Even experienced motorists sometimes do not immediately determine the causes of knocking from the front pillars. The noise is heard under the hood while driving and when turning. There is also a knocking sound in the shock absorber springs. Car control deteriorates, and noticeable play appears at the steering wheel.

The reason for these problems is most likely that the support bearing of the Priora front strut is faulty . The part itself is installed between the support cups; inside there are also rubber gaskets - vibration and noise insulators, which also wear out. “Priorka” is an unpretentious car, but failure of the “support” still happens from time to time.

If the front support bearings of a Priora (Kalina, 2110, 2112, 2111) are knocking, it’s worth doing diagnostics and replacement.

Types of bearings

There are two design versions of the upper part of the rack:

- The support bearing is included in the support design (can be found on a number of VAZ models);

- It is a separate element that is placed between the support and the upper spring cup.

But there are several support bearings themselves that are used in the suspension design:

- WITH BUILT-IN OUTER OR INNER RING. Its peculiarity lies in the possibility of rotation of elements that are in contact with both the outer and inner rings. Additionally, this option provides installation holes, so no pressure flanges are needed during installation;

- WITH DETACHABLE OUTER OR INNER RING. In this embodiment, one of the rings (depending on the design) can be separated, while the second is fixed to the support;

- SINGLE-SPLIT. Structurally, this option is the same bearing with a detachable ring, but has increased rigidity.

In general, there is no particular difference which type of bearing is used, the main thing is that it performs its functions.

Despite the fact that the upper part of the strut is installed inside a special niche in the wheel arch, dirt, sand and dust penetrate the support, and these contaminants are destructive to any bearing.

Additionally, the support bearing is almost constantly subjected to rapidly changing loads, including shock loads (due to the operation of the spring), which, in combination with contamination, leads to intense wear of the bearing components and its failure.

Due to rather difficult operating conditions, the service life of such a bearing is limited. Many manufacturers indicate that it must be replaced every 100 thousand km.

But in reality, due to the poor condition of the roads, they require replacement after 50 thousand km. At the same time, the resource of this node also depends on its quality.

It is not uncommon for a support bearing to be replaced after 10,000 km.

Approximate prices

A support bearing without support on a Priora will cost 500-800 rubles . When assembled with a support, the car part will cost approximately three times more. Typically, bearings are purchased together with the support. The estimated cost of such spare parts, depending on the manufacturer, is given below:

- AvtoVAZ - from 1700 rubles.

- SEVI - about 1200 rubles.

- SS20 – from 1500 to 3400 rubles.

- BRT – 1600 rubles.

- AMT – from 1500 rubles.

BRT

A used car part can be purchased for 200-900 rubles , depending on the type and condition.

Replacing struts on a Priora involves using the following tools

- You will need special spring ties to remove the supports from the struts.

- Socket wrenches for 19, 17 and 13.

- Socket wrenches for 22, 19 and 17.

- Steering wheel end remover.

- Hexagon 6.

- Hammer.

- Pliers.

Step-by-step instructions:

Lada Priora Sedan Logbook Replacing valve seals

Replacing the strut support begins with jacking up the right side of the car and removing the wheel. The brake hoses are released from the bracket on the rack. Carefully bend the locking pin of the steering tip pin, remove it and, using a 17mm wrench, unscrew the nut. Next, you need to use the steering wheel end remover. Turn the support and begin to unscrew the soured bolts securing the strut towards the steering knuckle. In this case, you may have to use a hammer. Unscrew the nuts securing the support to the body under the hood using a size 13 wrench. Remove the stand as an assembly from the wheel well. You can begin to disassemble the structure. Install the second coils above and below the spring of the spring tie

Pay attention to the symmetrical location of the second tie. Until the load is removed from the pore, we compress the spring. Use a 22 mm spanner to unscrew the nut securing the rod towards the support. We remove the limiters. Remove the spring cup, spring and compression buffer with boot. We inspect the removed rack. Before installing new strut supports, the strut must be bled and then kept in an upright position at all times until it is installed in place. We reassemble the new shock absorber, put on a small washer and a support with a pre-installed bearing

