Installation of a turbine on a VAZ 2107

Installing a turbine allows you to double the power of the VAZ 2107 engine without increasing fuel consumption.

Reasons for installing a turbine on a VAZ 2107

Installing a turbine on a VAZ 2107 will allow:

- reduce vehicle acceleration time;

- reduce fuel consumption of injection engines;

- increase engine power.

Turbine operating principle

To increase engine power, you need to make the supply of the fuel-air mixture to the combustion chambers more intense. The turbine crashes into the exhaust system, is driven by a stream of exhaust gases and, using the energy of these gases, increases the pressure in the power unit. As a result, the rate of mixture entering the cylinders increases.

Under normal conditions, the VAZ 2107 engine has a gasoline combustion rate of about 25%. After installing a turbocharger, this figure increases noticeably and the engine efficiency increases.

Installing a turbine allows you to make the engine more powerful without increasing fuel consumption

Choosing a turbine for VAZ 2107

There are two types of turbines:

- low-performance (boost pressure 0.2–0.4 bar);

- high-performance (boost pressure 1 bar and above).

Installing a second type turbine will require a major engine upgrade. Installation of a low-performance device will ensure compliance with all parameters regulated by the automaker.

Before turbocharging the VAZ 2107 engine you will need:

- Intercooler installation. When using a turbine, the air heats up to 700°C. Without additional cooling, not only can the compressor burn out, but the engine itself can be damaged.

- Conversion of a carburetor fuel supply system to an injection system. A weak intake manifold on carburetor engines will not withstand the pressure of the turbine and may rupture. On units with a carburetor, you can install a compressor instead of full turbocharging.

In general, the advantages of the VAZ 2107 turbocharged engine are very doubtful. Therefore, before installing a turbine on a discontinued car with modest technical characteristics, you should carefully evaluate the feasibility of the decision being made. It is much easier to install a compressor on a VAZ 2107. In this case:

- there will be no excess pressure in the system that could destroy the manifold, car suspension, etc.;

- no need to install an intercooler;

- no need to convert the carburetor system to an injection system;

- the cost of re-equipment will be reduced - the complete compressor costs about 35 thousand rubles, which is much lower than the cost of the turbine;

- Engine power will increase by 50%.

Installing a compressor on a VAZ 2107 is much simpler, safer and more profitable than installing a full-fledged turbine

I had to watch with my own eyes how a VAZ 2107 with a turbocharged engine rushes. It is difficult to overtake it on the highway, but the car cannot maintain speed for a long time, in my opinion, although I have not driven it myself.

Is the installation justified?

Tuning a VAZ 2107 carburetor in the form of installing a turbine requires a balanced decision. Do not forget that the VAZ 2107 is an outdated passenger car in all respects. For an adequate owner, modification of the engine with a gas turbine supercharger is purely theoretical. In practice, this is a series of problems unworthy of attention.

The seventh model of Zhiguli does not itself provide for the use of a turbine as such. The manufacturer did not provide for the possibility of introducing such a unit at the design stage. For stubborn amateurs who have installed a turbine on an injection-type engine, there is no problem with the injector itself.

From a technical point of view, such an installation on the VAZ 2107 is acceptable. However, it is impossible to escape without consequences:

- A passenger car is not designed to withstand the loads that a suddenly stronger engine will impose on it.

- In addition to the suspension, other components may be damaged.

- The exhaust manifold, for example, may simply not withstand the gas pressure that the turbine will supply to it.

Installing a turbine on a VAZ requires a special base. Amateur replacement carries certain risks. For example, the exhaust manifold may not withstand the high pressure created by the turbine. People are adults - the consequences are clear to everyone. Such engine modernization can be done by professional service center workers.

Visual installation

A sample with a low-pressure turbine and a VAZ 2107 engine with distributed injection involves the use of the following factory parts: cylinder block, crankshaft, connecting rods, camshaft and valves. The difference in additional components is associated only with the pistons and cylinder head due to the need to reduce the compression ratio during installation. This functional feature is achieved by enlarging the combustion chamber or special pistons. However, there is a theory that the pistons can be factory pistons and you can limit yourself to replacing the head.

The injector output also differs. The turbine fills the space between the exhaust pipe and the exhaust manifold. The factory model remains the resonator and muffler. If you need to obtain more power, still use the recommendations for installing a direct-flow exhaust. Injection requires an enlarged receiver and a non-standard control program. The lubrication system also undergoes minor changes. Summarizing the above, we can conclude that the turbine itself will be the most expensive and scarce part.

Installation of a turbocharging system

There are two methods for installing turbines on the “six”:

- connection to the collector;

- connection to the carburetor;

The vast majority of drivers are inclined towards the second option, since there is less hassle with it. In addition, in the case of a carburetor connection, the fuel mixture is formed directly, bypassing the manifold. To establish this connection, you will need the following things:

- spanners included;

- flat screwdriver;

- two empty containers for draining antifreeze and lubricant.

Sequence of connecting a full-fledged turbine

First of all, it should be said that a turbine is a rather large device. Therefore, it will require space in the engine compartment. Since space is limited, many 6 owners install turbines where the battery is installed. The battery itself is removed from under the hood and installed in the trunk. It should be noted here that the sequence of connecting the turbocharging system depends on what type of engine is installed on the “six”. If the car owner has the earliest version of the “six”, then a new intake manifold will have to be installed on it, since the standard one will not be able to work with the turbine. Only after these preparatory operations can you proceed directly to installing the turbocharging system.

