The car owner of a "tens" may be taken by surprise by a breakdown of the clutch system. This means that there will be unplanned expenses for spare parts and auto repair shop services. Replacing a VAZ 2110 clutch is not cheap, from 3,500 to 5,000 rubles, not counting the cost of spare parts. However, there is an option to save a significant part of your personal savings and replace worn-out parts with new ones - yourself. Let's face it, this is not an easy procedure. But, following the instructions, it is possible to deftly manage it in one day.

Removing the gearbox

To gain access to the clutch on a VAZ 2110, you need to remove the battery and air filter (completely, along with the mass air flow sensor).

Unscrew the drive (the so-called cable).

Unscrew the starter.

Unscrew the top bolts securing the gearbox to the engine.

Disconnect the speed sensor “chip” and remove the wiring harness fastening.

Now you need to “hang” (raise) the front wheels of the car. Let me clarify - we removed the gearbox only to repair the VAZ 2110 clutch, and the method that I describe and present in the photo allows us not to pull the drives out of the “box” and not to drain the oil from it. Loosen the drive nut on the right side of the gearbox almost to the end of the thread, and on the left, tighten it completely (from here we will pull out the drive).

Unscrew the suspension arm.

Now the ball joint.

As well as suspension arm bolts (two pieces).

The front suspension arm has been removed.

Remove the “mudguard” (lower engine protection). Disconnect the reverse light switch.

Unscrew the torque rod from the gearbox and remove the lower crankcase cover.

Loosen the nut on the collar of the rocker link (transmission control drive) and disconnect it. Note that after the repair of the VAZ 2110 clutch is completed and the box is installed in place, the link will need to be adjusted.

Unscrew the lower bolt and nut securing the box to the engine. Finding and unscrewing a bolt is not a problem, but finding a nut can be difficult. It can be “closed” by the drive located in the box.

Place the jack under the engine, being careful not to damage the sump.

Unscrew the gearbox from the “cushion”.

Lower the engine slightly on the jack and remove the gearbox.

As for my case, a complete replacement of the VAZ 2110 clutch was not required. The cause of the malfunction was the breakdown of the release bearing, and only the basket, disc and, naturally, the release bearing itself had to be changed.

This is interesting: Where is the ball joint located?

Technology for replacing the clutch disc on a VAZ 2110 car on your own

Some zealous car owners are starting to look for an accessible solution, for example, in the form of welding a layer of metal onto the legs of the basket. However, it is difficult to increase the same thickness; misalignment occurs, which again leads to uneven wear of the unit. Therefore, it is more reasonable to immediately install a new part, for which we will consider the procedure for implementing the repair:

- To prevent a short circuit, remove the negative terminal from the battery.

- Disconnect the mass air flow sensor connector, loosen the clamp securing the corrugated pipe and remove the air filter housing to gain access to the gearbox mounting bolts.

- Loosen the left wheel mounting bolts and lift the car on a lift or jack up the front part and install supports.

- Remove the front left wheel and remove the engine protection (if equipped).

- Using two 19mm wrenches, loosen the two cable fastening nuts and remove the cable from the bracket to the gearbox.

- Unscrew the top bolt securing the autostarter to the box using a 17mm wrench, then use a 19mm wrench to unscrew the nearby gearbox mounting bolt.

- Remove the speed sensor connector and disconnect the speedometer drive cable.

- Remove the torque rod of the gearbox drive, having previously made marks at the place where the clamps are attached, so as not to have to adjust the gear shift lever later.

- Unscrew the second starter mounting bolt and remove it.

- Unscrew the lower bolts securing the left ball joint.

- Before replacing the clutch disc on a VAZ 2110, dismantle the longitudinal extension with the transverse link.

- Using a pry bar, remove the drive from the gearbox, and instead insert some kind of plug (rolled newspaper or old hinge) to prevent rotation of the satellites. Repeat the same operation with another drive. Tie the drive with a rope to the stabilizer.

- To prevent the engine from twisting during repairs, place a support under it.

- Unscrew the remaining bolts securing the box to the engine and remove the gearbox.

- Unscrew the 6 bolts using an “8” wrench that secure the basket to the flywheel; you need to unscrew it one turn evenly on all sides so as not to deform the drive disk flange.

- In order for the driven disk to be located exactly in the center of the flywheel, a mandrel should be inserted into the driven disk through a new basket.

- Insert the mandrel into the crankshaft and tighten the basket mounting bolts in the same way as described above - each bolt one at a time.