Next comes a large washer and a rod securing nut. We remove the spring ties and orient the support so that the arrow points slightly forward into the body. We return the rack assembly to its place. The support bolts are screwed on, a stand is put on the steering knuckle, an eccentric bolt with a washer is placed in the upper hole, there should be a regular bolt at the bottom and then everything is tightened. Next, the steering tip pin is inserted into the rod on the rack, the nut is tightened, a cotter pin is inserted and the antennae are pulled apart to prevent the nut from unscrewing. Carefully thread the brake hoses into the bracket on the rack. So, the rack installation procedure is completed. Next, the wheel is placed, the car is lowered and the nut securing the rod to the support is finally tightened. To additionally pump the stand, the machine can be rocked slightly from the work side. On the opposite side, the entire procedure is repeated in a similar order. Upon completion, be sure to do a wheel alignment.

In general, the procedure under consideration, like replacing the front struts, is not complicated and can be done independently. If you are not sure about certain points, it is recommended to carry out repair work with a partner

As a result of operating the machine for several days after replacing the supports, the following improvements are observed:

- the suspension becomes more elastic;

- the former laxity is absent;

- no swaying of the car on uneven surfaces;

- turns are better;

- gravel road is much smoother;

- the steering wheel returns faster after a turn;

- more comfortable passage of speed bumps;

- at speed the car becomes more controllable;

It is worth noting that if you are carrying out such repair work for the first time, you should familiarize yourself in detail with all the nuances of the procedure and step-by-step instructions that will help you do everything as correctly as possible. Only in this case will car repair be effective.

Front upper strut supports 2170 Priora GOLD SS20 with bearing, 2 pcs 10116

Weight: 2.23 kg

Front supports SS20 Gold for VAZ.

We present to your attention a new level in the development of damping systems - SS20 Gold front supports for VAZ cars with innovative "Sliding damper" technology and the use of a unique noise-vibration-absorbing material - "Izolastan" (developed and patented by SS20).

Applicability:

- VAZ 2170-2172 (Lada Priora)

The advantages of the new strut support for popular VAZ cars are beyond doubt:

- silence in the car interior - a significant reduction in all noise and vibrations from the car suspension due to the use of innovative material “Izolastan”;

- smooth and easy rotation of the steering wheel - achieved by using the SS20 bearing, tested on Russian roads (commercially produced for other SS20 bearings);

- improved vehicle controllability and responsiveness to steering wheel rotation - ensured by minimal radial displacement of the rod in the support (less than 1 mm);

- safety - the design of the front support increases the caster angle by 1 degree, which allows the car to more clearly maintain its trajectory without additional steering, accordingly, driver fatigue and the risk of accidents at long distances during long trips are reduced, while the alignment of the wheels in the arches is not disturbed;

- high reliability and durability - a new patented material Izolastan, which is significantly superior to rubber in maintaining elasticity at low temperatures, and the design of the strut support with a damper pull-out locking system guarantees flawless operation of the support in any Russian road and climatic conditions.

Guarantee

2 years

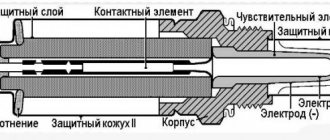

Support composition:

The SS20 Gold front strut consists of three main parts - the strut housing, the damping element and the inner bushing to which the shock strut rod is attached.

The “sliding damper” effect is achieved by a metal fluoroplastic guide mounted in the central part of the SS20 Gold front support housing. When the suspension is operating, the chrome bushing together with the damper moves inside this guide with minimal friction, i.e. "slips".

The damper itself is divided into two parts: the upper one works during the rebound of the strut, and the lower one takes the load when the suspension is compressed. Thus, in the design of the newly developed front support for the VAZ from SS20, a separate composite damper is used, each half of which perceives only a compressive load from above or below. While in other supports the rubber damper works with complex tension-compression loads and at the same time shear loads.

The upper and lower parts of the damper are assembled into a package. Between the parts of the damper there is a supporting platform of the body, and at the top and bottom of the damper pads they are pressed by limiters. These limiters are connected to each other by a polished chrome bushing. Thus, the damper is blocked from being pulled out, and therefore the strut support of this design will not let you down under any circumstances.

