January 15, 2015 Lada.Online 300 204 380

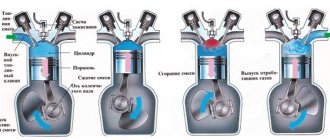

To start the engine, you need to ensure that a spark appears at a certain moment to ignite the air-fuel mixture in the cylinders. Problems with starting the engine occur if one or more elements of the system malfunction. The table lists possible reasons why the Priora does not start.

The starter spins for a long time when starting the Priora

The design and principle of operation of the VAZ 2110 starter

The starter of any car is simply a DC traction motor. No more, no less. Everything else is simple mechanics. The only hitch in the design of the VAZ 2110 starter may be the retractor relay, and even then, if you are dealing with it for the first time. There are absolutely no difficulties in either repairing or replacing starter elements. The main thing is to know the principle of operation and then you can find any breakdown in no time.

Briefly about the starter design. The picture shows the VAZ starter, as well as all the structural elements, which we see no point in listing. The design of the starter has a lot of minor parts, but there are also those that, if they are faulty, the starter will not even think about rotating the flywheel. In principle, there are only two main reasons for starter failure - mechanical and electrical failure.

The starter turns hard

The current travels from the battery to the starter a long way through the electrical network, which consists of a large number of connections and wires. During operation, oxidation processes occur, contacts and wires undergo corrosion. In addition, the wiring may burn out, which leads to disruptions in the integrity of the electrical network and interruptions or complete cessation of the supply of electric current to the starter.

Possible reasons

If the starter slips when starting, this is mainly due to damage to the contacts. First of all, you need to ring the wiring, check its integrity. Particular attention should be paid to the collector, where the wires often burn out. With prolonged use, the wiring may rot over time.

Solution

If problems are detected in the electrical network in the form of a breakdown or break, the damaged area must be completely replaced. However, you should not use electrical tape, as it will not last long.

To restore the working condition of the electrical network, it is necessary to clean the terminals and contacts in all parts of the starting system: oxidized contacts are the main reason for poor flow of electrical current.

Cleansing consists of the following steps:

- The power supply to the car is turned off by removing the negative terminal from the battery.

- Next, you need to clean the contact surfaces using fine-grained sandpaper.

- All connections, terminals and contact bolts should be treated with a degreaser: gasoline, alcohol, solvent.

- Before installing the terminals in place, it is recommended to lubricate them with lithol or grease and crimp them well.

Basically, replacing damaged sections of wiring and cleaning contacts is enough to eliminate the problem of hard starting. If a positive result could not be achieved, then the problem must be looked for in the starting device. To do this, you will have to dismantle the unit and look for faults.

Dismantling the unit from a VAZ 2112

When inspecting the unit, you should pay attention to the brushes, the condition of the armature, and check the nickels of the retractor relay for the presence of soot. Finally, using an ohmmeter, you need to check whether the starter windings are shorted together. If you keep the starter clean and in good working order, you can avoid unpleasant situations when the car does not start in the morning. It happens that when the tester checks everything is fine: there is voltage, but when starting, the starter turns weakly. So let's clean and check the contacts!

What to do first?

Disassembling the mechanism is not a priority task, since the starter’s power supply is connected to the battery, so you need to start with it. If the car is not too old, it is unlikely that the problems will lie in the design of the starter itself. It is enough to clean the contacts of the battery or the device itself for everything to work again in the desired mode.

Difficulties begin when the machine has worked for a long time and its operation has not been delicate. If, after a complete check of the electrical equipment of your VAZ 2107, the starter still does not start or continues to work intermittently, then the reason is inside the device and it is necessary to remove and disassemble the starter. On this model, both in carburetor and injection versions, it is installed rather inconveniently. To get to it normally, you will have to drive the car onto an overpass or inspection hole.

Disassembling the VAZ 2107 starter

After the ignition is turned off, you can begin the “operation”. It must be done in the following order:

- remove the ground terminal from the battery;

- if there is a protective mud casing at the bottom, then it must be dismantled;

- remove the electrical wires from the solenoid relay;

- unscrew the three mounting bolts (two upper, one lower);

- remove the starter.