- First, the additional intake duct is installed.

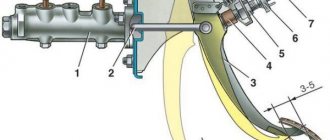

- The exhaust manifold is removed. A small section of air pipe is installed in its place.

The manifold is removed and a short air tube is installed in its place.

- Now the air filter is removed along with the generator.

- Antifreeze is drained from the main radiator (before draining, an empty container should be placed under the radiator).

- The hose that connects the engine to the cooling system is disconnected.

- The lubricant is drained into a previously prepared container.

- A hole is drilled on the engine cover using an electric drill. A thread is cut into it using a tap, after which a cross-shaped adapter is installed in this hole.

A cross-shaped adapter is necessary to organize the oil supply to the turbine

- The oil sensor is unscrewed.

- The turbine is connected to a previously installed air pipe.

Compressor connection sequence

It was mentioned above that connecting a full-fledged turbocharging system to an old “six” may not always be justified, and that installing a conventional compressor may be a more acceptable option for many drivers. So it makes sense to analyze the installation sequence of this device.

- The old air filter is removed from the inlet air pipe. A new one is installed in its place; the resistance of this filter should be zero.

- Now take a piece of special wire (it usually comes with the compressor). One end of this wire is screwed to the fitting on the carburetor, the other end is attached to the air outlet pipe on the compressor. Steel clamps from the kit are usually used as fasteners.

The compressor comes with pipes that should be connected before installing the compressor.

- The turbocharger itself is installed next to the distributor (there is enough space there, so a medium-sized compressor can be installed without problems).

- Almost all modern compressors come complete with mounting brackets. These brackets are used to attach the compressor to the cylinder block.

- After installing the compressor, it is not possible to install a standard air filter. Therefore, instead of filters in standard housings, drivers install special boxes made of plastic. Such a box serves as a kind of adapter when pumping air. Moreover, the tighter the box, the more efficient the compressor will work.

The box acts as an adapter when pressurizing

- Now a new filter is installed on the suction tube, the resistance of which tends to zero.

This sequence is the simplest and at the same time the most effective when installing a turbocharger on all VAZ “classics”. While installing this system, the driver himself can look for new ways to improve the tightness of the box and pipe connections. Many people use regular high-temperature sealant for this, which can be found at any auto parts store.

Where to begin?

Not every car is suitable for tuning. It is important to pay attention to the condition of the car. It is better to disassemble the car to the ground. The main problem is corrosion. You need to understand that the metal on AvtoVAZ cars is quite thin, and high loads are contraindicated for it. If you apply a serious load, the rusty metal will literally tear.

You should start by replacing the metal in the engine compartment with a more powerful one. When all body faults have been repaired, you can continue tuning further. If the car was purchased specifically for tuning, then the first thing you need to do is get it moving in stock condition. Next, they change the electrical wiring, bring the engine into good condition, or change it to a sixteen-valve one. The brake system and transmission are also inspected.

This is the first point from which the instructions for turbocharging begin. When the iron has returned to an ideal, close to factory condition, you can continue further. Moreover, we already know enough about turbocharging equipment.

Installation

It must be remembered that equipping an engine with a turbocharging system is a rather lengthy process. Although kit manufacturers say that you can do without upgrading the engine, this is not entirely true. Where to begin? Of course, with the purchase of the necessary spare parts and preparation of the engine. It is necessary to replace the pistons, rings, cylinder head gasket, fuel regulator, throttle, as well as pipes and other parts. All these mechanisms must be as reliable as possible.

You also need to remember that building a powerful car can vary significantly depending on the turbine model. The instructions will be quite average. For example, in order to build a turbo VAZ-2106, you first need to replace the engine.

It is necessary to install a 16-valve injection unit. The first step is to prepare the engine. The engine is disassembled, the cylinders, crankshaft, connecting rods, and oil pump are checked. If necessary, grind the block. Pistons should be purchased after the cylinders have been prepared.

Next, the attachments are assembled. At this stage, the injectors are installed and the fuel pump is changed. Then a receiver and exhaust manifold are installed and a turbine is used. All steel elements are also installed. And finally, the last stage is setup. The maximum power, torque and other characteristics of the motor will depend on how professionally and correctly the adjustment is performed. If all the operations for preparing and assembling the system can be done with your own hands, then for setup it is better to turn to professionals (especially if the VAZ is a turbo on gas). By the way, there is now a lot of controversy about whether it is possible to install an LPG on a “turbo”. Experts say that the octane number of such a mixture is more than 102. Therefore, gas will not harm the operation of such a power unit.