In addition, the damping element of the front support must perceive the tilt of the strut when the steering wheel is turned, as a result of which a conventional rubber damper welded to the support body experiences rubber ruptures and peeling. In the SS20 Gold support, the damper elements take the load only in compression, that is, the life of the elastic elements of the damper increases, it does not tear or peel off. The upper and lower parts of the damper are not welded to the body parts, and such a defect as the detachment of the damper from the body on the SS20 Gold support simply cannot occur.

Many manufacturers of auto parts try to make front supports with the softest possible damper to increase comfort in the car, but at the same time they get an increase in the displacement of the shock absorber rod in the radial direction when entering a turn, which entails a deterioration in handling - the car sluggishly obeys the steering wheel (one and the same the soft damper works both in the axial and radial directions). In the SS20 Gold support for VAZ cars, the metal fluoroplastic guide is welded through monolithic polyurethane into the support body. The polyurethane layer provides the shock absorber rod swing necessary for normal operation of the MacPherson type suspension, as well as a minimum radial displacement of the rod of 0.5 mm under a load of 300 kg. It is this very small movement of the rod in the SS20 Gold strut mount that ensures precise and easy control of the car.

Notice the sliding element we used in the SS20 Gold front support. It is taken from shock absorbers that our company produces commercially and whose reliability has been confirmed by many years of flawless operation. The polished chrome surface slides over fluoroplastic, applied in a thin layer to the metal. The result is an ideal sliding pair, which, according to technical conditions, can operate without any lubrication under significant overloads and over a wide temperature range.

Another benefit is that the SS20 Gold mount damper is offset from the stock mount damper, increasing the caster angle by 1 degree. The increased caster angle gives the car more stable movement in a straight line without steering. When cornering, the additional angle improves tire traction, the steering wheel returns to a neutral position better and the alignment of the wheels in the arches is not disturbed.

The front support for the VAZ SS20 Gold is equipped with a proprietary, highly reliable SS20 thrust bearing. The bearing races are rubberized, which reduces the transmission of vibrations and noise from the suspension to the body. The seal along the outer contour of the bearing is made similar to engine seals and reliably protects it from dust, moisture and abrasive particles, unlike other bearings with plastic housings. In addition, the SS20 bearing has a higher load capacity compared to the thrust bearing used in the standard support, and there is no brinelling effect (rolling grooves in the radial direction, i.e. across the treadmills, which leads to jerky steering). The lubricant does not require replacement during its entire service life. Thus, we obtain a highly reliable and well-protected thrust bearing for load-sharing supports, with good noise absorption and an unconditional company guarantee.

The power design of the SS20 Gold front support provides for load sharing:

- axial (vertical) loads from the rod of shock absorber struts and bump stops are absorbed by a composite “sliding damper”;

- radial (lateral) loads from the shock absorber rod are absorbed by a monolithic polyurethane ring;

- The weight of the car is absorbed by the body through the spring cup and the SS20 radial thrust bearing.

This division of the load makes it possible to achieve high reliability and increase the service life of all suspension elements of VAZ vehicles.

The front strut support, which shares the load between the vehicle's weight and the shock absorbers, was first developed and patented by SS20 in 2001. A sliding damper with separated axial and radial load is developed and patented by SS20 in 2012.

Thus, we obtain a highly reliable, well-protected support with impeccable noise and knock absorption, providing the vehicle with improved controllability and stability on uneven roads, when driving in ruts, and as a result, reducing driver fatigue. We are talking all this about the SS20 Gold strut support for VAZ cars - the result of the work of engineers, testers and car service workers of the SS20 company over 11 years.

Brand guarantee.

SS20 provides an unconditional guarantee regardless of:

- where and when the SS20 Gold front struts were purchased;

- whether they are installed in a specialized VAZ car service center or independently;

- whether the warranty card or receipt has been preserved - in case of loss, the guarantee is based on the date of marking on the product.

