Modern Lada car

Avid fans of the products of the domestic automobile industry and newcomers who are planning to purchase a car from the Lada series, among others, ask themselves the following question: is the body of the Lada Grant galvanized?

Scouring Internet resources, reading discussions on various forums and studying the documentation for this car, future mechanics cannot resolve their doubts. And all because some sources confirm, while others refute, information about galvanizing the body. Why is it so important to get reliable data?

The car body requires attention and expense from the car owner. The existence of a huge number of factors negatively affecting the body forces the car manufacturer to come up with ways to protect it. Such factors include adverse weather conditions (rain, snow), chemicals used to treat the road in winter, and much more. Of course, a layer of paint protects for the time being, until minor scratches and chips appear. But even a brand new car has unpainted areas of body parts that will begin to deteriorate first. This is why the question arises about treating all car surfaces with an anti-corrosion coating. But before you answer it, you need to understand what galvanization is.

What do official representatives of the domestic auto giant say?

At the factory, the metal body panels of the Lada Grant are treated with a zinc layer. The low cost of the model we are considering does not allow such coverage over the entire body area. The most vulnerable areas are subject to protection. This applies to:

- door panels;

- hind wings;

- niches for stern wheels;

- luggage compartment covers;

- protective body screen;

- bottoms;

- rear fender gutters.

This statement gives an understanding of the issue regarding the galvanization of body components of the Lada Grant. In this regard, discussions around the products of the domestic auto industry are heating up with serious force. While fans and owners continue to argue, AvtoVAZ is improving its car production strategy, the list of main priorities of which includes galvanizing body components.

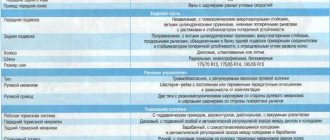

Factory conditions require the application of the following types of coatings:

- thermal galvanizing, which is the most reliable means of processing;

- galvanization, which involves obtaining a zinc layer on body panels formed by an appropriate solution under the influence of an electric current;

- a primer coating that involves the preliminary application of salts containing impurities of manganese, zinc and iron to the metal surface.

Coating Methods

Galvanization as a method of galvanizing a body

The first and most common option is called thermal or hot-dip galvanizing. The zinc alloy is applied to the car body even before it leaves the assembly line. This method is most often used on the luxury version of the Lada Granta and provides the greatest protection.

The second allows the use of galvanization for galvanizing surfaces. Most often used on the Lada Grant in the standard configuration. Sheets of metal are dipped into a bath connected to electrolytes and filled with a significant amount of zinc. When exposed to electric current, zinc adheres to the metal surface.

The third method is the most widespread and is used to cover any small parts of the Lada Granta.

Despite the massive application, this is the most complex method of galvanizing individual parts of a car. First, the surface is treated with salts containing large amounts of manganese, zinc and iron. Once the layer is completely set, an additional primer coating is performed.

As it dries, the surface is additionally painted with paint containing a high content of fine zinc. Therefore, this method cannot be considered full-fledged galvanizing, however, this car painting with the addition of anti-corrosion substances can protect the surface of your car for a long time.

Many future owners of the practical Russian model Lada Granta are haunted by one logical and pressing question: is the body of this car galvanized? This concern is easily understandable, because the body is the most expensive part of a Lada Granta car.

The presence of galvanization has a beneficial effect on resistance to corrosion and increases service life. In this article we will talk about whether the body is galvanized.

Various sources provide very conflicting information regarding this aspect. Official representatives of AvtoVAZ assure that the body elements of the Lada Grant are indeed galvanized, however, some dealer entities refute this statement.

Regardless of whether the body is galvanized or not, we will next consider methods and techniques for caring for the most expensive part of this car.

Now let's debunk some myths

1. Does the galvanized body confidently resist the onslaught of corrosion?

Even in a situation where the dealer gives a positive answer to your question about the presence of galvanized body on the Lada Grant, it is still too early to relax. The “Russian” coating has a small thickness, which entails a rapid loss of the protective zinc layer. Without the use of measures aimed at additional treatment of body components, the panels will still slowly corrode.

2. Does the new body need additional processing?

Practice has confirmed the imperfection of the factory protective layer. Despite the newness of the car, it requires immediate treatment in order to improve its anti-corrosion properties. The operation of a LADA Granta car implies exposure to various types of mechanical stress, which provoke the formation of cracks in the structure of the coating. The process is accompanied by the penetration of moisture, which leads to the appearance of corrosion centers.

