01 April 2020 Lada.Online 28 343 0

The fault indicator (Check Engine) on Chevrolet Niva cars is located in the instrument cluster. When the warning light turns on, it signals to the driver that the on-board diagnostic system has detected a malfunction of the ECM and the vehicle continues to move in emergency mode. To determine the cause, you should use a diagnostic tool, with which you can read error codes and decipher them according to the table below.

Signs of a malfunctioning knock sensor

Resistance that should be in the sensor in good condition

Before considering the causes, it is necessary to look at the symptoms of the malfunction. So, let's look at what could be a warning sign that the knock sensor has failed:

- The engine is losing power.

- Overclocking potential drops.

- Fuel consumption has increased.

- The CHECK light came on on the instrument panel.

- Smoky exhaust.

- Presence of detonation.

- The engine started to stall.

Of course, an important reason for the failure of the knock sensor is the fuel mixture, namely the quality of gasoline itself. The lower the octane number, the lower the resistance to detonation. If the fuel detonates, it will not completely burn through the engine and you will hear the muffler firing.

Knock sensor diagnostics

The sensor is checked with a multimeter. In this case, the sensor is “knocked” with a screwdriver

To diagnose the knock sensor, it is removed from the engine and a voltmeter with a measurement limit of up to 200 mV is connected to it.

Next, they “knock” the sensor on a hard surface and look at the voltmeter readings. When tapping, the readings should change. If they do not change, this means that the sensor is not working. If they change, then the sensor readings change, but whether they are correct is in question!

ECU signal about malfunction

Failure of the sensor will be immediately obvious by a characteristic knocking sound. Many motorists simply reset the “minus terminal” to reset the readings of the electronic control unit, but it is worth understanding the very reasons for the effect and eliminating them. Let's look at the ECU error codes that signal a failure of the knock sensor:

- code-0325 hints at network problems. For example, a break in the wiring or acidification of the plug contacts. In this case, we call the electrical circuit connecting the sensor, clean the electrical contacts ;

Reasons for the error

There are four main reasons that can lead to problems with the pressure sensor signal range:

- direct breakdown of the pressure sensor, leading to the transmission of incorrect information to the computer;

- contact problems resulting from oxidation on the sensor connector surface or pad;

- problems with the circuit through which information passes from the sensor to the ECU (short circuit or open circuit);

- Over- or under-tightening of the knock sensor during installation.

The last reason usually occurs if the knock sensor has failed, and it was replaced by the driver himself without complying with the necessary standards. It is recommended to install the sensor only after studying the reference literature and using a torque wrench.

IMPORTANT! In some situations, the cause of error P0326 may be a failure in the firmware of the electronic control unit

How does a mechanic diagnose a P0328 code?

When diagnosing this error code, a mechanic will do the following:

- Connects the OBD-II scanner to the vehicle's diagnostic connector and reads all stored data and error codes

- Clear error codes from the ECM and test drive the vehicle to see if P0328 appears again

- Find out if the engine makes a lot of noise during operation

- Inspect the knock sensor for damage

- Check the cooling system as well as the engine for damage

- Checks the octane number of the fuel, as well as the fuel system

- Check the knock sensor voltage

- Checks engine coolant temperature and fuel pressure

- Will check the ECM according to the manufacturer's procedure

Common errors when diagnosing code P0332

The most common mistake made when diagnosing the P0332 code is not performing a thorough check to properly determine the cause of the problem. This often results in the mistaken replacement of the knock sensor when the problem is, for example, worn or damaged electrical wires or connectors or a fault in the engine cooling system or exhaust gas recirculation system. Before replacing the knock sensor, it is necessary to perform a thorough diagnosis and consider all possible causes of the error.

Additional comments for troubleshooting P0328

When diagnosing the P0328 code, it is very important to follow the diagnostic protocol to ensure all checks and repairs are performed correctly.

To make a proper diagnosis, a mechanic will need a professional scanner that can not only read stored error codes, but can also view data from various sensors, such as fuel pressure and engine coolant temperature, in real time.

Need help with error code P0328?

The company - CarChek, offers a service - on-site computer diagnostics; specialists from our company will come to your home or office to diagnose and identify problems with your car. Find out the cost and sign up for on-site computer diagnostics or contact a consultant by phone

We only find out where the knock sensor is located when we encounter problems with it. And before we talk about its location, it is worth understanding what this element is and what it is needed for. Let's start with this!

Under what conditions is it diagnosed?

To diagnose error P0325 as accurately as possible, a number of conditions must be met.

- First of all, the possibility of false positives should be eliminated. Using a diagnostic scanner, reset the error and perform a test drive. If the P0325 error code appears again, go to the next step.

- Perform a performance check of the knock sensor (knock sensor). For these purposes, a multimeter is used, which determines the voltage level of the sensor under pressure. Then the circuit of the electronic control unit is checked for breaks.

- If you do not have a multimeter, the test can be performed mechanically. It's very simple. To do this, it is necessary to lightly hit the engine at idle speed as close as possible to the location of the knock sensor. If this device is working properly, the ignition angle will automatically change and the speed will decrease.

- Test the performance of the engine control module by contacting a dealer service center.

Knock sensor - how to find the element under the hood?

Everyone knows the fact that the productive operation of the engine depends directly on the advance angle. If it operates late, throttle response decreases, which accordingly increases fuel consumption, and this can also cause engine overheating. An equally sad outcome can occur if this parameter works ahead of schedule. Indeed, in this case, detonation occurs, which contributes to a decrease in power, and, as a result, the valves can burn out.

It is worth noting that there are 2 types of such sensors: resonant and broadband. The latter transmit the entire spectrum of noise as a signal. After this, the signal is processed, and a certain noise is released in it, which corresponds to detonation. Speaking of resonant sensors, it is worth knowing that they are tuned to the detonation frequency and are triggered only if it appears. It is the sensor that controls the advance angle. It informs the system that detonation has begun, and it, in turn, begins the process of adjusting the characteristics.