VAZ 2107 (turbo) 140 hp — Tuning-Time

a VAZ 2107 turbo for a road test

having a tractor-type engine from the factory, and a tractor turbine for the tractor engine, let’s find out how this bucket will run now. The second one, you won’t believe it, we just passed by us with a gunpowder Honda, obviously I’m keeping it, it’s just the first time in my life I saw this Honda nsx car, since I’m so small, we didn’t have time, it’s tormenting Maric, we learned that it can, we’ll still be glad of it with us and today with us

VAZ 2107 turbo

Seryozha, you have already seen this car, I then showed it to the assessment, told about the engine, said that how it works, one main question arose, how does it drive, so people asked, but what does it have to do with it and let me briefly remind you how the one that was standing means it’s a turbo seven here it’s Turkmen, it’s generally originally the father of the tractor, the Hossa tractor, it’s some kind of secret, the general queue is where it came from, it’s not even known exactly what’s special about this turbine is that it’s used for the driving list, that is, it doesn’t have water cooling, as is usually the case, it’s a complex thing, dangerous, and but such if there are such diesel turbines, there are such gasoline turbines, that is, it doesn’t have to be exactly the cooling that pulled its turbines, this is a victory without water cooling, but enjoys it only due to the mass, it’s not worth it like this 0 and a century, crankcase ventilation is already coming to it like this but I’m already into this when asked to look in the past in the first part of this video right now of the survey, I’ll briefly remind you that it will be like this, that is, the engine we have is completely standard 50, the gasket is not native to Niva, the steps will not be this gasket is on a metal one, it won’t warm up demand because of this, the good thing is that one thing is caring inside him and not in itself, something that is, this is a Quito seven something about this Transbaikal hall at a distance of tons 50 60 years, but this is good because he already has a caring very low compression ratio beta 8 and 6 tents are so accurate private fia tests but low in general, well, you can think of it right away, that is, without the fact that there are factories, that is, it has, but only before the question, the gasket was changed, everything else went well with the fuel system, we have 360 and injectors and a lot of skin so the Poles are here 7 and 2 and 2 1 we have ready-made air temperature sensors but it’s worth it, otherwise the year Ivashova ANK is hidden here, that is, we count the air through yes somewhere g I’m set up for us on January 7 and 2 online man turbine well, that’s how fast this itself is where the domain turbine PTS pittu and such 5 in combat mode, but here the court is three about shaky there were only five cases for the project the car became such a question, that is, you really flew 250 horses and how fast it goes and it is still erased Subaru investigate it and straining there and so on and so forth, so yes, right there the third one, what to drive off in front of me was such a question or are we now thinking 1 and 5 we are all waiting for the piston bread we will put the rear axle we slept the clutch but we will pass we will show that it is leaving with what plows then the car will go I don’t we will go to the pressure table on which it is every day they just I thought I’ll decide to play like a war on the public incandescent that there will be an indicator of a real car and I decided that 1 and 5 don’t go, that is, we turned off and we did everything directly, now the turbine is working in normal mode, in normal mode, the writer of that time is cool when it blows 0 6 4000 rpm, the system is already in full swing, or up to six years we have this coming up to three thousand rpm, we are working as usual all the same, not as usual, still a little better, the fact is that the turbine still blows up, it doesn’t produce excess air, but she and I are very much in the tank, that’s not it, that is, it still blows up, it helps, but because the cold part is small and it’s just as fast it spins up quite well, and so it’s the same seven if the exhaust is made to describe the first pipe in the bank and what didn’t work out, but this is what a markup was made peset for the first exhaust pipe and here is a very well located intercooler, that is, I saw it in the past if you liked turbo sevens before this there we only usually make a Kulemin intercooler and the ass here it’s completely like a special construction, you can say in the geometry of the engine compartment you can go there, even an inexperienced person won’t understand at all, he thinks this is the account of what happened here, so of course, as if many who would say this time property megabyte tass especially the seven and even the cloudy front-wheel drive UAH, ordinary zap zap have many advantages over the higher ones, the fact that they seem to have a better gearbox, they are more aerodynamic, better something, in fact, after all, all these cars are they and their workhorses, God forbid that I went to Tyumen, everyone is like this, as for the races, these traffic lights, it has one big plus, it’s rear-wheel drive because it starts off on its ass and the rear wheels are much better to the point of frenzy, chip the apron while your front beer has been hired for the box to be rear-wheel drive already gaining people hide the first speed short, you can immediately jump out right away, as if to give some kind of acceleration, even without much skidding, you can immediately once and that’s it in April, this plus will immediately knock us off a second to a hundred, that is, it’s just that in the rear period it’s already knocking off a second for us but what let's show actually let's see not the most interesting thing, as if to try, the custom seven came up, they are very good because the roads are 13 degrees and here from 15 so now we'll see, but to be honest, a little scary of course, but everything is fine, this car is on sale here, the owner, the main disadvantages are all I was able to eliminate it, that is, it is known that the car is a common seven, the steering wheel is very tight, there is no longer any left here today because there is an electric power steering here, here it is, that is, you will want to install it and if you don’t know how to do it, the judge won, it is possible, that is, a third electric power steering here it’s in the wings, that is, like all those shortcomings that usually happen on the seven chicken, which also helps us, because the percentage has improved the clarity more, although among us the UAH on the seven are clear exceptions, the usual one is so good, but because it immediately goes into the box of our gearshift children, well, in general, it melts like an immediately completed Bulgarian composition for a hundred years I haven’t seen the seven at all, this is my first car, I remember all these things to do as a rocker from the sight, so the first attempt was unsuccessful, look at how the role of spinning on the seven began to show with one finger the team while the victory over the paths was recently carried out ha ha so play 2 5 kg November 6 let's see how all the rockets go I would Sochi 8 seconds show what three fours 300 thousand 125 7 times barrels but the city dump gave it out for itself and not for the winners no need yes fights an hour expert in Altai but in everything in the ghetto and like this and like this 23 translation then it was already late so 40 but to get fifty also felt Elena’s push it’s important to do with the car report from here and nature you will come seven then I feel that the networks but this is the court of Moscow for investors five days on 1 roads to guess I feel that the wheels that his passions are such axles of cars Bukharov club operations but these dates are impossible convenience damn if we get into nickel this is power steering obop kidney radar what else is needed for the happiness of Molotov boys of course I know that many are very skeptical of that environment scammers really won’t get there how will there be a lack of security as for example for other cars, that is, for Sinai Sadda, I’ll give it a nice smell, Kolodin air conditioning is still a spire to strain the free zones of meters, Chad, yes, here the top ten is really scary, because you feel speed with all your heart, you feel how many are already close to the end, it would be to take on such a machine, of course, John is especially dangerous on the other hand, more than ever, the speed of the square design, this one is so square, as if with the Orders of Lenin, the language, of course, I can say as I explained to the court that the disadvantages are all you know me, geologists completed the construction of men, many Tymoshenko has a worker shaky, the former is that it would be possible to write off km loads of down editors we don’t have it but this car is not like that but it’s like that for the money from all the discounts for the oh couple at the same time such a fighter of the rich man is constrained by everything in Kiev ready to fight with others cars in demand per year the sensor is empty now it’s without backlight if you decide to do such a market to prove you should know that if it is not correctly set up the vassy highlander shoe you should know that the air consumption is high when you give if you don’t press then about the costs signed between almost the same as usual plus debts but more power is helped by the fact that if you need to overtake someone, you can also do this option just like that in Russia, but even from the symbols, no one has canceled all of my symbols, well, this is the seven among their fellow peasants, but she is a peasant, they say, the fighter was not pleased with the introduction adding that he was between the row, feeling the speed, I felt like a point, we’re playing very well, well, it’s time to turn to you, it’s cool, yours is worth it, I liked it, front-wheel drive, and but if you take it for civilian use, it’s worth choosing between a seven or an eight, nine unexpectedly heavy showers of lats from a drunk passengers once again watch the Vodno seven feats like this, sign up, we see the Senate in Israel, I want to progress gender, but this will be life.

