Starter VAZ 2107

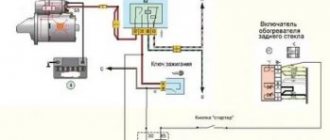

To start the VAZ 2107 engine, it is enough to turn the crankshaft several times. The design of a modern car allows this to be done without much effort using a starter, which in turn is activated by the ignition key.

Starter purpose

The starter is a DC electric motor and provides the vehicle's power unit with the energy necessary to start it. It receives power from a battery. The starter power for most passenger cars is 3 kW.

Types of starters

There are two main types of starters: reduction and simple (classical). The most common is the first option. A reduction starter has higher efficiency and is smaller in size, and requires less energy to start.

Reduction starter

On the VAZ 2107, the manufacturer installs a reduction starter. It differs from the classic version in the presence of a gearbox, and permanent magnets in the motor winding significantly increase the reliability and efficiency of the device. Such a starter costs about 10% more than a classic one, but at the same time has a longer service life.

A reduction starter differs from a classic starter in the presence of a gearbox

The weak point of such a starter is the gearbox itself. If it is made poorly, the starting device will fail before its usual time. The material from which the gearboxes are made deserves great attention.

Choosing a starter for VAZ 2107

The starter performs the most important functions in a car. Therefore, his choice should be taken as responsibly as possible. On the VAZ 2107 you can install starters from other cars, including foreign cars, with suitable fastenings and technical characteristics. The best option are models with a powerful gearbox - starters from the Chevrolet Niva or the injection seven.

When choosing a starter, you need to consider the following points.

- Domestic ST-221 starters with a power of 1.3 W, which were installed on the first classic VAZ models, had a cylindrical collector. The drive gears were driven by electromagnets. The device of such a starter includes a roller overrunning clutch, a remote control and a solenoid relay with one winding.

- Starter 35.3708 differs from ST-221 only in the design of the rear part and winding, which consists of one shunt and three service coils (ST-221 has two coils of each type).

These starters are more suitable for carburetor VAZ 2107. For sevens with an injection engine, it is proposed to install one of the following options:

- KZATE (Russia) with a rated power of 1.34 kW. Suitable for carburetor and injection VAZ 2107.

- Dynamo (Bulgaria). The starter design is optimized in accordance with consumer requirements.

- LTD Electrical (China) with a power of 1.35 kW and a shorter service life.

- BATE or 425.3708 (Belarus).

- FENOX (Belarus). The design involves the use of permanent magnets. Starts well in cold weather.

- Eldix (Bulgaria) 1.4 kW.

- Oberkraft (Germany). With small dimensions it creates a large torque.

All manufacturers of starters can be divided into original and secondary:

- Original: Bosch, Cav, Denso, Ford, Magneton, Prestolite.

- Secondary: Protech, WPS, Cargo, UNIPOINT.

Among starters from secondary manufacturers, there are many low-quality and cheap Chinese devices.

The average cost of a good starter for a VAZ 2107 varies between 3-5 thousand rubles. The price depends not only on the manufacturer, but also on the configuration, delivery conditions of the goods, marketing policies of companies, etc.

Video: features of the KZATE starter

Why does this happen

The reasons for this behavior of the starter can be several factors.

For those who may have forgotten, let us remind you: the starter is an electric motor with a short period of operation and, by definition, it is easy to assume that it is not intended for long-term operation. During braking, it engages with the flywheel, drawing voltage up to 350A. That is why, when forced to work for a long time, the device malfunctions.

The click that is heard when the starting mechanism supposedly breaks down does not actually belong to it, but to its traction relay. The latter has a pair of windings - one is designed for holding, the second for retraction. When the relay clicks, it is due to the following. One stroke of the appropriate purpose draws in the core. But a voltage deficiency develops in the holding winding, and the pull-in winding misses the core.

And so the process is repeated several times while the key is in the “starter” position.

Since the traction relay in any model is identical, the brand of the car does not matter: VAZ, KIA or even BMW - the principle is the same for all.

A working mechanism starts up on the second attempt at most, but mostly on the first. If it's broken, it won't start at three. Therefore, you should not mock the engine until the battery runs out.

Why does the solenoid relay break?

The main parts of the relay: body, contacts, armature, magnet with windings, return spring. When an electric current enters the magnet's retractor winding, an electric field arises. It attracts an anchor, which moves into the core. The latter, using the lever, moves the Bendix gear forward, forcing it to come into contact with the flywheel teeth.

