Each car includes a large number of different sensors in its design. These devices are necessary to monitor the status of the main components of the car and transmit information to the electronic control unit. Based on the received data, the ECU adjusts the operation of a particular system and makes appropriate changes if necessary.

The knock sensor on the VAZ-2114 is located between the engine cylinders. This arrangement allows you to achieve the greatest efficiency from this simple but extremely important mechanism. What is the main purpose of the knock sensor and what are the main signs of its malfunction?

How does the sensor work and why is it needed?

The operation of the mechanism is based on the principle of a piezoelectric element. This means that if vibration of a different nature occurs in the engine cylinder, a signal will be transmitted to the ECU using electronic pulses. In turn, the final element in this chain will make changes to the operation of the ignition angle.

This algorithm of actions allows you to protect components and parts from mechanical damage. On the “fourteenth” in most cases there are broadband mechanisms, but often the manufacturer also installed a resonant type of device, most often on the very first copies of the VAZ-2114

The fundamental difference between a resonant type device is that it is capable of capturing only noise at the detonation frequency.

The broadband mechanism is superior to its counterpart in that it has a wider range of capabilities. Such a sensor is capable of capturing noise of various frequencies, which undoubtedly gives the vehicle system additional stability.

The devices operate on different principles, therefore, if the resonant sensor breaks down, it cannot be replaced with a broadband one. The situation is similar in the opposite case. If there is an urgent need to replace or change the operating principle of the mechanism, you will have to purchase a new control unit.

Car engine knock sensor and its purpose

The main condition for optimal operation of a car engine is the normal combustion of the air-fuel mixture in the engine cylinders. And this depends on two main conditions - fuel quality and ignition timing. An engine that runs on high octane fuel and has the correct angle set provides maximum power output, economical gasoline consumption (as much as possible) and has good throttle response.

How dangerous is detonation combustion and what can cause it?

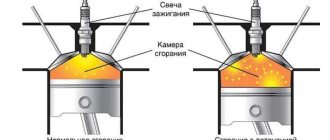

But if at least one of the conditions is not met, then there is a high probability of detonation combustion, which in the future can cause serious damage. The essence of this combustion is that part of the fuel, due to a number of prevailing factors in the combustion chamber, spontaneously ignites. Moreover, this happens before a spark forms between the spark plug electrodes, that is, the mixture ignites ahead of time.

The peculiarity of detonation combustion is that it is similar to an explosion. Combustion of the mixture occurs much faster and is accompanied by increased pressure and significantly higher temperature than during the normal combustion process of the air-fuel mixture.

The result of such combustion is melting of the piston bottom, burning out of it or the valves. In general, detonation in a power plant can cause enormous damage and require expensive and time-consuming repairs.

The cause of detonation may be:

- low-quality gasoline with a low octane number.

- design features of the power plant (compression ratio in the cylinder, shape of the combustion chamber, position of the spark plug, etc.);

- change in operating conditions in the cylinders (incorrect ignition timing, operation under load, the appearance of a significant layer of soot, deterioration in the quality of the air-fuel mixture).

How to deal with this?

One of the simplest methods of getting rid of detonation is to change the ignition angle. After all, this parameter significantly affects the operation of the power unit. With late ignition, the fuel does not have time to burn completely, which affects power, throttle response, and fuel consumption. And with an early ignition angle, detonation combustion occurs - the fuel burns ahead of time, which leads to the appearance of shock loads on the piston group and the crank mechanism.

In carburetor cars, detonation was eliminated by turning the distributor, ensuring later ignition.

In modern injection cars, it is impossible to manually change the advance angle, since this parameter is adjusted by the electronic engine control system. Essentially, the car itself regulates the ignition to provide maximum power output with the lowest possible fuel consumption. Moreover, this is achieved at a slightly early ignition, when the angle is set so that detonation combustion does not occur. But as already mentioned, the occurrence of this effect depends on many factors.