This part is located under the hood of the car, usually under the oil filter and oil sensor.

Speaking of where the knock sensor is located, it is worth noting that if you look from top to bottom, the oil filter can be a reference point. Behind it is the oil sensor, and under it is the required element. But it is not necessary that it will be located in this exact place. Its location depends on the car model and where it was placed during assembly. In any case, it will be next to the engine; to find it, it is better to first consult the car’s operating manual.

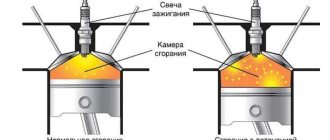

Engine operating principle

Detonation very often occurs when going uphill.

In this case, the car is moving slowly, and the speed is increased. But do not worry, since this phenomenon is called glow ignition, and it does not indicate that the engine is not working properly. Any internal combustion engine works according to the following principles:

- A mixture of gasoline and air is supplied to the combustion chamber of the cylinders, where it is ignited by a spark on the spark plug. Moreover, the piston should be literally a few millimeters from top dead center. As soon as the piston reaches the top position, the greatest pressure is generated in the cylinder. At this moment, the entire air-fuel mixture will completely burn.

- During normal operation of the knock sensor on the Chevrolet Niva, signs of this phenomenon will not appear. This device will help get rid of the manifestation of detonation. And it appears when the mixture begins to ignite much earlier than it should. This usually happens halfway to top dead center. And when the air-fuel mixture burns, a force is exerted on the upper part of the piston, which pushes it in the opposite direction. At the same time, the engine power is reduced, and significantly, and its parts wear out.

- A mixture of gasoline and air is supplied to the combustion chamber of the cylinders, where it is ignited by a spark on the spark plug. Moreover, the piston should be literally a few millimeters from top dead center. As soon as the piston reaches the top position, the greatest pressure is generated in the cylinder. At this moment, the entire air-fuel mixture will completely burn.

- During normal operation of the knock sensor on the Chevrolet Niva, signs of this phenomenon will not appear. This device will help get rid of the manifestation of detonation. And it appears when the mixture begins to ignite much earlier than it should. This usually happens halfway to top dead center. And when the air-fuel mixture burns, a force is exerted on the upper part of the piston, which pushes it in the opposite direction. At the same time, the engine power is reduced, and significantly, and its parts wear out.

High signal level - warning codes

Many motorists have encountered the problem of various knock regulator warning signals. One of them may be P0328 - high signal level of the knock sensor . It can cause not only a malfunction of the device itself, but also, for example, too noisy operation of the engine. The best solution to the problem is to contact a service station so that they can diagnose the car, in particular, the element itself.

In addition, there is another signal that the driver can receive from the system - 0327, this code means a low level of the detonation signal. As a rule, it occurs in several cases - either after a long descent with the gear engaged, or in a situation when replacing the sensor is already necessary. In any case, you will either have to check its serviceability on your own; for this it is better to dismantle it and connect it to special equipment, or do this with the help of specialists.

What does it indicate?

The appearance of error P0325 indicates incorrect operation of the knock sensor, or more precisely, the presence of faults in its circuit. The device is installed on the cylinder block or intake manifold. It is designed to detect engine detonation using a piezoelectric element located in it.

The sensor perceives vibration of the cylinder blocks as an oscillatory movement. The pressure is then converted into a voltage signal and transmitted to the engine control module. Error code P0325 occurs when the sensor voltage level is too low or, conversely, too high. This does not have a critical impact on the operation of the engine as a whole, and the driver has time to safely get to the service station.

Often, along with the P0325 error, related errors appear, which also indicate problems with detonation. All of them occur due to damage to the sensor or the use of low quality fuel.

- P0326 – the sensor signal is outside the permissible limits.

- P0327 - decrease in the signal level of the knock sensor.

- P0328 - signal level exceeded.

What causes a knock sensor error?

If you yourself decide to find out whether there is a malfunction of the knock sensor, then this can be done using self-diagnosis, which is encoded in the “brains” of this element. If it produces a “34” signal, you can find out whether it is operational or not using a kind of test drive. That is, you should reset this result and drive a couple of kilometers and check the sensor again. If this code appears again, then it is truly faulty and needs to be replaced.

In addition to signals, a sensor error often occurs. There are quite a lot of them, and each of them should not be ignored. After all, this indicates one or another malfunction in the car, which may sooner or later make itself felt at the most inopportune moment. Therefore, if a malfunction occurs, then at a minimum, consultation with a specialist is necessary. If, however, during the inspection it is necessary to replace the sensor, it will not take much time. The technician can replace it in 10-15 minutes. In addition, the cost of this work will not be huge; it depends on the car model.

How to fix

Fuel detonation, that is, its spontaneous combustion, can ultimately lead to engine destruction. Therefore, it is important that the sensor works correctly. To do this, it is highly recommended to resolve the P0325 error as soon as possible.

There are several effective solutions to this problem:

- Thoroughly clean the contacts or replace damaged wiring (depending on the actual cause of the error).

- Replace or repair the wiring in the area from the knock sensor to the engine control unit.

- Replace the damaged knock sensor, as this element is not repairable.

- Update the control unit software or replace this device.

Error P0325 is called Knock Sensor 1 Circuit Malfunction, that is, “a malfunction in the knock sensor circuit.” For its accurate diagnosis, a special device is used - a multimeter. There are several ways to solve this problem, depending on the specific cause. Typically, for these purposes, the contacts are cleaned, the wiring between the sensor and the control unit is changed, or the sensor or control unit is replaced, depending on which device is not operating correctly.