As you can see, nothing complicated. The only thing is that in the case of an injection model, mechanics advise removing the inlet pipe extensions as well. Now we have to disassemble the device itself.

Is it possible to crank the starter for a long time?

Yes, you can do this, but be prepared for the following problems:

- Dead battery. Each unsuccessful attempt to start reduces the battery charge. In order for the battery to recover the expended energy, you need to start the car and let it run for a while. But if you can’t start, then soon the battery will simply run out. Then you will need to charge it, ask for a light, or try to start it with a pusher.

- Starter failure. Excessive operation of the starter leads to overheating. And this has a very bad effect on its details. Very often they break down, and then you can’t start the car at all. The bendix, which engages with the crankshaft, also suffers. If it fails to start, the splines or bearing may be damaged. So if you turn the starter for a long time, get ready to replace it.

Malfunctions and repair of starter traction relay

The traction relay is located on the front cover of the starter and is designed for short-term engagement of the starter shaft with the flywheel ring. It is this, and not the starter itself, that most often fails. In addition to the wiring and contact problems discussed above, the most common traction relay malfunctions are:

The main sign of relay failure is the absence of a click when turning the key in the ignition switch. It means that:

In such a situation, after checking the wiring and contacts, the relay should be removed from the starter and diagnosed. This is done as follows:

Advice to a car owner

All external contacts of the starter should be cleaned before checking, since this is a fairly common malfunction and there is no need to remove it from the engine.

Even an initial check of the starter without removing it from the vehicle usually indicates a breakdown, reducing repair time, reducing costs and not taking much time.

Originally posted 2018-03-28 15:11:04.

VAZ 2106 starter repair

Most faults in the VAZ 2106 starter can be fixed on your own - all the necessary elements for this are available for sale. Therefore, if the symptoms described above appear, you should not immediately replace the starter with a new one.

Removing the starter

To remove the VAZ 2106 starter you will need:

- wrench 10;

- socket wrench or 10mm socket with extension;

- wrench 13;

- screwdriver with a Phillips blade.

The starter itself is dismantled in the following order:

- Use a Phillips screwdriver to unscrew the clamp screw on the air intake hose. Remove the hose from the air filter pipe and move it to the side.

Video: dismantling the VAZ 2106 starter

Disassembly, troubleshooting and repair of the starter

To disassemble, troubleshoot and repair the VAZ 2106 starter you will need:

- key to 8;

- key to 10;

- key to 13;

- Phillips-blade screwdriver;

- slotted screwdriver;

- hammer;

- pliers;

- calipers;

- special mandrels for pressing in starter bushings;

- ohmmeter

Why is it dangerous to turn the starter for a long time when starting the engine?

Starting an engine is a process in which the starter and battery are directly involved. They are the ones who suffer the most when starting the engine for a long time. Accordingly, the following problems are possible:

Low battery. Each time you try to start the engine, battery power is consumed. Moreover, if the attempt is not successful, then we can assume that the battery is consuming its charge “idle”. In order for the battery to charge, the engine must start and run for a while. Several unsuccessful attempts to start the engine, and you will get a discharged battery, which will need to be charged from the station, or you can start the engine “by lighting” in other cars;

- Starter failure. When the starter is cranked for a long time, it begins to overheat, which can negatively affect its components and lead to complete failure of the part. Also, do not forget about the bendix, which when trying to start the engine is connected to the crankshaft. If the engine does not start, there is a high risk of damage to the splines on the bendix or the bearing. If you constantly have to turn the starter for a long time when starting the engine, over time this will lead to its failure and the need for replacement.

Most often, you can solve the problem with the starter cranking for a long time when starting the engine without contacting a service center yourself, thereby preventing early failure of the starter.

Crankshaft wear

The reason why the starter does not turn on a hot engine may also be the crankshaft bearings - liners. Due to wear, oil starvation, poor-quality assembly and increased longitudinal (axial) play of the crankshaft, the liners may wear unevenly, which will give them an “wrong” shape, especially as a result of scoring on the surface. As a result, when the engine cools down, gaps appear between the crankshaft bearing journals and the liners, which makes it easier to crank the engine. When it warms up, the presence of these defects, on the contrary, can lead to complete jamming of the engine. In any case, when operating a car, it is advisable to respond as quickly as possible to its seemingly random “whims”.