- Remove the mandrel.

- Lubricate the gearbox input shaft, install the bearing on it and reassemble the components in the reverse order.

In the process of installing a new clutch on a VAZ 2110 car, it may turn out that you will have to change not only the friction mechanism, but, for example, the drive fork. In this case, it is necessary torque transmission

units

Causes of clutch disc wear

Wear of the mechanism in question is a completely normal phenomenon that occurs sooner or later. But sometimes it happens that the situation is strongly tilted in favor of “early”. Let's try to understand the reasons for the accelerated wear of the friction disc:

- Frequently holding the car on the verge of starting. For example, when you are stuck in a traffic jam, you constantly move without releasing the left pedal all the way.

- Off-road driving. In order not to stall, it is necessary to regulate the speed of rotation of the wheels with the left pedal.

- Sharp gear changes and aggressive driving style. It's no secret that this leads to increased wear of all machine parts.

- Low quality of parts - by saving on spare parts, you have every chance to repeat the replacement procedure in the near future.

The most interesting thing is that the cause of wear can be an incorrect setting of the driver’s seat, in which the left foot regularly holds the pedal in the pressed position.

Getting ready for replacement

If during operation at least one element of the mechanism has failed, be it the clutch basket, release bearing or driven pulley, then it is better not to save money and replace the device completely. This is also worth taking into account when changing from one imported mechanism to another, since the differences can be serious.

VAZ 2110 car

Which clutch is better?

This question is asked by every VAZ 2110 owner when he is faced with the need to choose a mechanism. Below are the results of reviews of devices by experts in the Russian automotive market. It is also worth noting that during the research process, the most popular manufacturers among domestic motorists were considered.

- Krafttek. The kit does not include a bearing, so you will have to buy it additionally, and there is also no quality mark. The basket is equipped with 18 petals and the driven shaft (Y 3200A B0206) has 4 springs. This mechanism is recommended for use in the VAZ 2110.

- German manufacturer Luke (Lamellen und Kupplungsbau). The set is complete, you don't have to buy anything else. The packaging contains the MT14 quality mark. In addition, the driven shaft is marked with markings for proper installation. The element basket also has 18 petals, and the driven shaft is equipped with 6 springs. It is also worth noting that the basket side is marked on the shaft.

- Valeo, manufacturer France. A complete set, you don’t have to buy anything extra. Moreover, this clutch comes with a lubricating fluid for the mechanism, as well as a CD with installation instructions. There are 18 petals in the basket.

- Russian. The kit does not include driven and pressure pulleys, as well as a release bearing. Nevertheless, the product received the AYA70 quality mark. There are 12 petals in the basket, and 6 springs on the driven shaft. The product has been approved for installation in the VAZ 2110.

- Pilenga, country of origin unknown. The kit does not include a pressure pulley and a release bearing, so if you decide to replace the mechanism completely, then these components will need to be purchased. There are 18 petals in the basket. There are 8 springs on the driven shaft. There are no approval marks on the packaging.

Clutch disc at installation location

Actually, any of the clutches listed above is suitable for VAZ 2110 cars. For example, the Luke cannot produce maximum torque, so engine power will be reduced when driving. Krafttek is a fairly reliable, time-tested mechanism, although you will have to purchase some additional elements to install it.

Apparently, the best option is Valeo.

It is worth noting that this unit also has many positive reviews on the Internet from other motorists. But keep in mind that if the package for this mechanism does not contain lubricating fluid and a CD with installation instructions, then this is a fake. Having installed such a device, be prepared for the fact that it may fail after 5 thousand kilometers.

How much does a new clutch cost?

Let's consider the cost of each individual mechanism for VAZ 2110 cars.

- Kraftek. Today the price for a set of Kraft devices is 1,800 hryvnia in Ukraine and about 6 thousand rubles in Russia.

- Luke. At the moment, the cost of the original on the Ukrainian automobile market is about 1,550 hryvnia (5 thousand rubles);

- Valeo. The cost is about 1,600 hryvnia in Ukraine and approximately 5-6 thousand in Russia;

- VAZINTERSERVICE. Its cost also averages about 1,500 hryvnia on the Ukrainian car market and about 4,500 rubles on the Russian one;

- Pilenga. It is the cheapest option presented. Its price at the moment is about 700 hryvnia in Ukraine and almost 2 thousand rubles in Russia.

