The knock sensor on the 16-valve VAZ-2112 has the same causes of malfunction as some GAZ, Toyota, Gazelle, Priora and Kalina cars. Of course, not every motorist will be able to determine that this is exactly the sensor, but you can consider the direct and indirect causes of the malfunction.

The video provides an overview of the main faults and diagnostics of the wide-band knock sensor on the VAZ-2112:

Purpose of the knock sensor

The knock sensor transmits a signal to the on-board computer indicating the frequency and intensity of detonation that occurs during engine operation.

The operation of all vehicle systems is constantly monitored by an on-board computer that receives information from sensors. A malfunction of one of them can become a serious problem that interferes with the normal operation of the vehicle.

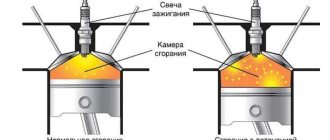

During normal engine operation, the knock sensor does not transmit any data to the control unit. But when detonation occurs during engine operation, the sensor transmits a certain signal to the computer, indicating its frequency and intensity. Next, the control unit goes into an operating mode that helps get rid of engine detonation - it sends a signal to change the composition of the fuel mixture and adjusts the ignition timing. After bringing the engine operation back to normal, the sensor “falls asleep” again until the next time.

It is on the basis of the values received from the sensor that the on-board computer adjusts the engine operating parameters, and if the knock sensor turns out to be faulty, then it is often not possible to normalize the operation of the engine.

Where is the knock sensor on the VAZ 2115?

The task of the DD is to record the states of fuel detonation during combustion. The device then transmits this data to the electronic control unit (ECU), which subsequently adjusts the ignition timing. If the DD is faulty, the ECU receives invalid data. Or there is no information at all. Consequently, the detonation process is not extinguished.

The knock sensor is located between the second and third cylinders on the engine block. In a VAZ 2115 with an 8-valve engine, the part is located quite conveniently, but in 16-valve cars, the arrangement of the engine compartment (in which there is some clutter of units) makes access to the sensor much more difficult. Therefore, finding it and removing it, for example, for diagnostics or replacement, can be difficult.

Operating principle of the sensor

Its design is simple - the sensor is based on a plate with a piezoelectric effect. When there is a mechanical impact on it (impact, as happens when a motor detonates), the plate begins to generate electricity. And the stronger the impact, the more current the sensor will transmit to the engine control system. The magnitude of the current corresponds to a certain level of detonation, and based on these readings, the computer executes an embedded algorithm aimed at eliminating its causes.

A knock sensor error is a consequence of the computer receiving incorrect data, resulting in instability in engine operation.

As statistics show, such a malfunction most often occurs with domestically produced cars - quite often the problem with DD is observed on a VAZ 2112 with a 16-valve engine - for this reason, car owners are recommended to always have a spare VAZ knock sensor on hand, since its cost is within 200- 300 rubles. Foreign cars, in most cases, are equipped with sensors whose service life exceeds the service life of the car itself.

Checking and replacing the knock sensor of the VAZ 2110

You can check and replace the knock sensor on a VAZ 2110 in just a few minutes. To do this, it is enough to have a multimeter on hand. Checking, and possibly replacement, is performed according to the following algorithm:

- Unscrew the sensor fixing bolt, disconnect the terminal block and remove the sensor from the engine.

- We switch the tester to voltage measurement mode within 200 mV.

- We place one probe on the minus of the sensor, the second on the free connector.

- Now gently tap the body with the handle of a screwdriver and look at the tester display. With each impact, the readings will change; the stronger the impact, the higher the impulse should be.

- It remains to check the integrity of the piezoelectric element. To do this, put the tester in ohmmeter mode and measure the resistance between the terminals. The nominal resistance of a healthy sensor is 9-10 mOhm. If the ohmmeter is silent or shows less resistance, the sensor must be replaced.

We install a new or tested knock sensor in the reverse order.

Causes of detonation

Gasoline with a low octane number or a large amount of impurities negatively affects engine performance and can cause detonation.

Knowing the signs of a malfunctioning knock sensor means taking timely measures to eliminate the problem, significantly reducing the likelihood of the need for costly repairs. This sensor is a mandatory element of the electronic systems of all modern cars that use gasoline as fuel. An inexperienced driver cannot always determine what is causing the malfunction, although the malfunction that occurs is often accompanied by fairly obvious signs.

Reasons for the error

The cause of error code P0327 may be:

- failure of the sensor itself (quite rare);

- contact failure in the electrical circuit;

- malfunction of the sensor wiring as a result of a short circuit, breakdown or break;

- incorrect installation of the sensor itself;

- malfunction of the electronic control unit.

The problem can occur on any gasoline vehicles equipped with an electronic control unit and a knock sensor, respectively.

