DMRV VAZ 2110 (mass air flow sensor) is an electronic device of a VAZ car, with the help of which the amount of air entering the cylinders is calculated. The MAF 2110 transmits the measurement data to the vehicle's electronic control unit, which, based on this information, determines the air-fuel ratio in the air-fuel mixture using a pulse signal.

It is not difficult to guess that the VAZ 2110 air sensor, which is responsible for the composition of the air-fuel mixture, is an important element; the fuel consumption and power of the internal combustion engine depend on the efficiency of its operation. For this reason, it is very important to monitor the condition of the sensor and correctly diagnose the malfunction. Next, we will look at what are the signs of a malfunction of the mass air flow sensor, as well as how to check and how to replace the mass air flow sensor on a VAZ 2110.

DMRV sensor 2110: how it works and works

The VAZ mass air flow sensor is a fairly simple device, consisting of a housing and a thermal anemometer located inside it (a device for measuring the amount of air). The hot-wire anemometer contains two platinum filaments that are heated by electric current. Air passing through one thread cools it, the second thread is the control.

The amount of air (air consumption of the VAZ 2110) entering the internal combustion engine of the car is determined by changing the current passing through a platinum filament cooled by the air flow. The sensor is located under the hood of the car between the air filter and the corrugated hose directed to the throttle valves.

Mass air flow sensor design

The most common automotive mass air flow sensors operate on the principle of the so-called “heated string”. The string is made of metal and can look different: for a GM device it is a wire with a diameter of about 70 microns, for a BOSH sensor it is a special mesh membrane. The string is placed in the flow of air entering the engine, which cools the metal.

An electric current is passed through the string, which in turn heats the string. Another similar string is placed outside the air flow and used as a temperature standard. The resistor bridge automatically supplies such electric current to the string in the air flow so that it remains heated to the reference temperature. The stronger the air flow, the greater the cooling of the string and the more electricity is required to maintain a stable temperature.

The string is made of platinum: the resistance of this metal strongly depends on temperature. This ensures high sensitivity of the device and accuracy in determining air flow speed. By measuring the voltage on the “heated string”, the device determines the speed of the incoming air. It is the speed of the flow, multiplied by the cross-sectional area of the channel, that determines the volume of air entering the engine per unit time.

In physics, there are two types of mass: gravitational (as in the law of universal gravitation) and inertial (as in Newton’s second law, connecting mass, force and acceleration). The injector sensor on the VAZ 2109 does not measure either gravitational or inertial mass at all. It determines not the mass, but the volumetric air flow. This is correct from the point of view of the theory of operation of the internal combustion engine, which is described in thermodynamic concepts. We are always talking about pressure, temperature, working volume of a gas, but not about its mass.

The electronic control unit linearizes the mass air flow sensor measurements and issues control commands to the injector taking into account the air temperature, its humidity and the current operating mode.

When you need to change the DFID sensor 2110: symptoms of sensor malfunction and check

During the operation of a vehicle, the mass air flow sensor 2110 can fail for various reasons, one of which is the long period of use of the device. When a sensor fails, it is usually not repaired; it is simply replaced with a new one. The following symptoms may indicate that the sensor is not working properly:

- “Check Engine” lights up on the car’s dashboard (you need to check the engine);

- fuel consumption increased, acceleration dynamics decreased;

- the car engine does not start;

- at idle, the car’s internal combustion engine operates jerkily (change in idle speed down or up).

All of the listed signs of sensor malfunction indicate that air is not being supplied to the mixture in the volume required. Taking into account the fact that this problem may be associated not only with a malfunction of the mass air flow sensor, before proceeding with dismantling the sensor, it is necessary to make sure that it is faulty.

In fact, the VAZ 2110 mass air flow sensor can be checked for performance using three methods: in motion, with a multimeter, visually. Checking the mass air flow sensor 2110 experimentally (in motion) is the easiest and fastest way. It consists of analyzing the operation of the vehicle’s internal combustion engine when the sensor is forcibly turned off.

