Gears engage with effort: gearbox malfunctions

In cars with a manual transmission, gear shifting is done by the driver himself. Using a lever from the interior, it acts on the rocker and then on the entire gearbox mechanism. Simply put, the driver moves the gears on the shafts.

Since the shafts rotate at high speeds, cooling is required. This is done using special gear oil. Oil also protects the surfaces of rubbing parts from premature wear. The lubricant must be changed on time. On average, this is done after every 40-50 thousand kilometers.

As for the reasons for tight gear engagement, there may be several of them. However, most often they are associated with problems in the clutch or the gearbox itself. If you study the list of the most common breakdowns, then you can highlight the following:

- the link is poorly adjusted. In particularly difficult cases, it may be necessary to replace the plastic bushings. This procedure, like adjustment, can be done on your own;

- hydraulic drive failure. If it leaks, you may not be able to engage the gear at all, since it is impossible to disengage the clutch;

- the clutch cable has broken or fallen off (in a cable clutch);

- The clutch basket has failed.

The exception is reverse gear, since it does not have synchronizers; By the way, when the reverse gear is difficult to engage, extraneous noises, clanging, and crunching often occur. Such phenomena directly indicate wear of the gear teeth.

Principle of operation

The working diagram of the gearbox is as follows. The drive shaft receives rotation from the driven clutch disc and transmits it to the intermediate one. If the gearbox is set to neutral speed, there is no engagement of the intermediate shaft gears with the driven one, the car is immobilized, since rotation is not transmitted.

When a gear is engaged, the driver engages the driven element gear with a specific intermediate gear. And rotation begins to be transmitted from the driven shaft to the wheels. The car starts to move.

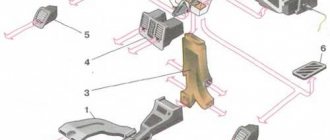

The necessary gears are engaged by a control unit consisting of three sliders and forks. Each of the forks is equipped with a special groove of the element. That is, the driver, using the gearshift lever and a special rocker, acts on a certain slider, moving it to one side. In this case, the fork on the slide pushes the gear, and it engages. The change in gear shift speed is influenced by engaging gears of different sizes and numbers of teeth.

To prevent the slider with the fork from returning to its original position, the box control unit is equipped with latches. The latter are spring-loaded balls that fit into grooves on the sliders. That is, the slide has grooves in certain places.

When moved to the desired position, the ball retainer jumps into the groove, eliminating the return of the slider. When changing speed, the driver must apply pressure on the slider that exceeds the force of the detent spring so that the ball pops out.

This is a simplified description of the design and operating principle of a manual transmission.

Typically, the VAZ gearbox of classic models operates according to this scheme. On some cars the scheme may be slightly different, but the essence of the work is the same - the slider with the fork acts on the gear.

In some cars, the slider in the gearbox, which is responsible for engaging the first gear, also ensures that the reverse gear is engaged. It happens to them that the first and reverse gears are difficult to engage. Of course, this breakdown cannot be ignored.

On other gearboxes, first and reverse speeds are separated and different sliders are responsible for turning them on. In such cars, problems with engaging first gear may not be reflected in engaging reverse gear.

There are several options why first gear does not engage well. It also all depends on how the cause manifests itself - it is impossible to turn it on, and everything is accompanied by a metallic grinding sound from the side of the box, or the speed turns on, but immediately turns off on its own.

What's the result?

So, the main reasons why gears are difficult to engage are problems with the clutch mechanism and gearbox. However, most of them can be eliminated yourself if you have tools, spare parts and certain skills.

Why may it be difficult to engage gears or why first gear, second, reverse, etc. may not engage? The main causes of gearbox malfunctions, recommendations.

Reasons for difficulty shifting gears with the engine running. Transmission oil and level in the gearbox, wear of synchronizers and gearbox gears, clutch.

How to change gears without a clutch: driving a manual car without a clutch in case of malfunction. Tips and tricks.

Manual transmission gears (speeds) do not engage after replacing the clutch: main reasons, settings and adjustments. Diagnosis of problems, useful tips.