Next, the core, reaching the end, closes the contacts through which current begins to flow to the holding winding of the magnet. The drive is turned on, which spins the starter shaft, transmitting force through the Bendix gear to the flywheel, which spins it. As soon as the engine starts, the current to the relay stops flowing, the magnet turns off, and the return spring returns the shaft and gear to its original position.

What malfunctions can occur during operation of the traction relay on VAZ-2106 and 2107 vehicles?

- Knock. It can occur if the battery does not have a charge, the terminals have oxidized, the connection is faulty, or the magnet holding winding is not connected to ground as a result of its damage.

- Lack of response from the solenoid relay and the starter as a whole after turning on the ignition. As in the first case, the problem is in the condition of the battery. For example, the connection of the holding winding to ground is lost, the contact between the additional and solenoid relay is broken, or the ignition switch board is burned out.

- Incorrect operation of the armature when, after turning on the relay, it does not rotate. And here, most often, the battery is to blame. This can happen if the starter contacts have oxidized or the armature winding has burned out, causing the wire to separate and the armature itself to become jammed.

Assessing the scale of the problem

If, when you turn the key in the ignition switch, the starter does not turn, no clicks or sounds are heard, then the reason may be this:

- the battery is discharged or faulty;

- battery contacts are oxidized;

- problem with the contacts of the starter itself;

- a break in the windings of the device or the electrical circuit of the car.

When the starter turns slowly, you can hear the traction relay clicking. then the reason could be this:

- there is a charge in the battery, but it is not enough to properly spin the moving parts of the starter;

- carbon deposits have formed on the contacts or they have oxidized;

- worn brushes or burnt commutator;

- short circuits in windings or brush holders.

Starter brush wear

Repeated operation of the relay and its spontaneous shutdown can be caused by a voltage drop in the network due to oxidized contacts or a malfunction of the traction relay. When the starter turns, but the flywheel does not rotate, there may be several reasons:

- problem with the freewheel (Bendix);

- drive or flywheel teeth are damaged;

- The bearings or springs of the traction relay are worn out.

These are perhaps the main malfunctions and their most common explanations. They are equally valid for carburetor models and injectors.

The starter hums, but the engine is silent

In this case, the cause of the breakdown is the bendix (it does not click).

And the buzzing is heard due to the fact that the anchor gets caught on the flywheel, and the launch does not occur. The starter works, turning the armature at high speed, but the engine flywheel does not spin up. Note: when the eccentrics stop functioning normally, the bendix begins to spin in different directions (should only go in one direction), and the gear rotates in the flywheel splines. And the result is a buzzing sound.

If you try really hard, in theory you can repair the gear, but it will be expensive, it will be difficult to find the eccentrics, and it may simply not be possible to put everything back together. In such a situation, it is more advisable to replace the entire assembly by first removing and completely disassembling the starter.

Take care of your car, carry out repairs in a timely manner, and it will serve you for as long as possible.

What to do if the starter does not turn?

It cannot be said that the VAZ 2107 starter has some unique set of faults. As a rule, these problems occur when operating any VAZ car model.

What actions need to be taken if the gear starter turns poorly or does not turn at all after turning the key in the ignition switch:

- The first thing you need to do is look at the warning lights; their dim light or periodic fading indicates that the battery is low;

- Check the pole terminals and tips of the battery wires, if they are oxidized, you need to clean them and lubricate them with Vaseline, tighten them tightly;

- Check the relay winding for a short circuit; if it occurs, the relay will need to be replaced;

- Check the relay connections for breaks in the power supply.

Diagnostics of VAZ 2107 starter faults

The VAZ 2107 starter can fail for various reasons.

The starter hums, but the engine does not start

The reasons for the situation when the starter hums, but the engine does not start, may be the following points.

- Over time, the teeth of the starter gear stop engaging (or do not engage well) with the flywheel. This usually occurs when the wrong engine lubricant is used. If you pour thick oil into the engine in winter, the starter will have difficulty cranking the crankshaft.

- The gear that meshes with the flywheel may be misaligned. As a result, the teeth engage with the flywheel ring with only one edge. This is usually due to a failure of the Bendix damper system. Externally, this manifests itself in the form of a characteristic hum or grinding noise and results in broken flywheel or drive teeth.