Video: Knock sensors

Knock sensor. Purpose and types

In order to eliminate the possibility of detonation in the engine, a knock sensor (DS) is included in its design. It has only one purpose - to detect the occurrence of detonation in the cylinders and send a signal about this to the control unit. And that, in turn, will simply reduce the advance angle (make ignition later), which will cause detonation combustion to disappear.

To operate, the knock sensor uses one of the features of detonation combustion. Its appearance is accompanied by shock loads and, as a result, a loud metallic knock and increased vibration. This is what the sensor reacts to. The operation of the sensor is based on the piezoelectric effect, the essence of which is the conversion of mechanical action into an electrical impulse.

Main symptoms of a malfunction

If the VAZ-2114 knock sensor begins to function incorrectly, then in most cases the driver will be able to notice a flashing Check Engine light on the dashboard. At the same time, it is easy to notice a malfunction by the very behavior of the car. The car accelerates poorly, does not overtake, and “chokes” when going uphill. The engine is unstable and shows obvious signs of failure. Other symptoms include:

- frequent overheating of the motor;

- when you press the gas pedal sharply, a detonation knock is clearly audible;

- The on-board computer generates an error, the interpretation of which indicates a sensor malfunction.

Detonation knocks often occur due to low-quality gasoline. If all of the above symptoms are present, it is best to conduct a full computer diagnostic of the car. Monitoring will allow you to determine at which stages of engine operation the worst performance is observed, and computer diagnostics will also allow you to find out the error code of the knock sensor.

Diagnostics can detect faults such as an open circuit, signal level exceeding or its value being too low.

If the diagnostics determines that the knock sensor is faulty, you still need to make sure that the device is not functioning correctly.

see also

Checking DD at home

How to check the knock sensor of a VAZ 2114 at home? It is possible to determine the performance of the mechanism using an ohmmeter or digital voltmeter. The first allows you to determine the resistance, and the second - the voltage between the contacts. A correctly functioning VAZ 2114 knock sensor has an almost infinite resistance. If this indicator is completely absent, then the mechanism must be replaced.

The procedure for measuring voltage with a voltmeter is as follows:

- Set the limit on the device to 200 millivolts.

- Connect the voltmeter probes to the DD contact.

- The sensor body must be tapped lightly, for example, with a screwdriver.

- Record the reading of the digital voltmeter.

How to replace the sensor

Replacing the mechanism yourself is not difficult. It is located between the second and third cylinders; you need to open the hood and provide yourself with unhindered access. It is important that the engine is turned off at this time. As soon as the DD is detected, it is necessary to disconnect the plug going to the sensor wires.

If the mechanism is broadband, then to complete all the work you will need a key set to “13”. In the case of a resonant device, you should arm yourself with a key set to “22”. You just need to unscrew the nuts from the stud with a “13” wrench or the piezoelectric sensor itself with a “22” wrench. It is also necessary to clean the contacts with sandpaper to remove all dirt and oxidation. This procedure should not be neglected, because the quality of the transmitted signal depends on the state of the contacts.

Oxidation and various types of plaque interfere with the transmission of a high-quality signal. As a consequence, this leads to a decrease in the level and accuracy of the impulse, which will leave its mark on the operation of the car. After which it is necessary to install a new mechanism and reassemble in the reverse order.

Replacing the VAZ knock sensor

The knock sensor on injection VAZ cars is located on the cylinder block in the front part. Before you begin to unscrew the mounting bolt, disconnect the chip from the sensor by pulling out the locking bracket. To unscrew the DD you will need a 13 key.

After removing the old sensor, do not rush to install a new one immediately. Before replacing, thoroughly wipe the sensor seat from oil, dirt and other debris to ensure a perfect fit of the sensor to the engine block.

The tightening torque DD should be within 10 - 24 N.m. If you don't have a torque wrench, you can lightly tighten it by hand, just don't go too hard.

Almost all modern gasoline engines have an electronic engine management system. The VAZ 2114 car is no exception - the distributed injection system is controlled by an electronic unit. The unit monitors the operation of various sensors and, based on their readings, regulates the fuel supply and commands the ignition system. Failure of any of them leads to malfunctions of the vehicle. The knock sensor on the VAZ 2114 is no exception; the stable operation of the engine also depends on it.

