Finding the cause of pedal failure

The most common reason, which accounts for up to 70% of cases of brake pedal failure while the engine is running, is airing of the system, that is, atmospheric air entering the pipelines and lines through which the brake fluid moves. This, in turn, may be caused by the following factors:

In addition, pedal failure is often associated with a rupture of the vacuum booster diaphragm. This type of malfunction is easy to diagnose - it only appears when the internal combustion engine is running, and the brake fluid level does not change while the pedal is depressed. This is explained by the fact that a torn diaphragm is not able to create the required vacuum in the amplifier chamber even with full pedal travel.

If the pedal does not fall completely, but moves jerkily, going through some areas easily, and others with considerable effort, we can conclude that the pads or caliper are not installed correctly or are poorly secured. However, do not forget that the first two to three hundred kilometers after their installation may also be due to the natural break-in of parts.

Causes of a hard brake pedal

If the brake pedal is either soft or hard, or the pressure is too tight, there are also several possibilities for the problem. The main reasons here include:

- clogging of the air filter of the vacuum booster. Basically, here you need to replace the filter itself;

- increased sizes of sealing rings in wheel cylinders.

Typically, in this case, the pedal became hard after changing the brake fluid.

You should not use low-quality death; it is better to buy the liquid recommended by the manufacturer. As a result, such a problem will not occur; - presence of mechanical damage on the diaphragm. The element should also be replaced;

- problems with the functioning of the tip in the amplifier. It is necessary to replace it with a working part;

- check valve stuck. These components cannot be repaired, so they should be replaced;

- Vacuum booster valve sticking. You just need to replace this element;

- presence on the hose between the intake manifold and the deformation amplifier or loosening of the fastening. First, try tightening the fastening clamp. If this does not help, you need to change the hose.

We discussed why a soft or hard brake pedal effect occurs. Regardless of the cause of this problem, malfunctions of the braking system are quite serious, so you should take a very responsible approach to diagnosis and repair. If you cannot fix the problem yourself, you should immediately contact a professional - in no case is it recommended to get behind the wheel of a car in which the brakes do not work correctly.

Solution

If your car has such a breakdown, the main thing is to solve it comprehensively. It happens that malfunctions are associated with several reasons at once. If the problem is that the pedal is simply rusty, it needs to be replaced. It is easy to correct the situation by replacing the brake fluid with a higher quality one. By the way, you will have to update the fluid in any case - in order to “update” the entire system. Otherwise, over time, the pedal will definitely begin to fail when pressed.

If cracks appear in the pumps, the brake may also begin to fail. Moreover, even microdamages can be the cause of such a breakdown. So if you want the brake to function and not fail in the middle of the road, you will have to replace everything that has stopped working. It turned out to be enough for me to make one replacement. At this point, the question of why the brake pedal failed was closed. To be convinced, it was enough to just start the engine. No extraneous sounds. And if before the return after pressing was too slow, now everything works perfectly.

The brake failed at full speed: what to do?

First, try pressing the pedal sharply several times: perhaps its functionality will be partially restored. Next, assess the situation and identify a place where you can gradually turn. Then tighten the handbrake (don't do it too hard) and start shifting (if you have a manual transmission) to a lower gear. At the same time, when the lever is in “neutral”, press the accelerator (perform “re-throw”) to “prepare” the gearbox gears for emergency operation. As a last resort, choose the lesser of two “evils” - it is better to run into some obstacle near the road (roadside bushes are a good option) than to collide with a car.

The master brake cylinder has failed

The main brake cylinder, if you remove the valve system and the division into circuits, operates on the principle of a conventional hydraulic drive. Almost like a syringe. We press on the rod - the piston pushes the liquid and supplies it under pressure into the system. If the piston cuffs are worn out, fluid will leak into the cavity behind it. And this will lead to a sinking pedal and almost no brakes. In this case, the liquid in the tank will remain in place.

