Purpose and design of the VAZ 2106 carburetor

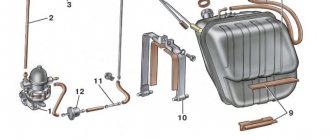

The VAZ 2106 car began production in 1976 and immediately gained great popularity among domestic car enthusiasts. To keep the small engine running smoothly, it required air, fuel, a powerful spark, and compression. The first two elements are mixed in a carburetor, designed to prepare an optimal fuel-air mixture. On the VAZ 2106, the manufacturer installed an “Ozone” carburetor produced by the Dimitrovgrad Automotive Assembly Plant (DAAZ).

On the VAZ 2106, the designers installed an “Ozone” carburetor manufactured by DAAZ

The operation of the device is based on the principle of jet propulsion. A powerful jet of air through the jets located in the diffuser carries fuel from the float chamber. As a result, a fuel-air mixture is formed in the proportions necessary for its ignition in the combustion chamber.

The carburetor consists of three main parts:

- The upper section is a cover with a damper to regulate the flow of air into the combustion chambers. Using a system of channels, it is connected to the throttle valve and the float chamber.

- The middle section consists of diffusers, fuel nozzles and a float chamber. The diameters of the jets are shown in the table.

- The lower section includes the throttle valves of the two chambers.

Table: calibration data for the Ozone carburetor

| Parameter | First camera | Second camera |

| Diameter, mm | ||

| diffuser | 22 | 25 |

| mixing chamber | 28 | 36 |

| main fuel jet | 1,12 | 1,5 |

| main air jet | 1,5 | 1,5 |

| idle fuel jet | 0,5 | 0,6 |

| idle air jet | 1,7 | 0,7 |

| econostat fuel jet | — | 1,5 |

| econostat air jet | — | 1,2 |

| econostat emulsion jet | — | 1,5 |

| air jet of the starting device | 0,7 | — |

| throttle valve pneumatic drive jet | 1,5 | 1,2 |

| accelerator pump nozzle holes | 0,4 | — |

| accelerator pump bypass jet | 0,4 | — |

| Accelerator pump flow for 10 full strokes, cm3 | 7 ± 25% | — |

| Calibration number of the mixture sprayer | 3,5 | 4,5 |

| Emulsion tube calibration number | F15 | F15 |

Any deviation in the composition of the fuel-air mixture from the optimal one affects engine performance. It becomes difficult to start a cold and warm engine, its operation at idle and in operating mode is disrupted, and acceleration dynamics deteriorate.

Carburetor operation on a VAZ

This device, located in the propulsion system, serves to ensure that the movement of fuel is carried out in a certain order. Proper operation of the carburetor helps to obtain the required composition of the combustible mixture. Then the mixture can move horizontally, downward or upward. This parameter depends on the design features of the device, but we will talk about this below.

Basically, the movement of fuel is carried out in the following order: from the fuel tank it enters the float chamber, and then through special nozzles it goes to the atomizer located in the narrowest part of the diffuser. It is at this moment that air enters through the outer tube. The role of throttle valves, through which the dosage of fuel entering directly into the engine cylinders, cannot be underestimated.

VAZ 2106 carburetor maintenance

During the operation of the carburetor, the narrow channels of the jets become clogged. This usually happens when using low-quality fuel, untimely replacement of the air filter, etc. The composition of the fuel-air mixture is disrupted and its flow into the engine is difficult. As a result, the power unit begins to operate intermittently, and its dynamic characteristics decrease. In such cases, it is necessary to flush the contaminated jets with a special cleaning compound and then blow them with air.

If the carburetor jets become clogged, they should be washed with a special agent and blown out with air.

In addition, it is recommended to periodically adjust the composition of the fuel-air mixture to the optimum using special adjusting screws. Otherwise, the engine will run unstably.

"Ozone" and its problems

Sometimes the pneumatic drive of the damper on the secondary chamber refuses to work normally.

Troubles also arise with a worn out diaphragm in the forced idle economizer system. If for some reason dirt gets into the mechanism or the adjustments are broken, then the second chamber may not open at all, or it may open, but with a serious delay. This leads to a significant decrease in dynamics. Power is lost, the maximum speed of the car decreases, the engine is unstable at high and medium speeds. Despite all

this is a carburetor

DAAZ-1107010 “Ozone” produces good dynamic characteristics with a fuel consumption of about seven liters per 100 kilometers. Naturally, the device must be constantly monitored and maintained. To avoid contaminating the internal chambers, it is recommended to periodically clean them. A special one is used

carburetor cleaner.

This

chemical

The product is sold in aerosol cans.