Marking:

Consequences of bearing wear and signs of damage

Lada Priora Sedan 16kl Kvartsukha Logbook REPLACING THE FUEL FILTER

Since the support bearing can be partially attributed to the steering (without it, rotation of the rack would be impossible), its failure primarily affects the controllability.

But here it should be noted that this depends on the design solution used.

For example, in a VAZ-2110, the inner race of the bearing acts as a bushing through which the shock absorber rod passes.

As a result of critical wear of the bearing, it begins to play and the rod is able to deviate from the axis.

The result of this is a violation of the wheel alignment angles, and consequently a deterioration in the car’s handling, as well as accelerated tire wear.

But on a car, where the bearing only provides rotation of the strut and does not interact with the shock absorber, alignment violation practically does not occur, since the rod is kept from axial displacement by a bushing pressed into the rubber damper.

But even with this design, bearing wear will have a negative impact on handling.

If the bearing has worn out, this will naturally begin to show. In this case, the symptoms of a malfunction depend on the design.

If we take the same VAZ-2110, then bearing wear will manifest itself in the form of knocking noises when driving over potholes and unevenness on the road; in addition, they can be heard when turning

Sounds in the support are caused by play in the support element; it is important not to confuse them with a knock in the shock absorber

In the case of a bearing that does not interact with the shock absorber, its malfunction most often manifests itself in the form of squeaks and squeaks when turning.

Support bearing Priora purpose, replacement features, PrioraPRO

Lada Priora Sedan constructor, assemble it yourself Logbook Mileage and clutch replacement

The front suspension is an element that allows you to easily overcome road unevenness, eliminating jumps and vibrations. To ensure its normal functioning, many consumable parts are used.

For a Priora car, the support bearing acts as a support and ensures proper operation of the suspension. If it wears out, a number of certain inconveniences arise.

Damage to the element leads to crunching and rattling noises when overcoming uneven roads. Such phenomena partially affect the operation of the suspension itself. Correct replacement of the Priora support bearing should be carried out when one of these problems occurs. The work is done quite easily and even a novice motorist can do it.

What to do if the support bearing on the Priora is worn out?

To complete the work, you will need to purchase a new component. You can find it in any car store.

The most expensive, but also the most reliable, are products from SKF, Koyo and SNR. They have a long service life, so replacing the support bearing on a Priora with one of these components will permanently solve the problem of rattling in the area of the front pillar when driving.

You can also choose a suitable element among offers from domestic manufacturers. The attractive low price of the support bearing for the Priora makes it affordable for many motorists.

You should purchase budget consumables from companies recommended by AvtoVAZ itself. You can consult with the craftsmen and purchase a replacement part from them.

The repair work is quite simple and takes minimal time. For Priora, replacing the support bearing can take about 3 hours. And if you carefully follow the instructions, it will not cause any difficulties. Carrying out the service in the workshop may take longer due to the busyness of the craftsmen.

The support bearing on the Priora is being replaced in a well-equipped garage. To carry out the work you will need a good lift. It is simply not possible to carry out renovations in an ordinary room. Therefore, you should select the location for the repair in advance.

How to replace support bearings on a Priora yourself?

First of all, the motorist will need to remove the assembly, which will allow him to get to the part being replaced. Therefore, you will first have to remove the wheel, and then unscrew the hub nut, the lower caliper bolt and remove the caliper itself.

Further work is carried out using a special puller: it is necessary to disconnect the steering tip. The last preparatory stage will be the removal of the ball joint, then the following tasks are performed:

1. The front pillar is unscrewed from the body.

2. Using zip ties, the spring is removed.

3. The central nut of the rod is unscrewed and the support is removed.

4. The bearing is being replaced.

Assembly of the unit is performed in reverse order. After this, the owner can independently verify the quality of the new element and the disappearance of squeaks. Travel will be much more comfortable. And given the possibility of saving on repair work, the support bearing of the Priora front strut can be replaced at any convenient time.

It is worth remembering that for Lada Priora support bearings may have different service lives. For some motorists it is about 30-40 thousand km, for some it wears out after 15 thousand km. The difference depends on the quality and operating conditions. Therefore, the reliability of the product can only be assessed after long-term use.