Cost of replacement at a service station

Depending on the region where you live, prices for installing the mechanism may vary. However, on average in Russia, installing a clutch by specialists will cost a car enthusiast at least 1,500 rubles. As a rule, the average price for installation fluctuates around 2 thousand rubles. In Moscow, prices for installing a device can range from 4 to 6 thousand rubles.

Sorry, there are no surveys available at this time.

Accordingly, in Ukraine, specialists at a service station will charge at least 500 hryvnia for installing the mechanism, but the driver should be prepared to pay a little more for a replacement. At Kyiv service stations, technicians can charge up to two thousand hryvnia for installation.

How it works and what it consists of

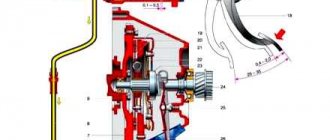

The VAZ 2110 has a single-plate clutch with a central pressure spring. The drive operates via a cable. The casing is attached simultaneously to the pressure plate and flywheel. The design also provides for a driven disk.

Device diagram

The factory clutch system for the VAZ 2110 is called VIS. Many people complain about it because it doesn’t work very effectively, although others are sure that there is no more worthy alternative for the “ten”. So opinions differ on this matter.

The main components of the system include:

- casing;

- Crankcase with a cover and supporting planes with which the unit is attached to the frame;

- Driven and pressure plate;

- Release bearing. It disengages the clutch;

- Flywheel;

- Shutdown plug;

- The cable wire that goes to the pedal (far left in the car interior).

VAZ 2110 clutch: main components and signs of malfunction

The VAZ 2110 single-plate clutch has a central pressure spring, the drive operates by means of a cable, the casing is attached to the flywheel and to the pressure plate. In short, the following elements can be distinguished:

- a crankcase with a cover and support planes, through which the clutch assembly is attached to the frame;

- casing;

- pressure and driven disks, flywheel and release fork;

- release bearing that disengages the clutch;

- cable wire going to the pedal.

As for breakdowns, the main malfunctions of the VAZ 2110 clutch are associated with its wear. However, there are many other reasons for clutch failure:

- drives the clutch, that is, there is deformation of the driven disc, breakage of the friction linings, deformation of the pressure plate, problems with the cable, etc.;

- incomplete engagement of the clutch (slippage) - burning or wear of the friction linings, the appearance of oil deposits on the surface of the discs and flywheel, jamming of the drive, etc.;

- when the clutch is working normally, jerking is observed - jamming in the drive, damage or deformation of the pressure plate, etc.;

- when turning off, the appearance of noise is noticeable - the shutdown bearing is coming out of position;

One way or another, if the clutch is faulty, the driver cannot control the car normally, gears are difficult to shift, the clutch slips, traction is lost, etc. The solution is to replace individual components or the entire assembly as a whole.

By the way, if the clutch is not very worn out, replacing only the failed components in some cases allows you to save significantly. For example, installing a clutch disc will cost less than replacing the clutch basket and disc assembly. As a rule, after troubleshooting, only worn clutch parts are often replaced (for example, only the VAZ clutch disc or release bearing is replaced).

However, if the condition of the unit leaves much to be desired, a complex failure of its main components is noted (VAZ clutch basket, release bearing, driven pulley, etc.), then this clearly indicates that it is better to replace the clutch completely. It turns out that everything will directly depend on the state of the node.

- As for the selection of clutches, today the market offers both original parts and an alternative to domestic kits (imported clutch kits). As practice shows, when choosing a VAZ 2110 clutch, price plays the last role, since it is important to purchase a high-quality solution.

In fact, the top five kits are:

- Kraft Tech (Turkey) – parts are able to cool well and remove wear products on their own;

- LUK (Germany) - has the property of damping vibrations, which maximizes comfort;

- Valeo (France) – high reliability, softness and wear resistance;

- Sachs (Germany) - thanks to production technology, withstands heavy loads in various operating conditions;

- VIS (VazInterService) is a popular domestic solution that is not inferior to imported analogues in a number of indicators.

Also check out

- How to replace a VAZ 2110 timing belt and tension roller at home

- Installation of a new VAZ 2110 starter

- How to make heated seats on a VAZ 2110 without going to a service station

- Unscrew the bottom bolt that secures the starter.

Replacing a VAZ 2110 clutch without removing the box and draining the oil

- Remove the 3rd transmission mounting bolt. Unscrew another nut located near the right CV joint.

- Remove the torque rod mounting bolts. There are 2 of them.

Replacing the VAZ 2110 clutch

- Loosen the nut located on the box control drive rod clamp and remove the rod from the box.