Clutch: basket, release, clutch disc. Purpose and design, principle of operation of the clutch basket. How to increase clutch life.

The automatic transmission does not change gears: the car does not move forward or backward, the automatic transmission does not switch to individual gears, reasons.

Transmission device

So, the gearbox diagram is quite simple.

There is a housing attached to the clutch housing. This housing contains three shafts - drive, driven and intermediate. The peculiarity of the arrangement of the shafts is such that the drive and driven shafts are on the same axis, and at one end the driven shaft enters the drive. An intermediate shaft is installed below them.

On each of the shafts there are gears of different diameters and with a different number of teeth, while some of these gears mounted on the driven shaft can move along it.

Types of checkpoints

Today, all cars are equipped with one of three types of gearboxes.

- Mechanical. Speed shifting is done manually using a special lever.

- Automatic. No external influence is required to change gears. Switching is carried out depending on the degree of pressure on the brake and gas pedals. In this case, reverse gear is engaged manually.

- CVTs. This is a mixed type of gearbox, where the bulk of the work is performed automatically, but if necessary, the gearbox is switched to manual mode.

Typical breakdowns

General view

Based on some signs, it can be determined that certain gearbox components on a VAZ 2114 car need to be repaired.

- When a certain gear is engaged, it does not lock properly and crashes. This indicates that the fastenings of the gear teeth and clutch are worn out. When reverse gear is difficult to engage on a VAZ 2114, you will have to take certain measures. Repair consists of replacing the damaged element. If the gear engages spontaneously, the reason may also lie in wear, delamination and cracking on the rubber element of the rear support. Just replace it.

- To engage the gear you have to apply more force than usual. If the reverse gear on a VAZ 2114 car does not engage, the problem is most likely hidden in loose or worn teeth attaching to the hinge. This may also occur due to deformation of the torque rod or the appearance of cracks in the plastic part of the gearbox drive.

- There is noise in neutral gear. The oil level may be too low or its original viscosity may have been lost. Plus, a similar symptom is characteristic of wear on the upper bearing of the input shaft. Check this element, inspect the oil level and quality.

- It is not uncommon for reverse gear to engage with a crunch on a VAZ 2114. The problem here is the wear of the synchronizer. If the problem is not corrected at the first sign of its occurrence, this may result in the need to replace the entire gear assembly and synchronizer.

- Noise is generated while the car is moving in certain gears. A similar malfunction occurs due to a damaged lower or upper bearing. Along with the noise, the lever may jam. The only option is to carry out a full diagnosis of the gearbox.

- A knocking noise occurs in a certain gear with or without load. The problem lies in the drive gear, which will have to be replaced.

- When the transmission is engaged, a cracking sound is heard. This indicates wear of the synchronizer blocking ring or the need to replace the satellite axle. The box will have to be sorted out to fix the damage.

- Oil leaks from the box. The reasons can be very diverse, so you will have to carefully diagnose the checkpoint.

Theory of gearbox operation

At the moment, all modern gearboxes are equipped with synchronizers, which are important elements of the gearbox. The essence of how synchronizers work is that they equalize the operation of the gearbox shafts.

Every driver, when switching from second to first gear, has encountered a situation where some kind of obstacle was felt. What prevents you from engaging first gear while driving. This is the synchronizer.

If you have a fairly new transmission, then when switching from an upshift to a downshift you will not find yourself in such a situation. Switching will be carried out without problems. This manifests itself as the components of the unit are used and worn out.

If you have problems with switching, come to Ankara for diagnostics and repair of transmissions of Mitsubishi, Toyota, Lexus, Land Rover, Jaguar, Infiniti, Mercedes, BMW, Audi and other brands.

Watch a video about the design and operating principle of the gearbox:

Checkpoint disassembled

The best way to prevent breakdowns is to take preventive measures. Unfortunately, even the most careful care is not able to protect the box from the occurrence of certain malfunctions.

Repair and replacement

It is quite difficult for novice motorists to even simply determine why their gearbox is not working. What can we say about replacing the gearbox seal on a VAZ 2114, which requires a certain skill and knowledge in the field of car repair.