3. Is the aluminum body free from rust?

In a real situation, there are no bodies made only of aluminum, whether the body is galvanized or not. In any structure there is the presence of steel components, which suffer the fate of being damaged by corrosion. Aluminum during operation of LADA Granta is subject to oxidation, which causes a weakening of its strength structure.

4. Is standard anti-corrosion protection capable of maintaining its condition for many years?

The rate of corrosion progress is directly influenced by the operating conditions and climatic factors, regardless of whether the body is galvanized or not. In just 6-7 years, a layer of metal with a thickness of 0.6 mm can corrode to through holes. This circumstance requires protective treatment of the body.

Prices and configurations of the Lada Granta in various body types

Granta liftback red

Let’s say right away that the price for the 5-door version of the Granta liftback, depending on the configuration, will be in the range of 314-477 thousand rubles. Granta sedan starts at 294 thousand rubles.

The most budget version of the hatchback is “Standard”. Everything here is done, so to speak, cheaply and cheerfully. The buyer will have to pay 314 thousand rubles for this model, which will be 20 thousand rubles more expensive than the sedan version. But the owner holds all the cards: there is a stylish design, a good engine, 14-inch wheels, and much of what was written about in detail above.

If we compare models among new cars at this cost, then this is ZAZ Chance, which costs about 295 thousand rubles in the basic version and 308 thousand rubles in a more advanced configuration with power steering and heated front seats.

Our liftback can also compete with the “Chinese” Lifan Smiley, valued at 309 thousand rubles.

Now about the “Norma” version. Dealers are asking about 345 thousand rubles for it, but everything on it is practically the same as on the “Standard”, except for the presence of an unnecessary rear wiper, ESD, ABS, headrests and better audio preparation.

In addition, a “normal” Grant liftback can be distinguished from a “standard” one by door moldings and B-pillar trims. The expensive version has moldings painted in body color, and linings are black.

Let's quickly take a look at the competitors. The players here are the same as those of Standard, with only one addition in the form of a 2013 Chery Very for 355 thousand rubles.

Luxury Granta

The “Lux” package is the most expensive version of the Grant liftback. For this AvtoVAZ asks no less than 420 thousand rubles. But there are much more additional systems here: climate control, cool multimedia, a more sophisticated security system, 15-inch wheels and much more.

Note. A “luxury” Granta with an automatic transmission will cost 57 thousand rubles more than a similar version with a manual transmission. Wow, you say, but it’s worth it, because it adds parking sensors, useful sensors and a stability control system.

What can you buy for the same money? Renault Sandero costs about 374 thousand rubles in the basic version, and for its “luxury” version you will have to pay at least 474 thousand.

A good option for the Russian-assembled Skoda Fabia. True, orders for this car are no longer accepted, but dealers are still selling the remaining models in stock. You can buy a car for 439 thousand rubles.

As for the “Koreans,” they also have a model for that price. This is a Hyundai Solaris hatchback for 453 thousand rubles.

And finally, for 489 thousand rubles you can buy the popular Renault Duster.

Finally, let’s say that Granta looks much better than its competitors in terms of purchase. Evidence of this is its body, which has been polished to perfection and is distinguished by good performance. Photos and video materials will allow you to learn more about the body types of the Lada Granta. If you are interested in repairing the body yourself, then read the detailed instructions posted on our website.

Vesta is rightly perceived as a breath of fresh air from AvtoVAZ. They released a car with a modern design and interior, high-quality assembly and decent equipment. These are obvious improvements, but not everyone remembers whether the body of the Lada Vesta is galvanized or not. And it should, because it depends on how soon rust begins to appear on the car.

Paintwork is not enough to protect the body. The slightest damage and moisture does its job, causing oxidation of the steel. The corrosion center, unnoticeable at first, grows, and the car has to be repaired.

One of the most effective ways to prevent rust formation is galvanizing the body. Auto industry leaders have been practicing this procedure for many years. Thanks to this, they can provide a warranty on the body for up to 20 years.

The body can be galvanized in the following ways:

- heat treatment;

- galvanic treatment;

- cold processing.

During thermal galvanizing, the car body is completely immersed in a special zinc-containing solution and heated to a certain temperature. This method is the most effective and is used on expensive cars.

The galvanic method involves the application of zinc particles during the electrolysis process. The body or part is placed in an acidic zinc solution and exposed to electric current. This method is not as reliable, but is cheaper.

Interesting!