- There have been disturbances in the power supply system to the starter (brushes are worn out, terminals are oxidized, etc.). Insufficient voltage does not allow the starter to accelerate the flywheel to the required speed. At the same time, the starter rotates unstably, a hum and buzzing appears.

- The pusher fork, which brings the starter teeth to the flywheel crown and removes them after the engine starts, has failed. If this fork is warped, the relay may operate but the drive gear will not engage. As a result, the starter hums, but the engine does not start.

The starter clicks but does not turn over

Sometimes the VAZ 2107 starter clicks, but does not spin. This may happen for the following reasons.

- There are problems with the power supply (the battery is discharged, the battery terminals are loose or the ground is disconnected). The battery should be recharged, the terminals should be tightened, demining should be carried out, etc.

- The fastening of the solenoid relay to the starter housing is loose. This usually happens when driving on bad roads or as a result of over-tightening the mounting bolts, which simply break while driving.

- A short circuit occurred in the traction relay and the contacts burned out.

- The positive cable going to the starter has burned out. It is also possible that this cable may become loose. In the latter case, it is enough to tighten the fastening nut.

- As a result of wear on the bushings, the starter armature became jammed. In such a situation, replacement of the bushings is necessary (removal and disassembly of the starter will be required). A short circuit or break in the armature windings can also lead to a similar result.

- Bendix is deformed. Most often, its teeth are damaged.

Bendix of the VAZ 2107 starter fails quite often

Video: VAZ 2107 starter clicks, but does not turn

Crackling sound when starting the starter

Sometimes when you turn the ignition key, a cracking and grinding sound is heard from the starter. This may occur as a result of the following faults.

- The nuts securing the starter to the body have become loose. Rotation of the starter causes strong vibration.

- The starter gears are worn. When starting, the overrunning clutch (Bendix) begins to make a cracking noise.

- Due to the lack or absence of lubrication, the bendix began to move along the shaft with difficulty. The assembly should be lubricated with any engine oil.

- Flywheel teeth damaged as a result of wear no longer engage with the starter gear.

- The timing drive pulley has come loose. In this case, a crackling noise is heard when the engine starts and disappears after warming up.

Starter won't start

If the starter does not respond at all to turning the ignition key, the following situations are possible:

- The starter is faulty.

- The starter relay has failed.

- The starter power supply circuit is faulty.

- The starter fuse has blown.

- The ignition switch is faulty.

It happened once to start the engine in winter, when the starter flatly refused to rotate through the ignition switch. I stopped the car at the lake where I went fishing. When I was putting it back together, the starting device was inactive. There's no one around. I did this: I found the control relay, removed the wire from it connecting the system to the ignition switch. Next, I took a long 40 cm screwdriver (I found one in my bag) and closed two starter bolts and one retractor bolt. The starter started working - it turned out that sometimes this happens with these devices due to cold and dirt. It is necessary to apply current directly to make the electric motor work.

Preparation for repair and dismantling of the device

The starter clicks, but does not turn: why and how to fix

The starter unit on domestic “sevens” is a four-lane electric motor equipped with four currents. This unit is a DC motor. If it breaks, the crankshaft of the power unit will not be able to turn when trying to start the engine.

Design of the starter device model 4216.3708-02 for VAZ-2107

Mechanism design 4216.3708-02:

- 1 — front protective cover of the device;

- 2 - sealing element, designed to protect the unit from moisture and dust entering the structure;

- 3 — overrunning clutch, equipped with a drive gear;

- 4 — the drive lever itself;

- 5 - partition separating the two components of the mechanism;

- 6 — tie rod;

- 7 - rod;

- 8 — mechanism retractor relay;

- 9 — washers intended for adjustment;

- 10 — anchor device pulley casing;

- 11 — lock washer;

- 12 — rear protective cover made of metal;

- 13 — brush mechanism holder;

- 14 — housing in which the stator device is installed;

- 15 — anchor assembly of the mechanism;

- 16 — axis on which the lever device of the drive unit is mounted;

- 17 — retaining metal ring;

- 18 — sealing element made in the form of a ring;

- 19 - limiter, made in the form of a ring and designed to limit the travel of the gear.

