P0342 VAZ - error 0342 viburnum

Decoding OBD-2 error p0342

Code p0342 stands for - lack of signal from the position sensor installed on the camshaft. This camshaft uses cams to open and close the intake and exhaust valves at the right time. Some engines have two of them for the intake and exhaust valves, respectively. They rotate due to the drive from the crankshaft pulley of the internal combustion engine.

The ECU needs the camshaft position to know exactly the right moment to open the injectors while the intake valve is open. This sensor is installed next to the camshaft. The principle of its operation is based on the Hall effect; a magnet fixed to the shaft creates a current in the sensor winding when rotating; the ECU perceives this current as a signal. In principle, this is a fairly reliable sensor and rarely fails.

A car with such a malfunction may behave differently depending on the cause of the p0342 error. The reasons can be either completely trivial or very serious. So the decision whether to travel by car, if at all possible, is yours to make.

Effect on engine operation of error p0342

The position of the camshaft is very important to know the ECU of an injection engine for proper operation. Error p0342 indicates that the ECU does not know this. Accordingly, the following engine operating symptoms may appear:

- Difficulty starting, or inability to start the engine at all.

- Power drop.

- Increased fuel consumption.

- Rough operation at idle.

- Dips when pressing hard on the gas.

Reasons for error code p0342

This error must be eliminated as soon as possible by understanding the reasons for its occurrence. Error code p0342 may appear in the logs for the following reasons:

- Sensor wiring faulty, open or shorted.

- Position sensor malfunction.

- ECU problem.

- Other errors found in the logs.

How to Troubleshoot or Reset Trouble Code P0342

Some suggested steps to troubleshoot and fix error code P0342:

- Inspect the wiring, looking for corrosion, poor connections or frayed insulation.

- Check the connector on the camshaft sensor. Look for corrosion and defects in the connector. Apply dielectric grease to the connection.

- Replace the camshaft position sensor.

- Test the battery condition. Low battery power may cause a code to set.

- Check the starter for excessive pull, indicating weak recoil.

Often replacing the sensor will correct the P0342 code, but not necessarily. Therefore, it is important to check all points.

Diagnosis and problem solving

First of all, you need to read all stored error codes using an OBD-II scanner. If there are no other faults, proceed to solving the problem.

It is necessary to check the wires, connectors and other electrical components of the system. If any defects are found, eliminate them. After this, you need to clear the error codes from the PCM memory again and recheck the system.

If the error code appears again, check the battery charge and also inspect the starter motor. Troubleshoot, then clear the PCM memory again and check the system to see if P0342 appears again.

This procedure must be performed every time after repair work is performed. This will help determine if the problem is resolved.

Check the camshaft sensor itself if you need to replace it. In most cases, these steps will help fix your vehicle's problem.

Lada 2114 “Nun › Logbook › Errors P0341 and P0343

These are the errors that settled in my ECU. The decoding shows that the problem lies in the phase sensor (also called the camshaft position sensor). This sensor is not installed in a carburetor engine, and in the first models of VAZ injectors it was not installed either, but in all 16-valve AvtoVAZ engines and on 8-valve engines with Euro-3 toxicity standard and with phased, sequentially distributed fuel injection , it exists. Why do we need a phase sensor? The phase sensor is designed to determine the engine operating cycle and generate a pulse signal. Phase sensor with an integral sensor, i.e. includes a sensitive element and a secondary signal-to-pulse converter. The sensor's sensitive element operates according to the Hall principle, responding to changes in the magnetic field. The secondary element of the sensor contains a bridge circuit, an operational amplifier, and an output stage. The output stage is designed as an open collector. The operation of the phase sensor represents the choice of stroke for the first cylinder: the camshaft determines which valve is open and which valve timing. Carburetor engines do not have this sensor. The fact is that a carburetor engine supplies a spark plug at the moment of compression and at the end of the exhaust gases, and for this principle of operation the readings of the crankshaft position sensor are sufficient. This type of engine operation is called the “ignition system”. On injection engines, when the phase sensor dies, the check light comes on and the engine switches from phased injection to the ignition system, that is, relying only on the DPKV readings. What is the advantage of phased injection? The phased injection system is designed as follows: the phase sensor transmits an impulse to the ECM, which controls the fuel supply and the injector injects gasoline into the cylinder just before the intake valve opens. When the valve opens, air is drawn into the intake valve and the fuel is actively mixed with the air. Where is the phase sensor located? The phase sensor is located on the engine on the air filter side, next to the cylinder head

Signs of a faulty phase sensor If you have the following symptoms, then the phase sensor is most likely faulty. — When starting the engine, the starter spins for 3-4 seconds, then the engine starts and the check light comes on. In this case, during startup, the computer waits for readings from the phase sensor, does not wait and switches to engine operating mode relying on the ignition system (according to DPKV). — Increased gasoline consumption. — Self-diagnosis mode failures. — Reduced engine dynamics. By the way, the check may not light up; if there is a temporary malfunction of the sensor, the error is recorded in the ECU memory, but the check does not light up.