There is only one way out of this situation: repair or replacement of the brake cylinder. Repairing this element of the system is now very rarely practiced and is not available for all cars. In addition, the repair kits from the cuff set do not always solve the problem. Sometimes the surface of the cylinder is damaged by corrosion, which eliminates the possibility of repair.

Brake system design

Before you begin to consider the problem, you need to understand the basics of the design and operation of the braking system. Most modern cars are equipped with drum and/or disc brakes with a hydraulic drive, which consists of:

- brake pedal - a control body that transmits the driver’s command to the system;

- vacuum booster - necessary to increase braking efficiency by increasing the pressure in the system;

- master brake cylinder – ensures separation of brake circuits and direction of forces to each wheel;

- working wheel cylinders - act directly on mechanical elements (caliper or expansion fist), providing wheel braking;

- pipelines and highways - connect all elements together and serve as guides for the movement of brake fluid.

The role of the working body directly responsible for braking is the pads acting on the brake disc or drum.

Causes

VAZ 2109 brake malfunction

Causes of malfunctions:

- For some reason, brake fluid leaks from the cylinders.

Note: Low brake fluid can be the cause of many vehicle problems. Therefore, you need to regularly ensure that it is in sufficient quantities.

- The brake pedal does not move well. In this case, when you press it, the brake setting does not reach the wheels in the optimal time, so there is a delay in the brake.

- Air in the brake system. In this case, air can get here in various ways (perhaps the car was recently repaired, and the mechanic did not keep track of something, or missed a valve).

Brake pedal doesn't work

VAZ 2109 does not brake the rear wheel

In this case, the pedal does not necessarily not work at all. It works, but not correctly. That is, when you press it, the load is slightly increased. And even if the driver does not press the pedal hard, the braking is too noticeable. In this case, the car brakes “abruptly”: at first it goes quickly forward, and then returns back. You can fix this problem like this:

- First, change the parts of the cylinders that are no longer working at full strength.

- The brake pads need to be thoroughly washed and dried (if they are too coated with oil, they will not function properly).

- You need to check the brake system for air in it. If it is still there, then it must be removed immediately.

Note: The air in the brake system is the same as the air in the human body. And when it reaches the periphery point, the body (car) will stop working correctly.

- Replace rings and hoses, and then bleed the system.

How to bleed brakes on VAZ cars

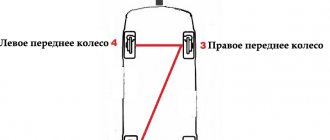

This is a procedure performed after repairs, replacement of individual system elements, or when replacing fluid. Pumping needs to be done by two people. But first, check the car's operating instructions, which should indicate the order of actions with the wheels. If there is no such point, start pumping from the rear right and left, then do the same with the front ones. You will also need to prepare:

- a thin hose or plastic tube with a diameter suitable for the bleeder fitting;

- a suitable small transparent container 0.5-1 l;

- key for unscrewing the fitting.

Next, place the car on an inspection hole so that you can get to each wheel from the inside. Have an assistant sit behind the wheel. Further actions:

- Fill the brake fluid reservoir to the maximum level.

- Clean the fitting, put a spanner on it and insert a tube, one end of which is lowered into a container containing brake fluid.

- Have an assistant press the pedal several times and keep it pressed.

- Unscrew the fitting and, holding it with a key, watch the nature of the liquid pouring out. If there are bubbles, tighten the fitting and instruct an assistant to repeat the operation.

- Pumping should be carried out until bubbles stop coming out.

How to bleed the brakes without an assistant is shown in the video below.

If air comes out despite repeating the procedure many times, the reason should be sought in depressurization of the system.

Brake fluid leak

You can find out where the brake fluid goes only by visually inspecting the brake valves, front calipers, and rear cylinders. The presence of drips will indicate a leak. If the fluid leaves, but no traces of it are visually visible, most likely the master brake cylinder is to blame, which allows fluid to pass into the vacuum brake booster chamber. This problem also does not arise instantly and before reaching a critical point, when the pedal goes to the floor and the brakes do not work, it will lose elasticity for some time until air enters the system.