The duration of the warranty directly depends on the galvanizing method and the thickness of the resulting layer.

With the cold method, the body is simply treated with a zinc-containing primer. In this case, manufacturers do not provide a long-term guarantee, because the protective layer may be damaged along with the paint.

Features of anti-corrosion treatment

Regardless of whether the body is galvanized or not, certain rules must be followed. The optimal time for implementing anti-corrosion measures in LADA Granta is a dry and warm period. It is recommended to carry out the work annually or once every two years (as appropriate).

If the procedure involves treating external and unprotected body surfaces, then bitumen-based mastic is perfect. The process is not complicated, so it can be easily done at home. There are mastics both drying and lacking this quality. The latter options are characterized by sufficient elasticity, but are not resistant to mechanical factors. Application of mastic involves achieving a layer thickness of 0.4 mm, which allows for maximum noise insulation effect.

To effectively treat hard-to-reach and hidden cavities on the body, it is recommended to use substances based on an oil structure. This allows you to effectively fill pores and cracks. Elastic mastics are also excellent, one of the advantages of which is the ability to effectively displace moisture. These processing agents have a paraffin or wax structure.

What is body galvanization and why is it needed?

As a rule, after 4 years of operation of the vehicle, corrosion appears on the body, which causes the iron to rot. The most commonly affected elements are sills, fenders and underbody. In order to prevent corrosion, increase resistance to mechanical stress and adverse environmental factors, vehicles are galvanized. This is a procedure during which the body is subjected to special treatment. When damage occurs, corrosion only destroys the zinc.

Let's sum it up

Now you know whether the body is galvanized. Only careful care of the LADA Granta car will keep the body presentable for a long time and ensure its trouble-free operation. And the question about the level of efficiency of galvanizing the Granta body will move to the background here.

Anti-corrosion treatment of the Lada Granta is mandatory, like any domestically produced car, despite the excellent performance characteristics of the vehicle: reliability, practicality, and efficiency.

About 30% of the car's parts are made of special alloys, but there are weak points in the Lada. These are the bottom, doors, hollow elements, welding joints. To avoid damage, you need to apply a special coating to such places.

Body

For the liftback, as for the sedan, the Lada Kalina platform is taken as the basis. Externally, the car looks impressive and even a little better than its counterpart in a different body. The new rear end blends very well with the face of the car. The entire body is made in a style that is vaguely reminiscent of some Renault models (for example, Sandero or Logan), but at the same time has Korean features. Despite this, the car looks more than decent, especially for its class. Basically, this was achieved thanks to the unusual shape of the car body, which everyone is accustomed to seeing in the form of a sedan. The upper edge of the rear roof has been lowered by 8 mm.

Main causes of corrosion

Lada Granta is a new AvtoVAZ car based on the Lada Kalina platform. The design of the car has been carefully worked out, the number of parts in different components of the car has been reduced, and the air intakes in the front bumper have been enlarged. The good quality, convenience and reliability of the car allow it to be used even in difficult weather conditions.

The condition of highways and the various preparations with which road services treat them cause corrosion of the car body in a short period of time, and the appearance of the car is also lost. Main causes of corrosion:

- improper care;

- poor quality factory coating;

- complex car design;

- operation in difficult conditions.

To increase the service life of cars, it is necessary to protect the body from adverse weather conditions, and it is not necessary to wait for obvious signs of corrosion to appear, but to do the coating earlier.

Features of the Lada Granta body

The new Granta body, of course, is superior in quality and characteristics to other models and cannot but please the owners. More modern technologies, galvanization and high-quality coating are big words that please the ear of a lover of products from the domestic automobile industry. But it should be taken into account that not the entire body undergoes anti-corrosion treatment, but only the areas most susceptible to destruction. Moreover, the manufacturer warns that the warranty for body protection against rust is 6 years, and then the car may need additional treatment. But a lot also depends on the operating conditions of the Lada Granta car. Compliance with all rules for the use of transport and appropriate care can increase the service life of factory galvanized steel up to 10 years.

Lada body structure

What parts of the Lada body are galvanized? First of all, these are niches for the rear and front wheels, as well as the bottom (on both sides), sills, luggage compartment lid, doors, pillars and hood.

Often in car dealerships you can find examples of Lada Granta cars, which are completely similar to other series and equipment, but much cheaper. The tricky move of many dealers is to convince the buyer that this car is simply participating in the promotion and is no different from its relatives. In fact, some batches arrive from the factory without galvanizing the body - this is an economical option.