Location of the knock sensor on the VAZ 2114

Replacing DD VAZ 2113 2114 2115

- We remove the chip with wires.

- Unscrew the nut connecting the DD to the engine.

- Remove the washer and detach the sensor from the stud.

- We install the new sensor in reverse order.

For a more detailed process of removing the sensor, see the video below:

Thank you for reading this material to the end. Subscribe to the channel, rate the recording |

Even more interesting things on our Zen channel and VKontakte group:

Related Posts

Design and principle of operation Malfunctions of the VAZ 2114 speed sensor Replacing the VAZ 2114 speed sensor Design and principle…

The mass air flow sensor is responsible for the engine mixture ratio. It is based on the readings of this sensor...

Many VAZ 2114 owners have a problem with the fuel remaining in the tank. The reason we serve...

The oil pressure sensor VAZ 2113-2114-2115 is a very important element of engine design. Oil in any internal engine…

DEVICE AND PURPOSE

The basis of the knock sensor (DS) is a piezoelectric element. When mechanically applied, an electrical impulse is generated on it, this impulse is sent to the engine control unit. The electronics detects the occurrence of detonation and, based on the data obtained, adjusts the ignition angle, thereby protecting the internal combustion engine (ICE) from mechanical damage.

To find out where the knock sensor is located on a VAZ 2114, you need to open the hood and look under the cylinder head between the second and third cylinders; it is installed on the internal combustion engine block (this can be seen in the figure above). On a 16-valve engine it will be more difficult to see right away; the cylinder head is more massive and blocks the view.

There are two types of DD:

- Resonant (single-contact),

- Broadband (two-contact) sensors.

What types of DD are there?

The resonant knock sensor was installed on early releases of VAZ 2113, VAZ 2114 and VAZ 2115 cars (they are completely interchangeable). It is rarely found on sale lately, and the price of the part is quite high. A single-contact knock sensor works on the principle of capturing the detonation frequency, while a broadband (two-contact) sensor receives the entire noise band, and then detects detonation noise in it. These devices are not interchangeable, as they operate on different principles. Replacing the wiring does not solve the problem, so when remaking the system, you also have to change the electronic control unit (ECU).

But replacing the ECU is ultimately worth it, given the difference in price of the parts. A resonant DD from GM costs approximately 2,600 rubles. At the same time, the price of broadband DD is in the range of 230-320 rubles. If desired, a spare part can be found even cheaper, for example, a two-pin DD manufactured by StartVolt is sold at a price of 170-210 rubles. It makes sense to redo the entire system once rather than constantly have to worry about finding and replacing a single-contact knock sensor.

Where is the knock sensor located in a VAZ-2115 car?

So, as we have already found out, the knock sensor, located directly on the engine block, closely monitors its operation immediately after starting. The exact location of the device is the gap between 2 and 3 cylinders. Finding it is not at all difficult, especially if you have experience in repairing your car and have repeatedly overhauled the engine.

The knock sensor can be either one-stroke or two-stroke - it depends on the configuration of a particular machine. In addition, all devices are divided into two main types:

- broadband sensors, which are round in shape and resemble a large tablet;

- resonant highly sensitive elements made in the shape of a barrel.

These types of sensors are not interchangeable, so before choosing a replacement product, you need to know which element is installed on your machine.

As practice shows, this device is very reliable; it can work for many years without creating virtually any problems. But sometimes even this sensor fails.

FAULTS

There are certain signs of a malfunction of the knock sensor on the VAZ 2114, which can be used to judge whether the part has failed:

- The Check Engine warning light in the vehicle interior lights up;

- The car accelerates poorly and there is a lack of power;

- When you sharply press the accelerator (gas) pedal, a detonation knock occurs (“fingers knock”);

- The engine overheats because, due to incorrect readings from the piezo sensor, the ECU sets the incorrect ignition timing.

