VAZ Priora cars replaced the flagships of the domestic manufacturer. Recently, more and more adherents of Russian cars are switching to Priora. But in these vehicles, as in any other, certain malfunctions may occur, especially when it comes to the gearbox. Today you will find out why first gear is difficult to engage in Priora and how to fix this problem.

Why might there be such interruptions?

The gearbox of any car is one of the most important components of the vehicle. Breakdowns in it can occur both due to improper operation and due to driving on bad roads. If on your Priora the first gear does not engage well or does not engage at all, then this is due to a breakdown of the gearbox.

VAZ Priora car

If your car was purchased second-hand and not from a showroom, then there is nothing to be surprised about. In any car, sooner or later the problem of unstable gear shifting may arise. Moreover, if at the beginning of the problem the speed is turned on, but poorly, then in the future the gearbox lever may not respond at all to the driver’s attempts. Of course, this is not very pleasant, because not every car enthusiast can move from a stop in second gear, and the situation on the road does not always allow this.

Let's consider the main malfunctions that may occur when it is difficult to change gears in a VAZ 2170 car:

- incomplete disengagement of the clutch. On Priors, the mechanical clutch cable can fly off. This can be determined very quickly: if the cable breaks, then the clutch pedal in the car will simply be recessed into the floor;

- failure of the gear drive control rod;

- failure of jet thrust;

- the fastening screws on the hinge or lever of the speed selection rod have become loose for some reason;

- incorrect adjustment of the gearbox speed shift drive;

- The service life has expired or the plastic parts in the gearbox control drive have failed;

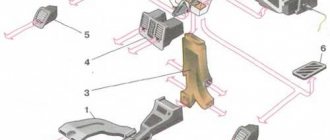

VAZ Priora gearbox disassembled

- the link is poorly adjusted. This device in the car performs the function of connecting directly the gearbox with the lever in the cabin. Also, the plastic bushings on the rocker may wear out;

- synchronizer malfunction. Synchronizers are brass bushings designed for easier gear shifting. Because brass is a soft material, it can wear away over time. To understand that it is the synchronizers that have failed, when it is difficult to switch gearbox speeds, you will regularly hear an unpleasant crunching or grinding noise. If you only hear sound from the gearbox, but the gears are switched without problems, then be prepared to soon encounter difficult gear shifting;

- bearing failure. The problem is not so common, even rare, but nevertheless occurs. If the manual bearings are jammed, then one of the gearbox shafts may stop rotating, as a result of which not all speeds can be engaged. As a rule, this problem only appears when first gear is engaged;

- gearbox shaft malfunction. This element is not subject to physical wear or heavy loads, but the problem may be a manufacturing defect. If minor errors were made during its installation at the factory, the shaft will fail. In this case, not only may it be difficult to engage the first gear, but the entire gearbox may fail. As a result, the vehicle owner is subject to expensive repairs.

It’s worth noting right away that there is no way to determine a faulty gearbox shaft or bearings at home. Only a competent technician at a service station with expensive specialized equipment will help you do this. Therefore, if you encounter problems shifting the gearshift lever, then you can only hope that the problem lies in the adjustment.

Gearbox lever of a VAZ Priora car without a casing

What to do?

Next, we will look at several ways to solve the problem that can be done at home. The process of repairing a transmission is not such a simple task, so if you are not confident in your abilities, then do not try to do it yourself. It is better to contact specialists, because if you make even a small mistake, it can develop into more serious problems in the future.

Tools

Regardless of what kind of breakdown you have, prepare in advance all the necessary tools that you may need to disassemble the gearbox:

A set of tools for dismantling and repairing the VAZ Priora gearbox

Step-by-step replacement instructions

Removing the manual transmission

- First of all, before disassembling the gearbox, it is necessary to drain the transmission fluid from the gearbox. To do this, find an oil drain hole under the bottom of the vehicle, place a previously prepared container and unscrew the plug. Wait 40-60 minutes until the oil is completely drained. Now you can begin dismantling the gearbox.