Now you can easily answer the question: is the body of the Lada Granta car galvanized?

The VAZ automobile plant produces Lada Granta cars, the body of which may or may not be galvanized. The galvanizing method chosen is not the most reliable; the effect will last only 6 years. In addition, it must be taken into account that only individual parts of the body are galvanized.

Types of anti-corrosion treatment

There is a huge range of materials on sale to protect the car body, which differ in application methods and characteristics. Modern, high-quality preparations provide reliable coverage that does not cause harm to health.

Anticorrosive treatment affects areas of the body that are not visible, so the appearance of the Lada Grant will not deteriorate.

For external treatment, aerosols are used.

All anti-corrosion agents can be divided into 2 groups: products for external and hidden surfaces. PVC materials, liquid plastic, bitumen mastic, materials with rubber are products for the external parts of the car.

For internal cavities, special preparations containing oils are used, which retain a liquid state for a long time. Products with paraffin are used, which form a waxy film. This anticorrosive agent retains its elasticity during temperature changes.

Lada Granta can be protected with D-11A plastisol, a special composition NGM-ML, and BPM-1 bitumen mastic. These materials tend to reduce noise in the cabin, which is an additional good quality. Other products can be used, but they must be certified and made by a reliable manufacturer. It is better to buy materials in specialized stores.

Everything that is known about galvanizing the body of Lada cars: Vesta, Granta, X Ray and Largus

Ladas have not yet caught up with foreign cars in protecting the body from corrosion, but they are moving in this direction.

Galvanized body means covering it with scrap zinc, which provides additional protection against corrosion. Thus, the better the body is galvanized, the longer rust will not appear on it. But is it necessary to carry out additional body anti-corrosion treatment on a Lada car, or do modern models do not need this?

For those who don’t want to read a lot: The frets are galvanized using the cheapest technology, which is why they rust a little better than foreign cars.

Galvanizing methods used by automakers differ. The higher the quality of galvanization of the body, the higher the cost of the car will be, and you can significantly save on using less reliable protection.

The most reliable method is hot-dip galvanizing - the metal is coated with a layer of zinc when the body is immersed in a special bath filled with molten zinc. This method is used by large manufacturers.

AvtoVAZ uses cataphoresis-type priming, when the “rough” body is dipped into a bath containing a special primer. In this case, the surface of the body is covered with a phosphate film, which acts as protection against corrosion. It is the quality of this layer that affects the durability of the body.

In addition, at AvtoVAZ, body parts are protected by cold galvanizing: a composition with zinc powder is applied to the surface. The process is somewhat reminiscent of painting.

Work technology, materials used

Anti-corrosion treatment of Lada Granta is carried out in several stages.

- washing;

- drying;

- visual inspection;

- removing rust;

- processing of internal cavities;

- coating of external surfaces of the body;

- assembly.

External processing is carried out on an overpass or from an inspection hole

To carry out the work you need to prepare:

- anticorrosive black "Tektil" - 5 kg;

- aerosol cans of Tektil ML - 4 pcs.;

- brushes of different widths and hardness;

- latex gloves;

- plastic tube;

- metalworking tools;

- solvent.

To work, you will need an inspection pit or overpass with a lift.

Types and types of body galvanizing

Before studying the list of galvanized cars, it is worth familiarizing yourself with the varieties, of which there are only three:

The best method is hot galvanizing. It gives the body high corrosion resistance, making the iron less susceptible to mechanical damage and even has the property of partial regeneration.

Galvanic treatment is a little worse, but is also often used by manufacturing plants. Ideally combined with paint and primer. Zinc metal is significantly worse than the first two options. It has weak anti-corrosion properties, since the metal has only an elastic zinc-based coating.

Galvanization also happens:

- Complete – even hard-to-reach parts are galvanized.

- Partial - nodal connections and vulnerable elements are processed, in particular, the bottom, thresholds, and bottom of doors.

- Only nodal connections - only welding joints, fasteners and other small parts are galvanized.

Do-it-yourself body protection

Despite the fact that such new materials as two-component polyester-based primers and two-layer metallized enamels were used to paint the Lada Granta car, the car needs protection from corrosion, because its operation, especially in winter conditions, is associated with a number of negative impacts.

The sooner the car owner does the body treatment, the more he will extend the service life and maintain the beautiful appearance of the car.

Salons offer protection when purchasing a new car. Anti-corrosion treatment by specialists costs about 6 thousand rubles, and 5 thousand is the price of the work.