Unfortunately, if you ignore the initial signs of a gearbox malfunction, this may result in a full-fledged need to replace the entire unit. Many are even afraid to ask the current cost of a new gearbox for the “fourteenth” model. But we will say. Today such a unit will cost you at least 15 thousand rubles. Moreover, this price does not include installation services. Changing an entire gearbox yourself is not an easy task.

Let's be frank. Situations in which a car is rendered unsuitable for transmission repair are very rare. Most often, something like replacing the gear selector rod seal on a VAZ 2114, gears, levers and other components is required.

It is difficult to carry out diagnostics on your own in a garage environment. To correctly identify a breakdown, you will need at least a lift and a driver’s extensive experience in car repair. But it is best to carry out diagnostics at a car service center with the appropriate equipment. Whether you entrust them with the repairs or handle this stage yourself is up to you.

The cost of repairing a gearbox on a VAZ 2114 is influenced by several factors:

- Location;

- Skill level of the craftsmen;

- Clauses of the concluded contract for the replacement or repair of the gearbox;

- Level of car service (regular garage-type service station or full-fledged car service with a large staff and new equipment).

Tips and tricks

It happens that a driver is forced to operate a car with a faulty gearbox for a certain period of time. At the same time, many are usually interested in how to engage a gear if, for example, the gearbox synchronizer is broken, the clutch does not work, etc.

- So, if the car has difficulty engaging the first gear, then you can start from the second, increasing the engine speed and releasing the clutch.

- If problems arise with the clutch, the driver engages first gear with the car turned off and starts the engine with the gear already engaged, then continues to drive in it. This method is not recommended without proper experience, but it can also be useful.

- Re-gasping and double squeezing.

The driver of the car moves the gear selector lever to the neutral position. Then he fully depresses the clutch pedal and with his right foot, without pressing the accelerator pedal too much, accelerates. Having reached the required engine speed (the tachometer needle should be at around 2500), the driver releases and depresses the clutch pedal again, then turns on the speed.

If you cannot turn on the desired speed with the gear selector lever the first time, you need to repeat all the necessary manipulations again. If everything was done correctly, it is possible to engage the desired gear, even taking into account problems with its synchronizer. Also, experienced drivers can engage gears without using a clutch at all.

New or refurbished old?

Disassembled gearbox

As practice shows, such gearboxes are approximately 30-70% cheaper than purchasing a new gearbox.

There is only one important condition for successful savings on such significant repairs. It must be a reliable, proven company. Such companies value their own reputation, so they do not deal with fakes or low-quality repairs. In order to receive positive customer feedback and attract new customers, they simply must do everything well, conscientiously. That’s why today there are fly-by-night companies and companies where, over the years of work, they have established themselves as a reliable and responsible specialist in repairing and replacing gearboxes. You yourself understand perfectly well who you need to contact if you have problems with your box.

Extending the service life of gearboxes

Transfer shaft assemblies There

are only two recommendations.

- Always try to monitor the oil level in the gearbox. If it drops, be sure to top it up immediately, do not delay the procedure until later. When the oil becomes unusable, change it completely, rather than fill in the missing amount.

- Avoid aggressive use, do not jerk the gears sharply, accelerate smoothly, and brake similarly. A simple caring attitude towards the gearbox will allow you to avoid wear and tear and numerous breakdowns.

As you can see, solving problems with checkpoints is not so easy. Therefore, the best option is to prevent their occurrence.

Troubleshooting gearbox

Troubleshooting the gearbox is done by removing it from the car, disassembling it, and troubleshooting parts if it is found that some of them are badly worn. Particular attention should be paid to the condition of the sliders and clamps. If burrs are noticed on the sliders, they must be removed with a file. You also need to check the condition of the springs and retainer balls. The springs must be intact, and the latch must move without problems in its seat. If necessary, worn or damaged elements must be replaced.

You should also carefully inspect the power forks for bending. Even a slight bend can affect the ease of gear engagement.

After assembly, gear shift adjustment must also be performed. To be precise, the position of the scenes is set.