- To begin, find in the cabin under the instrument panel the fastening nut of the clutch cable housing, which is connected to the pedal. It needs to be unscrewed. To do this, you will need an "8" socket or wrench. When the nut is unscrewed, remove the stop from the bracket.

- Then you need to dismantle the locking element and the housing of the wear compensation device for the driven shaft linings from the clutch pedal pin. To do this, take a slotted screwdriver and pry out the element.

- Now remove the plastic bushing from the pedal and then inspect it. If the bushing shows signs of wear or any physical damage, the bushing should be replaced. Before installing it directly, take “Litol” and lubricate the element so that it does not become dry.

- Next, dismantle the rubber seal of the clutch pedal cable sheath - it is located in the engine compartment.

- Then you need to remove the end element from the cable fork, after pulling it forward in the direction of travel of the vehicle.

Video “Repairing the gearbox of a VAZ Priora”

This video describes a complete repair of a manual transmission of a VAZ vehicle at home. The repair principle is identical for any VAZ cars, including Priora.

Did you find this article useful? Have you already experienced transmission repair on your car? Tell our users about it!

I've read a lot about this in the last hour and am confused about what needs to be done. And my situation is the following, I squeeze the clutch, the speed is tight... but it turns on (but very hard) with the second one in the same way, I also remember the words of the master at 15 thousand like turn it on through the second one), so now it’s not possible to turn it on through the second one, well, if it does to overcome this tight inclusion, then the subsequent times 1st and 2nd come in so that it breaks into a smile (very easily), there used to be moments when if you switched super sharply there was a crunch, for example from 1st to 2nd, but somehow I got used to it and everything went away, oil in korobos it is replaced by semi-synthetics.

So here’s what I’m confused about. In similar topics they often post this link or say that it’s the 1st and 2nd gear synchronizer, or they say that it’s the structure of the box. Like a VAZ - I don’t like comments like that, so they would be inappropriate here.

When the car is turned off, everything turns on very easily. The 3 4 5 speeds always turn on just as easily, the 12-year-old car already had a Kaliningrad car. The car is still under warranty, so it would be nice to sort this out.

PS the clutch pedal clicks when you press it and at the very end when you release it)

When the speed of the car begins to turn on heavily, it not only causes an unpleasant feeling, but also makes the operation of the car unsafe. In this article we will analyze the reasons why gears are difficult to engage or do not shift at all, which is usually associated with this.

The gearbox is a complex mechanism that requires constant maintenance. Including regular diagnostics and gearbox oil changes. Ignoring these measures often leads to problems with gear shifting.

Video “How to solve the problem of poor gear shifting?”

The Avto-Blogger channel made a video that describes all the nuances of poor gearing in a car when the engine is running and gives recommendations for solving such a malfunction.

I've read a lot about this in the last hour and am confused about what needs to be done. And my situation is the following, I squeeze the clutch, the speed is tight... but it turns on (but very hard) with the second one in the same way, I also remember the words of the master at 15 thousand like turn it on through the second one), so now it’s not possible to turn it on through the second one, well, if it does to overcome this tight inclusion, then the subsequent times 1st and 2nd come in so that it breaks into a smile (very easily), there used to be moments when if you switched super sharply there was a crunch, for example from 1st to 2nd, but somehow I got used to it and everything went away, oil in korobos it is replaced by semi-synthetics.

What are the reasons for poor gear shifting?

Difficulty shifting gears can occur as a result of improper operation of the gearbox, or due to operation of the vehicle on bad roads. Problems with the gearbox sooner or later occur in used cars.

If you have difficulties when trying to switch to another gear, you cannot shift or it takes a lot of effort, then there is clearly a malfunction. Most often, car owners turn to a car service center when they have difficulty engaging first gear or reverse gear . A fairly common problem on VAZ and Ford Focus cars.

Let's look at the faults that lead to difficult gear shifting:

- Clutch malfunction. In this situation, the gears will engage either poorly or not completely. A common occurrence in VAZ cars that have fur cables. the clutch is moving away from the mount.