Purpose of the knock sensor

The operation of all vehicle systems is constantly monitored by an on-board computer that receives information from sensors. A malfunction of one of them can become a serious problem that interferes with the normal operation of the vehicle.

During normal engine operation, the knock sensor does not transmit any data to the control unit. But when detonation occurs during engine operation, the sensor transmits a certain signal to the computer, indicating its frequency and intensity. Next, the control unit goes into an operating mode that helps get rid of engine detonation - it sends a signal to change the composition of the fuel mixture and adjusts the ignition timing. After bringing the engine operation back to normal, the sensor “falls asleep” again until the next time.

It is on the basis of the values received from the sensor that the on-board computer adjusts the engine operating parameters, and if the knock sensor turns out to be faulty, then it is often not possible to normalize the operation of the engine.

Where is the knock sensor of the VAZ 2114

It is located between the second and third cylinders on the engine block (if viewed from the radiator side). Its location from the point of view of providing simple, unobstructed access is conveniently implemented in eight valve engines. But in more complex engines (16 valves), some inconvenience appears. This is due to the high density and accumulation of units in the engine compartment.

Most common faults

In fact, cases of failure of the detonation detection device itself are not so common. In most cases, the reasons for incorrect operation are auxiliary factors, such as: - damage to the wires connecting the control unit to the sensor. As a result, the unit does not read signals from the device; — contamination of the metal part of the part; — corrosion (as a result of environmental influences); — chafing breaks and wires; - oxidation of one or both contacts. Less commonly, there is a complete failure of the internal piezo element (plate) of the device. In most cases, the sensor cannot be repaired, and the repair itself is not entirely rational in terms of effort, time and money. The surest way is to buy a new product; fortunately, it is not expensive.

Operating principle of the sensor

Its design is simple - the sensor is based on a plate with a piezoelectric effect. When there is a mechanical impact on it (impact, as happens when a motor detonates), the plate begins to generate electricity. And the stronger the impact, the more current the sensor will transmit to the engine control system. The magnitude of the current corresponds to a certain level of detonation, and based on these readings, the computer executes an embedded algorithm aimed at eliminating its causes.

A knock sensor error is a consequence of the computer receiving incorrect data, resulting in instability in engine operation.

Video replacement of the knock sensor on a VAZ and checking its functionality

As statistics show, such a malfunction most often occurs with domestically produced cars - quite often the problem with DD is observed on a VAZ 2112 with a 16-valve engine - for this reason, car owners are recommended to always have a spare VAZ knock sensor on hand, since its cost is within 200- 300 rubles. Foreign cars, in most cases, are equipped with sensors whose service life exceeds the service life of the car itself.

Where is

The knock sensor on the VAZ 2114 is located on the cylinder block in the middle between the second and third cylinders. This location was not chosen by chance, since most of the detonations occur in cylinders 2 and 3, because they are subject to greater temperature loads than the outer ones.

The DD is attached to a stud or a bolt (in different ICE models the sensor is mounted differently) to the BC.

Causes of detonation

Unstable engine operation is a consequence of many malfunctions:

- low quality fuel. Gasoline with a low octane number or a large amount of impurities also negatively affects engine performance;

- malfunction of the gas distribution mechanism. “Hanging” valves prevent the free exit of exhaust gases, resulting in detonation;

- ignition system malfunction. There may be several options, ranging from a stretched timing belt to low-quality spark plugs;

- problems that have arisen in the piston group. A large amount of carbon deposits accumulating on the pistons and valves of the combustion chamber also leads to a significant decrease in engine power and its unstable operation;

- clogged air filter. Obstruction of air movement leads to the formation of a mixture supersaturated with gasoline, which also leads to increased fuel consumption.

Signs of an error

The error manifests itself when the engine is warm - in order for fuel detonation to occur, the fuel must be warmed up and able to detonate. Problems with the sensor lead to deterioration in vehicle behavior:

- dynamic characteristics deteriorate;

- fuel consumption increases;

- the engine is unstable at idle;

- dips in engine speed appear.

The reason for the deterioration in performance is a command from the electronic control unit to switch to emergency engine operation when the signal from the knock sensor is low. The ECU specifically limits the engine's capabilities to avoid burning out valves and pistons as a result of excessive detonation. On some vehicles, emergency operation may limit the maximum speed to 3-5 thousand rpm and the maximum speed to 50 km/h.

How to change a knock sensor

The knock sensor for VAZ 2110, 2112 and 21214 with a fuel injection system is located in the front of the engine. If the engine has 8 valves, then the sensor is installed in the area of cylinder 4, if there are 16 valves, then between cylinders 2 and 3. On Grant, Priora and Kalina cars it is also located on the engine block between the cylinders.

Replacing it will take no more than 10-15 minutes:

- Unscrew the bolt holding it to the engine block.

- Disconnect the sensor from the terminal block. Remove the sensor and replace it with a working one.