Design of the starter device for the “seven” 57722.3708

Main structural elements of model 5722.3708:

- 1 - nuts, used to secure the back cover of the mechanism to the main part of the device;

- 2 — back cover of the unit, made of metal;

- 3 - bolts used to fix the brush mechanism;

- 4 — spring elements for brushes;

- 5 - brush mechanism itself;

- 6 — stator unit, equipped with magnetic elements;

- 7 — anchor device;

- 8 — thrust washer;

- 9 — anchor mechanism pulley support;

- 10 — central gear of the gearbox;

- 11 — planetary gears of the reduction mechanism;

- 12 — main shaft of the drive unit;

- 13 - external gear of the reduction device, equipped with internal teeth;

- 14 - a sealing element made in the form of a ring is used to prevent the negative impact of water and dust on the design of the device;

- 15 — drive mechanism pulley support;

- 16 — thrust washer;

- 17 — locking element for the drive pulley, made in the form of a ring;

- 18 - another locking component, only intended for the lever of the drive unit;

- 19 — washer;

- 20 — drive unit lever coupling;

- 21 — lever support;

- 22 — lever of the drive device;

- 23 — the drive unit itself;

- 24 — element for limiting the travel of the drive unit, made in the form of a ring;

- 25 — locking ring of the limiting element;

- 26 — mechanism retractor relay;

- 27 - bolts used to fix the solenoid relay of the device;

- 28 — return spring element;

- 29 — core of the retractor relay mechanism;

- 30 — protective cover of the mechanism, installed at the front;

- 31 — tie rods of the device.

It is more convenient to carry out work in a specially equipped room - a garage box. The VAZ 2107 is installed above the inspection hole; for repair and restoration operations, a set of wrenches, a set of heads with a wrench and a device for pressing out the bearing are required. In the event of a malfunction of several other components in addition to the bendix, it makes sense to replace the starter assembly. On a car where there is an injector in the power supply system, repair work is best carried out from below.

The procedure for dismantling the starter on a VAZ 2107 car is as follows:

- Disconnect the battery and remove it from the engine compartment.

- We unscrew the terminal and disconnect the terminal and the wire that supplies power to the starter.

- We unscrew the bolts securing the device that ensures engine starting.

- We remove the unit complete with the bendix feed mechanism from the hole in the housing.

On a VAZ 2107 car, an engine with an injector installed will require a number of additional operations. In this case, replacing the faulty unit is only possible from below. To gain access to the assembly, you need to remove the steel protection and boots covering the engine compartment from below. The remaining operations carried out on the starter are carried out similarly to those described.

Checking the VAZ 2107 starter

If the engine of a VAZ 2107 does not start, usually check the starter first. This is done as follows.

- The starter is removed from the body and cleaned of dirt.

- The output of the traction relay is connected by a separate wire to the battery positive, and the starter housing to the negative. If the working starter does not start to rotate, the test continues.

- The back cover of the device is removed. Brushes are checked. The coals should not be erased by more than a third.

- A multimeter measures the resistance of the stator and armature windings. The device should show 10 kOhm, otherwise there is a short circuit in the circuit. If the multimeter readings tend to infinity, there is a break in the coil.

- The contact plates are checked with a multimeter. One probe of the device is connected to the body, the other to the contact plates. The multimeter should show a resistance of more than 10 kOhm.

During the process, the starter is checked for mechanical damage. All faulty and damaged elements are replaced with new ones.

How does the starter start the engine?

Let's take a closer look at the principle of operation of the starter. After closing the contacts, the current flows to the winding of the traction relay. At this time, the anchor moves and extends the bendix. The gear of the latter is connected to the flywheel ring. When the armature reaches its final position, the contacts close, allowing current to flow to the starter motor winding. The device begins to rotate and the car starts.

The Bendix returns to its original position as soon as the flywheel begins to rotate at a higher speed than the starter shaft. And the supply of electrical energy to the device stops when the key returns to the first position. A gear starter is also installed on the VAZ 2107, in this case the current flow pattern is slightly different; it reaches the armature through a gear drive. Thanks to this, power is significantly increased. This is not the only difference that the gear mechanism has, but we won’t talk about that now.

This is interesting: How to remove a dent on a car with your own hands

VAZ 2107 starter repair - instructions

Type of VAZ 2107 starter

Often in VAZ cars the starter fails. In this article we will talk about what leads to such malfunctions. how to identify and eliminate them. The starter used by the manufacturer for installation on the VAZ 2107 can be of different types and differ slightly in design. However, the principle of their operation, of course, does not change. This mechanism generates direct current and creates the torque necessary to rotate the crankshaft.

