UAZ for the hunter: Three winches for one Loaf

You can scold the loaf, you can accuse UAZ of being retrograde, but so far no one in Russia has come up with a way to replace it.

For example, take a very good version of the UAZ for a hunter. We built a car for the specific needs of a specific person and assessed the investment; Hunting takes up quite a lot of time in a customer’s life and is not the least of his interests.

Preparation and correct final product. The air intake is organized through a hole under the roof - a useful solution for fans of “swimming”.

Headlight protection is not a sham, but real steel. Well, it looks evil.

The additional canister on the gate for the spare tire increases the load on the gate, but makes very good use of the space.

In terms of mechanics, the engineers took a classic approach: a 65 mm body lift, Ironman off-road shock absorbers, pneumatic axle locks, a transfer case kit with a 3.3 lowering and higher-torque main pairs (5.2).

To install Simex Jungle Trekker tires mounted on Wheels steel wheels, the arches had to be trimmed. RIF hubs are responsible for disabling the front axle shafts.

To get into the interior of the tall car, a real retractable step was installed.

A house for talking about hunting. Or fishing. Or…

The interior of the off-road bus was divided into cargo and passenger areas.

There is no luxury ahead - only utilitarianism.

The standard front seats have been slightly adjusted to match the car's condition.

In the stowed position, the table folds up and does not get in the way.

The passenger compartment is modest, but not without a certain luxury.

Place for shmurdyak is always a sore subject for travelers by car.

The cargo-passenger version would not fit here without the need for a large trunk.

Moreover, there was room for a spacious shelf above the cargo area.

The trunk can be washed under pressure - everything is sealed and will not get into the cabin.

Special rails are installed for loading the carcass.

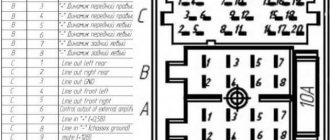

Runva 9500 winches are installed in the power bumpers, but in order to find the third winch, you will have to open the trunk.

A small winch for the quad is installed inside and is designed to drag the carcass of a hunted animal into it.

Electric windows made it possible to use the space for installing speakers.

In the stowed position, the canister does not extend beyond the reserve. It is almost impossible to damage it.

The final preparation of Loaf for life in the forest was completed by the Raptor protective coating.

The result was a good bus, capable of traveling along unknown paths of dense forests.

Nothing superfluous, but you will have to climb high for a shovel.

Off-road tuning UAZ Bukhanka

Another interesting project is the UAZ 452 Bukhanka. An individual approach is not just empty words here. I wanted not only to please the client, but also to make the SUV itself individual. Moreover, it should be beautiful, strong and modern.

Repainting the Raptor in camouflage. The most time-consuming part in this process is not the computer design and cutting of stencils on a plotter, but the consistency and accuracy of pasting and coating. After all, it is important to avoid dusting, blurring and do everything in your own order. Power kit. Without a power body kit, this is not an SUV. You won’t be able to cope with off-road conditions for long with plastic. Plastic for majors. Our cars are brutal and strong as a rock. Therefore, we threw out the standard bumpers and installed steel ones. A gate for a full-size spare tire was screwed onto the rear bumper. If you already have adult wheels, then if something happens - for example, a puncture, then driving on a small bald ride is simply ridiculous. Five full-size wheels! And their periodic, orderly replacement along the axes as they wear out.

