Fuel pump functions

The fuel pump is an essential component of the power supply system of any engine. The correct start and stability of the motor depends on how stable the device operates. As is correct, carburetor Zhigulis are equipped with DAAZ 2101 diaphragm-type mechanisms. This is a fairly simple device in terms of design features that can be easily repaired at home. On the other hand, it has to be repaired often.

The job of the fuel pump is to supply gasoline to the carburetor.

As mentioned above, the design of the mechanism is imperfect, which leads to frequent problems. The fact is that most often the quality of fuel at our gas stations leaves much to be desired. And the pump constantly works under high load. Gradually, problems with the fuel pump occur, which leads to unstable operation of the power unit.

How the mechanism works

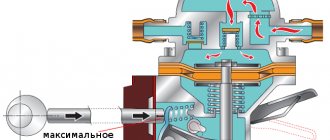

The fuel pump consists of a small number of parts that are connected using fasteners. The upper part of the body is equipped with two fittings through which gasoline flows into the carburetor. The presence of a lever allows the car owner, if necessary, to manually “pump up” fuel from the tank. This is done if the car has been idle for a long time.

The operation of the mechanism is based on the creation of pressure, which allows maintaining an acceptable level of gasoline in the carburetor chamber. The diaphragm can either reduce or completely stop the movement of fuel if the maximum pressure level is established in the fuel line. As a rule, the fuel pump is located on the left side of the engine compartment, on the side of the cylinder block. It is held in place with two pins. Gaskets and a thermal spacer are also used for adjustment. The spacer also acts as a guide for the mechanism rod.

The operating principle of the fuel pump is as follows:

- The timing mechanism drives the drive cam, which drives the fuel pump pusher.

- The membranes moving inside cause a vacuum or high pressure in the chamber.

- If the pressure is discharged, the outlet valve is driven closed. Gasoline begins to flow into the intake valve.

- When the pressure rises, the intake valve is brought to a closed state, and fuel begins to flow into the carburetor using a hose.

Where is the fuel pump located

The fuel pump is one of the most important devices in a car, performing the functions of pumping fuel. It takes gasoline from the tank, then sends it through a pipeline to the filtration system and then to the combustion chambers.

Often, the car owner needs to replace or temporarily remove this device; its location depends on the car model and the type of fuel system. In the VAZ 2107 it is located under the hood, directly next to the engine, so detecting it does not cause any difficulties.

How to choose a fuel pump for a VAZ 2107 (injector or carburetor)

It is often much easier to replace a fuel pump on a VAZ 2107 than to repair one that is broken. Today, the most popular models are from and DAAZ.

If a factory device costs about 600 rubles, then DAAZ pumps can be twice as expensive. Today you can often hear the opinion that these devices are more reliable, since at high temperatures the so-called vapor lock does not form in them. However, the experience of real owners shows that this opinion is wrong. And in terms of quality they are no better than their cheap counterparts. Do you think this is not true? Give your reasons in the comments!

Also today you can find representatives of the companies OTA (Italian equipment) and QH (equipment from the UK) on the market. These mechanisms are characterized by higher reliability and durability. But their price is almost three times more expensive.

VAZ fuel pump replacement - installation

When changing gaskets on a VAZ 2107 car with a mileage of 100 thousand km, before replacing the fuel pump, it is necessary to check the minimum protrusion of the pusher, since the correct position and stroke of the diaphragm unit of the fuel pump largely depends on it. If this is not done, either the fuel supply from the fuel pump will be reduced, or the diaphragm will fail prematurely due to a rupture. The protrusion of the pusher can be changed by selecting gaskets between the cylinder block and the spacer.

1. When checking the minimum protrusion of the pusher, you should take into account the gasket between the fuel pump and the spacer. For greater measurement accuracy, install two spacers (temporarily) between the spacer and the block.

2. Then set the minimum protrusion by slowly turning the crankshaft, pressing the spacer against the block, and measure the protrusion of the pusher. The amount of protrusion should not be less than 0.8 and more than 1.3 mm.

3. If the pusher protrudes by more than 1.3 mm, the gasket between the block and the spacer should be replaced with a thicker one, respectively, if the pusher protrudes less than 0.8 mm, replace it with a thinner one (0.3 mm).

If repairing the fuel pump is impossible and it has completely failed, you will need to replace the VAZ fuel pump; in this case, buy a model that is suitable for you and install it in the reverse order of disassembly.

How does a fuel pump malfunction manifest itself?

It is necessary to check the functionality of the mechanism if:

- the power unit refuses to start;

- the engine often stalls;

- you can feel the car's power and dynamic characteristics being reduced.

What causes problems?

The fuel pump may simply stop delivering gasoline . This happens when the filter elements are too clogged. Their price is cheap. Therefore, they can simply be replaced with new ones.

Other parts may also wear out:

- the diaphragm may be damaged;

- the spring may stretch and lose its rigidity;

- valves may be dirty;

- the unit may lose its tightness.