It is more economical to do the processing yourself

You can do high-quality processing yourself and save money. It is not necessary to have a compressor or other specialized equipment.

Anti-corrosion treatment will significantly slow down adverse processes that can reduce the service life of the machine. The work must be carried out in sunny weather, but it can also be done in late autumn. Be sure to read the instructions for the anti-corrosion drug to know all the conditions for its use.

The anti-corrosion treatment technology is simple. Before starting work, you need to remove the wheel arch liners and wash the car at least 3 times with warm water. First, the dirt is washed off, and then the car is washed with shampoo. The surface of the bottom is washed with hot water and dried with a stream of hot air. If you have time, you can dry the car naturally for 2-3 days.

Defects are identified that can be seen from a pit or on an overpass. If rust is found during inspection, it is cleaned off first with a spatula and then with sandpaper. All parts and assemblies that will not be processed must be closed or sealed with tape. Brake discs can be covered with plastic covers.

Cavities and hollow profiles are processed using a special device that applies a product under high pressure that forms a film when settled.

Internal surfaces should be treated with an aerosol

An easy way to protect interior surfaces is to use aerosol cans. The nozzle is inserted into the hole and the product is sprayed, trying to rotate the can. In this way you can process door pillars, hood, trunk lid, side members.

The wheel arches and the bottom need to be treated with a spatula or brush. The thickness of the coating should not be large, because a thick layer does not adhere well. Anticorrosive agent is applied to a cleaned and degreased surface. Next, drying is carried out, which takes at least a day.

You can treat car thresholds using a tube. One end is attached to the sprayer, and the other is attached to the aerosol can. The tube is then secured with electrical tape and wire for strength. The holes at the bottom of the threshold are closed with plugs so that the anticorrosive agent cannot leak out.

The tube is pushed into the opening of the threshold and the spray can is pressed. The second threshold of the Lada Granta is treated similarly.

The fenders, wheel arches, and underbody can be treated with black Tectyl using a brush. It is better to apply 2 layers of coating. Drying time: 7-12 hours.

At the end of the work, you need to wipe and rinse the mirrors, car windows and put back all the elements that were disassembled.

It is advisable not to drive on bad roads for several days so that the anti-corrosion layer has time to finally strengthen. The coating will protect the car for 2-3 years, and then you will need to carry out the work again, especially if you drive in winter.

Anti-corrosion coating is a modern, effective way to extend the life of a Lada Granta car.

Potential buyers and car owners are concerned with the question: does the Grant model have a galvanized body or not? The concern is easy to understand: the cost of the body is a significant part of the price of the budget car Lada Granta, galvanization protects the structure from the influence of adverse external factors.

Different sources provide conflicting information. Official representatives of the AvtoVAZ concern claim: the Lada Grant has a galvanized body, some sales dealers refute the statement.

Dealers' opinion

The only remark is that some AvtoVAZ dealers in the capital honestly state that their product does not have a galvanized body at all. This is due to the low price of the car. Therefore, you need to be especially careful when choosing a car and check the manufacturer’s promises in practice.

If there is no galvanization as such, then it will be necessary to use additional semi-liquid protective agents that are applied to the metal surfaces of the car. They significantly increase the corrosion resistance of even those vehicles that have not been subjected to additional anti-corrosion treatment.

Lada Granta body and its features»>

The body of the Lada Granta, produced according to modern standards, looks much more fashionable than previous VAZ models. It has both galvanized and good quality coating. According to experts, in terms of the number of galvanized parts, the modern Granta body surpasses even its predecessor on the AvtoVAZ assembly line - the Lada Kalina. We will find out from the article whether the body of the Lada Grant is galvanized and to what extent, as well as its other features.

Today, at the Togliatti plant, the processing of the body and its metal parts involves a standard layer of galvanization. True, not the entire area of the car is subjected to this process, but only the most vulnerable areas of the body, such as the bottom, etc. First of all, these areas are located close to the road surface, thereby being damaged quite often: chips, scratches and damage to the integrity of the surface paintwork Such places of the body are a common phenomenon.

Note. What does the galvanizing layer do in this case? It effectively protects the body frame from rusting, preventing the process from further progressing rapidly in areas of chips and scratches.

Lada Granta galvanized body

On the one hand, a layer of galvanization, of course, cannot completely protect the metal from corrosion. On the other hand, if it were not there, the elements would begin to rust in short periods of time, after some minor accident or the car falling off the jack.