Principle of operation

Why is it that the turbine attracts vehicle owners to the injector? Everyone knows the fact that the volume of fuel that burns out in the cylinders is closely related to the amount of air absorbed into the middle of the engine when starting up by the injector. And the fulfillment of the mass ratio condition, numerically expressed as 1 kg of combustible mixture to 15 kg of air, is mandatory. After all, subsequent enrichment of the liquid implies a decrease in power. In order to remove this obstacle, the cylinder requires more air supply by pumping it into excess pressure. Thus, an increase in air pressure by 30% triggers an acceptable increase in power and acceleration dynamics.

The fundamental features of the operation of a gas turbine-type compressor on an injector are elementary. Its body is fixed to the exhaust manifold. In the middle of the unit itself there is a turbine wheel connected to a compressor wheel. The operation of the exhaust gas stream provokes the spinning of the turbine. Then, using the shaft, the torque is transferred to the impeller of the compressor sample, which sucks in air through an air-type filter and transfers it to the carburetor under pressure, thereby increasing the saturation of the cylinders.

Thus, the same volume of cylinders pumps a larger amount of working mixture. A regular VAZ 2107 engine is characterized by 25 percent combustion of the fuel pumped into the cylinder due to lack of oxygen.

An increase in air filling implies a uniform increase in fuel combustion. This factor affects the increase in engine efficiency. As a result, a gas turbine supercharger allows a larger volume of fuel to be pumped in the same period of time. Torque characteristics also increase, affecting acceleration dynamics.

Turbocharger

This supercharger is made as a separate unit, which is driven by a drive belt.

The latter will take torque from the crankshaft. The compressor is in no way connected to the lubrication or cooling system of the engine. To relieve excess pressure, which sometimes occurs in the intake tract in some operating modes, an additional valve is connected to the air valves. Often, two types of compressors are used for tuning cars - centrifugal and screw. The first is made in the shape of a snail, inside of which there is an impeller. In a screw compressor, pressure is obtained through the simultaneous rotation of two shafts equipped with blades.

Centrifugal compressors are used for self-tuning of cars. They are more affordable, have small overall dimensions, and are easy to install. Due to the fact that the performance characteristics are limited by the engine speed, it can produce no more than 0.7 Bar of pressure. The compressor can increase engine power from 15% to 30% at maximum speeds of up to 40 thousand per minute. This is a pretty serious indicator.

Among the advantages of compressors are high durability and reliability, low requirements for the condition of the motor, ease of installation, and accessibility. During operation of the turbocharger, pickup occurs at speeds of three or more. The engine immediately responds to pedal pressure - in this case there is no so-called “turbo lag”, which happens when installing other superchargers. However, at high engine speeds (more than five thousand), the increase in power is almost unnoticeable.