Another common breakdown is that the pump works until it warms up. Then the device overheats and stops functioning. This is due to the fact that a so-called vapor lock forms inside, which closes the passage for gasoline. To eliminate the breakdown, you need to replace the gaskets, rod or entire pump. As a last resort, if you just need to drive to the nearest auto repair shop, you can cover the fuel pump with a wet rag to enhance heat transfer. If it overheats, run cold water over it until you arrive at your destination.

Fuel pump assembly

- Fuel pump assembly

Essentially, there are no more parts that can wear out or cause problems. Assuming that we have everything we need, we proceed to assembly.

- We will need the following gaskets: for valves - it is best to earn extra money in the same way as the old ones, and for the sump bowl - you need to buy or add additional ones. Cork gaskets are best suited, but you can often find rubber gaskets in stores - they will also perform their function. We begin the assembly by connecting the lever to the diaphragm arm by inserting the bushing. It's worth using a little lubricant. Then we insert all this into the hole of the lever and, having positioned the holes of the bushing and the pump base in an axial manner, drive in the pin.

- If everything moves correctly, without resistance we can install the diaphragm with spring and socket. We insert the assembled assembly into the base of the pump, paying attention to which direction the diaphragm rod hole faces. When compressing the spring, it is necessary to pass the cable so that the tip of the hand passes through its hole. At this point we have the pump base filled, it's time to take the housing.

- We install the valves keeping in mind the gaskets and making sure the valves are mounted with the good sides in the holes. We screw the clamp to press the valves to the body and secure them correctly. Their opening direction must correspond to the direction of flow. So we have the complex main parts - the body and base, which we now screw together, installing the body in the correct position to the base, as it was before dismantling - the technical drawing is best to help.

- After properly twisting all the housing bolts alternately, press the sump seal into the socket, then place the glass and tighten it. With glass sumps, be careful not to break them. If we didn't move the hand pump arm, we basically have a complex pump, if it was disassembled, it needs to be reassembled, keeping in mind the proper mounting of the axle. Now all we have to do is check the functionality of our device. To do this, it is best to pump a little gasoline, thereby flushing the inside of the pump from any remaining water or kerosene with which we washed the parts. You need to make sure that the fuel does not return!

- After regeneration, we can screw a properly functioning pump to the engine, keeping in mind a fairly thick insulating pad; if it is too thin, we must buy a new one. For installation, we use, of course, new gaskets. The seals between the block and the pump should be additionally lubricated with high-temperature resistant silicone to prevent oil leakage. Now you can enjoy proper engine operation.

How to independently diagnose the fuel pump on a VAZ 2107

You can check the performance of the fuel pump yourself without resorting to the help of specialists. To do this, follow these steps:

- Loosen the clamp and remove the hose leading gasoline to the carburetor. There is some gasoline left in the pipe. So be careful not to get dirty. It’s better to place a small container and drain.

- Using a special lever we pump up gasoline.

- If gasoline flows from the fitting, then the pump is working. If not, follow the next steps.

- Remove the pipe from the pump supply fitting.

- We place a finger at the inlet of the supply fitting and try to pump up the pump. If your finger is sucked in, then the device is working well. If not, you need to disassemble it and look for the cause of the problem.

Fuel pump drive repair

The fuel pump on the seven works using an eccentric and a rod according to the following principle:

— the “pig” (intermediate shaft) rotates under the influence of the timing chain;

— the eccentric presses on the rod;

— the rod presses the pump lever, forcing it to work.

The weak point in this system is the rod. Today it is made from very bad metal. Therefore, the rod can wear out within the first thousand kilometers of use. Its edge is wrinkled. Naturally, the part in this case must be replaced.

Repair of fuel pump VAZ 2107

You don't need many tools to remove the device. It will be enough to prepare a screwdriver and a key crosswise at 13 millimeters.

Dismantling is carried out in the following sequence:

- We wipe the fuel pump so as not to get dirty.

- Remove both clamps and pipes.

- Now, using a wrench or socket, unscrew the two fastening nuts and remove the pump.

Now you can safely disassemble the mechanism:

- Unscrew the cover bolt

- Remove the cover and take out the filter

- Unscrew all six bolts connecting the two parts of the pump

- Now we have the opportunity to separate parts of the device body

- Let's continue the analysis. To do this, rotate the diaphragm 90 degrees and remove the spring.

- Unscrew the nut

- We completely disassemble the assembly and carefully inspect all components for wear.

- Filters need to be cleaned and worn parts replaced.

Cause of fuel pump failure

There are usually two reasons. The first is severe contamination of the fuel filter, the second is the car owner’s habit of driving with a half-empty tank.

We have figured out the purpose and location, now I bring to your attention instructions for replacing the fuel pump, that is, further we will talk about how to replace the VAZ fuel pump with your own hands.

1. First of all, you should prepare the car for this procedure; to do this, use a rag to clean the engine, cylinder block, as well as the fuel pump itself from dust and dirt, using white spirit or a special cleaner.

2. For the next stage, you will need two M8 bolts to plug the holes in the hoses, since when they are disconnected, fuel will leak out.

3. Next, using a Phillips screwdriver or an “8” wrench, loosen the fastening clamps that hold the fuel hoses and remove the hoses from the fuel pump fittings.