- When installing a new sensor, carefully tighten the mounting bolt - unstable contact with the engine body will lead to errors in the operation of the motor.

conclusions

It is quite easy to determine the malfunction of the VAZ-2112 16 valve knock sensor. The first sign will be the presence of errors in the electronic engine control unit and the “Check Engine” light on the instrument panel. Next, a simple check with a multimeter will show whether this particular product has actually failed or not. If the sensor is faulty, it must be replaced.

1) Hello guys, car VAZ 21099 injector has this problem: It doesn’t give me any peace anymore. The knock sensor has changed about 15 of them and every other day it gets stuck. On board there is an open circuit in the knock sensor. The wiring is fine, that's what the electrician told me. Help me figure it out Question from id69484279 Question from: @ id69484279 Separate topic: 2) Guys, help the VAZ 14ka, the check is flashing and the engine starts to misfire, what is the reason? Question from: @id214249623 Separate topic: Write the number of the question you are answering! To the authors of questions: be sure to write in the comments how you solved your problem! Open circuit of the knock sensor of the VAZ 2110.

Similar articles

Checking the functionality of the sensor

Do not rush to throw away the old sensor - first you should check its functionality. Often the problem lies in faulty wiring, in which case replacing the sensor will not help.

To test the knock sensor, you should connect it to a multimeter, setting the latter to test DC current. When hitting the sensor, the multimeter should show a voltage of about 15–30 mV. The more intensely you hit it, the more voltage it should generate. If the multimeter shows nothing when hitting the sensor, then it definitely needs to be replaced.

If you notice even a slight manifestation of a sensor malfunction, it is necessary to diagnose the vehicle. But often, when a single error occurs, the malfunction icon on the dashboard is constantly lit, although there are no other signs of a sensor malfunction - in this case, it is enough to reset the computer errors.

Priora knock sensor

Sensor check

Checking the DD is carried out using diagnostic tools or using a multimeter. A multimeter, also known as a tester, allows you to check a large number of automotive sensors by measuring resistance and voltage. Checking the DD consists of measuring the voltage at the sensor output.

Since the sensor operates on the principle of a piezoelectric element, therefore, when it is struck, it must generate voltage.

Let's start checking

- Remove the knock sensor;

- On the tester we set the constant voltage measurement parameter to a limit of 20 Volts;

- We connect the tester probes to the sensor connector;

- Then, using a metal tool (for example, a screwdriver), we hit the metal part of the sensor. An N-quantity voltage of 1V and higher should appear on the device screen for some time.

If the device does not display voltage when the sensor is struck, then the DD is in a faulty state and must be replaced.

Priora knock sensor

A knock sensor is a device that detects the knock levels of internal combustion engine processes. The installation location of such a device is the cylinder block. Maintaining it makes it possible to obtain high power, as well as achieve good fuel economy without causing damage to the engine.

The detonation process is the main defect of an internal combustion engine, since the force is considerable and it is impossible to ignore it. Among several different devices that are used as performance optimizations, the knock sensor is used to prevent knocking fuel combustions. Fuel detonation can be controlled thanks to the main indicator - the manifestation of high-pitched and ringing metallic sounds, which, according to indicators, are sometimes mistaken for the clicking sounds of the cylinder-piston group. If the process is strong enough, with faulty knock prevention systems the engine begins to fail.

Detonation device on Priora

The knock sensor on the Priora is made in the shape of a circle, it has a hole for connecting wires. Inside it, in a special place, there are certain threads that, when detonation occurs, begin to emit impulses. The threads are made of a thin and rather soft alloy, and even though they are protected by a certain substance, it is under no circumstances recommended to throw the sensor forcefully onto the floor.

Detonation device on Priora

Where is

To improve the sensitivity of the knock sensor, it was installed on the Priora engine block. It is attached to a special ledge, as well as a platform, which is located near the second cylinder. This is where the noise from the detonation process is strongest. This place is located on the radiator side, just below the engine itself.

If the Priora is equipped with such technologies, in particular as power steering, air conditioning and many others, then access to them will be a little complicated, but still possible. Simply put, it is accessible from the front bumper of the car.

knock sensor location

Symptoms of a problem

The main malfunctions in the car's knock control system are:

- The device has failed.

- The wire to it broke.

- The device connector is broken.

In all these cases, eliminating all these troubles is an easy task. The main thing is to be able to identify them correctly. In any case, when working with a car with an ECM, diagnosing problems is a rather complex and important area of repair. Fixing the first two problems will require having the following kit on hand:

- Multimeter tester.

- Indicator light.

- Wires.

- Insulating tape.

- Wire cutters or knives.