Sometimes on Lada Priora, replacement of the support bearing is not required for a long time. Even if the trips are often on rough roads.

Such bearings are the best and indicate the cost-effectiveness and practicality of installation. They should be used during repairs and in the future, which will ensure that there is no extraneous sound in the rack area.

Priora front strut supports, their features

The front shock absorber elements of front-wheel drive cars are not only a device that compensates for unpleasant road irregularities, but also a part of the turning mechanism. This makes adjustments to the design of these supports. Due to the fact that the strut is essentially a lever for turning the caliper, a special bearing is built into the upper support. That's what it's called - support. This allows you to reduce wear both on the support cup itself and on the shock absorber rod that goes into it. The presence of this bearing ensures the stability of the vehicle's steering.

The malfunction of this part is expressed in a decrease in the car's controllability and the appearance of extraneous sounds when the Priora hits any obstacle.

Bearing replacement

No matter what kind of car the support bearing wears out, but if it uses a MacPherson strut, then the technology for disassembling the unit for replacement is identical, with the exception of some nuances regarding the suspension design.

Therefore, we will consider how replacement is carried out on a VAZ-2110 car, and then we will indicate the features of the operation on other models.

Tool.

So, it has been revealed that the support bearing requires replacement. All work can be done in a garage, but some specialized tools will be required.

In general, you will need:

- Standard set of keys, hexagons, heads with collars and rods;

- Jack;

- Steering wheel end remover;

- Spring ties;

- Rags.

A new support will also be required, since on this car the bearing is included in its design.

Of course, you can disassemble the support itself to replace only the bearing, but most car owners prefer to replace the entire assembly.

Additionally, you can purchase a spring vibration damper that is installed between the upper cup and the spring.

Sequencing.

Below we will consider the sequence of actions, and we will indicate small tricks that will make the work easier.

Disassembly and replacement is done as follows:

- We place the car on a level surface and immobilize it using the hand brake and wheel chocks;

- Take a 30mm socket and loosen the nut securing the drive to the hub. It is better to do this while the car is standing on all wheels (unscrewing this nut with the wheel removed is more difficult, since it will be more difficult to block the hub from turning). It is also worth noting that this nut is pinned, so it is difficult to tear it out of place and you cannot do without extending the wrench;

- We open the hood and, using a spanner wrench and a hexagon, tear off the shock absorber rod nut (the hexagon holds the rod itself, and the wrench loosens the nut. In this case, you only need to loosen it a little; it is strictly forbidden to twist the nut completely, otherwise the unheld spring will “shoot”). It is better to do this operation before removing the rack (it is much more difficult to remove the nut on a removed unit);

- After removing these two nuts from their place, you can continue disassembly. Jack up the required wheel and remove it;

- Unscrew the fastening of the ball joint of the lever to the rack;

- Using a puller, press out the tie rod end;

- Completely unscrew the nut securing the drive to the hub;

- Loosen the brake caliper mount (there is no need to disconnect the tubes from it), remove it from the disc and move it to the side;

- We take hold of the brake disc and pull it towards ourselves, pulling the hub from the splines of the drive shaft end switch;

- We go into the engine compartment and unscrew the three nuts securing the support to the car body. At the same time, we ask an assistant to hold the support so that it does not fall to the ground. After this, remove the assembly;

- We install the couplers and tighten the spring until its upper coil moves away from the thrust cup;

- We completely unscrew the nut securing the shock absorber rod and remove the support (after this you can check the performance of the shock absorber, check the condition of the boot and bump stop).

- Before installing a new support, we check the condition of the support cup, clean it of rust and dirt, install vibration dampers under it (if purchased);

- Before installing a new support, we install the spring correctly (the ends of the coils at the top and bottom should fit into special recesses in the cups);

- We install a new support and screw the rod securing nut until it stops;

- We remove the ties, constantly monitoring the position of the ends of the spring;

- We install the assembled rack on the car. After assembly work, it is necessary to additionally tighten the rod fastening nut.