Replacing the phase sensor begins by disconnecting the power from the battery. In this case, the control unit memory will be reset. If this is not done, it will continue to operate in the same mode as with a faulty phase sensor. Normal operation will begin after a few engine starts. The tool that will be needed is just a ten key. Next, disconnect the wires from the phase sensor, unscrew the mounting bolt with a wrench and remove the sensor. Reassemble in the reverse order: insert the sensor, tighten the bolt, connect the wire to the sensor, connect the battery. We start the engine and enjoy the work.

What are the errors that determine the malfunction of this mechanism?

Error code - 0340

A fairly common phenomenon occurs when the “meat grinder” on the dashboard (check engine) lights up. This process appears like this: when starting the engine, the starter works for several seconds, and then phase sensor error 0340 is displayed. The thing is that when starting the car, the electronic unit The engine control waits for a certain signal from the phase sensor. If it is absent, the control unit does not send an impulse to the ignition system and fuel supply system. Consequently, the engine does not start, and the engine control lamp comes on, indicating “error 0340” on the VAZ 2114. You can diagnose the breakdown using the car’s on-board computer, or contact a specialized service center.

Check engine error on VAZ 2114

Symptoms of this problem:

- Increased fuel consumption.

- Difficulty starting the engine.

- Perceptible noise when turning on the ignition key.

Error code - 0343

Indicates a high level of the regulator pulse; this error in the VAZ 2114 phase sensor is less common than the first, and it is directly related to a malfunction of the device itself. The problem is solved by completely replacing the unit; it does not require diagnostics or visits to specialized salons. Error 0343 may be associated with simple oxidation of the wires on the mechanism, which need to be cleaned and their integrity checked.

Attention: there should be 12V at the mechanism terminal and at pin A, and 0V at the rest.

An error in the phase sensor can be caused by a malfunction of the crankshaft position sensor, it is also possible that the timing belt has slipped onto a tooth, the key of the generator belt pulley has been turned out, the crankshaft gear has become loose, wear has occurred on the upper and lower gears. As you can see, there can be many clues; the main thing is to correctly diagnose and effectively fix the problem.

Signs of a malfunction of the phase sensor on the VAZ 2114 associated with this error may be:

- deterioration in speed gain when accelerating a car;

- problems in engine operation, when starting the unit;

- The starter spins for 4 seconds when starting and the check light comes on;

- diagnostic mode failure;

- exhaust gases become transparent, the level of carbon dioxide emissions increases.

Attention: the “Check Engine” control signal (a light on the instrument panel that indicates a malfunction in the engine control system), with a working engine, should go out 0.6 seconds after starting. This is quite enough for the diagnostic system to state that everything is in order.

If the light continues to light, then there is a malfunction, and the error on the VAZ 2114 is an exact confirmation of this. It can be identified using a professional scanner at a service station or “with your own efforts.” We are talking about a superficial diagnosis of the cause, which can give an idea of the approximate identification of a product malfunction. What to do next is up to the car owner to decide; you can replace the sensor with a new one and get rid of all “instrument errors”, and you can also do a general cleaning of the mechanism wires, completely rinse the entire sensor in a special liquid.

Attention: there is such a situation - I changed the sensor, and after a few hours the light comes on again. This problem can arise when refueling with low-quality fuel, or the mechanism is incorrectly installed and requires professional intervention from specialists! You can also get caught in a marriage, and this happens. It is necessary to do initialization after changing the sensor in order to avoid such a problem.

If the car is on the road and error 0343 or 0340 appears, then the following option can be used as a temporary solution to “treat the problem”: rotate the sensor a few degrees around its axis, and then securely fasten it again.

This method will help regulate the fuel supply in the correct mode and reduce fuel consumption when driving the car.