Then connect the multimeter to the 2 holes of the connector and turn on the ignition. If everything is fine with the circuit, the tester will indicate a voltage of up to 5 Volts. And if nothing happened to the indicators, then the circuit may have broken and needs to be found. You need to disconnect the connector from the ECU and examine both circuits. Find the break and fix it using wires and electrical tape. If the tester shows a working circuit, then the problem is with the sensor.

Knock sensor error

If a network break occurs, this error appears under code 0325. In many cases, the cause of the error is oxidized contacts. But the problem may also not be in the sensor or even in the wiring: so check the timing belt, maybe it has slipped a couple of teeth - check the marks.

Purpose and location of the knock sensor

A knock sensor (DS) is a device that is installed on the outside of the cylinder block wall to monitor the appearance of abnormal vibrations caused by detonation in the engine, that is, explosive self-ignition in the combustion chamber of the working mixture. The DD produces an alternating current signal, the voltage amplitude and frequency of which depend on the vibration parameters of the cylinder block.

Photo of Priora knock sensor

Each level of intensity and frequency of oscillations of the engine walls corresponds to its own signal. The engine control controller constantly analyzes the data received from the engine. When detonation occurs in the cylinders, the amplitude of vibrations of the corresponding frequency increases, and the DD generates a signal, after processing which the controller adjusts the ignition timing, making it later, which leads to the suppression of detonation of the working mixture.

When is the DD changed on Priora?

The DD is removed for inspection or replacement if signs of its malfunction appear or if it is diagnosed at an engine operation test bench. The sensor cannot be repaired, and if it breaks, it must be replaced. When the DD or the electrical circuit from it to the controller fails, the latter (control unit) signals this to the driver by turning on a warning lamp on the instrument panel.

Photo of removing the knock sensor

At the same time, the controller switches to another engine control mode, called reserve, in which the ignition timing is constantly at a late angle. This mode is characterized by increased fuel consumption and lower engine power.

The error code indicating a breakdown of the Priora DD is 0327.

In the photo there is a breakdown of the knock sensor

The appearance of this error is the main reason why the sensor is changed. However, in some cases, the DD may be only partially faulty, that is, it will work, but incorrectly. In this case, the warning lamp will not light up, no error will be displayed, but the engine will begin to detonate in certain modes. However, there can be many reasons for such motor operation, and if a malfunction of the motor is suspected, it is removed for inspection.

Symptoms of a knock sensor failure

Failure of an element is accompanied by the following symptoms:

- Jerking of the engine, which makes it seem as if the whole car is jerking.

- Engine power has decreased significantly.

- Fuel consumption began to increase.

- The engine temperature increases (data about this is reflected on the dashboard).

- The engine heats up very quickly, as evidenced by the data on the panel.

- There is a smell of gasoline in the cabin, but no signs of leaks were found.

- The on-board computer shows the following error codes: 0325, 0326, 0327.

Although sometimes these same symptoms can be caused by other malfunctions, most often the presence of several of them at the same time indicates a breakdown of the DD.

It is worth considering that problems in the operation of the sensor are not always caused directly by its malfunction. The cause of failures can be a break in the wires that connect the motor control unit and the ECU, corrosion, or even simple contamination of the part. All these nuances can be found out by examining the sensor and its surrounding elements.

How to remove and check the sensor?

Access from above to the Priora DD is difficult due to the intake module located above it. The easiest way to get to the sensor is from below, first removing the engine protection or at least unscrewing and folding its front part. When working from above, you will have to do everything by touch. In any case, before starting work, it is necessary to disconnect the ground wire attached to the “negative” terminal from the battery.

To remove the crankcase protection, you need to:

- unscrew 5 nuts with a 10mm head;

- unscrew the 2 19 nuts installed on the back of the shield;

- remove protection.

- by pressing the metal latch of the DD connector, disconnect the block of wires going to the controller;

- using a 13mm wrench, loosen the bolt securing the sensor;

- Unscrew the bolt and remove it from the threaded hole, removing the sensor.

Photo of dismantling the knock sensor

- We connect a multimeter to the DD terminals. We set the device to voltmeter mode, choosing a measurement limit of up to 200 mV.

- We take a metal object - pliers or a bolt - and lightly tap it on the DD.

When you tap on a working sensor, the voltmeter will show voltage surges. A faulty DD will not react in any way. A more accurate diagnosis of a removed sensor can only be done using a special stand.

In the photo - diagnostics of the knock sensor

Installation of a new DD is carried out in the reverse order of dismantling. Experts recommend installing a similar Bosch instead of the “native” one. Before going to the store for a new sensor, you should write down the markings of the removed sensor. The bolt securing it to 13 must be tightened with a slight force - 10.4–24.2 Nm (1.1–2.5 kgf). Tightening too tightly will affect the operation of the sensor.