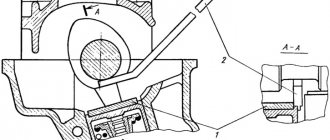

Cleaning the jets

Before adjusting the carburetor, it is necessary to clean the channels and jets of dirt and deposits. To do this you need:

- unscrew the fuel and air jets;

- soak them in acetone or some other carburetor cleaner for ten minutes;

- blow out the jets with compressed air;

- Install cleaned and dried jets into the carburetor.

Before adjusting the carburetor, it is necessary to remove and wash all air and fuel jets.

Working with a carburetor is associated with an increased fire hazard. All precautions should be taken before starting work.

The VAZ 2106 carburetor is a rather complex device consisting of many small elements. Nevertheless, any car owner can wash the jets and strainer, as well as adjust the supply of the fuel-air mixture. To do this, you just need to consistently follow the instructions of the specialists.

When to clean the carburetor

Unfortunately, the fuel we put into the tanks of our cars is not always of high quality. Dirt, corrosion products and water are essential components of any gasoline purchased at our gas stations. They are the cause of contamination of the unit.

Signs of a blockage

Symptoms indicating that the carburetor is clogged include:

- difficult starting of the power unit;

- failures when sharply pressing the gas pedal;

- malfunction of the engine in idle mode;

- increased fuel consumption.

But here it is necessary to take into account that the listed signs may indicate other malfunctions, both in the fuel system and in the ignition system. However, if the unit has not been serviced for more than a year, cleaning it will not be unnecessary. Additionally, before starting work, it is recommended to replace the fuel filter in order to be sure that after servicing the device will receive purified gasoline.

Rinse or blow out: which is better?

A carburetor is a complex and precise device consisting of many parts. To remove contaminants inside some of them, washing alone will not be enough. Yes, the body and lid can and should be washed, and if necessary, also cleaned.

With small details things are a little different. Let's take, for example, jets with their channels with a diameter of no more than 2 mm. You are unlikely to be able to wash away the dirt from there at home. The best option here would be to blow out the channels with a stream of compressed air. But it’s better to do this after these parts have soaked a little in one of the liquids that helps dissolve the dirt. It is also recommended to soak large items before washing and cleaning.

Carburetor adjustment

Tuning the VAZ 2106 carburetor is not a delicate matter. Basically, all advanced car owners replace their original carburetor with Solex or Ozone, their design is very similar, as is the adjustment. You shouldn’t just get into the carburetor, because if everything works fine, then you don’t need to touch anything. However, if the following signs of malfunction occur, you will have to study the device and climb inside:

- Dips when accelerating the car (after pressing the pedal, the car does not accelerate, or accelerates very slowly).

- Car jerks when accelerating.

- Very slow acceleration, albeit smooth.

- Cascading dips during prolonged acceleration.

Carburetor Ozone

Adjusting the fuel level

Adjusting the fuel level is where carburetor adjustment begins. On Solex and Ozone carburetors this process is practically identical, so that it will help the user of both types. First, warm up the engine a little; you can carry out this operation after the trip. We start by disconnecting the fuel line hose; this must be done carefully so that the hot fuel does not burn you. Next, we remove the top cover of the carburetor (after first freeing the carburetor from the air filter “pan” covering it. Then we disconnect the cable of the choke lever and carefully remove the cover, this must be done so as not to damage the floats. Now we arm ourselves with a ruler, preferably, in fact, a caliper , but a ruler will do. You need to measure the distance from the top edge of the gasoline to the cap, it should correspond to about 24 mm. The fuel level in the chambers may vary, since the carburetor is very rarely located perfectly horizontally, so you need to take the average result. If the result is outside installed frame.Then the adjustment on the Solex carburetor comes down to the fact that you just need to bend the float holders in the desired direction.

Idle speed adjustment

The Solex device is such that all adjustments can be made absolutely easily with just instructions. Adjusting the idle speed comes down to turning the screw with a screwdriver. First, we find the hole with this screw; it is located at the bottom of the Solex carburetor, next to one of the holes for attaching the carburetor to the manifold. Now we tighten the adjusting screw until it stops and unscrew it back 5 turns of the screwdriver. Next, start the engine and completely remove the choke. Now you need to rotate the screw to set the idle speed to the minimum value at which the engine will operate stably. If the tachometer shows a number of about 850 rpm, this will mean that the Solex is functioning quite properly.

Selection of jets for Solex

The Solex carburetor provides that the jets can be replaced after their service life has expired or at the request of the owner, for example, due to the need to adjust the efficiency of the car. Jets allow you to change the dosage of incoming fuel or air. With their help, you can easily achieve stable engine operation or increase its efficiency. Jets are selected according to special tables, taking into account engine power; these tables can be found on the Internet or in books dedicated to the car.

How to correctly configure the carburetor unit of Lada 2106?