Replacing the VAZ 2110 clutch

- Place the support under the engine, unscrew the 2 nuts that secure the rear cushion (the purpose of this is to avoid a possible breakthrough of the hoses).

Self-replacement of VAZ 2110 clutch at home

- Carefully remove the gearbox from the engine and release it to the floor. It should hang on the axle shafts.

Self-replacement of VAZ 2110 clutch at home

Self-replacement of VAZ 2110 clutch at home

- Alternatively, replace the clutch release bearing immediately.

Clutch VAZ 2110

Clutch VAZ 2110

- Assess wear, replace the disc, install a new clutch basket if necessary, check the paddles.

Assembly is performed in reverse order.

Thus, the installation of a new VAZ 2110 clutch without removing the box and draining the oil was successful.

Self-replacement of the clutch of a VAZ 2110 car on video:

This is interesting: How to reset the counter on a Peugeot 3008

Replacing the clutch VAZ 2110-2112

Replacing a VAZ 2110-2112 clutch, on the one hand, seems to be a rather labor-intensive process, but in fact everything is extremely simple - the main thing is to follow the step-by-step instructions, observe the technology and safety precautions. To do this, you will need a standard set of tools that almost every motorist has, an inspection hole or a lift, and the help of a second person to remove and install the gearbox.

Removing the clutch VAZ 2110-2112.

To remove the VAZ 2110-2112 clutch, the first thing you need to do is remove the battery and the air filter casing (together with the filter and the mass air flow sensor - mass air flow sensor) - to do this, you need to pry the fasteners with a flat screwdriver and remove them from their seats. Next, you need to remove the starter, after which we gain access to the bolts securing the engine and gearbox. Unscrew the bolts and disconnect the speed sensor in the gearbox.

Then you need to lift the front of the car on jacks (the car must be on the parking brake or the rear wheels must be locked) so that the wheels sag, unscrew them and remove them. In addition, it is necessary to unscrew both locknuts in the hubs. Then, on the wheel side, you need to unscrew the ball joint and all the bolts of the suspension arm to remove it.

If there is a crankcase guard or a mudguard, remove them. Then you need to jack up the engine, and in order not to damage the crankcase, you need to place a wide board under it. After this, remove the jet thrust, loosen and disconnect the rocker. We unscrew the box from the pillow (if the rear one is installed, then from it too). Now you need to lower the engine a little, without bringing it to the level of sagging - this way you will have to put in less effort to remove the gearbox from the rod. If possible, it can also be jacked up for convenience. Now we disconnect the left and right drives, and the holes need to be plugged with a wooden chip, a rubber plug or other available means, only after which we remove the box (this is where the help of a second person will come in handy). Now we have access to the clutch. It is necessary to unscrew the bolts that press the basket with the help of brackets and remove it. Then remove the old clutch disc.

Installation of clutch VAZ 2110-2112.

When installing a VAZ 2110-2112 clutch disc, two basic rules must be followed. First, the disc must be installed on the same side as the one in front of it, since incorrect installation will lead to poor clutch performance, grinding and squeaking, and wear of the springs. Secondly, under no circumstances should you put on the VAZ clutch disc manually. To do this, you need to use a piece of metal pipe, slightly larger in diameter than the rod, with which you can stuff the disk into its seat. If the disc is installed skewed, get ready to quickly buy and replace another clutch kit.

After the basket is installed, we attach the mounting bolts passing through the brackets. You need to tighten them gradually, crosswise - top left, then bottom right, and so on. If you are going to replace the bearing, you also need to put it on using a piece of metal pipe of the appropriate diameter so as not to warp. After the new clutch is installed, install the gearbox in the reverse order.

As the ancients said, it is not the Gods who burn the pots. So in this case - it is not necessary to go to a service station to replace the clutch. Yes, indeed, this work takes quite a lot of time, but you will be sure that you did it not carelessly, but conscientiously. And we also saved money on mechanic services.

Tip: Once the transmission is removed, you have a great opportunity to check the chassis of your car. Inspect the anthers, the condition of the silent blocks, levers, ball joints and their anthers, tie clamps and cushions.

Replacing the VAZ 2110 clutch is a simple operation that anyone can perform. This part of the car is most susceptible to wear and tear, and if not repaired, driving becomes very difficult, which can lead to accelerated wear of the engine and gearbox. For this reason, you should not postpone repairs for a long time and fix the problem as soon as possible.

First, let's look at the clutch device. It includes:

Clutch problems are easily detected when changing gears, when the car is moving, or when starting off. Replacement is not always required; sometimes simple adjustments can be done.