Galvanizing the Lada Granta body

There is a lot of controversy regarding galvanizing. In particular, the question concerns the following: is the body of the Lada Granta sufficiently galvanized, if we keep in mind the percentage ratio. Here is what I would like to say about this:

- Lada Granta is considered a budget car, which automatically excludes full processing;

- It is precisely because the Granta is a budget car that it has fewer body elements designed to work in harsh conditions.

On the other hand, all “vitally” important body elements of the car are, of course, coated at the factory with a layer of galvanization. This happens in the press shop, where zinc is applied to the steel sheet on both sides.

Is it worth carrying out additional anti-corrosion treatment on the Lada Granta? Car owners often ask on forums. The manufacturer does not advise doing this, hinting that he has foreseen everything himself. On the other hand, no matter what guarantee against corrosion AvtoVAZ gives for the first 6 years of car operation, we were not born yesterday, and we understand that the manufacturer’s guarantee is one thing, but the real situation is completely different.

Here are the areas of the domestic car that are most at risk:

- Rear wheel wells and fenders;

- Trunk sides;

- Bottom;

- Door pillars and trim;

- Protective components, etc.

Some car owners claim that some Grants do not have galvanization at all, which explains the low cost of the car. Is it really? AvtoVAZ categorically denies this information, claiming the opposite. Yes, galvanizing does not occur in full, but the strategy of protecting the most important areas of the body is carried out without fail.

In general, quite a lot of myths about domestic car models have been appearing lately. Some people, supposedly cool specialists, come to various topics and start spouting all sorts of nonsense that AvtoVAZ products will soon crumble before our eyes. It is noteworthy that most of the “false experts” are personally unfamiliar with modern versions, but judge products based on old models from the 90s.

The modern corrosion resistance of VAZ models, even the most budget ones, has improved significantly. Modern paint booths, “smart” robots, universal stamping shops with the appropriate equipment - all this is available and working at AvtoVAZ today. And the result does not take long to wait: body gaps have decreased, parts have been fitted perfectly. In addition, all surfaces of the body undergo appropriate treatment, since the entire body is immersed in a bath of primer. If earlier it was difficult to imagine, today no one doubts the power of a robot that can easily lift a heavy body as a whole and dip it properly into the composition.

What is the Lada Granta body made of?

It is also worth noting that today any car produced by AvtoVAZ undergoes rigorous testing. For example, it is kept in a saline solution for more than 2 days, then scratched to the metal. So what: corrosion only shows up slightly, but the Niva’s body, painted using old technologies and not galvanized, also subject to a similar test, is literally eaten away by rust.

The issue was successfully resolved today and with. The same Lada Granta, despite its budget, is equipped with a reinforcing “bulkhead” in the rear. This applies to the sedan, but the liftback, which will be described in detail below, has been worked out even more carefully in terms of body rigidity. The fact is that 5-door modifications do not provide rear reinforcement, which is why maximum rigidity is given in this case. Compared to the “chisel”, the body rigidity of the Lada Granta (hatchback) is increased by 2 times!

Lada Granta body number

By the way, for those who are interested, the body number of the Lada Grant can be found in the engine compartment right on the edge near the shock absorber strut on the front passenger side.

Information from official representatives of AvtoVAZ

At the concern's factories, metal body elements are treated with a layer of galvanization. The low cost of the car does not allow covering the entire metal area; they protect the most vulnerable areas susceptible to corrosion:

• doors; • hind wings; • rear wheel niches; • luggage compartment lids; • body protective screen; • floor; • protective casing; • frame details; • rear wing groove.

The main vital structural elements are treated with a coating, which eliminates the question of whether the body of the Lada Grant is galvanized or not.

Which body parts are galvanized?

Double sided hot rolled zinc!

This applies, first of all, to the underbody of the car, its sills, doors, pillars, hood and parts of the body. It is these places that receive the greatest impact from the road surface, resulting in chips, scratches and other types of surface damage. This is where the galvanized layer comes to the rescue, acting as a protective primer, which prevents corrosion processes from spreading through the metal too quickly.

Parts of Lada Granta that received galvanization

Future side opening of the Lada Granta (photo from the factory)

If you believe the official data, then the Lada Grant has galvanization on the following parts.

- First of all, we're talking about the rear wheel wells and rear fenders. It is there that a fairly large amount of moisture collects, which can turn into rust in just a few months if the steel does not have additional protection.