Now you can actually plug the ends of the fuel hoses with the previously prepared M8 bolts.

4. Replacing the VAZ fuel pump continues and the next step will be to remove the fuel pump; to do this, unscrew the two fastening nuts that secure the fuel pump to the cylinder block, using a key set to “13”.

5. When everything is ready, you can begin to remove the fuel pump from the studs, while paying attention to the condition of the gasket and, if necessary, replace it.

6. Remove and clean the heat-insulating spacer from dirt and dust, just as in the previous case with the gasket; if necessary, replace the gasket located between the cylinder block and the heat-insulating spacer.

Replacing fuel pump valves on a VAZ 2107

To repair the fuel pump, repair kits are purchased.

To replace a worn valve, you need

- Remove cores using a needle file

- The old valves are then pressed out using extensions

- Instead of the old valves, we install new ones and core them.

Installation and adjustment of the fuel pump on the VAZ 2107

Installation can be done in the reverse order of removal. This is a simple job that does not need additional explanation. Anyone who removed the mechanism can easily return it to its place. The main thing is to monitor the thickness of the gaskets.

If you have replaced the gaskets on your device, then you need to adjust the fuel pump.

- Place the gasket on the engine block studs.

- Now insert the rod into the spacer

- Place it on the studs.

- Don't forget to install the shim.

- All seals must be pressed as tightly as possible to the block. Now you need to use a key to slowly turn the engine crankshaft onto the pulley, placing the rod in a position that would allow it to minimally protrude from the surface of the gasket for adjustment.

- The output of the rod is determined by a caliper. If it does not reach 0.8 millimeters, then you need to install a thinner gasket. The normal value of the rod output is considered to be from 0.8 to 1.3 millimeters. If the value becomes too large, then the gasket needs to be thicker.

The fuel pump is an important device that is responsible for the proper and stable operation of the engine. Anyone can diagnose, replace or repair it. And these instructions will help you do everything right! You can print it on a printer and safely go to the garage)

Main causes of malfunction

The fuel pump can stop functioning only for two main reasons - lack of fuel in the beam or the occurrence of malfunctions.

In the second case, the causes of breakdowns are usually as follows:

- Using poor fuel that does not meet quality standards.

- Valve failure. Most often, they simply become clogged, in which case it will be enough to dismantle the lid and mesh of the device and then clean them. If the valves are loose and their position is unreliable, the pump will need to be completely replaced.

- A blockage in the filtration system through which the fuel passes, causing excessive pressure to be applied to the pump, preventing it from functioning properly.

- Lack of timely refueling and driving a car with a minimum amount of fuel in the tank. This causes the device to idle, which quickly leads to its malfunction.

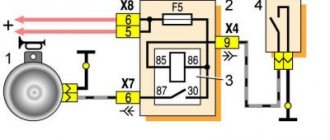

- Relay or fuse failure.

The VAZ 2107 is equipped with an injection pump - this is a fairly reliable device that rarely fails.

In most cases, all breakdowns occur due to the driver’s fault; If you suspect a malfunction, you can check the fuel pump in the following way:

- Using a screwdriver or a special wrench, loosen the clamp of the incoming hose through which the fuel is supplied, after which it can be removed from the studs.

- Install a plug using a bolt with a diameter of 8 mm; it will prevent fuel from leaking out.

- Make several movements using the hand drive lever. At this moment, it is necessary to monitor the outlet fitting - a sufficiently strong stream of fuel should shoot out of it, which will indicate that the device is in good condition. If this does not happen, you will need to move to the next step to continue the diagnostic process.

- It is necessary to loosen the clamp of the outlet hose and install a plug in the same way as was done before.

- A damper is placed on the inlet fitting; you can simply hold it with your finger, and then operate the manual drive lever again. The absence of a feeling of vacuum and suction of the finger inside will indicate that a breakdown has been detected: the fuel pump should be replaced or repaired.

- If no faults are detected at the previous stages, it is necessary to check the fuel line; most likely, it will be the cause of the breakdown.

We recommend:

Do-it-yourself replacement of a VAZ 2110 fuel pump: step-by-step instructions

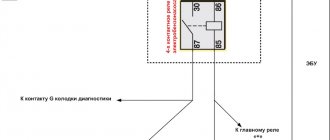

Unlike older models, the VAZ 2107 was equipped with an electric fuel pump, so its transition to operating mode and the start of operation is indicated by a characteristic buzzing sound that occurs after turning the winding key. Its absence may indicate a failure of the relay and fuse, so these parts of the device should be checked first.

It's quite easy to do this:

- You need to find a bracket with fasteners for these elements; it is located under the front panel near the glove box. It should have 3 relays and 3 fuses installed.

- Initially, the outermost fuse on the left side is inspected; there should be no signs of burnout on it.

- Next, the relay located in the middle is checked - you will need to check the voltage readings between the body negative after turning on the ignition and the pink wire.

- If there is a voltage of 12V, you need to short the pink wire to the gray wire, which will allow you to connect contacts 30 and 87 of the relay. The start of operation of the fuel pump will indicate a failure of the relay. This can be checked by temporarily installing a working relay removed from another vehicle.