UAZ Bukhanka front bumper OJ, winch STOKRAT HD9.5WP, lensed optics

There is a winch on the front bumper. The winch should not be plastic and dead. It must be reliable and powerful. In the end, we chose a HUNDRED TIME model HD9.5WP. Its feature is a durable 6hp engine, engine and gearbox seals to prevent moisture from entering, and enlarged struts. Enlarged racks (sidewalls) are a huge advantage. Having pulled out the displacement of the cable and winding it to one side, you can steal away... ruin any winch in a couple of minutes! After all, the force of the winch is enough for it to wind up the entire cable on one side and break the ties and the ears of their fastenings on the sidewalls. With such a breakdown, the operation of the winch and its easy repair is impossible. But this model has high stands, which means the drum volume is larger, which means that even if you had too much beer and got carried away with off-roading and forgot that you sometimes need to keep an eye on the cable, the likelihood of a breakdown is much lower than in comparison with other models. Instead of a steel cable, which can become frayed over time and turn your palms into rags if not handled carefully, there is a synthetic cable and a fairlead made of aluminum alloy. This not only creates comfort when using the cable and operating the winch, but also reduces the weight by about 15-17 kg. Only free-friction differentials are installed inside drive axles at the Ulyanovsk Automobile Plant. Those. Whichever wheel is lighter will rotate. This means that, for example, if you get up to pee on the highway and slide one side off the asphalt onto the roadside slurry, you may no longer be able to get out. But it would seem... We throw the free diffs into scrap metal and install self-blocks. We chose ValRacing self-blocks as the most accurate in quality and very reliable. They really, even to the naked eye of a specialist, look like a factory branded product, and not a piece of shit assembled in a garage on one’s knee. Lock preload 7.0. Light. He is called upon to fight the night, the darkness and everything that hides there. Halogen, xenon, only grandfathers will tell you how they assembled chandeliers on trestles from them. Our cars feature only the latest achievements in chandelier construction. LED technologies. High light output, low energy consumption, variety of choice, but the price... In order to defeat all the demons of darkness, we did not waste time on trifles and attached a 245Wt LED light bulb to the trunk. How do you like it? Bright enough? A beam with a bunch of LEDs with a combined design of diffusers and a panoramic shape. Bun type combo. Wide illumination angle. Beam length 130cm. Lensed LED optics were installed instead of the standard headlights. The formation of the luminous flux corresponds to low and high beam. I heard critics with higher technical education jump up from their seats in the hall and shout: “This is not in accordance with GOST!” Hmm, what in your life according to GOST? To blind all the critics from behind, to illuminate the camp, to skin a hunted wild boar or elk, to perform a maneuver in reverse, of course, we will not use a flashlight of one and a half glow plugs that is installed at the factory. We will use the best possible work light, ProLight. The same is naturally LED. Filling, economical, bright, indestructible.

UAZ 3962 “Grey” › Logbook › Installing a winch.

I bought the winch almost immediately after buying the car. Having studied I-Net, I came to the conclusion, agreeing with many practitioners, that the power of the winch should be twice the maximum permitted weight. I have a UAZ 39625 with a title of 2720 kg * 2 = 5440. A friend recommended the store polniyprivod.ru/, where I bought a winch for 17,000 rubles. Electric Winch 12000 with wired and wireless remote control, 30 m steel cable and 3 connectors (one for the front, one for the rear of the machine and one for the winch). As I later found out, the connectors hold no more than 200A of current, and the consumption of my winch at maximum loads can briefly exceed 400A. There was a need to find the appropriate wiring. Again, many days of searching for information, formulas, etc. Again, I had to rely on the opinion of experts that for every 10A a cross-section of copper wire (core) of 1mm2 is required. Accordingly, I took welding wires of about 40 mm2. The longer the wire, the more the losses in the conductor increase; accordingly, it is necessary to increase the cross-section of the core. The standard wires were short, so I had to disassemble the solenoid block and replace the positive wire with my own. Thanks to the guys, in the workshop they crimped the terminals with a special tool, put on the casings, it turned out no worse than at the factory, but it’s just enough from the bumper through the hole in the tunnel under the speedometer cable to the battery. In the future, I want to replace the battery (battery) with a 90 Ah instead of 60, replace the generator with an appropriate one (I’m still studying the characteristics) and install a winch power cut-off relay from a button on the panel (many complained that it sometimes shorts inside and the winch rewinds without responding to the buttons of the remote control and As a result, it breaks the bumpers, platforms and its own body). Also in winter, on the advice of friends, I will shorten the cable by 10 meters. When winding too long a cable to the side, a heap accumulates at the edge of the drum, which can break the transverse fastenings of the winch if you don’t keep track. So it’s better to interchange with a short cable several times.