If symptoms of a malfunction of the camshaft position sensor are detected, it is necessary to visually check the mechanism. There may be a problem with one of the following:

- external damage;

- condensation has formed or deposits have formed on the contacts;

- The integrity of the electrical wiring near the unit has been damaged.

Symptoms of malfunction

The main driver symptom of P0342 is the MIL (Malfunction Indicator Light) illumination. It is also called Check engine or simply “check light”.

They can also appear as:

- The “Check engine” warning light on the control panel will light up (the code will be stored in the ECM memory as a malfunction).

- Decrease in engine power.

- Possible misfires in the engine cylinders. The car engine may also become unstable.

- Floating speed, as well as attempts to stall at idle.

- The engine stalls or has trouble starting.

- Increased fuel consumption.

The vehicle will most likely run with this trouble code. But it may be difficult to start, and there may also be a drop in power and unstable engine operation. To avoid damage to other engine components, if this code is detected, it is recommended that the problem be repaired as soon as possible.

Phase sensor (DF / DPRV); errors 0340, 0342, 0343

Reg.: 10/22/2013 Messages: 98 From: Russia, Rostov-on-Don Age: 32 Car: VAZ 21310 2008, Multitronics TC 740, Gena 100A

Reg.: 05/17/2011 Messages: 3213 From: Ulyanovsk Age: 57 Car: VAZ-21213 1999, Chevy Niva 2007

Reg.: 11/06/2013 Messages: 236 From: Lysva Age: 48 Car: VAZ-21214, 2008

I already installed it, let it stand. I used very little sealant. I think the oil will definitely not ooze.

Added after 1 minute 56 seconds:

By the way, the sensor came out of its seat without any problems. There is no visible damage on it

Added after 4 minutes 10 seconds:

Rikki, the contacts in the connector were dry and clean. Poking the chip into the sensor did not give any result. The error came out again. Although in meaning, yes, it seems like a cliff.

Added after 2 minutes 1 second:

For some reason the controller gave 1.2 V less... And in the manual there should be 2 to 3 volts below the on-board voltage.

Reg.: 10/22/2013 Messages: 98 From: Russia, Rostov-on-Don Age: 32 Car: VAZ 21310 2008, Multitronics TC 740, Gena 100A

Reg.: 11/06/2013 Messages: 236 From: Lysva Age: 48 Car: VAZ-21214, 2008

Name: Alexander Reg.: 07/26/2011 Messages: 29 From: St. Petersburg Age: 64 Car: LADA212140/2011 213100/2017, KIA Bongo4WD/2014

Reg.: 01.11.2006 Messages: 610 From: Moscow Age: 33 Car: Niva 21213 1.7 carb., 2000, LPG “Lovato”, mileage 130 thousand km (sold) >> Shniva LC* 2011 V.

Reg.: 10/22/2013 Messages: 98 From: Russia, Rostov-on-Don Age: 32 Car: VAZ 21310 2008, Multitronics TC 740, Gena 100A

Reg.: 01.11.2006 Messages: 610 From: Moscow Age: 33 Car: Niva 21213 1.7 carb., 2000, LPG “Lovato”, mileage 130 thousand km (sold) >> Shniva LC* 2011 V.

Reg.: 10/22/2013 Messages: 98 From: Russia, Rostov-on-Don Age: 32 Car: VAZ 21310 2008, Multitronics TC 740, Gena 100A

Reg.: 01.11.2006 Messages: 610 From: Moscow Age: 33 Car: Niva 21213 1.7 carb., 2000, LPG “Lovato”, mileage 130 thousand km (sold) >> Shniva LC* 2011 V.

Name: Evgeny Reg.: 03.26.2008 Threads / Messages: 126 / 4815 From: Irkutsk Age: 35 Car: Jimny 2013

Reg.: 01.11.2006 Messages: 610 From: Moscow Age: 33 Car: Niva 21213 1.7 carb., 2000, LPG “Lovato”, mileage 130 thousand km (sold) >> Shniva LC* 2011 V.

Does the tightening torque of the sensor matter?

I quickly checked the corrugation for damage and found nothing. The bundle of wires on the controller also pulled a little to the sides as far as it could fit. Removing and inserting the connector seemed like an unrealistic task (I didn’t remove the glove compartment - I couldn’t get under it).

Overall, I'm confused.

Name: Evgeny Reg.: 03.26.2008 Threads / Messages: 126 / 4815 From: Irkutsk Age: 35 Car: Jimny 2013

I would also repeat the measurement on contact 3, taking the mass not from contact 1, but from some other place. And then I would look at the ignition system harness, but I still have to remove this connector from the controller. There is something wrong either in the harness/connectors or in the controller itself.