Problems when starting off

Jerking and crackling noises when engaging a gear indicate that the clutch is most likely faulty or requires adjustment. Vibration or jerking may be due to the flywheel having an uneven surface. At the moment when we release the clutch pedal, the contact of the driven disk and the flywheel does not occur over the entire surface, but only in those places where there are protruding parts.

Problems with gear shifting occur due to the fact that the gearbox itself or the shift mechanism is faulty. In case of clutch problems, the flywheel and driven disc are not completely separated from each other and the torque from the engine is transferred to the input shaft. This is possible when the basket's legs are badly worn, the cable is not adjusted correctly or is torn, or the fork is faulty (in this case they say that the pedal has failed).

Choice

If you plan to simply replace the disk, purchasing a completely new node does not make sense from a financial point of view. But when the old clutch leaves much to be desired due to the quality of its work, it’s worth thinking about completely replacing the unit.

Set

According to a study conducted among VAZ 2110 owners, the five best kits for the domestic “ten” were determined:

- Kraft Tech.

- LUK.

- Valeo.

- Sachs.

- VIS.

As we have already noted, VIS is installed as standard and works quite well. An important advantage compared to European counterparts is financial accessibility. But if your wallet allows it, replace the old clutch with a better and more expensive one.

In defense of the VIS system, we note that repairs often require simply adjusting the pedal and tightening the cable . And if you are going to completely change VIS to VIS, it will not cost you a pretty penny.

What's the result?

As you can see, if you have certain skills, the process of replacing the clutch disc is not difficult. The most time-consuming operation is gaining access to the clutch itself, especially on front-wheel drive vehicles.

As for replacing the disc itself and how to correctly install the clutch disc, as well as the frequent question of which side to place the driven clutch disc, you need to take into account that the disc is placed towards the basket with the part where the damper springs protrude.

Manual transmission gears (speeds) do not engage after replacing the clutch: main reasons, settings and adjustments. Diagnosis of problems, useful tips.

How to replace the clutch on a DSG/S-Tronic robotic gearbox. Signs of the need for replacement, removal and installation of the DSG clutch, calibration and adaptation.

Double clutch: device, purpose, operating principle and features. How a dual-clutch transmission works, reliability, service life, pros and cons.

Types of clutch drive. If the clutch pedal falls, the clutch has become soft, problems have arisen with the clutch: causes and repair of major faults.

DSG robotic gearbox: the main disadvantages and weaknesses of this transmission. Reliability of DSG (DSG 6 and DSG 7), warranty on the box, DSG service life.

How to change the oil in a DSG gearbox: changing the oil in a DSG gearbox. What to consider when replacing, selecting oil for DSG, tips and tricks.

Source: krutimotor.ru

Which clutch is better to put on a VAZ 2110

Below are the most famous companies that produce clutches for the VAZ 2110, I suggest you familiarize yourself with them and make your choice.

| KraftTech – there is no marking on the factory release bearing, but the thrust bearing is designated as X2200C; driven disk – Y 3200A B0206. Main features: four damper springs, there are 18 petals on the diaphragm spring. The box bears the designation: 2110 W3200C B2240. | Luk – the kit does not include a release bearing, its marking is: SKF 500 063820; the pressure plate is branded 2 D24 120 0252 10, and the driven disk is branded 320 030810. The latter has marks for precise orientation during installation. The driven disk has six springs, the basket has 18 petals. The side is last marked. | Valeo - marking is applied only to the bearing: Valeo SNR BB 126 18S50. The kit includes a mandrel for precise installation. The spring element of the pressure plate consists of 18 petals. There is a mark on the package - 21102-21103-21108-2111-2112 826622. |

| VIS - there are no marked parts, the only special sign is the approval mark - AYA70. The pressure plate spring has 12 lobes, the driven disk has 4 large and 3 small damper springs. On the box: 2110-1601180. | Pilenga - there are no markings or designations on the parts, but on the packaging it is noted: CK-P-4005 2110. The driven disk is equipped with 4 small and 4 large damper springs. The pressure plate spring includes 18 lobes. | FINWHALE and QML - smooth start of vehicle movement from a standstill; uniform movement of the car without jerking; the softness of the clutch pedal ensures comfortable driving and reduces driver fatigue; high safety properties make it possible to increase the service life of gearbox synchronizers and other transmission parts; predictable stable resource, reliability and durability; ease of installation, the clutch kit includes a centering mandrel and lubricant, it is possible to replace the clutch in the absence of special tools and materials, there is no need to buy them; and, finally, an excellent price-quality combination. High quality clutch kit at an affordable price. |