Reasons and actions

The first reason for prolonged torsion of the starter suggests itself a priori. If the car is used, then it is likely that the starter brushes are worn out. You need to disassemble the starter, remove the cover, and replace both brushes.

Difficult starting can also be caused by a clogged fuel tank. The FTO (cleaning filter) becomes clogged and a lot of debris gets inside the combustion chamber. The solution is to clean the debris using liquid aerosols, change the filter, or go to a service station for diagnostics in particularly severe cases.

The air filter, if it sucks in large amounts of dust and debris during vehicle operation, can also cause the starter to spin for a long time. It simply gets clogged and fails to cope with its direct responsibilities - to enrich the combustible mixture by letting air through.

Kilometers traveled for a car are like years for a person. Over time, compression in the engine cylinders decreases significantly. Because of this, a problem arises that can be represented as follows. Gases enter the crankcase and the entire ignition process loses its power. The solution is a major overhaul, if everything is so neglected, or replacement of the rings.

If the car has a carburetor system, then it is quite possible that the cause of the difficult start was bad spark plugs. It is recommended to unscrew them and check for quality. You need to pay attention to the color of the electrode, which should be light brown. The remaining colors only indicate problems: a rich or lean mixture, metal impurities in the fuel, etc.

DIY diagnostics and repairs

So, if the engine refuses to start when hot, you need to diagnose the starter unit. We will tell you more about how to check and repair the device below. The starter mechanism is an electric motor that starts working, receiving energy from the battery. One of the main characteristics of this unit is the consumption of high current at the moment of starting the internal combustion engine, but this only happens for a few seconds. And even then, thanks to the ability of the battery not to discharge.

If the unit does not work well when hot, but all units, mechanisms and circuits are operating normally, it is necessary to repair it. This procedure is not a simple one, so you need to have certain skills and knowledge. As a rule, this unit is mounted in the most inconvenient place for the car owner - at the bottom of the engine. For repairs, prepare standard tools, including a set of wrenches. For greater convenience, you will have to use an extended socket wrench (the author of the video about malfunctions, as well as detailed repairs of the device at home, is the Exin Plus channel).

In any case, you first need to dismantle the mechanism; this procedure is individual for each car, so we will not describe it. After the unit is removed, you need to disassemble its structure. If you do not want to encounter assembly problems after repair, then before disassembling the structure, make the appropriate marks on the body.

When disassembling the mechanism, pay attention to the condition of the following elements:

- Nodes and contacts. If you notice that there is a bad contact somewhere, it needs to either be cleaned or replaced. In some cases, stripping can eliminate scorching or oxidation.

- Overrunning clutch or bendix, this component also needs to be carefully checked. Make sure that the component can continue to be used. If the Bendix splines are worn out, then it would be better to change it.

- Anchor. If this component fails, problems with the operation of the motor may occur. The armature is equipped with a commutator, which can burn out as a result of severe wear of the brushes. In addition, no burning of any kind is allowed on the collector, and the same applies to blue plates. At the same stage, the integrity of the windings along with the insulation should be diagnosed.

Also, when this unit is disassembled, it will be necessary to carry out preventive maintenance of all components. All parts without exception must be cleaned of dirt and dust, as this may cause the unit as a whole to malfunction. In the event that the cause of interference in the operation of the mechanism is due to burnt contacts, they must be replaced; if the brushes are worn out or sticking, then you can try to repair them. If the repair does not produce results, then the brush assembly is replaced; for this, you can purchase a special repair kit at any automobile store. In the event that the mechanism simply cannot be repaired, it will need to be replaced with a functional one.

If the need for repairs causes you difficulties, it is better to seek help from specialists. Even if you pay money, you will be confident in the correctness of the actions performed and the functionality of the node.

Low battery charge

If the Priora has an old battery installed, then in cold weather it discharges faster. This means that starting a cold engine in the morning can be problematic. Sometimes even a new battery drains quickly. In this case, you should look for current leaks. It may be in the wiring or the leak is occurring in some device.