Replacing the knock sensor VAZ 2112 16 valves

- Deviations from the optimal ignition timing parameters are as follows:

- A late ignition timing is fraught with deterioration in vehicle dynamics, engine overheating and increased fuel consumption;

- An early ignition timing angle, in turn, manifests itself in the form of microexplosions in the combustion chamber (detonation), which entails a drop in power and increased valve wear (valve burnout).

- To remove the two-pin sensor, disconnect the electrical connector with the ignition off (for clarity, we perform the operation on a dismantled engine).

- Using a 13" wrench, unscrew the sensor mounting nut...

- ...and remove the washer and sensor from the stud.

- To remove the single-pin knock sensor, disconnect the electrical connector.

- Use a 22" wrench to unscrew the sensor...

- To check the sensor, we connect a tester to its contact and body.

By lightly tapping the threaded part of the sensor with a soft metal mandrel, we measure the voltage pulse. Depending on the intensity of the shock, the voltage pulse of a working sensor varies within 40–200 mV.

- Install the sensor in reverse order.

- Tightening torque 20–25 N•m.

- Signs of a malfunctioning idle speed sensor follow the link.

How to check

How to check the knock sensor

Prepare the end face at “13” or “22” (depending on the type of sensor). Multimeter or voltmeter.

- Screwdriver.

- Remove the sensor from the engine block.

- Turn on the voltmeter or multimeter in operating mode with a limit of 200 mV.

- Connect the multimeter electrodes to the knock sensor terminals, then use a screwdriver to tap the part body.

While tapping, observe the changes on the device display; depending on the strength of the blows and frequency, the voltmeter readings should change. If your knock sensor readings do not change, it is faulty and needs to be replaced.

Removal and installation of the knock sensor VAZ 2110, VAZ 2111, VAZ 2112, Lada Ten

Two types of sensors can be installed on VAZ 2111 engines: single-contact and two-contact.

To check the sensor, we connect a tester to its contact and body.

- Install the sensor in reverse order.

- Tightening torque 20–25 N•m.

- A single-contact knock sensor is screwed into the upper part of the VAZ 2110 cylinder block, a two-contact sensor is mounted on a stud.

The operation of the sensor is based on the piezoelectric effect: when a piezoelectric plate is compressed, a potential difference occurs at its ends. When detonation occurs, voltage pulses are generated in the sensor, by which the controller regulates the ignition timing of the VAZ 2110.

Knock sensor VAZ 2110 - check and change if necessary

One of the important factors for stable operation of a car engine is the optimal selection of ignition overtaking angle indicators. In cases where this angle is too late, the engine heats up greatly and fuel consumption increases.

If it is early, there is a danger of valve burnout, engine power decreases, and detonation occurs.

To avoid such situations, special control systems are installed on modern vehicles, the task of which is to maintain the specified angle at maximum intervals, but only in such a way that they do not fall into the detonation zone. And their proper functioning depends precisely on the sensor we are considering in this article.

Before detonation begins, it sends a signal to the control system, which, based on it, adjusts the ignition characteristic. In other words, the sensor eliminates the possibility of detonation, since its message allows the electronic unit to adjust the ignition timing in fully automatic mode.

Checking the functionality of the sensor

The self-diagnosis system of the VAZ 2110, when the described device fails, displays error signal 34. It tells the driver that the sensor needs to be replaced.

You will have to install a new mechanism after such a message in any case. But sometimes he can work for a while longer.

In order to find out how quickly (immediately or a little later) you need to change the element, you can follow these steps:

- reset the indicators generated by the self-diagnosis system;

- then travel 2–4 kilometers by car;

- restart the self-diagnosis system.

A completely non-functioning sensor is indicated by the appearance of the same error 34. If the message does not repeat, it is allowed to operate the device for some time. But remember that you need to replace it as quickly as possible.

If the car does not have an ECU, the following phenomena may be symptoms of a breakdown of the VAZ 2110 knock sensor:

- poor acceleration dynamics of the vehicle;

- “triple” of the engine at idle;

- the appearance of the “CHECK” indicator on the dashboard at the beginning of a trip or when accelerating the car.

What is a knock sensor and why is it needed?

This part is found in cars that use gasoline as fuel. It is intended for injection types of engines. The sensor is located on the engine cylinder block. This is an important part of the control system, the main purpose of which is to control the level of detonation.

There is a similar article on this topic - What is engine chip tuning, pros and cons.

In answering the question of what the knock sensor is responsible for, it should be noted that thanks to it the following vehicle capabilities are realized:

- Fuel economy.

- The ability of the engine to develop maximum power.

Detonation is the electrical impulse created during ignition. It is thanks to detonation that the car starts, complex chemical and physical processes occur inside the engine, and the fuel ignites.

The sensor monitors the vehicle's starting system and regulates its proper operation.

What are the main components of a knock sensor?

The main details of this mechanism are:

- Vibrating plate.

- Piezo type electrical element.

- Signal wire.

- Braid.