| Engine model | Clutch pressure plate | Driven clutch disc | Clutch release bearing clutch |

| VAZ-2101,21011, 2103,2105 | 2103-1601085 | 2107-1601130 | 2101-1601180 |

| VAZ-2106, 2121 | 2121-1601085 | 2106-1601130 | 2101-1601180 |

| VAZ-21213,21214 | 2121-1601085 | 21213-1601130 | 2101-1601180 |

| VAZ-341 (diesel) | 2121-1601085 | 21045-1601130 | 2101-1601180 |

| VAZ-2108. 21081, 21083 | 2109-1601085 | 2109-1601130 | 2110-1601180 |

| VAZ-2110, 2111 | 2110-1601085 | 2110-1601130 | 2110-1601180 |

| VAZ-2112 | 2112-1601085 | 2112-1601130 | 2110-1601180 |

| Driven clutch disc | Friction lining | Internal diameter of the lining, mm | Outer diameter of the lining, mm | Distinctive features |

| 2106-1601130 | 2106-1601138 | 130 | 200 | 12 rivets for fastening the linings, arranged in pairs |

| 2107-1601130 | 2107-1601138 | 142 | 200 | 12 rivets securing the linings |

| 2109-1601130 | 2109-1601138 | 130 | 190 | 18 rivets for fastening the linings |

| 2110-1601130 | 2110-1601138 | 140 | 200 | 18 rivets for fastening the linings |

| 2112-1601130 | 2110-1601138 | 140 | 200 | 18 rivets, two springs have white stripes |

| 21213-1601130 | 2110-1601138 | 140 | 200 | 18 rivets for fastening the linings |

| 21045-1601130 | 21045-1601138 | 140 | 200 | 16 rivets, arranged in pairs |

Popular problems and their solutions

There are several characteristic faults that occur on the VAZ 2110. Let's try to understand the reasons for their occurrence, and also consider ways to solve the problem.

- The clutch drives. The reasons may be:

- The pedal has insufficient travel and the tension is too tight. To eliminate this, you need to adjust the drive;

- The driven disk is deformed. Only replacement will help here;

- The driven disc hub sometimes gets stuck. If so, try washing it and lubricating the input shaft splines. If the element or the shaft itself is worn out, then replace them;

- The friction linings are broken and the rivets are loose. The best solution is a complete replacement of the casing, which includes a spring and a disk;

- The pressure plate is warped or warped. Replace the linings, but first make sure that there are no deviations in the end runout of the disk;

- There were problems with the cable. Pull it up. If there is no result, replace with a new one.

- The clutch cannot fully engage, slipping is observed. There may also be several reasons, as well as solutions:

- The friction linings on the driven disk often burn or wear out. There is only one solution - replacement;

- The surfaces of the discs and flywheel are coated with oil. This indicates that the engine and gearbox seals should be replaced. Plus check for leaks through the flywheel fixing bolts. If there are leaks, treat the fasteners with sealant and wash the oily areas;

- The drive is stuck. Check its condition, replace damaged components.

- The clutch works almost normally, but there are jerks. This could be caused by the following:

- Oil has reached the surface. We have already described how to solve the problem above;

- Jamming occurs in the drive. Find out exactly where it is stuck and fix the problem;

- The pressure plate is deformed or damaged. In such a situation, replacing the casing with the disk will help.

- Increased noise is observed when switching off. First of all, check the release bearing. It was probably worn out, deformed, and began to lose oil. What to do? Of course, change it.

- Strong noise is observed already when turned on. Almost certainly the problem lies in broken damper springs. Partial repairs will not help; replace the entire driven disk at once.

- When working for a long time, it suddenly turns off. The release bearing is probably stuck. This element is located on the guide sleeve of the gearbox. If it wears out, simply replace it with a new bearing.

- The clutch may turn out to be extremely tight or, on the contrary, disappear when trying to overtake on the road. If there is slipping, try to drive slowly to the garage. If there is no hook at all, stop and call a tow service.

What you need to know

The release bearing is not the weakest link in the clutch system, but for some reason it is the one that causes problems and troubles.

coupling

Some car owners have gotten used to the whistle and simply ignore it. But this cannot continue for long, since untimely solution to the problem can lead to even more complex and expensive repairs. If the situation gets worse, then a simple replacement will not be enough for you.