The sensor can be left alone for now. And don’t put a connector on it, there will be fewer problems.

Reg.: 01.11.2006 Messages: 610 From: Moscow Age: 33 Car: Niva 21213 1.7 carb., 2000, LPG “Lovato”, mileage 130 thousand km (sold) >> Shniva LC* 2011 V.

Phase sensor errors on VAZ 2114: identifying faults, checking and replacing the sensor

The phase sensor, also known as the camshaft position sensor (hereinafter referred to as CF), is an element of the ECU (electronic on-board engine control) system, which is present exclusively in injection-type engines. This sensor is equipped with all fourteen engines with a 16-valve engine, as well as 8-valve engines that comply with the Euro-3 standard and have sequential phased injection of the fuel mixture.

From this article you will learn the principle of operation of the DF, typical problems that can arise with the device during operation and their symptoms, as well as phase sensor errors on the VAZ 2114 and their interpretation.

Phase sensor for VAZ 2114

DESIGN FEATURES AND OPERATING PRINCIPLE

The VAZ 2114 FAZ sensor is an integrated device, the main function of which is to receive information about the current operating cycle of the power unit and transmit it to the ECU via pulse signals.

Structurally, the DF consists of two parts - a sensitive element and a pulse signal converter, which in turn consists of an operational amplifier, a bridge circuit and an open-collector type output stage.

The DF sensitive element operates according to the Hall principle; it is a microcircuit that responds to fluctuations in the magnetic field, which gains the ability to transmit an electrical signal only when there is a magnetically conductive material next to it, which is the steel head of the valve.

The location of the VAZ 2114 camshaft position sensor is as follows: it is located on the end of the cylinder block, not far from the air filter.

Location of DF

There is a lot of discussion on the Internet about which phase sensor is best to buy from which manufacturer. We recommend giving preference to devices from the German company Bosch. It is she who has the license to manufacture sensors operating on the Hall principle, so, in essence, you get a reliable and durable device produced by the direct owner of the technology by which it is made.

SYMPTOMS AND INSPECTION

Signs of a malfunctioning camshaft sensor, by which you can determine that the device has failed, are as follows:

- Increased fuel consumption;

- Problems in the vehicle self-diagnosis mode;

- Reduced acceleration dynamics;

- The “Check Engine” sign or errors 0343 or 0340 appear on the dashboard.

The “Check Engine” icon, as a rule, lights up when the DF is completely out of order. The following happens: you turn on the ignition, after which the starter starts working, at this time the ECU unit should receive a signal from the sensor, but since the DF is broken, it is not there, and the electronic control switches the engine to twin injection mode (based solely on the data received from the DKPV ), turning off the phased injection of the fuel mixture.

If you find any signs of malfunction, you need to check the DF. You can do this yourself; you only need a tester (multimeter), which can be purchased at any car store for 400-600 rubles. The device is inexpensive, but useful - you will need it several times when diagnosing a car.

On fourteenths with a 16-valve engine, DF models 21120-3706040 are installed, on 8-valve engines - 21110-3706040 . Checking each of them has some features.

Scheme (for 8th grade)

- On the multimeter probe (V1 mode), which will be connected to contact “E” on the sensor, set the voltage to 13.5 V, on the second probe (connect to contact “B”) - 0.9 V;

- We close the probes on the corresponding contacts. We bring a metal plate to the end part of the DF (a screwdriver will do). If the device is working normally, the multimeter will show that the voltage at pin “B” has dropped to 0.4 V (should return to 0.9 when the plate is removed). Differences in readings – the sensor needs to be replaced.

Checking the DF of a 16-valve engine:

Scheme (for 16 cells)

- We switch the tester to V2 mode. On the probe of contact “E” we set the voltage to 13.5 V, on contact “B” - 0.4 V;

- Insert a screwdriver into the hole at the end of the DF housing. When the sensor is working, the voltage at contact “B” will increase to 0.9 W and drop back if the screwdriver is removed.