- Next comes both sides of the trunk lid and the floor with a body guard. Here, as you might guess, rain and puddles on the road have a noticeable effect on the condition of the metal parts.

- A similar statement applies to the rear fender groove, extension and doors. And, of course, we must not forget about the protective casing and all the parts from which the body frame is made.

According to information that became known to our portal from employees

Metal that ended up in the press shop (photo from the factory)

Features of Lada Granta body galvanization

In fairness, it must be said that galvanizing is not able to provide complete protection to metal parts from rust. For example, the consequences of an accident or a car sliding off a jack will be such that the galvanizing layer will be torn off, and those body elements that it covers will begin to rust at an additional speed.

It is necessary to monitor the body and remove such saffron caps in a timely manner; they threaten to develop into a major corrosive problem. There's nothing you can do, it's a budget car

Pay attention to hard-to-reach places where rust can form: under the front and rear bumpers.

The Lada Granta is classified by the manufacturer as a budget series of cars, so the number of galvanized elements is reduced to the required minimum. But, regardless of this, the most important parts are covered with the layer in question.

Galvanized steel body elements receive their protection in the press shop. There, hot-rolled zinc is applied to the sheet on both sides. This concerns, first of all, the front and rear wings, the side opening, as well as the door reinforcement on the inside and some other parts.

Factory galvanizing methods

Discussions about domestically produced cars do not subside. They argue about the Lada Granta, whether the body is galvanized, how the price corresponds to the quality, meanwhile the giant AvtoVAZ continues its strategy of improving the cars it produces and improving galvanization as well.

The factories use the following coating methods:

• thermal galvanizing – the most reliable;

• galvanization, when zinc is deposited from a solution on the surface of parts under the influence of electric current;

• coating with a primer with preliminary application of manganese, zinc and iron salts to the metal surface.

Four types of technologies

A little about why zinc (Zn) protects steel - it is a non-ferrous metal, has a more negative potential and corrodes first (that is, when it collapses, it protects the coating underneath), and the protection works even when it is damaged or partially destroyed.

It becomes clear that the larger and thicker the zinc layer, the longer the car body is preserved and no corrosion occurs.

To apply particles of protective metal to the body, there are only four main technologies, I will list them from best to worst.

- Hot method.

When the fully assembled body is dipped into a bath filled with zinc. Moreover, the temperature stays around 460 – 500 degrees Celsius. The method is very expensive and costly. Used by expensive brands on luxury cars - PORSHE, VOLVO, now on some premium HYUNDAI, etc.

- Galvanic method.

The method consists in the process of deposition on the cathode (in our case, part of the body), positively charged particles (ions) of zinc from aqueous solutions (electrolytes). This technology works by passing a direct electric current through it. This is a less expensive and simpler technology, used by Mercedes, BMW, TOYOTA, Honda, Mitsubishi, KIA, etc. - Zinc metal.

It is used mainly by KIA, on cars from the “C” class. This is a kind of plastic coating that consists of two layers. - Cold method.

In essence, this is a kind of painting. A powder is applied to the body parts, which contains small particles of zinc powder. Used by many brands (Chevrolet, KIA, HYUNDAI, TOYOTA) including AVTOVAZ.

As you understand, VESTA is processed using the third technology; you choose where and in what volume to apply this layer.

This is where the disadvantages appear, namely the uniformity and thickness of the coating. It is also worth remembering that this layer is not 100% corrosion protection; it needs to be further strengthened.

Debunking myths

1. Does a galvanized body not rust?

Even if, when buying a car, when asked whether Granta is galvanized or not, the dealer gives you a positive answer, it’s too early to calm down. Due to the very thin coating layer and its partial nature, rapid reduction of the galvanizing layer is guaranteed.

Without additional treatment, the body will still rust.

2. Does a new car require additional body work?

Factory protection is imperfect. Even a new car requires preventive anti-corrosion treatment. During operation, the body coating is subjected to strong mechanical stress, causing cracking of the coating, moisture entering the cavities and corrosion of body elements.

3. Does the aluminum body not rust?

In fact, the entire body cannot be made of stainless aluminum; steel is also used, it is susceptible to corrosion. Aluminum oxidizes over time and turns into powder.

4. Will the factory rust protection last for many years?

The rate of metal corrosion largely depends on operating conditions and climatic conditions. A metal layer 0.6 mm thick can rust through in six years! The body needs to be treated.

5. Mud flaps and fender liners, plastic covers are useless?

Not true. The equipment reduces the abrasive effect of dirt and sand on the body.