The clutch serves to act on the leaf spring of the clutch basket. It is also called diaphragm, so don't be confused if you hear this designation. Due to this impact, the driven disk is disconnected from the flywheel and the pressure plate of the basket. This disengages the clutch.

If the squeezer is faulty, this can lead to various consequences:

- The clutch fork will be damaged;

- The integrity of the clutch spring petals will be compromised;

- The guide bushings are deformed.

In order not to pay twice, or even three times, promptly react to the appearance of a whistle in the clutch and try to quickly take action.

Clutch repair

Unscrew the bolts securing the basket. The photo shows that its petals are very worn out (“used up” by the release) and the basket will have to be replaced. I’ll say right away that I found this part from friends, it’s not new, but in excellent condition.

Remember, if when installing the disk it is allowed to shift (no matter in which direction), then it will not be possible to install the gearbox in place. Before changing the clutch disc on a VAZ 2110, you need to prepare a mandrel or use the gearbox input shaft. Insert the disk with the mandrel into the flywheel.

Then the basket or all at once. The basket fastening bolts must be tightened in a circle, gradually, over three or four turns of the flywheel.

Lubricate the shaft and install the release bearing.

Removing the VAZ 2110 clutch mechanism

To perform a procedure such as replacing a VAZ 2110 clutch disc with your own hands, you will need a standard set of tools. Drive the car into the pit and follow these steps:

- Disconnect the ground from the battery.

- Remove the left wheel.

- Remove the mass air flow sensor and air filter.

- Remove the clutch cable (2 nuts).

- Unscrew the top starter bolt and the 1st gearbox bolt.

- Remove the speedometer cable after first disconnecting the speed sensor connector.

- Remove the starter mount (bottom bolt), and then the 3rd gearbox mount bolt.

- Remove the recoil rod by unscrewing the 2 bolts.

- Remove the transmission control rod.

- Having previously placed a support under the engine, remove the 2 nuts of the engine bracket cushion.

- Carefully lower the gearbox to the floor.

- Unscrew the six basket bolts evenly and remove the mechanism.

This method eliminates the draining of oil from the gearbox, which greatly simplifies the task.

Instructions for self-replacement

Why pay if you can do all the work on changing a component of the transmission system yourself? Of course, if you do not have experience in this, then it is better to entrust this matter to specialists. But if you follow the instructions, there should be no problems with replacement.

Getting ready for replacement

- new clutch for your car;

- a set of wrenches, you will also need socket wrenches;

- screwdriver;

- crowbar;

- jack;

- bricks.

Step by step instructions

So, if you decide to change the clutch device yourself, but do not want to bother with dismantling the gearbox, then we will look at the replacement process without removing the box. Let's get started:

- Unscrew the screws securing the left wheel of your car and place the front part of the VAZ 2110 on a jack. To protect yourself, place bricks under the car body. Also place wheel chocks under the rear wheels.

- Next, you need to completely remove the wheel and unscrew a few mounting screws that hold the ball joint in place.

- After removing the wheels, open the hood and disconnect the battery. To do this, it will be enough to remove the negative terminal from the battery. This is done in order to prevent short circuits during repair work.

- Now you need to remove the air filter element housing. This must be done in order to gain access to the screws with which the gearbox is attached to the internal combustion engine.

- If there is engine protection, then let's start removing it. Unscrew all the screws around the perimeter of the motor protection and remove it.

- Remove the long screw that secures the anti-roll bar.

- Now let's get down to one of the most crucial moments in this work process. If you decide not to dismantle the transmission, you will still need to move the unit to the side. In order for the unit to move freely, it is necessary to remove the left mudguard. After this, unscrew all the ball joint bolts.

- Next, move the left strut behind the wheel drive. Otherwise, you will not be able to move the gearbox.

- After this you will need to disconnect two connectors from the transmission. To the right of the unit there is a plate responsible for fastening the jet thrust. By the way, the other part of the plate is located at the gear shift lever. Visually remember the location of the jet thrust fastener, otherwise you will have to sweat later to adjust the unit selector to the working position.

- With the connectors disconnected and the torque rod removed, the transmission is essentially freed from its main mounts. Now you need to disconnect it directly from the internal combustion engine. Here, use wrenches and remove several bolts (usually no more than three) and one nut.

- Now it is necessary to dismantle the rear cushion, which, in fact, attaches the gearbox to the engine. This should be done so that the engine is not released too much, so it is better to place the internal combustion engine on a jack or on supports.

