraid the handbrake cable jacket has become thin or has gained moisture.

In general, we took off the wheels and everything became clear: – there is a lot of dirt on the calipers – the guides have soured and accumulated dirt – moisture must have accumulated in the cable jacket since the warm autumn – the handbrake cable spring has become weak

How to replace the handbrake cable spring? Here's my main question

Post by serg 799 » 18 Dec 2009 22:52

Post by krenkel » Dec 23, 2009 12:56 pm

serg 799 now agree 100%. I caught a wedge again after a police U-turn. And what got into that cable? How to spill it now? And with what?

In general, I came to my work and began to figure it out. – the hub is still alive; – the caliper is not wedged – the pads will need to be replaced in the near future – the verdict – the cable.

The cost of the cables is approximately 2000 per pair. They are there as a non-separable set. Having removed the anthers from the ends of the cables, it became clear the reason for the jamming - dirt inside the cables. Since it was necessary to do something to prevent jamming, there were several options: 1) replace the cables (not available in any store at that time) 2) remove cables and ride before purchasing them and installing them later 3) try to wash the inside of the cable jackets

WE took 3 paths. We are not looking for easy ways. We needed a vice to fix the end of the cable, which is attached to the caliper, and a VDshka cylinder for threading the cable. 2-4 nylon ties From the VDshka bottle, insert a tube under the boot. At the same time, the boot is fixed to the cable jacket. We tighten the tube to the boot with a tie so that during up and down movements the tube does not fly out from under the boot. Now we begin interesting movements - the cable is secured in a vice with the ends down. Gradually pouring in the liquid we will mix the shirt up/down. This will have to be done for quite a long time. During the transfer, you can also twist the cable jacket in any direction to quickly penetrate the VDshka further along the cable. So we twisted both cables for a total of about 40 minutes and the result was on the floor. From the reverse side of the cables, a VDshka came out the color of sand and thick as jelly in a huge puddle. This meant that it was full of dirt and all sorts of poop, which we washed out with this procedure. Now the cables began to move “like clockwork.” Later we thought that we could also pour oil from the variator into it. At that time it was on hand and turned out to be the most liquid. We tried to do this, but there wasn’t much time left. We spilled a total of a couple of 10ml medical syringes and killed them. The infusion procedure is identical to the VDshka, so much was poured through a needle from a syringe and no longer secured the needle to the boot with a tie. Everything was assembled and the handbrake began to work like new, and the brakes became much smoother than before and did not immediately grab with a stake. This meant that my handbrake did not I've been leaving for a long time, because I've had the brakes for a long time. At the same time, they sentenced a replacement tomrozuha. There was no time to do this anymore. So suddenly now.

Soured the cable for the handbrake.

Moderator: sensey08

Soured the cable for the handbrake.

Andrey309 » Sep 17, 2010, 11:32 pm

Re: Soured the handbrake cable.

ZOREVESTNIK » 18 Sep 2010, 20:08

Re: Soured the handbrake cable.

Andrey309 » Sep 18, 2010, 20:20

Re: Soured the handbrake cable.

ZOREVESTNIK » September 18, 2010, 20:27

Re: Soured the handbrake cable.

Andrey309 » Sep 19, 2010, 10:14 pm

Re: Soured the handbrake cable.

» Apr 03, 2011 07:27 pm

Re: Soured the handbrake cable.

Morfius » May 15, 2011, 6:44 pm

One of my right handbrake cables has gone sour. Doesn't come back. That's what I think. I once took a long ride with the handbrake until the brake pads smelled. Probably the tension springs of the pads have lost their springing properties. Plus a lever that moves the pads apart. Plus the torso is sour.

Added after 4 minutes 32 seconds:

Re: Soured the handbrake cable.

ZOREVESTNIK » May 15, 2011, 20:10

Re: Soured the handbrake cable.

Morfius » June 13, 2011, 11:00

Morfius wrote: One of my right handbrake cables has gone sour. Doesn't come back. That's what I think. I once took a long ride with the handbrake until the brake pads smelled. Probably the tension springs of the pads have lost their springing properties. Plus a lever that moves the pads apart. Plus the torso is sour.

Added after 4 minutes 32 seconds:

Re: Soured the handbrake cable.

Mechanic » June 13, 2011, 07:24 pm

To prevent such a disaster, it is useful to treat the brake mechanisms with the following remedy:

Re: Soured the handbrake cable.

by Andrio » Sep 15, 2011 4:37 pm

Re: Soured the handbrake cable.

Max » 15 Sep 2011, 17:02

Re: Soured the handbrake cable.

Wolk » 15 Sep 2011, 18:38

Re: Soured the handbrake cable.

Wenik » December 17, 2011, 05:27 pm

Mechanic wrote: Re: Soured the handbrake cable. Mechanic » June 13, 2011, 8:24 pm

To prevent such a disaster, it is useful to treat the brake mechanisms with the following remedy:

Re: Soured the handbrake cable.

Kruger » 11 Feb 2013, 21:20

I changed the left cable in the fall. It turned out to be quite simple. And it took about 1 hour. Initially, you remove the central tunnel along with the armrest, there are several screws and clips. (It’s easier to look in the repair book.. there are plenty of them on the Internet.) I don’t remember the exact sequence.. But something like this: At the feet of the passenger and driver there are plastic covers, you pull them towards you on clips, where you unscrew a pair of screws. Then you lift the leather cover of the gearbox and remove the plug from the handbrake. Then we pull the entire cover at the lever back and up; it is on the latches behind and under the ashtray. Disconnect the wires from the cigarette lighter, USB and socket. Then we unscrew a couple of screws at the gearbox lever. Unscrew a couple of bolts in the armrest. after that we pull the entire tunnel towards ourselves and remove it. After this, remove the cable from the wheel, unscrew the cable fastening to the bottom of the car and take it out.. Reassemble in the reverse order.

Like so. I've already climbed there three times. First, while I was waiting for the cable, I removed the old one. Then, when moving backwards, the pads began to jam. I had to take them off too.

How to lubricate the parking brake cable?

Because You are not logged in. To come in.

Because you are not a trust user. How to become a trustee.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Advertisements on NN.RU - Auto

Manufacturing of a broken-type platform with retractable ramps on the GAZ-33023 Gazelle-farmer chassis. Technical characteristics of the tow truck.

Wide selection of hydraulic pumps and hydraulic motors of all series. Axial piston hydraulic motor. Splined shaft, reverse rotation. Analogs - (many. Price: 1,000 rub.

A wide selection of hydraulic pumps and hydraulic motors of all series: spline hydraulic pump of right rotation. It is used in road construction and... Price: 1,000 rub.

The broken-type towing platform produced in our company has a highly reliable design, which is confirmed by many years of use.