The most common cause of detonation knocks is low-quality gasoline. Detonation also occurs when the engine overheats, and with a faulty motor, it can be clearly heard.

If there are signs of a faulty knock sensor and the engine warning light on the instrument panel comes on, computer diagnostics should be performed. For this purpose, the best option would be to use the Ascan diagnostic tester. On the scanner you can observe all the characteristics of the engine during its operation in all modes, and see what kind of knock sensor error is present.

Malfunctions of the knock sensor are also detected on the Ascan scanner; there are error codes:

- Error 0326 – exceeding the permissible DD signal level.

- Error 0327 – signal level is too low;

- Error 0325 – open circuit in the DD circuit.

A low knock sensor signal level is not only due to a faulty piezo sensor; there may be poor contact in the connecting plug or the sensor itself is poorly screwed to the cylinder block. Perhaps the contacts on the DD have oxidized; you can try cleaning them with sandpaper.

Open circuit of the knock sensor on a VAZ 2114 - three main reasons:

- The part itself is faulty;

- Power does not arrive or the control signal does not respond to the DD contacts;

- The DD housing has rusted at the mounting location in the cylinder block.

If there is rust on the DD body, the surface is also sanded, and if there is severe oxidation, the broadband sensor is easier to replace - it is cheap.

CHECK AND REPLACE

Even if the scanner showed a malfunction of the DD, it’s a good idea to make sure that the part is not working.

The knock sensor is checked using an ohmmeter by measuring the resistance or a digital voltmeter by measuring the voltage between the contacts. The resistance of a working sensor on VAZ car models is almost infinite, but if it is small or absent altogether, the sensor must be replaced.

The voltage is measured as follows:

- Set the measurement limit on the voltmeter to 200 millivolts;

- The probes of the device are connected to the sensor contacts;

- Gently tap the DD body with any medium-heavy object (screwdriver, pliers);

- At this moment they look at the voltmeter readings.

At the moment of impact, the voltage on the device increases by 20-40 mV, depending on the force of the impact. The stronger the blow, the greater the tension.

REPLACEMENT

Replacing the knock sensor on a VAZ 2114 is very simple. If the DD is broadband, then you will need a combination key of 13; for a single-contact sensor you will need a key of 22. Do it as follows:

- We turn off the engine;

- Open the hood;

- We disconnect the connector plug on the wires going to the DD;

- We unscrew the 13 nut from the stud (in the 2-pin version) or the piezoelectric sensor itself with a 22 wrench (resonant DD);

- We put the new part in place and connect the plug.

That's it, very simple. You also need to take into account the tightening torque - the force is small, about 2 kgf/m². With greater force there is a risk of breaking the thread.

OPERATIONAL CHECK

If typical signs of a malfunction are detected, it is necessary to check the operation of the DD. To do this you will need a regular screwdriver and a tester.

A tester, also known as a multimeter, can be purchased at any automotive store. It is inexpensive, about 500-600 rubles, and will come in handy in the garage many times (it is used to check all systems and devices of the car that consume electricity), so there is no need to skimp on the device.

The DD functionality check is performed as follows:

- We dismantle the sensor (how to do this is written in the next section of the article);

- We connect the multimeter probes to the DD contacts (if it is two-contact), if it is single-contact, the first probe to the wire, the second to the device body;

- We switch the tester to voltmeter mode and set the upper measurement limit to 200 mV;

- Tap a screwdriver (or any metal object) on the sensor body;

- If the device is working properly, the multimeter will show voltage surges, the magnitude of which should be directly proportional to the force of the impact (this indicates that the device retains the ability to convert mechanical energy into alternating current). If the multimeter readings do not change, the DD does not work.

Article on the topic: Checking the operation of the generator on a VAZ 2114: how many volts (V) it produces

If you find out that the device itself is working properly, but DD errors are displayed on the on-board computer or the car is not working as it should, the problem is most likely in the oxidized contacts of the sensor. Treat them with WD-40 or a similar solvent, install the DD in place and check the result. If that doesn't help, replace the knock sensor.