How to check the knock sensor?

Unfortunately, the knock sensor can also fail. In this case, a person without special knowledge will be able to notice this only by the lit indicator. No other obvious signs will be noticed. The car will continue to operate in the same mode and start without any signs of breakdown.

At this point, it is necessary to remember that this device is not mechanical, it is part of an electronic system, and therefore the breakdown is considered electronic.

A knock sensor malfunction can happen for a number of different reasons, including:

- There has been a breakdown inside the sensor itself.

- Closure.

- The signal wire or braided shield is broken.

- Damage to the engine control unit.

Thus, it will not be difficult to identify the breakdown. In order to determine it, it is necessary to conduct a test.

The easiest way to check is to go to a car service center. There, experienced craftsmen will open the engine protection and identify the breakdown in just an hour.

But those who are not looking for easy ways can always carry out this simple process on their own. Self-checking occurs according to the following scheme:

- First, we remove the protection in the garage. You will have to work directly with the engine block.

- Now we rule out a break in the signal wire and shielding braid. If it is torn or the braid is torn, you need to check the fastening of the plug and socket of the sensor. The integrity of the braid must be checked.

- If a break is excluded, the outlet itself is assessed. It is possible that its connection is faulty and requires replacement.

- You can detect faults in the device itself using a voltmeter. In this case, the car must be started and idling.

- You also need to check the condition of the device contacts.

You can check it yourself in a slightly different way. For this you need a multimeter. This device is very often found among car enthusiasts.

A multimeter is a combination device that combines the functions of an ohmmeter, ammeter and voltmeter. You can use either a mechanical or an electronic device.

Checking the knock sensor with a multimeter is carried out only after it is removed from the engine. When checking, they knock on it with something metal. This method is the simplest.

Knock sensor VAZ 2112

Where is the DD located: on the cylinder block stud, on the front side. To ensure access for the purpose of prevention (replacement), it is necessary to first dismantle the metal protection.

Knock sensor for VAZ 2112: location, what it is responsible for, price, part numbers

| DD "Auto-Trade" 170255 | From 270 |

| "Omega" 171098 | From 270 |

| "AURORA" 104816 | From 270 |

| "Auto-Electrika" 160010 | From 300 |

| "GEOTECH" 119378 | From 300 |

| "Kaluga" original 26650 | From 300 |

| "Valex" 116283 (8 valves) | From 250 |

| Fenox (VAZ 2112 16 valves) 538865 | From 250 |

Common causes of detonation

- Low octane fuel mixture;

- Specificity of the engine design, combustion chamber volume, number of cylinders;

- Atypical operating conditions of the technical equipment;

- Rich or lean fuel mixture;

- Incorrectly set ignition timing;

- There is a large accumulation of soot on the inner walls;

- Increased heat transfer level.

Operating principle of DD

The functionality is based on the operation of a piezoelectric element. A piezoelectric plate is mounted inside the DD structure. When detonation occurs, tension is created on the plate. The voltage is not great, but quite enough to create oscillations.

The higher the frequency, the higher the voltage. When fluctuations exceed the maximum range, the electronic control unit automatically adjusts the angle of the ignition system towards a decrease. The ignition is advanced.

When the oscillatory movements disappear, the ignition angle is restored to its original position. Thus, maximum operating efficiency of the power unit is achieved under specific operating conditions.

Signs of DD malfunction

- The electronic engine control unit (ECU) on the dashboard displays errors: P2647, P9345, P1668, P2477.

- At idle speed the engine is unstable.

- When driving downhill, the engine reduces speed, requiring a shift to a lower range of gears. Although the climb is not long.

- Fuel consumption has skyrocketed without good reason.

- Difficulty starting the engine “hot” or “cold”;

- Unreasonable engine stops.

How to check the knock sensor and replace it yourself on a VAZ 2112

Notification of the presence of a system error on the dashboard does not guarantee 100% malfunction of the DD. Sometimes it is enough to limit yourself to preventive maintenance, purging, and the functionality of the equipment is restored.

In practice, few owners know or use this. Most often, they are replaced with a new one. This is not always rational from an economic point of view.

Sudden alarm activation occurs after washing the car, driving through puddles, or in rainy weather. Water penetrates inside the controller, the contacts close, and a power surge occurs from the circuit. The ECU regards this as a system error, giving a signal on the device in the form of P2647, P9345, P1668, P2477.

To ensure objectivity of the data, carry out comprehensive diagnostics using digital equipment. In “garage conditions”, use a device such as a multimeter. The sensor is available to most car enthusiasts.

If the device is not available, it can be purchased at any auto store, car market, or online catalogues.