- The same must be done with the gearbox, having first moved it to the required distance. Here you may need help, since it will not be easy to move the unit and place supports under it alone. In addition, everything must be done carefully to prevent mechanical damage to the unit.

- You now have access to the clutch mechanism. Replace it, and then reassemble all parts in the reverse order. Tighten the transmission-to-engine screws securely. After replacing the clutch, you need to center the disc.

How to change the clutch yourself: sequence of work performed

So, replacing the clutch on a VAZ 2110 can be done by specialists or with your own hands in a regular garage. Note that the procedure for replacing the clutch on a VAZ 2110 is not complicated. If you have the knowledge and the necessary tools, repairs and replacements can be done independently.

Preparatory work for replacing the clutch:

- new clutch kit for VAZ 2110;

- a set of socket and wrenches;

- screwdriver, crowbar, jack, bricks (“goats”).

Self-replacement of the VAZ 2110 clutch:

- Having loosened the bolts securing the left wheel, lift the front part of the car with a jack, substitute the “goats”;

- Having removed the left wheel, unscrew the two fastening bolts of the lower ball joint;

- Having removed the negative terminal from the battery and removed the connector from the mass air flow sensor, loosen the clamp securing the corrugation to the mass air flow sensor, remove the car air filter element housing;

- Having removed the clutch cable from the clutch fork, loosen the two fastening nuts of the cable to the bracket on the gearbox;

- unscrew the M3 mounting bolt to the gearbox housing and the first mounting bolt of the gearbox itself;

- Using a wrench with a “19” head or a pipe-wrench, unscrew another fastening bolt of the gearbox, loosen the fastening nut;

- unscrew the upper mounting bolt of the starter and remove the connector from the speed sensor, unscrew the speedometer cable;

- remove the longitudinal brace with the lever;

Unscrew the lower mounting bolt of the starter and the third mounting bolt of the gearbox (the gearbox mounting nut is located in the area of the internal constant velocity joint of the CV joint). - unscrew the two reaction rod mounting bolts;

- loosen the nut on the gearbox control rod clamp and remove it from the gearbox;

- After freeing the gearbox from the main fastenings, use a wrench to disconnect several mounting bolts and one nut and disconnect the unit from the vehicle’s internal combustion engine.

- unscrew the two nuts of the rear cushion, which secures the gearbox to the vehicle’s internal combustion engine, and remove it;

We also recommend reading the article about why your car may have a tight clutch and what are the reasons why the clutch is tight. From this article you will learn about possible malfunctions and repair methods, as well as solutions to the problem when the clutch pedal is tight. - when dismantling the rear cushion, it is necessary to place a support under the vehicle’s internal combustion engine to avoid lowering the engine too low, as this may lead to the separation of the interior heater hoses;

- just like the internal combustion engine, raise the car’s gearbox, moving it away from the engine in advance;

- Having gained access to the unit for replacement or repair, perform the necessary operations to replace the clutch or repair it;

- after work has been carried out to replace the clutch or repair its individual components (release bearing, clutch disc, VAZ clutch basket, linings, etc.), the parts are installed in the reverse order

- during the assembly process, it is important not to forget to tighten the fastening screws of the gearbox to the internal combustion engine;

Let us also add that after replacing the clutch, it is necessary to center the disc. After dismantling the clutch housing, it must be inspected for various damages (cracks, thread wear, weakening of the “grip” of the paws holding the housing).

The total scope of repair work depends on the condition of the units. We also note that to install the clutch disc and basket, you must use a simulator of the gearbox input shaft.

Preparatory stage

Before changing the clutch on a VAZ 2110, you need to prepare a place for repairs and tools. For this process, the most suitable solutions are: a car lift or an inspection hole. If there are no such conditions, due to a hopeless situation, it is possible to replace the clutch with a 2110 in “Spartan conditions”. It is enough to find a flat surface area in a garage box, a parking space or in the yard.

Also, for repairs you will need:

As for the clutch itself, it is sold in sets (3 in one, 2 in one) and parts separately.

The system includes 3 replaceable elements:

It is more practical for a car owner to ask in advance how much new clutch parts will cost to replace a VAZ 2110. This will help prepare the necessary budget. The price of spare parts varies and depends on the manufacturer. Among manufacturers of quality parts, the leaders are: Sachs, Luk, Valeo and Krafttech. These spare parts are guaranteed to fit the vehicle and have a long service life. Poor quality parts may not fit at all or may fail in the first days after repair.