I would like to share my development for installing a removable winch on a non-lifted UAZ 39625 (loaf, tablet) with standard bumpers. The task was unusual (I set myself the Technical Assignment), install the Electric Winch 12000 winch on a loaf without changing the appearance and without making changes to the design, so as not to register with the Technical Department, not to worry about technical inspections, not to cut the bumper, etc. Moreover, the winch must be removable and installed both front and back for all occasions. The winch platform should not be lower than the edge of the bumper. The rear footrests and standard towbar should be preserved (they are very comfortable). Centering the winch in the middle is recommended, but not required. Inspired by the idea on YouTube:

After much research on the Internet, I decided to make an American towbar: a square pipe is attached to the frame of the car, a square pipe of smaller diameter is inserted into it, welded to the platform with the winch and secured with a pin or a cotter pin. Having told the idea to the specialists (the head of the metalworking shop), they came to the conclusion that the lateral loads of the UAZ require a minimum of 2 square meters. On the Internet I found a picture with the sizes of the holes and the distances between them on the winch platform for the UAZ Patriot on the forum uazpatriot.ru/forum/viewt…pic.php?t=18614&start=210,

They coincided with the drawing in the instructions for the winch and sent it to the workshop. They did it in a week, slowly, but efficiently. The only point is that this platform should immediately be attached to the frame of the Patriot, and on my copy, on the right and left, I cut off the protruding ears with a grinder. We found a rectangular pipe, but there was no smaller diameter! We got out of the situation by taking solid pieces of metal, machined them and welded them to the site. The weight turned out to be the same! All that remains is to attach it to the frame. The hooks must first be removed. They are attached to the frame not with bolts, but with rivets, and are installed “hot”. I spent several hours sawing off the heads of each rivet with a grinder on both sides. I tried to knock it out - it was useless. I had to drill out first with a small drill, then with a large one, and only then was I able to break out the hooks. The left one also turned out to be welded to the frame along with the steering gear mounting spar - but it still broke off! What a pleasure! Next, I measured the width of the frame with a tape measure, estimated the width of the plate, and sent the drawing drawn on my knee to the workshop. Afterwards, the finished plate was attached to the frame, holes were marked on it along the holes from the hooks and again to the metalworking shop. The next time we assembled a ready-made structure.

UAZ 3962 Tabletos › Logbook › Installation of the Electric Winch 12000 winch (part 1)

A short report on the installation of the winch. The winch was installed on a 22 channel and two angles on a 4.

I offer my version of installing a winch on a loaf.

We throw out the original bumper and cut off the mounting ears. I removed the hooks because I want to install hinges on the winch platform.

I pre-cut the channel along the entire length and try it on, this is the main IDEA, install it inside the frame.

Next we raise the Vacuum Unit, we managed to raise it by 10cm. I actually had to cut out the fastening a little and move the stiffening jumper.

I screwed the corners 4 cm to the frame. I used the holes from the tow hook mount.

We cut the channel along the edges so that it fits into the frame, at a corner.

and final inspection before welding the entire structure.

The bolts in the corners coincide with the original mounting holes for the tow hooks.

cut off the excess, clean it and screw the winch.

I checked the design with a hi-jack, everything is holding up just fine.

All that remains is to lay the power cables and take the control unit into the cabin.

We make a winch for a UAZ Bukhanka with our own hands

The question of how a winch is made on a UAZ Bukhanka will certainly be of interest to those owners of an all-Russian SUV who do not yet have this device installed on their car. And it can, under certain conditions, make life much easier for the owner. And for those who are constantly accustomed to traveling off-road, hunting or fishing, a winch is an absolutely irreplaceable thing. As they say, where an ordinary passenger car cannot pass, a Russian SUV will definitely get stuck! But jokes are jokes, but we have to get out. And here an ordinary winch comes to the rescue.

The winch on the UAZ Bukhanka can be installed mechanical, electric, or hydraulic. And there are also hand winches, driven by human physical force using a lever. All of these options have their pros and cons. But let's talk in more detail about each of them.

The device is connected to the shaft. The source of interaction is transmission. The winding speed is controlled by decreasing/increasing engine speed. Other advantages include high stability and traction power (achieved by motor torque). This type of winch is driven by the transfer case of the car. The main disadvantage: the winch directly depends on the serviceability of the motor; for successful operation it requires a properly running motor. If there is a problem with this node, it simply stops functioning.

This kind of device is attached to almost any car that comes with a hydraulic mechanism (UAZ included). The advantages: it works quietly and has small dimensions, powerful and has high performance. Of the minuses: its operation will be directly related to the hydraulic booster (if not, then the device will not function).

For homemade winches, as a rule, starters or generators can be used for loading. The electric winch can also operate on a dedicated electric motor installed in the car. But usually such a winch is mounted on the basis of a converted starter and must operate at sufficiently high speeds, otherwise it will not cope with a heavy machine. Therefore, some install batteries with large power reserves on their cars. Pros: high speed of operation, autonomy (can work regardless of whether the motor is on/off), simplicity of design. Of the minuses: it does not tolerate moisture well, the battery drains quickly.