Bringing the Chevrolet Lacetti to Mind

18.11.2020 . . I decided to remember from the very beginning how this problem began with the camshaft position sensor, with its Error P0342 - weak signal. Maybe it will be useful to someone. After I installed the new original sensor GM# 96253544, several problems disappeared. Now we can say with confidence that the culprit was the camshaft sensor itself. It all started after 4 years of operation, at which time the mileage was about 50,000 kilometers. Usually I came to the garage in the morning, and the car started with half a turn. But as soon as I left the garage, turned off the engine, went to lock the locks on the gate, got back into the car and started the engine, the first time it wouldn’t start, and the second time again with half a kick. It used to happen when it’s hot - you go into the store for cigarettes, you come out, and the engine starts the second time. Naturally, there were no errors, and the thought began to appear that the injectors were not holding well. And at the moment of starting, a rich mixture is obtained in the cylinders. Then the engine turns over, and the incoming air expels the rich mixture, and the second time everything starts. The same thing happens on carburetor cars when the carburetor overflows. But all this happened very rarely, maybe twice a month, so it didn’t cause me much trouble, but it was still unpleasant. Over time, this problem began to appear more often - perhaps a couple of times a week. There were no mistakes.

And just at this time I started working on firmware. And just in the same summer, Error P0342 popped up for the first time - a weak signal from the camshaft sensor. Based on the logs and old videos, I was able to figure out that the error occurred on the same day that I installed the firmware from Icebreaker . Pay attention to this, since we will return to the Icebreaker later. The firmware is playful, economical, 850 rpm at idle, which seems to be all the engine needs. Many people like this firmware, and everything is fine with them, but it turned out that not everyone did. Personally, when washing my car, when the engine braking mode is turned on, it’s as if someone sharply tugs the tail once. And I know several other comrades who have the same problem on the Icebreaker firmware. At that time I thought, but I still didn’t understand why this was happening. Then I installed other firmware, looking for something that the engine, and therefore me, would like. A whole year passed like this. On other firmwares, no one pulled the tail, but I had already forgotten about Error P0342. But it turned out that she had not forgotten about me, and this summer she began to come out almost every month. Then I decided not to eliminate all possible problems at once, because then you won’t understand what was causing it, but I checked one thing, drove it, looked, then another. In general, this is the sixth video about the camshaft sensor. You probably remember that in the fourth video I tried to change the position of the DPRV itself, moving it to the right side. And then I noticed that in this position the sensor stands a little further from the camshaft pulley. And if something happens, I have the last option - to press it closer with the help of a construction pencil, it was just the right thickness. And then we got ready to go to our relatives in Sharya. Usually this trip takes me about 800-odd kilometers. And in order to save gasoline for this trip, I decided to re-upload the firmware from Icebreaker EURO 2 , since it is the most economical for my engine. And on the highway, engine braking is activated very rarely. I went to the garage, started it half a turn, drove up to the house, went to get my laptop and uploaded the firmware. I started to start it, but it wouldn’t start. The second time I didn’t let go of the key - first I grabbed it, then it stalled, but it started. And immediately Error P0342 popped up. But I had one last option - to insert a construction pencil and press the sensor closer to the camshaft pulley. I tried it on, broke off a pencil to size and inserted it. The sensor moved almost close. I cleared the error and started it again - it started with half a kick and even somehow softly. I decided to take a ride and - OH A MIRACLE! The Icebreaker's firmware stopped pulling the car's tail when braking with the engine. It appears that this firmware does not like a faulty camshaft sensor. In short, we went to Sharya, came back 4 days later, drove around the city for a couple of days - there were no errors, it started with half a kick, no one pulled the tail. And then I receive an SMS saying that your order is ready, come and pick it up. This is a new original camshaft sensor GM# 96253544 MADE IN CHINA for 2,600 rubles.

I went to the store and felt that somewhere in the middle of the journey the tail tugging started again when braking the engine. Then I started turning on neutral, I looked, and the speed began to freeze. The tachometer needle drops to 1,800, then rises to 2,000, and so on a couple of times. Then it drops to 1,000, then to 1,200, again to 1,000 rpm. And so he walks until the car comes to a complete stop. Apparently the old sensor realized that he was going to be fired and decided to die right on the job. I went to the store, picked up a new sensor and drove back. I’m driving and thinking, shouldn’t I check the DPRV again as a last resort, so that I can install a new one with peace of mind. I pulled into the parking lot, disconnected the chip from the crankshaft sensor and started running it on one camshaft sensor. The engine started reluctantly, but ran fine. Then my wife called, and I talked to her for about three minutes. I started putting the phone in my pocket, and my engine stopped. I launched it again and waited about five minutes - it worked as if nothing had happened. I drove about a kilometer and stopped at a traffic light. Everything is fine - everything works. But as soon as the light turned green, it died out again. I'm about to start, but the engine doesn't want to start at all. I had to turn on the emergency lights, run out of the car and reconnect the crankshaft sensor chip. The engine started immediately. Here my assumptions were 100% confirmed that the sensor sometimes works, sometimes it doesn’t, and the error simply does not have time to pop up. Even with the chip removed from the camshaft sensor, it only pops up the third time the engine is started.