Reverse gear does not engage on VAZ 2114: troubleshooting

Sometimes during the operation of the car, motorists are faced with the fact that the reverse gear on the VAZ 2114 does not engage (or it does, but with great effort).

You can diagnose such a breakdown yourself, guided by the signs of wear of certain components presented below:

- When switching, the gear “flies out” and does not lock—wear of the coupling and gear teeth. The solution is to replace worn parts with new ones;

- the gear engages spontaneously - the rubber part of the rear support is worn out or cracked. The solution is to replace the rubber part with a new one;

- When switching to neutral, a loud noise appears - the oil level is very low or it does not meet the requirements (for example, viscosity). The solution is to add/change the oil;

- Reverse engages with a crunch - the synchronizer has worn out. The solution is to replace the synchronizer with a new one (if you continue traveling with a worn synchronizer, you will soon have to replace both the synchronizer itself and the entire gear block);

- When driving in reverse (or any other) gear, noise appears - the lower or upper bearing is worn out. The solution is to replace the bearings (it is advisable to conduct a full diagnosis of the box);

- When driving in any gear, a sharp knock occurs - the drive gear has failed. The solution is to replace the drive gear;

- When changing gears, a cracking noise occurs - the pinion axles are worn out or the locking ring is broken. The solution is to replace worn elements.

How to extend the service life of a gearbox on a VAZ 2114?

You can do without repairing the box if it is used correctly. Gearboxes on VAZ cars do not like heavy loads and sudden shifts. Monitoring the oil level in the box is also an important component of the long life of the unit. Approximately every 70-80 thousand kilometers it is necessary to change the transmission oil in the gearbox, although many people neglect this procedure altogether. Aggressive driving, abrupt starting from a standstill, slipping - all this affects the service life of the mechanism.

The condition of the clutch disc and release bearing also affects the shifting of the gear lever. If the clutch disc is worn out, normal engagement of speed without effort and crunching is impossible. Timely replacement of these consumables allows you to avoid expensive repairs of units for a long time.

In a situation where the reverse gear on the VAZ 2114 does not engage, to continue driving, you can try to engage first gear and drive a little forward. Then try again with reverse gear engaged. The condition of the synchronizers also plays a role in the smooth operation of the mechanism. Extraneous noise and crunching when switching are a clear sign of a damaged synchronizer.

It is impossible to replace them without removing the unit, so when overhauling the gearbox, all worn parts should be replaced. The design includes shafts, gears and transmission mechanisms. Wear on these parts increases with poor oil condition, hard gear shifting and sudden acceleration. Without understanding why the reverse gear does not engage in the VAZ 2114, you should not immediately contact the service center and remove the unit. Often the cause of such a problem is a small problem with the loosening of the link or the destruction of the spring in the structure. Weakening of the cardan also leads to a similar problem. If visual diagnostics do not allow you to determine the source of the problem, then you can proceed with removal and disassembly.

Lada cars are not designed for fast and aggressive driving, so the factory gearboxes installed in cars are quite difficult to withstand heavy loads. Despite the low cost of repairing any unit in a car, you should still use the box in a gentle manner.

Repair or replacement

If, during checking the condition of the box, serious damage to its elements was revealed, then serious repairs cannot be avoided.

It should be immediately noted that independent dismantling, repair and reassembly of a gearbox requires not only very good equipment (nominally a pit or overpass, a lifting device, as well as a large set of tools are required), but also very serious knowledge.

That is why, if the gears of a VAZ 2114 do not engage, such repairs should be entrusted to specialists from car service centers.

It should be remembered that independent repair or replacement of the gearbox automatically leads to the loss of all warranty obligations from the manufacturer. For this reason, repairs to a car that is under warranty should be entrusted to branded repair shops.

If we talk about the choice between repair and complete replacement of the unit, then in most cases you should choose the first option. This is due to two reasons. Firstly, the cost of a completely new box exceeds 15 thousand rubles. (moreover, this amount is indicated without taking into account the cost of its installation). In any case, repairs will be much cheaper. And secondly, complete wear of the box (to a state unsuitable for repair) is extremely rare.