If the search for current leakage does not produce results, then it is recommended to check how the generator charges the battery. If the charge is insufficient, then the battery will not charge fully. As a result, the starter will turn much harder than if the engine was cold.

If the starter turns poorly when the battery is charged, then the breakdown, in most cases, is in the engine starting device.

The reason for the low engine speed, in this case, may be:

- Wiring fault.

- Starter failure.

- Solenoid relay malfunction.

- Thick oil.

Before you begin to identify the above reasons, you should make sure that the battery produces sufficient current to start the engine. To do this, you can use a load fork. If the battery is serviceable, it is necessary to measure the density of the electrolyte.

Wiring faults

The starter of an internal combustion engine is the most energy-intensive piece of electrical equipment in a car, so poor-quality fastening of wires and terminals can reduce the efficiency of this device.

The current strength that occurs when the starter is turned on is so high that an electric arc can form in wires that are not well attached. Part of the energy will be spent on maintaining this effect, as a result of which the starter will rotate very slowly.

In addition to insufficient current in the circuit, an electric arc can lead to a fire, so if the battery does not turn the starter well, you should first inspect the battery connection terminals, and also check the quality of the connection of the positive wire, which is connected from the “+” battery to the solenoid relay.

You should also check the cable that connects the engine housing to the car body; there may also not be good enough contact in this place.

In addition to electrical leakage and loose nuts and bolts, the starter may lack electrical power due to oxidation of the battery terminals. In this case, a layer is formed of a substance that poorly conducts electric current, which is the reason for the deterioration of the starter’s performance.

This problem can be easily solved if you use a soda solution to remove the resulting oxidation layer:

- To prepare the solution, use ordinary soda and warm water in a ratio of 1 to 10.

- You can use a rag to clean the terminals, but the most suitable tool for this job is an old toothbrush.

Defective solenoid relay

A very common breakdown that can cause poor performance of the car’s starting mechanism.

If a short circuit occurs in the electromagnet winding, then this part will need to be completely replaced, but in most cases the reason for the unsatisfactory operation of the solenoid relay is a malfunction resulting from burning of the relay contacts.

In order to restore the functionality of the device, it is necessary to remove the solenoid relay from the starter housing and remove the ebonite cover to which the wires are connected.

Inside the device, there will be a copper plate that closes the relay contacts. It is this part that is most damaged. The surface of the plate that comes into contact with the contacts must be cleaned of irregularities that arise due to elevated temperatures during contact closure. To do this, you should use a velvet file, but remove the metal very carefully so that the plate does not become too thin, otherwise there will not be good contact between the electrical conductors.

Electrical faults

Starter connection diagram

Let's divide possible breakdowns into two parts - those that relate directly to the starter, and those that are related to the supply of voltage to it.

No voltage supply to starter

The reasons for the lack of power supply to the starter may be:

- Low battery. Operating the car (including the battery) on short trips, with numerous consumers turned on (headlights, heated steering wheel and seats, heated rear window, etc.) does not help the generator fully restore the battery charge. And the battery itself is perhaps no longer in its first youth. During a cold start, a small force is required to crank the crankshaft since the compression in the cylinders of a cold engine is less, since on a cold engine the gaps between the parts of the connecting rod and piston group are larger. After the engine warms up, the gaps, due to thermal expansion of the parts, decrease, which causes compression (pressure) in the cylinders to increase, and the starter does not turn the hot engine.

- Some cars are characterized by “burning” of the ignition switch contacts when the car does not respond to the ignition key . This “disease” is especially typical for cars that do not have an additional starter relay - it is this that protects the contact group of the ignition switch, preventing excessive sparking of the moving contacts. But, even if such a relay is present, it may also fail. In any case, the starter power circuit can be checked by closing its “positive” contacts with a metal object (screwdriver). If even after this the mechanism does not show “signs of life,” then most likely the starter itself is faulty.

- Be sure to carefully check the power “positive” wire from the battery connected to the solenoid relay. It is quite possible that a poorly tightened terminal on the starter was burnt. Also check the negative wires and their connections to the body and engine.