Step-by-step diagnostics

- We install the machine on the inspection channel. As an alternative, we use a hydraulic lift;

- Open the hood to improve visibility;

- From under the bottom, unscrew the six screws that fasten the metal protection. We remove it from its seat;

- The DD is pre-installed under the exhaust manifold housing. Carefully pry up the block with the wires and disconnect the contact;

- We connect the multimeter terminals to the limit switches;

- We measure the actual resistance and compare the results obtained with the standards specified in the operating instructions;

- Based on the data obtained, we make a decision on the advisability of further use of the equipment.

Guide to replacing the knock sensor on a VAZ 2112

Required materials and tools:

- Open-end wrench set to “14”;

- Knob, knob extension;

- New DD;

- Additional lighting as needed.

Regulations:

- We install the machine on the inspection channel;

- Disconnect the power terminals from the battery;

- Unscrew and remove the metal protection from the oil pan;

- Disconnect the block with wires by carefully prying the terminals with a flat-tip screwdriver;

- Using a wrench, unscrew the locking nut and remove the DD from its seat;

- We replace equipment with new ones;

- We put on the block with wires;

- Screw on the metal protection.

- We assemble the structure in reverse order. Replacement is complete.

The average service life of a DD is unlimited, but in practice no more than 4 - 5 years. The duration of the resource depends on the conditions of use, climatic characteristics of the region, and frequency of operation.

Source: https://zapchasti.expert/datchiki/datchik-detonacii/datchik-detonacii-vaz-2112.html

Symptoms of sensor malfunction

You can determine whether the sensor is broken without a dashboard. But this will require experience and a special approach to your car. You need to know him very well. We list the signs by which you can understand that the device is broken, from here it will be immediately clear what the knock sensor affects:

- Fuel efficiency will drop. This may not be noticeable right away, but over time the driver will definitely notice it.

- Also, as the throttle increases, the engine detonates longer than usual. The knock sensor affects the acceleration of the car.

If you determine the breakdown yourself, then it’s not far to independently diagnose the sensor, as well as replace it yourself. In principle, this is not difficult, but it requires some understanding of the process.

Decarbonization of engine piston rings. - there is more useful information here.

If it requires replacement, then it is necessary to purchase a new device and install it as soon as possible. All car enthusiasts are primarily interested in the price of a new device. It is low and depends on the make of the car and on the country in which the part was manufactured.

Replacement can be done in several ways, the easiest way is to contact a specialist and pay money. On average, all this will cost 2000-3000 rubles.

You will be interested in this article - Flushing the injector, cleaning the injectors with your own hands.

You can carry out the replacement yourself when the engine has cooled down by disconnecting the negative terminal of the battery. It is necessary to achieve the most convenient access to the sensor so that it can be removed. The fact is that it also depends on the car model.

You can remove it with a 12 mm wrench; to do this you need to unscrew the bolt. Before you pull out the faulty device, unplug it. A new sensor is installed in the same place, and everything is repeated, but only in reverse order.

Thus, the knock sensor is a simple device, yet very useful for an electronic control system. It is not difficult to determine its malfunction; you can check it yourself, even in rural areas.

It will also be inexpensive to replace the sensor. It doesn’t matter whether this is done by a specialist or independently.

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

The knock sensor (DS) is designed to detect the occurrence of detonation in the cylinders of gasoline piston engines.

The piezoceramic element of the knock sensor, reacting to vibrations of the cylinder block, sends a signal to the controller.

The controller (ECM), in turn, processes this signal and, in the event of detonation, reduces the ignition timing. In this case, the ignition timing changes for each cylinder separately. This is due to the fact that the temperature of the cylinders, when arranged in a row, is different. The coldest is the first, the hotter is the fourth or last, then the second and the hottest is the third.

From the driver’s point of view, the presence of a detonation elimination system makes it possible, if necessary, to use low-octane gasoline (keep in mind, the controller will assume that you have A-95). Another advantage is maximum efficiency and excellent dynamic properties when using gas-cylinder equipment. Indeed, in this case, you can safely set the maximum acceptable ignition timing for starting, without the risk of running into “knock of fingers” (the popular name for the sound that occurs during detonation).

The sensor is mounted on the cylinder block (see photo).

1 — knock sensor on engines 21126, 11194

Knock sensor on engine 21214.

DD cost

The knock sensor is a part that, unfortunately, cannot be repaired. If it breaks, you just need to replace it with a new one. The device can be found in most stores with auto parts for VAZ. The average cost of a sensor is 300 rubles. Of course, there are parts that are much more expensive (around 1000 rubles), the price will depend on the manufacturer. However, many car owners note that high cost does not always guarantee reliability and quality. Therefore, there is no point in overpaying. It is better to choose models in the mid-price category. For example, these could be parts produced by the following (Kaluga), Pekar or KRAFT. Judging by the reviews, these domestic brands have proven themselves well, and their products last quite a long time.