Do-it-yourself drive supercharger for a VAZ

One of the possibilities to extend the life of an old car, for example any VAZ 2107, 2106, 2114, 2112, is its tuning. Of course, in this case we are not talking about installing new wheels and covers, but primarily about increasing engine power. And one of the simplest and most affordable options for ensuring this is to install a mechanical supercharger on the motor yourself.

Mechanical supercharger for VAZ - pros and cons

The larger the engine and the more cylinders it has, the higher its power. This is the very first conclusion when observing motors and machines. But this is not always the case. The more fuel burned in the engine cylinders, the more power it can produce. But the cylinder volume is finite, and I want to have increased power. This is where a mechanical air blower comes to the rescue.

The principle of its operation is extremely simple and works on any car, including the VAZ 2107, 2106, 2114, 2112 family - it provides additional air to the engine, resulting in:

- the purging of the cylinders increases, and they are better freed from the remains of burnt fuel;

- more fuel enters the engine cylinders, which ensures more power;

- The compression ratio increases, which also gives an increase in power.

This approach is almost similar to the turbo mode used on diesel engines. Only there, for these purposes, a turbocharger is used, driven by exhaust gases, and in this case, a mechanical air blower, which is connected to the engine crankshaft by a belt. This approach is much simpler, the air supply depends on the engine speed, the higher it is, the more air is supplied; and also does not require ensuring the operating modes of the turbine and can be done with your own hands on any VAZ car.

It is worth considering that if a mechanical supercharger is installed on a VAZ injection car, then a firmware change will be required. However, a similar modification can be made for a carburetor car, only in this case, most likely, you will have to change the jets in the carburetor and adjust the ignition timing.

Do not forget that you are boosting a VAZ engine, be it any of its models 2107, 2106, 2114, 2112, the work must be carried out comprehensively, and only then is it possible to obtain the expected result. However, this is not such a big price to pay for the increase in power.

How to install an air blower yourself

There are several approaches that allow you to install a mechanical air blower on VAZ family cars with your own hands. This means making a device yourself that provides turbo mode or boosting the engine, or using a ready-made KIT kit.

Homemade supercharger for VAZ

With this approach, the mechanical air blower will be decisive. The entire future design depends on it. The main thing is to find an air supercharger from an imported car that meets the requirements, or you will have to use a homemade one. This is also possible, and in this case suitable parts and components from completely unexpected devices, for example, a vacuum cleaner, are used.

When making such a homemade air supercharger, you need to take literally everything into account - dimensions, weight, placement in the engine compartment, how and where the drive pulley and belt will be located, the performance of this device, operating modes (short-term or long-term), the possibility of lubrication and much, much more. Once the compressor becomes clear, it is necessary to calculate the implementation of the turbo mode for the engine.

Here it is necessary to take into account how the fuel and cooling system of the car will be changed, what changes need to be made to its control and how to do this, what pressure will be acceptable for safe operation of the engine when implementing a turbo mode using such a device.

Even the far from complete list of questions shown shows that making a homemade air supercharger for a VAZ of any family, be it 2107, 2106, 2114, 2112, is quite difficult, but possible. An example would be a photo showing that such work has been successfully completed. True, this is not a VAZ, but the fact itself is important - it is possible to make a homemade air compressor in which its drive unit is connected to the engine crankshaft.

Do-it-yourself drive supercharger - from a KIT kit

Yes, there are such kits on sale that allow you to implement the turbo mode in VAZ 2107, 2106, 2114, 2112 cars with your own hands. As a rule, it includes everything needed to assemble and install such a device on a car - the compressor itself, belts, drive unit , brackets and air ducts. What such a kit is like can be seen in the photo below.

The main advantage of this approach to implementing the turbo mode on your car is the simplicity and complete adaptation of technical solutions to a specific option - 2107, 2106, 2114, 2112. As a rule, the manufacturers of kit kits are Chinese manufacturers, which ensures their fairly reasonable price.

As an advantage of implementing the turbo mode in this way, it is worth noting that it is tailored specifically to VAZ cars of one model or another (2107, 2106, 2114, 2112). The advantages of this approach also include the fact that under some conditions, when the level of additional pressure created is not more than half a bar, no intervention is required in the vehicle’s fuel system.

It is inappropriate to describe the procedure for implementing the turbo mode from such a set; each of them has its own assembly instructions. The disadvantages include the country of origin, but it depends on your luck. What the car looks like after modification and how to do it, the video will additionally help you understand.

One of the ways available to car enthusiasts to boost the engine of an old car and give it a new life is to install an air supercharger. You can do this work yourself if you use commercially available KIT kits for VAZ cars.

ZnanieAvto.ru

Final result

During the research, the turbine installed on the VAZ 2107 engine injector showed the following results: provided that the clutch and tires are of high quality, the acceleration time to 100 km/h is reduced by 5 seconds (compared to the base engine). The same principle applies to elasticity: acceleration time in 4th gear from 60 to 100 km/h is also reduced by 5 seconds.

Practical implementation

The idea itself is simple. However, it is difficult to implement it on the VAZ 2107. Representatives of companies that will undertake the production of turbochargers are counted on the fingers of one hand. But turbine kits for installation on a conventional injector began to appear on the market. The kit includes all the pipes, a new block cover, the turbine itself and the intercooler.