Where does the repair begin?

All work starts somewhere. And this one is no exception. First, you need to understand what is wrong and only then think about what can be done and how to fix the problem.

Troubleshooting.

To correctly determine, you first need to think and see what the cause of the problem may be:

- If, after turning the key in the ignition, the engine does not start, check the lights on the display. Extinguished or weakly burning and fading light bulbs indicate a malfunction in the battery: it is discharged, or the terminals are not tightened properly. Every driver has a tester in his car that allows him to check the voltage and capacity of the battery without removing it.

- If the battery has nothing to do with it, you need to check the position of the speed switch and, if necessary, put it in the “P” position.

- Next, you need to find out whether power even reaches the starter from the ignition switch?

Advice! The easiest way to do this is on the red wire connector connecting the starter and the unloading relay.

This work can be done in two ways:

- Method 1: - take a copper wire with a cross-section of 2.5 mm2 and insert it into an open connector. One end to the battery terminal and the other to the starter. In this way, ignition is simulated.

- Method 2: - here you need two people: one turns the key in the ignition switch, and the second uses a control probe to touch the tip of the wire coming from the unloading relay. If the warning light comes on, it means there is no damage to the ignition switch or the relay.

The starter clicks but does not turn, what is the reason?

Good afternoon. Many car enthusiasts are familiar with the situation when the starter clicks but does not turn. As luck would have it, such situations happen at the most inconvenient moments, for example, at gas stations or when leaving for work.

In today's article, we will tell you how to determine the malfunction and, if possible, start the car to get to the repair site.

Before telling the troubleshooting algorithm, let's look at the starter device. For clarity, watch this video:

As you can see, the starter is a regular DC motor and relay. When you turn the key in the ignition and hear a click, it is the solenoid relay that clicks (the coil and contacts at the top of the screen in the video). If the starter does not rotate, but clicks, the following options are possible:

- The battery is dead.

- starter relay failed

- The contact coins in the solenoid relay are burnt.

- The starter brushes are worn.

- the starter armature is jammed.

- power plus is not supplied to the starter (because if there is no mass there will not even be retractor clicks)

Below we will analyze each of these faults in detail, and tell you which faults will allow you to start the car on the spot, using the existing starter, in order to get to the service station.

A severely discharged battery is the most common cause of clicking noises when turning the ignition key.

The error looks like this:

In our video you can see that when starting, at first, the starter barely turns the engine, and then it just crackles…. If the battery is severely discharged, the starter will not even try to crank the engine but will immediately make nasty clicking noises.

The fact is that the battery voltage is not enough even to operate the solenoid relay!

Options to solve the problem:

- light a cigarette from another car (we have a separate article about this on our website).

- start the car from a pusher/tug (if it has a manual transmission).

- remove and charge the battery.

Your starter is working!

Starter relay failure.

Relay failure manifests itself as a quiet click when turning the key.

In this case, you can start the car using a simple screwdriver. This is done like this:

Attention! If you are not confident in your abilities, you should not do this. It is better to contact specialists or call a tow truck. If you make a mistake when starting this way, the vehicle may move unintentionally or catch fire due to a short circuit.

Vehicle with manual transmission:

- set the parking brake.

- turn on neutral gear.

- open the hood and prepare a flathead screwdriver.

- turn the key in the ignition switch to the ignition on position.

- Using a screwdriver, we close two contacts on the solenoid relay (as in the video).

- After starting the engine, remove the screwdriver and drive to the repair site.

Car with automatic (+variator and robot) gearbox:

- install a car parking brake (for robot and variator).

- open the hood and prepare a screwdriver (possibly two).

- turn the ignition to the on position, press the brake, move the gear selector to the parking position (P).

- Using a screwdriver, we close two contacts on the solenoid relay (as in the video).

- After starting the engine, remove the screwdriver and drive to the repair site.

The contact coins in the solenoid relay are burnt.

This malfunction manifests itself in the form of loud clicks when the key is turned to the start position and the key is released. In some cases, the starter may trip.

Here is a video example of such a malfunction:

How to quickly diagnose contact patches?

Everything is extremely simple - open the hood, take a screwdriver, and bridge these two terminals:

If a spark jumps when the connection is made and you hear the sound of the electric starter rotating, you can be sure that your contact pins are burnt.

In this case, the car can be started with a screwdriver!