Since a purchased winch, and even more so its installation, is not always available (most often due to the high cost), craftsmen have gotten used to constructing the structure with their own hands. By the way, this is quite possible to do if you have the necessary tools and certain skills. And yet, our homemade device must have a high torque, otherwise it simply cannot be used for a heavy UAZ (for example, to pull the car out of a mud hole). And most importantly, building a homemade winch will allow you to save a lot of money!

We make the structure itself using a welding machine and an angle grinder from pipes, 5 mm thick sheets of metal for the manufacture of drum discs, a chain with sprockets and a hub. All work is carried out clearly according to pre-drawn drawings. And remember the golden rule: you need to measure repeatedly before cutting.

After the winch structure itself is ready, you can install it on the UAZ Bukhanka. First, we carefully prepare the site. But first we decide: we will install the winch in front or behind. Typically, many people prefer a front location in the central part of the bumper. A channel is usually used as a platform for the device. A piece of it fits well on the car frame.

Approximate width of the piece: 240 mm, it should be about a meter long, and up to 10 centimeters high. Then you will have an ideal site for installing the device. To carry out the work, we remove the bumper (with a guard, if available), and the radiator grille to facilitate access. We mount the structure with powerful bolts (4 will be enough) on a platform made from a piece of channel.

It must hold very firmly, because the weight of the machine is up to 2 tons. It makes more sense to place the drive unit itself in the cabin, since there it will be less exposed to weather conditions. Well, the winch on the UAZ Bukhanka is ready for use. You can begin to test the structure for strength and performance, and it is better to do this in the field.

Installation of a winch on a UAZ

The electric winch on the car is an optional equipment. This is a special device for moving and lifting loads; it also serves to self-pull out a car stuck in the mud.

Winches come in three types: mechanical, manual, and electric. It is clear that it is better to choose an electrically driven winch. Because, if necessary, there will be less work.

Today there are a huge number of similar devices on the market, and it is difficult for an inexperienced buyer to choose which brand to prefer.

Which winch to choose

In order to choose the most suitable winch, you must be guided by its strength, stability, absence of distortions and deformations of the body, as well as compliance with the dimensions of the winch.

Almost all Chinese winches, the traction force of which is 4-4.5 tons (9000 - 10000 lbs), fit well inside the frame of UAZ family cars.

Popular brands include winches from the American manufacturer – WARN and RAMSEY. These winches are reliable, time-tested and strong. As a rule, they are installed on cars that constantly participate in competitions.

“Americans” have proven themselves to be excellent in difficult operating conditions; they turn the cable without any overheating of the housing and gearbox, which is especially important in harsh temporary conditions.

American winches are the most expensive on the market; on average, the price of such a unit for a UAZ varies between 40-90 thousand rubles. Despite such a high price bar, WARN and RAMSEY have been operating for more than seven years, which directly confirms their quality and reliability.

COME UP

The brand's electric models are manufactured in Taiwan and are a reasonable replacement for American models at an attractive price. Such winches operate in difficult conditions without breakdowns for five years, helping their owner in difficult situations.

The average cost of COME UP in Russia is 30-35,000 rubles, which, along with quality, plays an important role when choosing a buyer. The owners have not identified any disadvantages in using this winch; there are only the most positive reviews about it. However, 30-40 thousand rubles is quite a large and unaffordable amount for many, and then we recommend the following option.

ELECTRIC WINCH

This is the most popular and cheapest winch in its segment. Perhaps the most popular in Russia at the moment, because its average price is only 15,000 rubles. The winch is reliable, it is ideal for expeditioners, those who prefer hunting and fishing to competitions.

The only negative noted by the owners is the insufficient amount of lubricant in the gearbox. The solution is simple - disassemble the winch gearbox yourself and add grease.

Winch configurations

The additional equipment of the electric winch includes:

• the device itself, • a cable on the drum, • a hook, • a joystick • a remote control • a shift lever • a solenoid block • cable rollers (they are called lips) • fastening bolts • instructions for using additional accessories are not included in the standard kit, therefore, If you decide that you cannot do without a corrosion-protective sling or pulley block, purchase them separately.

When purchasing, you should pay attention to the rollers on which the cable is laid. The distance between the vertical and horizontal lips should not be greater than the thickness of the cable, otherwise it will bite when winding.