The difficulties of installation and further adaptation to the injector are as follows:

- The exhaust gas temperature level that the turbine must withstand is theoretically between 900˚C and 950˚C.

- The working speed of the rotor injector with the impeller is numerically represented not only in tens, but in hundreds of thousands of revolutions per minute.

- The functional resources of the volume of engine compartments of passenger cars are limited, and therefore require the manufacturer to place the unit within a specific framework.

Based on the above, a turbocharger must have high heat resistance, be compact, well-balanced, and at the same time inexpensive.

How is oil supplied to the turbine?

A complete turbocharging system cannot function without oil. So the driver who decides to install a turbine will have to solve this problem. When the turbine is installed, a special adapter is screwed to it (such adapters usually come complete with turbines). A heat dissipation shield is then installed on the intake manifold. Oil is supplied to the turbine through an adapter onto which a silicone tube is first placed. In addition, the turbine must be equipped with a cooler and an air tube through which air will flow into the manifold. Only in this way can an acceptable temperature of the oil supplied to the turbine be achieved. It should also be said here that sets of pipes and clamps for supplying oil to turbocharging systems can be found in spare parts stores.

A set of turbine pipes will save the driver a lot of time

This set costs from 1200 rubles. Despite the clearly inflated price, such a purchase will save the car owner a lot of time, since he will not have to bother with cutting and adjusting silicone tubes.

About the pipes

Pipes are needed not only for supplying oil. Exhaust gases from the turbine also need to be removed. To remove excess gas not used by the turbine, a massive silicone pipe on steel clamps is used. In some cases, a whole system of silicone pipes is used to remove the exhaust (their number is determined by the design of the turbine). Usually there are two of them, in some cases - four. Before installation, the pipes are carefully inspected for internal contamination. Any, even the smallest, speck that gets into the turbine can cause a breakdown. It is for this reason that each pipe is thoroughly wiped from the inside with a cloth soaked in kerosene.

Exhaust pipes are usually made of silicone

When choosing clamps for pipes, you should remember: silicone is not a very durable material. And if, when installing the pipe, you tighten the steel clamp too much, it can simply cut the pipe. For this reason, experienced motorists recommend not using steel clamps at all, but instead using clamps made of special high-temperature plastic. It provides reliable fastening and does not cut the silicone.

8-valve engine kit

The turbo kit for the 8-valve engine has the following characteristics. It is capable of generating pressure up to 0.5 Bar. With this kit you can increase power to 120 horsepower and torque to 190 Nm. Installing this kit does not affect the life of the power unit in any way. Installation is quite simple, and all parts from the kit are hinged. There is no need to modify the engine in any way for installation.

The turbo kit includes:

- Steel manifold.

- Turbocharger.

- Gaskets.

- Oil supply hose.

- Coolant supply system.

- Valve for releasing excess pressure.

- Connecting elements.

- Fasteners and other parts.

The set for 16-valve units is completely similar. Its technical characteristics are also similar. On sale you can find a turbo kit for an 8-valve engine with a power of up to 250 horsepower. A turbocharger with a pressure of 1 bar is used here.

Turbo VAZ

How to assemble the optimal turbo engine for the city.

Recently, many owners of VAZ cars have been interested in how to assemble the optimal turbo engine for the city. In this regard, we decided to provide you with specific recommendations on how to assemble it most competently and without extra costs.

The basis of our future turbo engine will be the currently very popular VAZ sixteen-valve engine with the index 21126 from the Lada Priora car. But our guide can be considered universal, because following it, you can assemble a turbo engine on any other base. The key point is not so much the specifics of individual engines, but rather the approach and scope of their future transformations.

And so, the first thing you need to do is disassemble the engine and assess its condition. If the engine has “good mileage”, then the cylinder block is given for boring to the next repair size. When assembling the block, so-called turbo pistons are used. The most common and well-proven option is turbo pistons, modified from pistons. They are distinguished by an enlarged (up to 20 cc) combustion chamber and counterbores for a sixteen-valve cylinder head. Standard Priorov connecting rods are also not suitable for a turbocharged engine. The best replacement for them would be the standard VAZ 2110 connecting rods. But the crankshaft remains “original” - 75.6 mm. As a result, we get an engine with the same volume (1.6L), but with a compression ratio reduced to 7.6:1. Similar “bottom” configurations are actively used in the construction of turbo engines with power up to 400 hp.

At the next stage, you need to decide on the turbine itself. In our opinion, the most suitable for everyday use is the TD04L turbocharger (standard for the Subaru Impreza WRX); it is characterized by early pickup and a fairly wide operating range - an excellent choice for driving in the city. The maximum power is about 250 hp, which will also allow it to demonstrate decent results in amateur Drag-racing competitions. If you want more power, then choose a TD05 or GT28 turbocharger. The selected turbine will require an appropriate turbo manifold. You also need to supply oil to the turbine and implement oil drainage, organize the supply and drainage of coolant. It is very important to use reinforced oil supply and silicone reinforced antifreeze lines. It is the reinforcement of these nodes that will allow you to forever forget about possible problems with them.