Reasons for incorrect startup

Among the existing reasons why the engine does not start well, it is worth highlighting several:

We find out and eliminate the reason why the starter turns poorly

With the onset of cold weather, many car owners experience all the “delights” of the cold season - difficulties begin with starting the engine. The reasons may actually be both the battery and the starter. This problem, when the starter turns poorly when cold, is quite common, regardless of the make of the car. As for the battery, the battery may be old or dead. And many people remember such a concept as “lighting a car.” To understand what exactly is the cause of the identified problem, you need to understand where to “dig”, in what direction to move?

Hot

So, the car drove some distance. In the morning it started up with a half-turn, and forward. But then some distance was covered, a stop was made, the key was turned to “start” and... Several painful revolutions, and only then the engine started working. What's happened? As a rule, there can be many reasons. Conventionally, they can be divided into groups:

- The fuel system is acting up.

- Errors or breakdowns of sensors or actuators of the control system.

- Engine wear.

Starter diagnostics

Dismantling. Once we are convinced that this is the cause of poor rotation of the starter when cold, it will need to be removed from the car for diagnostics. It is advisable to carry out the procedure when the engine is cold, so as not to get burned on the elements of the exhaust system. Before dismantling the starter, you need to remove the terminal from the battery. Depending on what brand of your car it may be more convenient to first unscrew the mount of the starter itself, and then disconnect the power wires and the solenoid relay wire, and possibly vice versa.

Inspection. After dismantling the starter, we need to inspect it. If it is heavily soiled, we clean it. First of all, we check the solenoid relay. If we observe signs of severe wear or any visible damage, the relay should be replaced. Naturally, the new relay must be installed with the same parameters.

Disassembly. If everything is in order with the relay, we move on to the starter. It is worth considering that starters come in different designs. It is necessary to remove the rear cover of the starter, under which the brush assembly is located. The back cover at the same time protects the rotor. We evaluate the condition of the brushes and replace them if necessary. Brushes can be attached either with bolts or by soldering. In addition to the brushes, we pay attention to the bushings. If there is severe wear, the rotor warps at the moment of starting, a lot of force is created, the starter consumes a lot of current and therefore turns hard. If there is 0.5 mm play on the bushings, they should be replaced with new ones. To ensure good contact between the brushes and the rotor, the rotor must be cleaned of dust.

One of the important points is the correct diagnosis. Some people succeed easier, some more difficult, some don’t succeed at all. Much also depends on experience and whether the person has encountered this problem before. There are also car owners for whom such words as “starter” and “generator” are something completely incomprehensible. The article is intended for those who have decided to independently search for the causes of poor engine starting with a starter and eliminate them.

Friends, remember: despite the fact that a car is just hardware, it nevertheless requires periodic attention. Only in this case can we talk about reliability and be confident in your car. Good luck to everyone on the roads!

Source

Which brushes are better – graphite or copper-graphite

Let's say everything is fine with you. The first thing we do on the starter is to do without any disassembly, completely remove and change the brushes. It's quite easy and takes minutes.

When replacing brushes, pay attention to the pressure springs. They must be in good condition - not twisted or damaged. These springs ensure good contact between the brushes and the starter motor armature.

- Graphite brushes. If, when removing the brushes, you discovered that you have graphite brushes, and these were factory supplied, then there is no need to reinvent the wheel. No matter what advice or recommendations you are given, use only graphite brushes. They are softer and put less pressure on the lamellas of the engine armature, so the lamellas are less subject to wear. Imagine, if you change brushes, your slats already have a little wear because they have worked for a certain period of time. If you install copper-graphite brushes, which are stiffer, then this wear will only increase. Thus, in the near future it will come down to disassembling the starter and repairing the armature.

- Copper-graphite brushes. Today you rarely see this, when there are graphite brushes on the starter, copper-graphite ones are still installed there. Copper-graphite brushes differ from graphite brushes in color; they are a little shiny because they contain copper additives. But the main feature is that copper-graphite brushes are not only stronger, which means they last longer, but also have lower resistivity. They have higher electrical conductivity and a lower voltage drop, which allows the starter motor to operate more efficiently. This means that preference is given to copper-graphite brushes.