Recommendations for installation and operation

As a rule, installation of additional equipment should be carried out in special workshops. If this is not possible, you can install the winch on the car yourself, without the help of a specialist. Here are some tips:

- Determine where the winch will be installed: in front or behind the car.

- Prepare a platform for the winch: find a suitable piece of channel that should fit perfectly into the car frame.

- We install the winch on the bolts that are included in the package. To avoid damaging it when tightening the bolts, place the bolts on the corners.

- Install the winch straight, it should not be at an angle, otherwise there is a risk of breaking the unit in half when pulling the car.

- Experienced people recommend removing the standard generator and replacing it with a generator from the Bychok bus. The 90-amp Bychka generator will allow you to pull out the car without the risk of draining the battery.

- When winding the cable onto the drum, make sure that the cable lays flat, this way you will extend its service life.

- It is recommended to remove the solenoid block under the hood, or better yet, directly into the interior. Because your car will drive through puddles and creeks, and when it gets wet, the block will close.

- When operating a winch, always throw a jacket or thick rag into the middle of the metal cable. The cable can break under load, and it’s good if there are no injuries.

That's probably all. Of course, each UAZ owner will decide for himself which winch to purchase; we hope that this article will help you better navigate the world of additional equipment for the UAZ driver.

DIY winch for UAZ

Active recreation has become more accessible than twenty years ago. Many thrill-seekers equip Soviet SUVs UAZ and Niva and try to overcome places where an ordinary passenger car cannot go. But even an experienced driver can find himself in a situation where he needs to pull his car out of a hole or mud. And it’s good if there are people and equipment nearby. What if you’re in a deep forest alone or with your family?

In this case, only a winch can save you. You just need to find a suitable support (a fairly thick tree pole or boulder) and secure it with a cable. Rest assured, the winch installed on the UAZ Patriot, for example, will slowly but surely pull your car out of the sand, mud or hole. But there is one drawback - the price. This device is not affordable for every car enthusiast. That is why in our review today we will talk about how to assemble a winch for an UAZ using a homemade method.

Winch for UAZ 469: Choosing the right one and installing it yourself

A new, very detailed material about the winch on the UAZ 469 has been released on our website. We are happy to share it with you!

There is a strong opinion among car enthusiasts that installing a winch in a service center is the most reliable, proven option. If they have the finances, many people prefer to entrust the configuration of their SUV to professionals. However, an impressive proportion of UAZ owners like to tinker with their equipment themselves. If you understand the design and devote enough time to studying this topic, you can independently install a winch on your UAZ 469.

How does a hand winch work?

The manual winch (built into the UAZ Bukhanka, for example) has the simplest design. The cable is wound onto the drum using a lever (you can use a small crowbar or a pry bar). This device has its advantages:

- independence from energy sources and other resources;

- fairly small dimensions and light weight;

- availability (low price);

- As the lever increases, the winch's thrust increases.

Disadvantages include discomfort when working in unsuitable conditions (rain, snow, frost, dirt).

Installation of a winch on a UAZ in Balashikha

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

A toll-free number 8-800 is available on the seller's website. To go to the site, click “Go to store”

“One-click ordering” is available on the seller’s website. To go to the site, click “Go to store”

Electric winch

This type is the most popular among many car enthusiasts. The main part of this winch is an electric drive, which is powered by on-board wiring. It's quite easy to operate. The advantage of an electric winch is that it can work without a running engine, that is, autonomously. The principle of its operation is simple: you need to unwind the required length of the cable, fix it and start the electric drive. It is attached to a special power bumper (its diagram is shown below).

- sufficiently high operating speed of the electric drive when winding the cable;

- independence from running engine;

- ease of use;

- the ability to equip the device with additional sensors.

Disadvantages include moisture intolerance, relatively low battery charge and high cost.

Now let's move on to the pressing issue. How to make a winch on an UAZ with your own hands?

Making a homemade part is quite possible. To do this you need to have the necessary tools, materials, skills and patience. An installed winch (on a UAZ), made by yourself, must have a high torque in order to pull heavy vehicles out of mud or sand. Some car owners do not believe that a reliable device can be made at home. But it's real. And most importantly, this will save money and not buy an expensive item.