When choosing an intercooler, remember that airflow with a standard bumper is very poor. When installing a large intercooler, the radiator airflow will be completely ineffective, which means you are guaranteed constant overheating. For use in the city, you can limit yourself to a 450x180x65 intercooler. It fits under a standard bumper, completely satisfying your cooling needs. In addition, it is better not to create an air line with a large diameter in a city car. You shouldn’t complicate the installation process and end up with turbo lag - this is a slow response of a turbocharged engine to pressing the gas pedal due to the need to increase the pressure in the air line itself. Based on this, the smaller its volume, the less turbo lag there will be. Use an aluminum piping kit with a diameter of 51 mm - this is the best choice for installing the air line. If you are building a motor with a power of about 300 hp. and plan to participate in competitions quite often, choose a 550x230x65 intercooler and piping with a diameter of 57 mm.

The standard receiver will need to be replaced with a special turbo receiver, which differs from the atmospheric versions in its small volume and modified geometry. It is advisable to replace the standard throttle pipe. The most suitable pipe is with a valve diameter of 54 mm. An excess pressure relief valve, in other words a blow-off, is installed on the air line in front of the damper. It is this part that produces a spectacular “zilch” when changing gears, i.e. when releasing the gas pedal.

Be sure to select the correct fuel injectors. This must be done based on the engine power, because it is important to provide the increased amount of air with the required amount of fuel supply. Planned engine power 200 hp. – stop at ACCEL 378 cc injectors. For the needs of a 250 hp engine. you should use injectors with a capacity of 432 cm3/min from FORD RACING or ACCEL 462 cm3/min. But for an engine more than 300 hp. Nozzles with a capacity of more than 600 cc/min are recommended, for example, SIEMENS Deka 630 cc/min or their analogues.

Along with the injectors, we also change the fuel pump, which also has greater performance. For example, the Walbro fuel pump is characterized by the fact that it can withstand the loads of the most powerful engines that can be found in most racing cars.

In addition to the fuel supply, modify the engine management system itself. In particular, it is better not to use a traditional mass air flow sensor (MAF); it is usually replaced by an absolute pressure sensor (MAP) and an air temperature sensor (ATS). This way, you will ensure reliability and the ability to work with all the cutting-edge programs that control the operation of the motor.

When selecting an absolute pressure sensor, choose the model whose upper range is closest to the performance characteristics. In other words, if you plan to use approximately one bar of pressure in the turbo engine, then it is not advisable to use a DBP with an upper value of 3 bar, otherwise you will not be able to fine-tune the turbo engine. When solving the problem of choosing the best options for sensors and injectors, it would be most rational to take the advice of a specialist who will be involved in tuning the assembled turbo engine.

Another important point is the selection of camshafts. The whole difficulty is that their choice is individual for a separate turbo engine. So, for a simple project, standard camshafts will suffice. But they will have to be replaced if an increase in power in the uppermost range is planned. Our advice is to install camshafts designed specifically for turbo engines. Such turbo camshafts allow the engine to perform excellently, both in the urban cycle and in competition conditions.

Assembling a turbo engine also affects cylinder head issues. So, for city driving you can limit yourself to a standard cylinder head. But if you plan to get the most out of the engine, and the car is being prepared for drag racing, then installing a cylinder head with enlarged ports and valves is advisable. This will allow you to get more power and move the torque plateau to higher speeds.

The output of a turbo engine will be maximum as the diameter of the exhaust pipe increases, starting from the downpipe itself and to the end can. Remember that by narrowing the line in at least one place, you will reduce its entire diameter. For engines with power from 200 hp. It is considered optimal to use an exhaust system with a pipe diameter of 60 mm. As a ready-made solution, you can safely use a resonator, bend and universal muffler made of stainless steel from the Russian manufacturer MG-RACE. These elements of the exhaust system have proven themselves and are often used in practice.

The clutch for a turbo engine, in particular a city engine, is a particularly important point. We recommend using the PILENGA Sport kit with a metal-ceramic driven disc with a damper. Of course, using such a clutch in city traffic jams causes some inconvenience, but it does an excellent job of transmitting the torque of an engine with a power of up to 300 hp.

From all of the above, we can draw an important conclusion that converting a standard engine into a turbo engine is much easier, cheaper and more profitable than working with a model that has undergone full atmospheric tuning, because Almost all engine elements are replaced. Carefully select components, pay attention to every detail when assembling, do not skimp on qualified tuning of the assembled turbo engine - this is what guarantees a long service life and power characteristics of your engine.

For your convenience, we have added full-fledged turbo kits to the catalog, which include all the necessary parts for assembling a turbo engine. By purchasing such a kit, you significantly save your time and money.

What's better?

The answer to this question can only be given by the owner of the VAZ 2107. A cheaper option would be to install a conventional compressor. It won't take much time or money.

But if you want your car to “fly”, then you need to install a turbine.

As stated above, this is a more complex procedure in which you will need to change some components of the car and invest a lot of money in such tuning. But you will definitely be pleased with the result.

What you need to know about supercharging

Turbocharging is the forced injection of air into the combustion chambers by creating a high-pressure zone at the inlet of the intake tract. When the driver of the car presses the pedal and the throttle valve opens, significantly more air will enter the intake manifold than if it were supplied at atmospheric pressure. As the amount of oxygen increases, the carburetor or injector also increases the amount of fuel. Due to this, the engine power increases.