- Problems in the drive of the switching mechanism. Broken traction leads to difficult engagement of 1st and reverse gears.

- The jet thrust is faulty.

- Wear of plastic parts in the box control drive.

- The slide is incorrectly positioned. A weighty element, incorrect adjustment leads to malfunctions.

- Bearing wear. This is a fairly rare occurrence; anyone can experience this, especially when you have a manual transmission. In such a situation, it is usually difficult to engage first gear.

- The box shaft is faulty. By itself, it is not subject to heavy loads, which could lead to wear. A factory defect may cause the entire unit to be replaced.

- Clutch failure. Often found among owners of cars with an automatic transmission. The malfunction is eliminated by replacing the clutches.

- Faulty synchronizers are the most common problem among gearbox breakdowns. They are made of brass, and this metal itself is quite soft. During use, it wears out and wears out. The breakdown is usually accompanied by a grinding noise when switching to another speed.

Why is it difficult to engage manual transmission gears?

manual gear shifting

- The most common problem is clutch failure. In such a situation, reverse gear turns on with a bang. This happens because the gear overlaps the tooth. Reverse speed is the only gear in the box that does not have synchronizers. For this reason, clutch failure is so obvious on it.

- The second reason is a defect in the mechanism responsible for selecting the gear. This breakdown occurs when the car is stationary and you try to shift into gear.

- The third is severe wear of the gearbox synchronizers. Mostly, breakdowns occur with those that are most often used. These are first, second and third gear. Severe wear of the synchronizers only appears when switching while driving.

To prevent possible gearbox malfunctions, perform regular maintenance, change the oil on time, and in case of minor failures, rush for diagnostics . This will save you time and money in the future.

Watch the video for what not to do with a manual transmission:

What to do if it is difficult to engage reverse gear?

If you have difficulty engaging reverse gear, do one of the following :

- When you feel that the gear has not reached the end, release the clutch slightly, and the gear will be inserted all the way.

- Fully depress the clutch and only after a few seconds engage reverse gear.

- Depress the clutch, set the gear to neutral and release the clutch. After this, press down and engage reverse gear.

- Shift into reverse through another gear. For example, first engage 4th and then shift to reverse.

How to properly engage reverse gear on a Hyundai Solaris, watch the video:

It's hard to engage first gear

Many drivers who encounter this situation try to force the gearbox selector to engage 1st speed. But this is fundamentally wrong and should not be done this way.

In this situation, it is necessary to use the regas method . Its essence is as follows:

- While driving in second gear, depress the clutch and set it to neutral and then release the clutch.

- After this, you need to press the gas pedal, increasing the speed to 2.5 thousand.

- The next step is to engage the clutch again by pressing the pedal all the way and turn on the first gear on the gearbox. If you still have difficulties with this, then you need to repeat it, because... You gave too little gas, there were too few revolutions.

- If all the steps are performed correctly, the first speed will turn on without any difficulties or sounds.

However, this method should not be used on an ongoing basis when it is difficult to engage 1st gear. This method is temporary in order to at least get to the service station without any problems. In any case, the box will have to be repaired.

What to do when it’s hard to engage 1st gear on a car, watch the video from a driving instructor :

The procedure for replacing synchronizers requires experience, relevant knowledge and special tools, so it is better to contact professionals. Automotive technicians will perform the replacement quickly and efficiently, and will also advise you on further operation and maintenance of the box.

Why is reverse gear difficult to engage?

Regardless of what type of transmission is installed on the car (automatic or manual), poor engagement can be encountered at any gearbox. In such a situation, it is necessary to identify the breakdown and make repairs, since it is impossible to drive a car without reverse gear. Let's look at each reason in more detail.

Wear of the rocker bushing

Sometimes turning on reverse gear is accompanied by a lot of vibration and a characteristic crunch. The gear knob moves hard. In this case, the adjustment of the link, which connects the rod and the gear shift lever, may be disrupted. In addition, plastic bushings wear out quickly and must be replaced on time.