In this article, we clearly demonstrated where the knock sensor is located on a VAZ 2115. We described the symptoms of failure of this sensor, and also showed how to check it yourself. If you have any questions, be sure to ask them in the comments.

Replacing the knock sensor

Removal

- To replace the knock sensor, first turn off the ignition.

- Then remove the wiring harness block by first pressing the latch.

- Unscrew the fastening bolt with a replaceable head x13 or an appropriate wrench (the head is preferable to prevent “licking the edges”).

Installation

Install the sensor in place so that the connection block is directed towards the free space.

Touching hot engine parts may damage the insulation of the wiring harness. Touching cold elements is a point of chafing due to the natural vibration of the engine in relation to the body.

Try to keep the block “looking” down in case of water ingress. Make sure the pad is clean and dry - the fastening bolt is wrapped in a block and thus connected to ground. Contact between the bolt and the pad through a layer of dirt that has been exposed to oil or water will lead to engine malfunctions.

The fastening bolt must be tightened using a torque wrench with a replaceable head of 13. The tightening torque is 15. 24 N.m. In this case, the correct tightening torque affects the sensitivity of the sensor to engine vibrations. Incorrect tightening leads to malfunction of the motor.

Replacing the knock sensor VAZ 2114

Usually, the work does not cause any problems or difficulties, and is easily carried out even by beginners. “It is worth knowing that depending on the type of engine (8 or 16 valve), the complexity of installation and dismantling may differ.” Therefore, for eight valve models, the most convenient way to dismantle the part is to be located on top of the engine. For sixteen valve versions, the entire procedure can be carried out from the bottom of the car (after removing the engine protection). This approach will greatly simplify the entire process.

So, after receiving a large block of theoretical information, we will proceed to practical exercises and thoroughly analyze the entire process of replacing (removing) the sensor.

Engine 8 valves To perform the work you will need a 13mm wrench or socket.

- We gain free access and unscrew the fastening nut.

- Then disconnect the contact wires from the device connector.

- We extract the part.

Reinstallation is carried out in the opposite sequence. Everything is quite simple.

Engine 16 valves We use the same tools as in the first case. The only addition is the need to remove the internal combustion engine protection and ensure a convenient position and access under the bottom of the car. To do this, you can place the car on an overpass or repair pit. The removal and installation process is similar to the first example.

Useful tips

Recently, cases of selling defective spare parts and sensors without the necessary internal contents have become more frequent. Therefore, immediately after purchasing the product you need, it is recommended to check its performance with a multimeter. You should know that on older VAZ 2114 models the knock sensor (resonant) differs from modern products (broadband) in price, design features and operating principles. Therefore, you should buy a product that is designed specifically for your car model. A device with a resonant type of operation cannot be replaced by modern products without modifying the ECU.

Knock sensor malfunction

The most common fault is “low signal level” code 0327 . With the ignition off, the integrity of the circuits from the sensor block to the controller, and from the block to the sensor, is checked. It’s a good idea to check the tightening torque. If the torque was insufficient and it was necessary, you can restore it and test for the absence of code 0327.

If the circuits are serviceable, the serviceability of the knock sensor is determined. Here are a couple of methods for checking the sensor itself without using special diagnostic tools.

- With the engine idling and the wiring harness block disconnected, connect a voltmeter to the sensor contacts in AC mode. The presence of a signal on the DD contacts indicates serviceability.

- The second method is to remove the DD from the engine. Then a bolt is installed in the sensor hole and a voltmeter is connected to the contacts. By lightly tapping the head of the bolt, the presence of a reaction to vibration is determined by the deflection of the voltmeter needle.

If the circuits and DD are working properly, the fault relates to the controller. When a breakdown of the knock sensor is determined, many drivers recommend using the Bosch sensor from the injection Volga as a replacement.

Signs of a malfunctioning knock sensor

Resistance that should be in the sensor in good condition

Before considering the causes, it is necessary to look at the symptoms of the malfunction. So, let's look at what could be a warning sign that the knock sensor has failed:

- The engine is losing power.

- Overclocking potential drops.

- Fuel consumption has increased.

- The CHECK light came on on the instrument panel.

- Smoky exhaust.

- Presence of detonation.

- The engine started to stall.

Of course, an important reason for the failure of the knock sensor is the fuel mixture, namely the quality of gasoline itself. The lower the octane number, the lower the resistance to detonation. If the fuel detonates, it will not completely burn through the engine and you will hear the muffler firing.

Knock sensor diagnostics

The sensor is checked with a multimeter. In this case, the sensor is “knocked” with a screwdriver

To diagnose the knock sensor, it is removed from the engine and a voltmeter with a measurement limit of up to 200 mV is connected to it.

Next, they “knock” the sensor on a hard surface and look at the voltmeter readings. When tapping, the readings should change. If they do not change, this means that the sensor is not working. If they change, then the sensor readings change, but whether they are correct is in question!