The next day I replaced the sensor, but placed it offset to the right side; if anything, I’ll return it to the vertical factory position. It started with half a kick, and even the engine began to run somehow softer. I didn’t go anywhere that day, but went to the garden the next day. But the Icebreaker’s firmware also jerked when braking with the engine, and the revs in neutral also floated to a complete stop, as on the old sensor. The first thought is that the sensor is defective. In the garden I checked the entire throttle assembly and found nothing suspicious. I reset the adaptations with a smartphone with ELM 327 and went home. The revolutions began to drop normally, then float again. The next day I moved the new camshaft sensor to the factory vertical position. And immediately everything settled down - the speed does not fluctuate, and the Icebreaker’s firmware does not pull the tail when braking the engine. And the question immediately arose - why does the sensor work better for some when shifted all the way to the right, while for others it works better in the factory vertical position? I won’t throw out the old sensor, but I’ll try to revive it. Throwing away 2,600 rubles every time is a bit expensive, and many people complain about non-originals that they don’t work and begin to believe in the proverb that the miser pays twice. Using a tester, I found poor contact between the signal and negative contacts of the sensor when it was bent. Either there is contact or there is no contact. And it does not leak inside the sensor itself. Most likely at the junction of the external contacts that we see and on which the chip is placed - with the internal contacts. Now I realized that when I inserted a construction pencil to bring the sensor closer to the pulley, what played more was that the sensor simply bent, the contacts were restored and the sensor worked without interruption for almost a whole week. To make it clearer, I inserted a piece from the following video about resuscitation of the DPRV. It shows how the instrument needle twitches when the sensor is bent, and the sensor is on the engine, and there is always vibration when the engine is running. What kind of signal can the ECU receive from the sensor, when there is contact, then there is none. It’s good if the sensor dies immediately, but in this situation the error may not appear at all. So one of these days I’m going to dig out the old sensor, get to the junction of these contacts and solder it. At least the people on Drive2 write that they managed to restore the sensor in this way. So we will dare.

. . 11/25/2020 Already wrote an article and made a video Repairing the Camshaft Sensor .

Go to Main page

DF ERRORS

If the VAZ 2114 is equipped with an on-board computer, if the device malfunctions, it will display one of the errors with code 0340 or 0343. Let’s analyze each of them in more detail.

- FAZ sensor error 0340 - indicates the absence of a DF signal. The cause of this error can be anything from oxidized contacts to mechanical damage to the device. Solved by replacing the part with a new one.

- Error 0343 – high signal level of the phase sensor. Its cause, as a rule, is damage to the wiring itself or the terminals in the contact block, or their loose/oxidized connection.

Errors in the VAZ 2115 phase sensor are completely similar to the errors that occur on the fourteenth.

It is worth noting that in addition to a malfunction of the DF itself, the cause of errors may be a slipped timing belt or a loose crankshaft gear.

Phase sensor - error P0342

#1 lazy7

- Users

- 3 messages

- Car make: VAZ

- From: Perm

this problem has arisen.

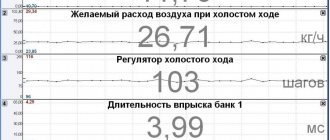

In the summer, the car constantly picked up speed on its own and held it, you stand at a traffic light at xx, the speed picks up to 2.5 or even 3 thousand. I reset them constantly by giving gas, but that’s all it does. They also swam on the bottom all the time. . there was no time to solve this problem. It’s getting colder now, and it’s already stopped holding and gaining momentum.

Something else came out. Now the check light is constantly on, the computer shows “phase sensor - low signal level” (P0342), at first it showed that on the contrary it was a high level, and sometimes that the signal level was completely incorrect. But mostly – low signal level. For some reason I bought a new phase sensor, same thing. )))

Also, during acceleration there is a failure, which is why the car jerks a little, then acceleration is normal. Well, what remains is a floating of revolutions at the bottom.

____ And to be honest, after all these problems appeared, the car became kind of stupid. He doesn't really want to go.