How to start a car with the starter when the contact pins burn?

Attention! If you are not confident in your abilities, you should not do this. It is better to contact specialists or call a tow truck. If you make a mistake when starting this way, the vehicle may move unintentionally or catch fire due to a short circuit.

In order to start the car when the contact pins burn out, you must simultaneously bridge all three contacts on the solenoid relay.

Closing the two contacts under the nuts is necessary to rotate the armature, and closing the control contact so that the overrunning clutch (Bendix) engages with the flywheel.

The procedure for starting a car if the contact pins fail:

Vehicle with manual transmission:

- set the parking brake.

- turn on neutral gear.

- open the hood and prepare a flathead screwdriver.

- turn the key in the ignition switch to the ignition on position.

- Using a screwdriver, we close all three contacts on the solenoid relay (sometimes one screwdriver is not enough and you have to take two).

- After starting the engine, remove the screwdriver and drive to the repair site.

Car with automatic (+variator and robot) gearbox:

- install a car parking brake (for robot and variator).

- open the hood and prepare a screwdriver (possibly two).

- turn the ignition to the on position, press the brake, move the gear selector to the parking position (P).

- Using a screwdriver, we close all three contacts on the solenoid relay (sometimes one screwdriver is not enough and you have to take two).

- After starting the engine, remove the screwdriver and drive to the repair site.

The starter brushes are worn.

The malfunction manifests itself in the same way as burning of the contact coins (loud clicks when turning the ignition key), the only difference is that when the brushes wear out, the starter will never rotate.

This is checked in the same way when bridging the contacts of the solenoid relay with a screwdriver.

like in this picture:

The starter does not start to spin, it is sincerely not observed.

How to start the car?

Unfortunately, it is impossible to start the car with this starter; it must either be repaired or replaced.

If the car is equipped with a manual transmission, it may be possible to start it by push or tow.

If the car is equipped with an automatic transmission, it makes sense to call a tow truck or tow truck.

The starter armature is jammed.

The author of the article has encountered such a malfunction several times, but, as a rule, the brushes immediately become unusable and, without analysis, you will not be able to distinguish between armature jamming and brush wear.

If, by some miracle, the brushes hold up, then when you turn the key to the start position, you will hear a very loud click, and then, for a while, all the devices will go out (you may feel a specific smell)! Burning out of the mass manifests itself in exactly the same way!

In any case, the car will not go anywhere on its own. It is necessary to carry out diagnostics and use a tow truck/tug to proceed to the repair or parking area.

No power plus is supplied to the starter.

For clarity, look at this picture:

Without a test light or multimeter, you will not determine this malfunction! And in general, without instruments, it can be confused with brush wear!

As you can see, if the power wire running from the battery to the solenoid relay breaks, the starter will not work, but the solenoid relay will click.

If, upon visual inspection of the direct battery-starter wire, you do not see any damage, call a tow truck and go to the place of repair and diagnostics.

That's all for me today. Don't let the situation where the starter clicks but doesn't turn happen to you anymore. If you have any questions or if you want to add to the article, write comments!

Brushes and winding

The starter design consists of four metal cores, which are also called shoes, and a winding connected into a circuit.

The voltage supplied to the winding comes from the central input. In turn, the output is output to positive copper-graphite brushes going to the commutator. They also connect negative brushes coming from the starter mass. Several small springs constantly press the brushes. Graphite is not a strong enough material, so sooner or later they break. When the life of the brushes comes to an end, the solenoid relay stops receiving voltage.

When such a problem occurs, the starter will not spin or make sounds. In case of repair, the unit is disassembled, the condition of the brushes is assessed and replacement is made. If the brushes can still fulfill their intended purpose, then the problem usually lies in the winding. When the winding is completely burned out, then the varnish coating should also burn out.

And the copper color turns black. In such a case, you can change the winding or replace the part with a new one.

Bushings

These elements are located on both sides of the starter. Their task is to control the rotation of the shaft. If the bushings are too worn, then the starter will not start and will make clicking noises. Problems can arise if the starter is not installed correctly and is not in the right place. There could also be a short circuit in the winding.

Heavy cranking may indicate poor performance of the bushings, even if the power unit is warmed up.

The failure of the bushings is not a serious failure, but if you do not want to encounter a problem when the car refuses to start, then they need to be changed in time. Moreover, the bushings can cause the starter shaft to jam, which can lead to self-ignition.