The cost of the repair work itself varies from service to service and depends on:

- the size of the locality (and, as a consequence, the presence of competitors);

- type of breakdown;

- the size of the car service (and whether it is official);

- additional clauses in the terms of the contract.

Replacement box - new or old?

If the reason why the gears on the VAZ 2114 are poorly engaged is due to very severe wear of the gearbox components, and it turns out that its repair will be more expensive than a complete replacement, then the motorist is faced with a choice - install a new gearbox or give preference to a “restored” one.

The first option is certainly preferable, but the fact is that a new gearbox is not cheap at all (as mentioned above).

The cost of a refurbished one is much less (sometimes such a box costs 70% less than a new one).

A rebuilt gearbox is an excellent option, which is almost in no way inferior in quality to a new gearbox, but at the same time costs much less. The only thing to remember is that such units should only be purchased from trusted companies that professionally restore them and provide a guarantee for their products.

It should also be remembered that if there is a choice, it is better to give preference to the “middle option”. You should absolutely not purchase refurbished boxes from little-known companies at a very low price.

Advice for motorists

Above we have already talked about why the reverse gear on the VAZ 2114 does not engage and how to correct this situation. But it should also be noted that proper and timely care of the gearbox will help either completely avoid such a situation or postpone it for as long as possible.

There are only two basic rules for this care:

- Change gears, as well as accelerate and brake the vehicle as smoothly as possible, without jerking.

- Periodically check the oil level, replenish it as it is used, and also replace the entire volume if it is worn out.

These simple rules will help to significantly increase the service life of the entire box and its individual parts.

Reverse and other gears slip out

The synchronizer blocking ring and gears have specially shaped teeth with which the clutch engages when changing speeds. If the coupling splines, teeth on the ring and gear are ground down, then when the load is applied and the gas pedal is released, the transmission spontaneously switches off. In this case, it will not be possible to limit yourself to replacing synchronizers; you should definitely change the gear of the damaged transmission and the gear shift clutch.

Note. Regardless of the brand of your car, the breakdown principle is almost the same for all manual transmissions.

The speed will be knocked out even if it is not turned on completely. Possible causes of manual transmission malfunction:

- wear of the rod, gear shift fork;

- cable jamming;

- incorrect installation, wear of the intermediate shaft bearing;

- wear of the manual transmission cushion, which causes the box to shift under load;

- loose gearbox housing bolts.

Gears don't engage well: the main causes and breakdowns of the gearbox

As a rule, malfunctions in the operation of the box are caused by errors during operation of the unit. In any case, diagnosis is necessary. In this case, problems that arise when switching the gearbox may be associated with the following malfunctions:

- Incorrect operation of the clutch (air in the clutch release hydraulic drive, wear or break of the clutch release fork, failure of the basket, wear or break of the clutch release fork, broken cable, etc.)

In this case, shifting the reverse gear may be difficult and be accompanied by a characteristic crackling sound. If the clutch pedal does not move and is sunk into the floor of the car, then the clutch cable has broken. - Breakage of the drive rod for controlling the gear shift mechanism. Switching first, reverse and other gears is difficult.

- Incorrect operation of the transmission thrust. The reaction rod prevents spontaneous gear shifting and, if it is damaged, changing gears will be difficult. The problem is solved by replacing the jet thrust.

- Loosening the fastening bolts located on the gearbox selector with the rod. The problem is solved by tightening the mounting bolts.

- The link is poorly adjusted or the plastic bushings are worn.

The linkage is the connecting mechanism between the gear shift lever and the rod. Shifting first, second, reverse and other gears is accompanied by crunching and vibrations. The gear shift knob is difficult to move. The problem is solved by correctly adjusting the link or replacing it with a new part. - Worn gearbox input shaft bearing.