Algorithm of actions:

- opening the hood, disconnect the mass air flow sensor connector;

- start the car engine;

- since the car will operate in emergency mode, the “Check Engine” light will come on and the amount of air in the fuel mixture will be determined depending on the throttle position;

- Having driven a car operating in emergency mode, you need to pay attention to its dynamics and compare them with the dynamics before the sensor was turned off;

- If the car accelerates faster with the sensor turned off, the air flow sensor is faulty.

The next stage of diagnosis may be checking the mass air flow sensor 2110 with a multimeter. This method of checking the sensor for functionality involves the use of a measuring device (multimeter).

Before checking, you need to understand the design of the device and find out its “pinout” (soldering of wires on the board). There are four wires coming out of the MAF. Typically these are the wire to the main relay (pink/black or pink), ground (green), power (gray), and signal input (yellow).

To check you need:

- set the multimeter to constant voltage measurement mode, setting the limit to 2 Volts;

- without starting the engine, turn on the ignition;

- connect the black multimeter probe to the ground wire, the red one to the signal input of the multimeter sensor, inserting the multimeter probes through the rubber seal of the connector;

- take measurements and use the results to determine the state of the sensor.

Based on multimeter readings:

- voltage 0.996-1.01 Volts (new sensor);

- voltage 1.01-1.02 Volts (working sensor in good condition);

- voltage 1.02-1.03 Volts (sensor working, with long-term operation);

- voltage 1.03-1.05 Volts (sensor is worn out and may fail);

- voltage from 1.05 Volts and above (the sensor is faulty and requires replacement).

If the device is not at hand, the faulty sensor can often be determined by its appearance, that is, by visual inspection. In this case, it is necessary to dismantle the device and carefully inspect it for mechanical damage or for the presence of liquid in the sensor and air pipe.

The reasons for liquid and dirt getting into the sensor can be different (for example, the oil level in the crankcase is increased, dust gets on the hot-wire anemometer due to untimely replacement of the air filter, the oil sump of the crankcase ventilation system is clogged, etc.).

Cleaning the sensor

If you observe signs of a malfunction of the mass air flow sensor, then you can try cleaning the device.

By the way, this is the most expensive sensor of all in the line of front-wheel drive VAZ cars. But if yours is broken, don’t rush to change it. There is a small chance of restoring his “health”.

For the cleaning process you will need a special liquid that is used to clean the carburetor. Star keys are also useful. Unscrew the clamp, as well as the two “10” bolts.

Remove the pipe and take out the sensor. Spray the liquid onto the wire and tube. Work with extreme care, wait until this liquid has completely evaporated and leave the device to dry.

While the device is drying, remove the throttle assembly. You will see plaque inside the throttle assembly. It needs to be removed with liquid.

This dirt causes problems with the entire system. Because of it, problems with the mass air flow sensor appear, signs of a malfunction of the VAZ 2115, which bother beginners on automobile forums.

Do not remove the throttle cable. Place the knot on a cloth and treat particularly dirty areas with the liquid. Don't forget to clean the idle air control valve and the space underneath it.

After this, most likely, all signs of problems with the mass air flow sensor will go away, of course, provided that the sensor has no mechanical damage. Therefore, do not wait until you have the first signs of such problems, but take such prevention this coming weekend. It won't take you much time, and your car will truly breathe.

You won't recognize your engine. It will start much better, its traction will improve, and you will notice an increase in the power of your engine.

Carry out such preventive maintenance regularly, and your car will thank you.

The automotive market does not stand still; manufacturers are constantly improving car engine power, fuel consumption, aerodynamic values, and coming up with options for changing overall comfort. The main and obvious improvement was the transition from the use of a carburetor method of power supply to a more efficient injection system.

How does the latter work? Regulates the quantitative supply of fuel according to a single dosage for the operation of the power plant in different formats of activity. This allows you to reduce the amount of air consumption and ensure maximum power output from the power structure.