The legendary “six”, which was almost the main car in the country, is becoming less and less common on our roads. Nowadays, few people specialize in the repair and maintenance of VAZ classics, and it is quite difficult to find a specialist to set up its power system. However, any car owner is able to independently set up a unit for preparing a combustible mixture; it is enough to use the recommendations of experienced drivers.

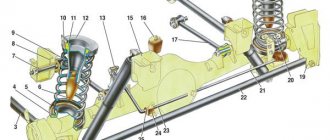

Briefly about the features and structure of the “six” carburetor unit

Before adjusting the carburetor on a VAZ 2106, it doesn’t hurt to know its design features. After 1980, Ozone and Solex began to be installed on Tolyatti cars. The purpose of the unit’s operation is to prepare a combustible mixture before feeding it into the car’s cylinders. Down to the subtleties, this is not a driving school, we will not disassemble the design, it is enough to familiarize yourself with the main components that ensure optimal operation of a carburetor internal combustion engine:

- Fuel dosing system.

- Mechanisms for controlling throttle valves and enriching the mixture.

- Idle system.

- Accelerator pump and econostat.

- Float chamber.

A chamber with a float and a needle valve is responsible for the stability of the fuel level. Next, gasoline, flowing through the spray tube, enters the chamber, where it mixes with air from the inlet pipe. The amount of mixture is adjusted by the throttle valve, which is connected to the accelerator pedal.

Precise adjustment allows you to prepare the correct mixture of gasoline and air in a ratio of 1:15. During long-term operation of the car, the settings get lost and you have to think about how to adjust the carburetor on a VAZ 2106 on your own. The adjustment technology is the same for both Solex and Ozone.

When is adjustment needed?

Adjusting the carburetor unit is no more difficult than adjusting the clutch drive on a VAZ 2107, since it only involves adjusting the jets. In some cases, they need to be cleaned of resins and other contaminants; the presence of contaminants is felt by power dips in the process of accelerating. Many car owners claim that Ozone carburetors are not a very good option and recommend replacing them with Solex.

However, the signs that the device has begun to prepare an enriched mixture and needs to be adjusted are the same for both types of units:

- Increased fuel consumption.

- Frequent overheating of the motor.

- Black smoke from the exhaust pipe and pops.

- Loss of power.

The preparation of a lean mixture is characterized by the following characteristics:

- Popping sounds in the carburetor.

- Loss of power.

- Engine overheating.

Of course, you don’t always need to immediately grab a screwdriver and turn the adjusting screws - perhaps it’s something else. For example, when the idle speed floats, air may leak through the intake manifold gasket, or there may be a breakdown of the brake booster diaphragm. But even the reasons listed are not all the options, so specific recipes for eliminating certain problems cannot be given. The issue should be addressed comprehensively, taking into account the connection between vehicle systems.

Full adjustment of the combustible mixture preparation unit requires a systematic approach. The entire cycle consists of the sequential execution of the following steps:

autobann.su

Blend Setting

Regardless of which carburetor is installed on the VAZ-2106, the principle is the same. This setting allows you to adjust a good stable idle. But you need to remember that the setting only affects operation at idle and in transient modes, when the main dosing system is not yet activated.

The first step is to start the engine and warm it up. It is not recommended to adjust on a cold engine. Then, using the fuel quantity screw, set the speed at which the engine will operate stably. Then, by rotating the quality screw, they find the position in which the speed is at its maximum and does not increase any further. This will be what you need. Then simply use the quantity screw to reduce the speed to normal at idle.

In this position of the quality and quantity screw, the engine will operate in optimal modes and at the optimal mixture.

What do we have after proper adjustment of the carburetor unit of the “six”?

Checking the adjustments of the fuel mixture preparation unit is the same important maintenance step as monitoring the condition of the car battery . An integrated approach to setting up the carburetor guarantees not only a comfortable mode of movement, but also a lot of useful points:

- An increase in power and a confident increase in speed.

- No failures in the operation of the internal combustion engine in the low and medium speed sector.

- Improved dynamic characteristics - the car picks up speed faster and accelerates in a short time.

- Optimal engine response, which is expressed in the responsiveness of the gas pedal.

The listed qualities make it possible to effectively use the combustible mixture, which is necessary both in urban traffic jams and on country roads. Therefore, proper adjustment of the carburetor unit will help the car gain speed in a timely manner and complete the planned maneuver.

A carburetor is a component that prepares the fuel mixture for the engine. Its task is to ensure the correct proportions of mixing air with gasoline. The ideal ratio is: 1 portion of gasoline per 15 portions of air. During operation, the adjustment of the VAZ 2106 carburetor gradually gets lost, which leads to excessive enrichment or depletion of the fuel mixture with gasoline.