Such a breakdown leads to quite unpleasant consequences, since a faulty bearing not only affects the rotation of the gearbox input shaft, but can also damage the gearbox housing. In this case, changing first gear will be difficult. The problem is solved by replacing the bearings. We also recommend reading the article about why the automatic transmission does not change gears. From this article you will learn about the main reasons why gears in an automatic transmission do not change. - Defective gearbox shaft. Failure of this part may be due to a manufacturing defect. If design errors were made during the production of the box, then during the operation of the vehicle the box shaft may break. In this case, the first speed does not engage well. The problem may turn out to be serious, that is, it can only be solved by replacing the box itself.

- Breakage of clutches. This failure usually affects the automatic transmission. The problem appears when engaging both first gear and others. Often the problem is solved by replacing the clutches.

- Wear of box synchronizers. Synchronizers are brass bushings that ensure equalization of the speeds of the driven shaft and gear when the gear is engaged. During the operation of the vehicle, this part of the gearbox may be subject to wear.

There is a loud noise or grinding noise when shifting the gear lever. Most often this happens when engaging first, second or third gear. This does not apply to the reverse gear, since it often does not have a synchronizer. The problem is solved by replacing the synchronizers.

Reverse gear does not engage on VAZ 2114: reasons, repairs

The situation when reverse gear does not engage on a VAZ 2109 is one of the most common problems with this car model. In addition, the VAZ 2108/09/099 “Samara” and VAZ 2113/14/15 “Samara-2” cars were equipped with the same type of gearbox (gearbox), so this transmission malfunction is typical not only for “Nines”.

Often, an attempt to engage a gear is accompanied by a strong crunch of gears, and if the gear is able to be engaged, the gearbox makes noise when moving in reverse. Other owners are faced with a situation where the gear shift lever moves forward all the way, but reverse gear does not work. At the same time, there are no complaints about shifting forward gears.

Reverse gear, first and other speeds do not engage when hot

Owners of cars with a manual transmission often encounter the problem of poor gear engagement, which occurs after starting and warming up the engine, that is, “on hot”. In this case, engaging one or more gears may not only be difficult, but also be accompanied by extraneous noise or unnecessary vibrations.

In this case, the gearbox shifts normally when the engine is turned off. Next, we will look at the common reasons why this malfunction occurs, as well as what to do if the gears are difficult to engage when heating.

Causes

The reasons why reverse gear engagement is poor or difficult may be as follows:

- loosening of the fastening clamp of the rocker, due to which the length of the rod is not enough to fully engage the gear;

- jamming of the reverse speed lock;

- spring breakage and debris getting into the guide grooves of the gear selection mechanism;

- spontaneous loosening of the selection mechanism mounting bolts;

- the clamp bolt is cut off;

- wear of the clutch disc and release bearing;

- incorrect adjustment of the clutch and clutch pedal;

- low oil level in the box or the need to replace it.

Manual transmission bearings

And the last thing that could be the bearings - although they are very strong in the box, sometimes they also “stick”. The box will work like a tractor, especially when warm.

In any case, if you have problems in the gearbox itself, then this is an expensive repair. It is also better to entrust it to professionals, because the gearbox is a very complex mechanism.

As you can see, there are quite a few reasons, but in fairness it is worth noting that mechanical transmissions are a fairly reliable unit; they themselves break down quite rarely, especially if you change the transmission fluid on time and pour a branded one of very good quality.

If the gears do not engage, then these are most likely “attached” problems, starting from the rockers and cables, ending with the basket, clutch disc and flywheel.

Now let’s take a look at a short video version of my article.

And that's ALL for me! I think the information will definitely be useful, read our AUTOBLOG.

( 10 votes, average: 4.70 out of 5)

Similar news

How to change the oil in an automatic transmission (automatic transmission) or variator (CVT). .

How much does it cost to change the oil in an automatic transmission? Detailed material.

Why does the automatic transmission kick and jerk? Or when switching.

Troubleshooting

Many transmission malfunctions that cause the reverse gear to disappear or fall out can be eliminated without removing the unit from the car.

If the cause is a loosening of the bolt securing the clamp on the rod, then to correct the defect it is necessary:

- Place the car on a lift.

- Completely loosen the clamp nut.

- Place the gearshift lever in the fully engaged reverse gear position.