However, mechanics argue that the design of the carburetor system is technologically simpler, because the carburetor operates mechanically, which means that the mechanism can be assumed to be highly reliable. The VAZ-2110 is equipped with such a system. The advantage of the device is that the fuel-air mass is formed in the carburetor and in the cylinders through vacuum, which is created by the pistons.

Replacing the air flow sensor

To replace the VAZ 2110 mass air flow sensor, you need a part suitable for this model (the new sensor must have the same markings as the old one). In terms of selection, there are three price categories:

- Chinese-made sensors (relatively inexpensive);

- mid-price sensors from the manufacturer AvtoVAZ and some foreign manufacturers;

- high-quality and reliable, but quite expensive imported sensors;

When choosing a new sensor, you should focus on both the price and the manufacturer (Siemens, Bosch, etc.). In any case, you can buy a VAZ mass air flow sensor at any auto supply store, taking into account financial capabilities and personal preferences.

We also recommend reading the article about what kind of oil to pour into a VAZ 2110 gearbox. From this article you will learn about the features of selecting a VAZ 2110 gearbox, how much oil is in a 2110 gearbox, and what you need to consider when choosing a lubricant.

Replacing the mass air flow sensor itself involves dismantling the old device and installing a new one. The procedure is quite simple, accessible to every car owner and can be done with your own hands. Before replacing the sensor, it is necessary to carry out a number of preparatory work:

- buy a mass air flow sensor with the same markings as on the body of the old sensor;

- prepare the necessary set of tools, screwdrivers of different sizes, wrenches or socket wrenches or wrenches with socket heads;

- multimeter (if necessary).

General procedure:

- Place the car on a level surface, lift the hood, remove the negative terminal from the battery;

- disconnect the mass air flow sensor connector;

- loosen the fastening screw of the corrugated hose with the mass air flow sensor housing;

- using a “10” wrench, disconnecting the hose, unscrew the two mounting bolts of the sensor with the air filter housing;

- Remove the old sensor housing and replace it with a new one, installing it in the reverse order of removal.

Please note that after the repair it is necessary to make a test drive to check the dynamics and power. You may also need to replace the air filter if the existing filter element is too dirty. It is also recommended to blow out the air filter housing with a compressor before assembly.

Troubleshooting methods

You don’t have many options for solving the problem - you can either try to clean the sensor or replace it with a new one. The cleaning and replacement procedure is described below:

- First you need to dismantle the mass air flow sensor. To do this, loosen the bolt that secures the corrugated hose to the device body, then disconnect it.

- Next, you need to unscrew two more screws, with which the mass air flow sensor is fixed to the air filter housing. Having done this, you can dismantle the controller. If you decide to change it, then you will simply need to install a new mass air flow sensor and perform the assembly in the reverse order. But if you want to try to restore its functionality, you can clean the device.

- After dismantling the regulator, it must be disassembled. There are spirals on the device, so when dismantling the regulator, be careful not to damage them. As practice shows, these spirals are very sensitive; there are even cases where car owners, simply wiping the mass air flow sensor with a rag, put it out of action.

- Now you will need a special carburetor cleaner, which can be purchased at any store. Before cleaning, make sure that the pressure from the cylinder is not strong, since excessive pressure can also damage the device. The device body itself should not be heavily processed, since the plates and spirals are the most contaminated, so these components need to be processed as much as possible. It should be noted that this process must be carried out in several stages. The point is to let the device dry a little after treatment - this will allow the dirt to dry out as much as possible. The procedure must be repeated several times at short intervals; eventually, the air flow sensor will need to be washed. The cleaning process itself is repeated until clear, clean drops of cleaner begin to flow from the sensor. Then you can reinstall the device by assembling all components in reverse order.

Let's sum it up

As you can see, the VAZ 2110 mass air flow sensor is a fairly important component of the car in the ECM device. This sensor closely interacts with the computer and determines the degree of enrichment of the fuel mixture with air.