Materials needed to make a winch:

- square frame pipe 30x30 mm;

- pipe with a diameter of 150-180 mm for the future drum;

- four metal sheets (5 mm thick) for making the working surface and drum discs;

- metal pins (M12 and M14) 200 mm long - six pieces;

- six sections of 12 mm pipe, 200 mm long;

- chain, two sprockets, hub for installing the shaft and drum.

You will also need a cable of a certain length, a reliable carabiner, a welding machine, an angle grinder, and paint and varnish materials.

How to Install a Winch on a UAZ 469 with Your Own Hands.

A winch is a fairly popular automotive equipment. It is used to move various loads and also pull cars out of mud and other obstacles.

The UAZ 469 is often used in off-road conditions, as it has high cross-country ability. Accordingly, how to install a winch on a UAZ is a rather pressing question for owners of such cars.

Choosing a suitable winch. There are many different modifications of such equipment on the market.

The winch for 469 UAZ can be:

manual, mechanical, electric.

Naturally, electric ones are the ideal option. They have excellent characteristics, and are quite simple and convenient to use.

Although, if desired, you can consider other options. However, priority is given to options with a towing force of 5 tons or more. This winch will be a great help if you need to tow another car.

Installation Having figured out which winch to install on the UAZ, it’s time to get acquainted with the main points of its installation. Many people prefer to immediately contact a car service center, where specialists will do all the work.

However, with the proper approach and desire, a do-it-yourself winch can easily be installed on an UAZ.

Self-installation involves the following action plan:

preparing the site, fixing the winch with bolts, installing a new generator, testing.

The winch can be installed on the UAZ 469 either from the front or the rear. All winches are universal in design, so installation from any side is allowed.

The platform is made of a channel, which is securely fixed to the vehicle frame. The equipment is already installed on the prepared site.

Levels and securely fastens with powerful bolts. As soon as the installation of the winch on the UAZ is completed, everything needs to be carefully checked and tested.

See how smoothly the cable lies. If no problems are identified, you can fully use the winch. It will be a great help for off-road driving enthusiasts.

Stages of making a winch for a UAZ with your own hands

- We take a grinder and cut a square pipe, and then use welding to connect the parts. We check their perpendicularity, equal angles, and dimensions. The platform for the winch on the UAZ is fixed, then we make special holes in it with which the motor will be attached. The essence of the next stage is to clean, prime and paint the resulting structure. Then we start making the drum.

Yes, regarding the time spent on work. As a rule, installing a winch on a UAZ is not too long. Ten hours is enough.

UAZ 39095 diesel with automatic transmission, 39 rollers › Logbook › Installing a rear winch on a UAZ Bukhanka

Take a 20 cm wide channel and place it in the frame immediately after the diagonal jibs of the rear cross member using M12 bolts; the channel can be made lighter by cutting out windows in the bottom shelf

the lips are placed on a bracket screwed from below to the frame immediately under the tow bar so that the lips do not bend downwards, we reinforce it either with a towbar under the ball or with spacers from the bracket to the channel

READ Rav4 how to install navigation

without this reinforcement, when lying sideways, the lips will bend along with the bracket

DIY ratchet winch

For a device of this type we will need a brake mechanism from a KamAZ truck. This mechanism can withstand loads of up to six tons.

We disassemble the gearbox, take out the gears, disassembling the so-called “worm mechanism”. To do this, we need to knock out the splined shaft with a hammer. You can squeeze it out with a press, but not everyone has it.

We weld the resulting parts together according to the plan. We remove the gear and fix the pipe vertically in a vice. Between the slots and the tube we drive nails opposite each other. This will help center the mechanism relative to the gear.

After this, we cut off the heads of the nails to the root and strengthen the structure by welding. We insert the gear into the body of the gearbox, simultaneously with the “worm”. The shaft gets hammered into the “worm”. To install the drum, take two washers and weld them to the drive shaft.

The work is finished, now you can install the winch on the UAZ and use the useful device.

DIY motorcycle winch

You won’t believe it, but a winch can be made from an old motorcycle lying around, or rather, from some parts that are great for making a “homemade” mechanism.

As in previous versions, we fix the motor to the frame. The working part of the winch is made of the main sprocket (it is located on the engine). A motorcycle chain is perfect for our needs. We secure the drum with previously prepared nuts and bolts. If the design allows, then longitudinal holes can be made on the frame. They will allow the drum to move, which will help regulate chain tension.