The combustion chamber has a fixed size, and its volume is a constant value. On a standard engine, only a limited amount of the fuel mixture fits into it. To increase power, it is necessary to place a larger volume of fuel in the cylinder. This is achieved by creating high pressure, which will compress the mixture. Then it will take up less space. This is why turbocharging is needed.

Suitable engines

The easiest way is to make a VAZ turbo based on a 16-valve unit. It has a fairly simple design and is therefore also easy to tune and maintain. And most importantly, it is ideal for motorsports, as it can produce sufficient power at minimal cost.

Old engines equipped with a carburetor power system are practically not amenable to such tuning. But some craftsmen still build a turbo VAZ-2106. 8-valve injection engines would be suitable for civilian use, but in motorsport every horsepower is needed and important. Auto tuning experts recommend using 16-valve VAZ engines.

How to install a turbine on a Zhiguli

“Piping” is a rather fascinating concept, especially when you consider that this component will also be useful to you. In fact, there is nothing complicated in the meaning of the designated concept. These are connecting elements that are located between the turbine and the intercooler, as well as between the intercooler and the intake receiver.

From the impeller in the exhaust manifold, the movement is transmitted to the compressor, the design of which allows it not to be afraid of high temperatures and to serve for quite a long time. As a result, air flows under enormous pressure are pumped into the power system, which increases the engine power.

During the removal and installation process, we wash all the pipes (I used carburetor cleaner, it took 3 bottles) and change all the gaskets. You also need to remove and clean the intercooler, its pipes and the throttle valve. Which was done the next day. After 500 km I plan to change the oil again, because... There was too much dirt in the pipes and in the oil itself.

The service for repair and restoration of a turbocharger includes the replacement of all worn or broken parts with completely new ones, with the following multi-stage and complete balancing.

- turbines for SsangYong Kyron;

- turbines for SsangYong Actyon;

- turbines for SsangYong Stavic;

- turbines for SsangYong Rexton;

- turbines on Ssangyong Musso;

- turbine for SsangYong Rodius;

- turbine on SsangYong Korando;

- turbines at SsangYong Chairman.

Which turbine to choose

Electric turbine for a car. is it possible? Is it possible to do it yourself? only the real truth

The most common equipment for installation on the VAZ 2106 is a turbo kit. It is designed specifically for 16-valve engines of VAZ cars. Turbines are sold along with everything necessary. Installation of the kit does not require modifications to the engine. Power increases to 130-140 horsepower. Moreover, this complex can be subjected to tuning in the future.

Some car enthusiasts prefer turbines and Mitsubishi. Productive and reliable compressors GT25R, GT28R, GT28RS are chosen from the Garrett series. They allow you to develop power up to 250 horsepower.

https://youtube.com/watch?v=wSiwbD_9-Ds

The VAZ 2106 turbo is designed for high-speed driving on city roads and is not at all similar to the usual Soviet “six”. Do not forget that any car equipped with additional equipment requires attention and care, monitoring the operation of systems and periodic technical inspection.

What does turbocharging do for a car?

Since the VAZ 2106 is not equipped with a turbo system at the factory, like many modern foreign cars, all work to increase the car’s power will have to be done independently in a garage or by hiring a specialist. But it should be borne in mind that installing a turbine is quite a difficult task, and if you have no experience, you should seek help from professionals.

The operating principle of turbocharging is to pump treated and compressed air into the combustion chamber, which leads to mixing gasoline with air and increasing the power of the power unit. The turbine is usually located between the exhaust pipe and the intake manifold. The processed and released gases leaving the combustion chambers rotate a special turbine connected to a compressor. The last unit forces air into the cylinders. The quality of turbine operation directly depends on the amount of used gasoline.

Turbo kit for the "six"

Installing a turbine on a VAZ 2106 has its advantages:

- the turbocharger is fairly lightweight;

- the turbine can be adjusted for any car engine, for any carburetor;

- turbo can be installed on a motor that has undergone tuning;

- installation of the unit does not interfere with further modernization of the car;

- The turbine is suitable for an engine of any size.

There are 2 types of turbines. A low-pressure unit is a cheaper option, and its installation does not require major changes to the design of the car, which saves money. A high-pressure turbine involves tuning the main components of the machine and is expensive. To install this unit, you will have to redo the exhaust system, injection system and perform engine chip tuning. The car becomes sporty, sharp, agile and dynamic.

Turbine check

Before installing the turbocharger, it is recommended to change the oil, as well as the air and oil filters. The turbine is checked in the following order:

- the oil drain and supply parts of the compressor are inspected for the presence of foreign impurities;

- the catalyst is checked (excess exhaust gases will negatively affect the operation of the compressor);

- all air supply channels are inspected for dirt and blockages;

- The rotor rotation speed is checked.

In other words, checking a turbocharger comes down to:

- control of the quality and quantity of gases released from the collector;

- checking the quality of fresh air supply to the compressor;

- checking the output of hot gases from the turbine;

- checking the compressed air output from the compressor.

Video: testing a tractor turbine on a VAZ 2107

Thus, installing a turbocharger on a VAZ 2107 is quite complicated and expensive. Therefore, it is easier to immediately turn to professionals. However, before this, it is necessary to carefully evaluate the feasibility of such tuning.