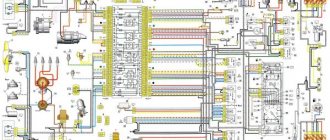

During the operation of a car, problems with the starter quite often arise. Moreover, even if the battery is charged and power comes to the starter after turning the key in the ignition, the device still does not work and the engine does not start.

In such a situation, there are only two ways to start the engine:

- starting the engine “from the pusher”;

- attempt to close the starter directly;

Although the second method is less common, in some cases this method is more “convenient”. The main thing is to know how to bridge the starter correctly to start the power unit. Read more in our article.

Why doesn't the starter work?

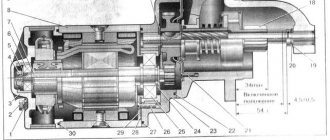

The car starter is actually an electric motor that is “attached” by its gear (Bendix starter gear) to the flywheel (flywheel crown), rotates the crankshaft and is then disconnected after the engine starts.

In this case, there are a number of reasons why the starter does not work:

- problems with wiring and contacts;

- the starter relay does not work;

- The starter solenoid relay is faulty.

- the starter winding burned out;

- the overrunning clutch has worn out, etc.;

As a rule, the main and most common problem is the failure of the starter solenoid relay. If the retractor is faulty, the starter will not turn the engine. A problem with the retractor is indicated by a click that can be heard when turning the ignition key.

If the starter clicks, the relay is turned on, but the overrunning clutch is unable to turn the crankshaft. In the case when the starter does not work precisely for the specified reason, you can try to supply power to it directly (close the starter).

Basic starter failures

The starter ensures the engine starts. It creates crankshaft torque at the required speed for the degree of compression and combustion of the combustible mixture. If the starter starts to work intermittently, you need to find out the reason for this behavior.

If the starter does not want to turn or does it slowly

- pay attention to the electrical circuit and battery:

If the starter does not work or simply does not turn on,

this could be: a relay malfunction, a short circuit in the winding of the starter itself.

If the starter armature rotates, but the starter cannot crank the crankshaft

this is: slipping of the freewheel or tight running of the screw thread drive.

There are times when the starter does not turn off after starting.

The reasons may be: drives jamming on the armature shaft, jamming in the ignition switch, bearing wear. Such breakdowns can be corrected by replacing damaged parts.

If you notice that the starter has started to make noise.

This could be: the drive gear is out of mesh, the fastening or the starter poles are loose.

The starter is subject to heavy loads, since it has to rotate a large flywheel and drive the engine piston group. Therefore, you should treat it carefully and carry out diagnostics to avoid breakdowns.

How to close the starter

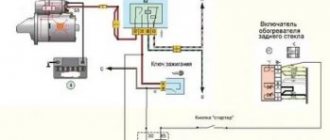

To close the starter, you need to connect the starter power contacts with a metal part of a suitable tool. This will allow voltage to be applied to the winding directly. To do this, you need an assistant who must turn the key in the lock to the “start” position.

In general, the process looks like this:

- the car is put on the “handbrake”, the manual transmission is switched to neutral or the P mode is switched on “automatic”;

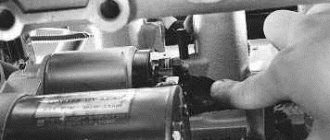

- The contact plate is removed from the starter, after which the contacts need to be short-circuited with the tip.

In this case, it is important that a current conductor of suitable length and cross-section be used as a jumper. Typically, a screwdriver with a thick shaft or a wrench with an insulated handle is used for these purposes.

To understand how to close the starter with a screwdriver, you need to pay attention to the following:

- you need to close the contacts of the power line precisely on the solenoid relay.

- All actions should be performed carefully and carefully, without touching other elements under the hood;

- Do not touch the starter housing with a screwdriver, etc.

- after starting the engine, the screwdriver must be removed;

In this case, closing two power contacts on the solenoid relay with a screwdriver is similar to closing them from the inside with the relay armature. In fact, the operation of a retractor starter motor for connecting the electric motor is simulated. If the ignition is turned on, the starter will start working with such a short circuit and the engine will start.

Please note that when the contacts are closed there will be sparks, since the starter connection is direct. Another disadvantage of the method is that not all cars have direct access to the starter (it is impossible to close the contacts on the solenoid relay). After the engine starts, the screwdriver will need to be removed from the contacts, after which the starter will turn off.

If we take a closer look at the question of how to connect the starter directly, pay attention to the following points:

You need to find the control (pin that looks like a petal). Other contacts (one with potential +12 has a thick wire). Another contact is an electric motor contact. You need to close the control terminal (usually closed with a rubber cap) and the contact tab (usually closed with a plastic plug).

Preliminary diagnosis of the problem

Before closing the starter, a very important step is testing in order to determine the sources of possible malfunctions and try to correct at least some of the problems. The most serious damage is considered to be complete or partial wear of the bendix, deformed or completely burned out due to high temperatures, starter winding, lack of functionality of its relay and solenoid relay. If you notice at least one such problem, then you can try methods for starting an engine whose starter has actually failed. There are few options, but they are effective.