- Fully engage reverse gear at the gearbox using the shift rod on the crankcase.

- Tighten the clamp mounting bolt.

Backstage adjustment

If tightening the clamp does not help get rid of the problem, then you need to check the condition of the shift drive parts. One of the reasons why the reverse gear does not engage may be a poorly adjusted rocker.

To make adjustments to the mechanism, you may need the following tools:

- two wrenches with a size of 13 mm, preferably a socket design;

- any wrench or 10 mm socket;

- small hammer;

- slotted screwdriver.

Since the cause of malfunction of the link can be wear of parts, spare parts may be needed:

- universal joint of the rocker;

- Sometimes the shift rod seal may need to be replaced.

Two people are required to adjust the rocker or replace parts of its drive. One person must change gears from the passenger compartment, and the second must adjust the travel of the shift rods.

The order of work is as follows:

- Provide access to the bottom of the car by placing it on a pit or a lift.

- Using a 13 mm wrench, loosen the clamp installed on the gear shift rod.

- Remove the rod from the box rod.

- Using a screwdriver, carefully remove the boot.

- Using a 10 mm wrench, unscrew the fixing bolt on the cardan shaft.

- Knock off the cardan shaft with light blows of a hammer. It is important not to damage the shaft.

- Remove the universal joint seal boot.

- If there is an oil leak, the sealing gland on the box rod must be replaced.

- Install a new boot (or leave the old one if it is intact) and install the universal joint on the shaft.

- Align the hole on the cardan with the notch on the shaft.

- Tighten the 10 mm clamp and install the boot completely in place.

- Install the rod on the cardan rod and adjust the gearshift lever travel.

- The second person should sit in the driver's seat, set the gear shift lever to neutral, move it slightly to the right and hold it in that position.

- After this, you need to tighten the 13 mm clamp nut.

Typically, after such a repair, the reverse gear starts to engage without problems. In addition, the operation of the entire gear selection mechanism on the VAZ-2109 becomes clearer.

Replacing the backstage

Changing the gearbox oil

If the oil seal on the rod is damaged, oil leaks out of the gearbox housing, and dirt can get into the box itself. These factors may be the reason why reverse gear stops engaging. In addition, the oil in the box loses its properties during operation, so it must be replaced preventively at least once every 35–40 thousand kilometers. Before replacing, you need to check the condition of the oil in the box. To do this, you need to remove the oil dipstick installed in the gearbox housing and visually assess the quality of the oil. The presence of metal and dirt particles in the oil on the dipstick is unacceptable. The oil itself should be quite liquid and not stick to your hands in a thick layer.

To replace, you will need the following materials and tools:

- New oil. When purchasing oil, you need to consider the type of gearbox. For fairly rare four-speed gearboxes, three liters of oil are required, for newer five-speed ones - 3.3 liters. The oil itself must have a tolerance of 80W-85, the manufacturer does not matter.

- A container for draining old oil with a volume of at least 4 liters.

- A funnel with a hose for pouring new oil or a syringe.

- Wrenches 12 and 17 mm of any type.

- Rags and cleaning solvent.

The actual work order is as follows:

- Place the car with the heated gearbox on the pit.

- Remove the rubber plug from the gearbox ventilation valve installed on the top of the crankcase.

- Clean the valve and plug from dust and dirt. It is convenient to clean parts with thin wire and a rag.

- Reinstall clean parts.

- Wipe off dirt from the bottom of the box. Unscrew the plug on the bottom of the box housing.

- Place a container under the drain hole and drain the oil. It will completely merge in at least 20-25 minutes.

- After this, screw the drain plug back into place and carefully tighten it with a wrench. First, the plug and hole must be thoroughly wiped with a rag.

- Pour fresh oil through the oil level dipstick hole in the box.

- During filling, it is necessary to check the oil level, which normally should be between o and “MAX” on the dipstick rod.

- If there is an overflow, the oil can be pumped out with a large medical syringe with a tube on the spout.

- Within a few days after the change, it is advisable to check the level and appearance of the oil. You also need to make sure that there are no leaks through the plug and box seals.