Installation of elements is carried out using self-tapping screws, external joints are treated with anti-corrosion coatings. Mud flaps are attached with maximum adherence to the wings and body.

Regardless of whether the Granta body is galvanized or not, preventive treatment of the body must be performed.

Galvanization of VAZ Granta body

Considering the age and quality of zinc treatment of this car (under normal operating conditions), body corrosion has only just begun.

It is difficult to notice if the car has not been subjected to shocks or scratches.

Considering the age and quality of zinc treatment of this car (under normal operating conditions), body corrosion has only just begun.

It is difficult to notice if the car has not been subjected to shocks or scratches.

Considering the age and quality of zinc treatment of this car (under normal operating conditions), body corrosion has only just begun.

It is difficult to notice if the car has not been subjected to shocks or scratches.

Considering the age and quality of zinc treatment of this car (under normal operating conditions), body corrosion has only just begun.

It is difficult to notice if the car has not been subjected to shocks or scratches.

When a galvanized body is damaged, corrosion destroys the zinc and not the steel.

.

Over the years, the processing process itself has changed. A younger car will always be better galvanized!

The presence of zinc particles in the soil covering the body does not affect its protection and is used in advertising materials. Full information.

Test results of cars that came off the assembly line with the same damage (a cross) on the lower part of the front right door. Tests were carried out in the laboratory. Conditions in a chamber with hot salt fog for 40 days correspond to 5 years of normal operation.

Hot dip galvanized vehicle

(layer thickness 12-15 microns)

Galvanized car

(layer thickness 5-10 microns)

Cold galvanized vehicle

(layer thickness 10 µm)

Car with zinc metal

Car without galvanization

— Over the years, manufacturers have improved the galvanizing technology of their cars. A younger car will always be better galvanized!

— Coating thickness from 2 to 10 microns

(micrometers) provides excellent protection against the occurrence and spread of corrosion damage.

— The rate of destruction of the active zinc layer at the site of damage to the body is from 1 to 6 microns per year

. Zinc degrades more actively at elevated temperatures.

Car anti-corrosion treatment

The most favorable period for carrying out work is in dry, warm weather. Frequency: once every one or two years.

At home, bitumen-based anti-noise mastics are used for anti-corrosion treatment of external unprotected parts of metal. They can be drying or non-drying; the latter retain high elasticity, but do not have high mechanical strength. The mastics are applied in a thick layer up to 0.4 mm. Thanks to this, a good sound insulation effect is obtained.

To treat hidden body cavities, either oil-based preparations are used, which can fill them during the formation of microcracks, or elastic, paraffin- or wax-based preparations that are good at displacing moisture.

Careful car care will help increase its service life in any case, regardless of whether your Lada Granta has a galvanized body or not.

Is Lada Vesta's paintwork reliable?

The quality of the paintwork is also at the highest level. Amateurs and automobile experts checked whether the Lada Vesta's paintwork was reliable. No imperfections, scuffs or various coating defects, which often happened on previous models, were noticed.

Although the small thickness of the Lada Vesta LPC may raise doubts. But this trend is characteristic of many modern cars - environmental standards impose restrictions on the depth of the paint and varnish layer. High-quality soil protects the iron well, and corrosion is unlikely to spread due to ordinary chips.

The bottom, sills and arches have been additionally treated with a layer of anti-gravel. In total, the thickness of the body metal is about 0.7 mm.

On a note!

If a Lada Vesta with a galvanized body rusts during the warranty period, do not hesitate to contact the dealer. You have the right to demand reimbursement of the cost of repair or elimination of this problem.

Let's sum it up

Now we know which cars have a galvanized body. The lists are gradually increasing as manufacturers are able to use proven and inexpensive methods, for example, adding zinc to primer or paint. Therefore, you need to take into account some nuances highlighted by auto experts:

- Reliable protection of the vehicle body by galvanizing is possible only with expensive models, since investing in budget options is considered unwise - they simply will not pay for themselves.

- In the modern world, the level of body preparation is much worse than it was 10-20 years ago. While cars produced in the 1990s were built to last for decades, today this period has been reduced to 7 years, after which the car can be scrapped. Therefore, you should not believe dealers who claim that the service life of any new model is at least 10 years, because its body is galvanized - this is a marketing ploy, nothing more.

- In the technical specifications, any manufacturer may indicate that the machine is galvanized, although in fact it is not. At least this applies to the already mentioned budget models, when only some body elements were subjected to this procedure.