An experienced driver may notice excessive looseness and play in the lever. But if the wear occurs gradually, then it is difficult to notice the increasing free play. All repair work can be done directly from the salon. It is enough to remove the gear knob cover, remove the rocker and replace the bushing. After adjustment, the inclusions become clearer and softer.

The durability of a plastic part depends on the quality of the material used by the manufacturer. After adjusting the stroke of the rocker and replacing the bushing, this problem disappears. Sometimes craftsmen replace the factory mechanism with a shortened stroke. But they often forget that for it to work properly, it needs to be more accurately configured.

Electronics faults

Vehicles are equipped with different gearbox locking devices. Some vehicles use electromagnetic locking. In this case, the electrical wiring is located under the bottom of the car and is not protected by anything. In off-road conditions, the wires must be protected from damage, otherwise they will quickly become unusable. As a result, the supply of electricity to the interlock will stop and a problem will occur related to gear shifting.

Transmission traction is broken

Some cars are equipped with transmissions in which the shift rods are located outside the mechanism housing. In difficult climatic conditions (dirt, snow, icing), the free movement of traction is disrupted. This is especially noticeable when switching reverse gear, since it is rarely used. But in the morning it is necessary to leave the garage. To avoid such problems, in difficult conditions it is recommended to use a car that does not have external gear shift rods.

Note! Sometimes the length of the rod changes due to the loosening of the adjusting nuts, making shifting difficult. In this case, you will need to adjust and adjust the length, and the issue will be resolved.

There is not enough oil in the gearbox or its properties are reduced

If you do not take care of your car, a problem with engaging reverse gear may occur due to insufficient oil in the box or a deterioration in its performance properties. Inexperienced drivers believe that oil is poured into the gearbox all the time, and there is no need to change it. In reality, even high-quality lubricant with high mileage (about 100 thousand km) becomes unsuitable for use. These data correspond to a gentle driving mode.

We recommend: DSG gearbox: what is it

But if the car is operated in difficult conditions associated with temperature changes, city traffic, and frequent switching, then the oil needs to be changed much more often. Over time, the properties of the lubricant change. Additives no longer work properly, harmful deposits, wear products, and dirt appear.

With dirty old oil, the gearbox mechanism works with difficulty not only when engaging reverse gear, but also other gears. It is necessary to pay attention to the presence of leaks under the car. If the lubricant leaks and its level is reduced, then the gearbox parts will wear out much faster than the period set by the factory.

Wear of release bearing, springs, gears, forks

Failure of the listed parts is accompanied by extraneous knocking or noise while driving, which is easy to hear. Reverse and other gears will be difficult to engage, or will become inaccessible altogether. To eliminate such malfunctions, you will need the help of specialists from a car repair shop. In this case, the gearbox will have to be removed from the car, so you should not start repairing this important unit yourself. This way you will save money and prevent further breakdowns.

Usually the fault is detected on the road: you stop at a traffic light, and when you try to shift into gear, difficulties arise. Cracks often appear on the shift fork, which even under light loads lead to the destruction of the entire part.

It happens that when starting off on loose snow or sand, the reverse gear switches off spontaneously. The handle has to be held forcibly.

The reasons may be the following:

- Displacement of the motor on the cushions and knocking out the speed.

- Worn synchronizer clutch or gear.

- The fastening of the link is loose and does not hold the fork in the desired position.

Note! The driver can independently tighten the engine mounts and secure the rocker. To do this, the car will need to be installed on a pit or overpass.

Incomplete clutch disengagement

The gearbox and motor are connected by the clutch mechanism. When changing speed, the driver presses a special pedal to disconnect the gearbox from the engine. Then the desired gear is engaged and the clutch pedal is released. After this, torque is again transmitted to the wheels.

Problems with automatic shifting

An automatic transmission is very demanding in maintaining the oil level and its condition, unlike a manual transmission. Too high or low oil level can lead to machine malfunction. In addition, due to a lack or excess of oil, difficulties may arise in switching gears.