For example, the first method requires the help of several strong men, since you will have to accelerate the car by pushing from the trunk. At this moment, the driver must turn on the ignition key and shift into first gear. In general, the more actively the assistants push the car from behind, the faster it will be able to start. This method is the most popular due to its simplicity.

Another method is towing. The essence of the action is that the “leading” car tows the car with a non-working starter over a certain distance, using a strong cable. However, when resorting to this method, you need to be extremely careful, since after successfully turning on the engine, the car will begin to accelerate and should be controlled. When the “leading” car slows down, you need to brake to avoid a collision.

I advise you not to turn off the engine when you stop the car in order to get out and unhook the cable.

There are other methods that involve direct intervention in the insides of the machine. This refers to a way to close the starter using a screwdriver.

Connecting the starter directly from the battery

It happens that problems arise with the wiring or contact group of the ignition switch. In this case, the engine can be started by supplying power from the battery to the starter. To do this, you need a copper wire, a connector and an alligator clip.

The wire is soldered to the connector. Next, the power wire to the starter is disconnected, and a copper wire with a connector is inserted instead. Then the “crocodile” must be connected to the “plus” of the battery. If the starter is working properly and there are no other problems, the engine will start. After starting, you need to remove the crocodile from the battery terminal.

The main thing is to perform all actions carefully, connecting the starter directly to the battery. Do not short the wire with any elements under the hood. After starting the engine and removing the copper wire from the connector, the starter plug can be returned to its place. It is also important to remember that you should not connect the wires to the battery and the connector for a long time, so as not to drain the battery.

Recommendations

- It is important to ensure that contacts other than the control terminal and spade contact are not short-circuited or accidentally connected.

- Taking into account the fact that access to the starter is usually from below, you need to be prepared for the need to remove standard or additional protection

- On many cars, the control terminal has the form of a threaded outlet (a nut is screwed onto a bolt), while the terminal is of the “petal” type.

We also recommend reading the article about what to do if the alarm blocks the engine from starting. From this article you will learn how to remove the engine blocking alarm if a failure or error occurs.If there is such a possibility, it is better to close the contacts not with a screwdriver, but with a wrench that has a handle (the handle should be well wrapped with insulation).

- After completing the process of starting the engine, you should check the fuses separately, as they can burn out if mistakes are made;

- Considering that the traction voltage uses 30-50A and higher, the connection points may stick.

- Owners of old cars, where the switch does not control the voltage supply to the coil, need to remember that when the starter closes, the coil may fail;

We close the starter “in French” (special cases)

Access to the starter is always open from under the bottom - you just need to remove the crankcase protection. An example is in the photo below.

Under the bottom of Renault Megane 2

It is difficult to reach the starter from the engine compartment. In the best case, it is closed by a filter (VAZ), in the worst case, by a battery. You can remove the filter, but what about the battery?

Starter installation location (circle)

Everything is done so that the starter can be changed, repaired, but not short-circuited.

What does terminal S look like?

On Renault cars, the terminal looks like a threaded outlet. The nut screwed onto it is “white”, although it itself is made of copper (see photo).

Starter Renault Logan, phase 1

We have already talked about the VAZ - they use a plug. If you remove it, you can see the “petal”.

What's the result?

As you can see, if the engine does not start, the starter may be the main cause of this problem. In this case, the culprit is often the starter solenoid relay or problems with contacts, wiring, etc.

We also recommend reading the article about why the starter clicks but does not turn the engine. From this article you will learn about the main reasons why the starter makes clicking noises but the crankshaft does not turn.

In any case, you need to know how to start the starter directly from the battery or by closing the contacts if the engine starting system has failed. However, it should be understood that connecting the starter directly is a last resort and is used only in emergency cases.

If there is such a possibility, it is better to refuse to try to start the engine from a pushrod in a car with any type of automatic transmission, and also not to try to directly connect or close the starter. In some cases, a short circuit of the starter or errors when trying to close the device lead to a short circuit, blown fuses, breakdowns of the vehicle’s electrical equipment, etc.

Finally, we note that knowing how to close the starter with a screwdriver to start the engine still does not solve the problem. First of all, this method may not be effective in many cases. For this reason, it is important to accurately determine the nature of the malfunction, and only then decide on which method to start the power unit.

Method two - towing

No less efficient and even more reliable, but you need another machine more powerful than your car. It will be enough to tow the vehicle for a short distance, and then start the engine in the same manner as described above. In this case, I would like to give a couple of practical tips:

- Do not turn off the car after it has started and then go straight to the service center;

- Do not forget that after starting the car, it will pick up speed if it is in second gear and you press the accelerator pedal;

- Don’t forget that after starting, the car towing you will stop. Therefore, you will need to have time to slow down.