It is quite obvious that any malfunction of the sensor will sharply reduce the efficiency of the engine. At the same time, selecting and replacing the sensor is not difficult. The main thing is to choose the right device and follow the instructions above.

We also recommend reading the article on how to replace the cabin filter on a Lada Granta. From this article you will learn when to change the cabin filter on a Grant, as well as how to change the cabin filter on a Grant with your own hands.

Finally, we note that if the sensor is dirty, it is not necessary to immediately resort to replacement. At the initial stage, it is cleaned, as well as the pipes are treated to remove accumulated debris, dust and dirt, and at the same time, all components of the sensor are inspected. However, if there is no positive result, it is necessary to purchase and replace the device.

Main symptoms

So. If you have problems with your mass air flow sensor, the signs of a malfunction can be very different. Among them are failures during acceleration, lack of traction, and decreased power.

There is a persistent feeling that the car simply “does not go.” If there is no proper response when you press the gas, then this is one of the signs. High fuel consumption is also a signal for diagnosing this sensor.

When your car stalls when shifting from gear to gear, it makes sense to check the MAF sensor. The VAZ 2110 has the same symptoms of malfunction as other cars.

If you have difficulty starting a cold engine, if the engine operation is unstable, if the speed spontaneously increases or, conversely, decreases, if detonation occurs under load - these are all signals for checking and diagnosing the sensor.

Mass air flow sensor device (English abbreviation - MAF)

- The housing is made in the form of a cylinder, the diameter of which coincides with the air duct of the intake manifold. Installed at the outlet of the air filter (using the example of a VAZ 2112). The housing itself is a calibrated measuring channel.

- To protect against foreign objects, a deflector and a metal screen in the form of a mesh are installed at the entrance. The correct air flow is formed through them.

- The air flows through the flow sensor itself, which operates on the thermal anemometric principle. There are two resistors installed inside (reference and variable), connected to a common circuit using a ballast circuit. Variable, precision, changes resistance when cooling and heating. The thread of this resistor is made of an alloy of iridium and platinum. The control board monitors that the resistance is the same. To do this, a platinum thread cooled by an air flow is heated by electric current. The resistor is constantly supplied with voltage, the value of which varies with an accuracy of 1/1000 volt.

- The value of this voltage is output by the MAF circuit to pin No. 5 of the connector. The signal is read by the ECU controller and programmatically converts this value into air mass (kg/hour).

For the fuel-air mixture to work efficiently, gasoline and air are mixed in a ratio of 1 to 15. Therefore, it is important that the mass air flow sensor produces accurate data.

We check the mass air flow sensor on a VAZ-2110 with a multimeter

The sensor block, the first wire may not be there - this is normal.

To do this, we need to understand the pinout and the sensor connection diagram. As you can see, the block has only five wires:

- + 12 Volt.

- + 5 Volts.

- Total ground (green wire).

- Air temperature output signal.

- Air flow signal output (yellow wire).

Electrical diagram for connecting the mass air flow sensor.

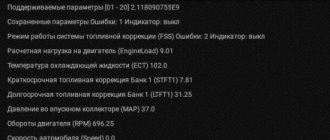

The pinout may differ in different firmware versions and on different sensors. Everything is clear with the first two contacts - take a multimeter and check the presence of voltage when the ignition is on. If there is no signal, we look for the cause either in broken wires or in poor contact. Now we check the main indicator - the accuracy and magnitude of the air flow signal. By the way, this can be checked without a multimeter, using the on-board computer, if one is installed:

- We go to the menu, look for sensor parameters.

- Find the voltage Udmrv.

- The rating for all of the above modifications is from 0.996 to 1.01 V.

The platinum thread gets tired over time and distorts the impulse upward. A change of even one hundredth of a Volt is unacceptable. If the computer is not installed, we use a multimeter. We check the voltage between 3 and 5 (minus) contacts , setting the measurement limits on the multimeter to 2 V. Turn on the ignition, but do not start the engine.