The most common automatic transmission faults:

- Forward gears do not engage.

- There is no reverse gear, forward there is only 1st and 2nd.

- All speeds are engaged except reverse.

- The gears don't engage at all.

The oil level in the automatic transmission is checked using a dipstick. If the oil level is low, add.

Basket

This element is installed on all cars with a manual transmission. As for “automatic machines,” a torque converter or, in common parlance, a “donut” is used. So, why don't the gears shift when the engine is running? Over time, wear occurs on the clutch basket petals. They bend or break. As a result, gears are not engaged when the engine is running. Visually inspect the condition of the item. If the petals are damaged, then the element needs to be replaced.

But this is not the last reason why gears do not engage when the engine is running. If the gears are difficult to engage and the car shakes at the start, a worn clutch disc is to blame. The element looks like this:

This is what the new element looks like. After 100 thousand kilometers it will take on a slightly different appearance.

If the disk is worn out, burnt, or the springs have fallen out, it should be replaced. By the way, there is also wear on the flywheel, but it is not so significant.

Theory of gearbox operation

At the moment, all modern gearboxes are equipped with synchronizers, which are important elements of the gearbox. The essence of how synchronizers work is that they equalize the operation of the gearbox shafts.

Every driver, when switching from second to first gear, has encountered a situation where some kind of obstacle was felt. What prevents you from engaging first gear while driving. This is the synchronizer.

If you have a fairly new transmission, then when switching from an upshift to a downshift you will not find yourself in such a situation. Switching will be carried out without problems. This manifests itself as the components of the unit are used and worn out.

If you have problems with switching, come to Ankara for diagnostics and repair of transmissions of Mitsubishi, Toyota, Lexus, Land Rover, Jaguar, Infiniti, Mercedes, BMW, Audi and other brands.

Watch a video about the design and operating principle of the gearbox:

First gear doesn't engage well - what to do?

Many drivers, when operating used cars, are faced with the fact that the gear does not engage well, in most cases it is the first one. What to do and how to improve gear engagement ?

How to engage first gear without harming the gearbox

Often, novice drivers, shifting the gear lever from second gear to first, notice certain difficulties: first gear does not want to engage. And the driver, using force, literally drives the lever into the position of engaging the cherished gear.

Some drivers who were “lucky enough” to notice such a drawback of a manual transmission even came up with a kind of rule: the first gear is intended only for starting the movement, and then the second, third, fourth, fifth are used.

We recommend: Do-it-yourself gear knob reupholstery: experimenting with leather and other materials

Of course, this rule is completely wrong, since it is necessary to select a gear based on the ratio of the current speed of movement and the engine crankshaft speed. In fact, you can even park normally only in first gear. Parking in second gear means you'll be firing the clutch or maneuvering unreasonably fast.

Therefore, absolutely any driver needs to acquire an extremely simple skill that allows him to engage first gear on the move.

Theory of gearbox operation

Modern passenger cars equipped with a manual gearbox have synchronizers. A synchronizer is an integral part of a mechanical gearbox that acts as a shaft speed equalizer and is also responsible for the shockless engagement of gears.

It is in the process of pushing the gear lever from the second gear position to the first gear position that we come across some obstacle that prevents us from moving the lever to the first gear position. This obstacle is the synchronizer.

If the first gear synchronizer is new, then the process of shifting from upshift to downshift occurs without any serious delays. If the car has a high mileage, then the synchronizers begin to stop performing their direct functions.

The driver has to remember the old-fashioned methods of controlling a manual transmission - these are various throttle shifts combined with double clutch release. Re-throttle with double squeeze acts as an equalizer of the angular velocities of the articulated gears.

The higher the difference in angular speeds, and the higher the wear of the synchronizer for a given gear, the more you will have to throttle. When the angular speeds are equal, the driver will immediately feel it: the gearshift lever will easily move into the first gear position.

No force is needed.