Now about the features of the replacement with Priora, Kalina, X-Trail. Removing and disassembling the strut for these cars is the same as described above.

But it is not necessary to change the support itself on these cars (if the condition is satisfactory); after dismantling, it is enough to remove the bearing from it (installed on the side of the support cup), and put a new one in its place. And then everything comes back together.

Below is a table of the designation of support bearings according to GOST, designations (full, main, foreign analogues), their size and weight.

When carrying out replacement, special attention should be paid to safety precautions. You should not try to disassemble the rack without ties, since a “firing” spring can cause serious injury

Checking VAZ support bearings.

Step-by-step instructions for replacing a support bearing

In a specialized car service, you will have to pay at least 500 Russian rubles for replacing the 1st “prop” with a LADA Priora. rub., however, the replacement can be done independently, the work does not take much time.

Step-by-step instruction:

- The car must be parked on a level surface.

- Use a jack to lift the side from which the replacement will take place.

- We dismantle the wheel.

- Using a 19" wrench, unscrew the steering tip nut.

- If you have a special puller for pressing out the tip pin, you can use it. If there is no puller, you can press it out using a hammer and a small pry bar. The main thing in this process is not to damage the thread of the finger.

- Using the same wrench, unscrew the 2 nuts that secure the strut in the so-called steering knuckle.

- We remove the lid from the “glass”, then you need to unscrew the 3 nuts that secure the upper support to this very “glass”.

- Pull out the shock absorber completely, as if from underneath.

- In order to unload the upper support, you need to compress the shock absorber spring using a pair of ties.

- 9" and 22" wrenches will help tighten the nut securing the support to the rack.

- We remove the support and disassemble it in order to remove the support bearing.

- All that is required is to replace the worn “support” with a new device.

- We attach the support to the shock absorber.

- Assembly is carried out in reverse order.

Experts recommend replacing the bearings on both sides at the same time, and only after that adjusting the angle of the front wheels of the car.

In the cold season, it is more important than ever to install an electric heater in a car, which simplifies starting the engine in cold weather; on the website https://sto.ms/electric-heaters-installation you can order such an installation at a favorable price and with a guarantee.

The important role of MacPherson struts

But MacPherson struts have another important function - they also serve as steering knuckles. That is, the stand with the wheel hub attached to it can rotate around an axis, which allows the drive wheels to be steered.

Naturally, where there is rotation, a bearing is used; in the case of this type of suspension, a support bearing.

To figure out where the support bearing is installed, let's briefly look at the car suspension structure.

Its main components are:

- Shock absorber;

- Frame;

- Spring;

- Support.

All these elements are assembled into a single whole, which provides the possibility of compressing and decompressing the spring and moving the shock absorber rod in the body (which is what the suspension is actually for, since vibrations are damped during these movements).

To ensure all this, the rack is assembled like this: a shock absorber is installed in the body and all this is installed in a spring.

To support the spring from below, a cup is used, attached to the body (welded to it).

To ensure that the spring is pressed, another cup is installed at the top, which rests against the support.

The spring extension limiter is the shock absorber rod, the end of which passes through the support and is secured with a nut.

Additionally, the support not only acts as a stop for the spring, it also provides the upper fastening of the strut to the body (it is attached to it with levers from below).

Verification methods

Checking the condition of the support bearing is not difficult, but the technology depends on the design features of the rack itself.

It is worth noting here that such a check will not give an accurate result; you can verify that the bearing is faulty only after removing it from the car.

But, nevertheless, by performing a number of simple steps you can determine the condition of the upper support.

If we take the VAZ-2110 model, then its support bearing is installed in the support itself.

To check its condition, you should ask an assistant to rock the car in the transverse direction (not too much), while at this time we place our hand on the protruding part of the pillar in the engine compartment.

If the bearing is worn out, play will be felt by hand. Also, in a damaged element, such rocking is usually accompanied by the appearance of third-party sounds - creaks, clicks.

If all this is found during the inspection, it’s time to inspect the support.

On models such as Lada Priora, Lada Kalina, or, for example, Nissan X-Trail, the bearing is not included in the support structure, so it cannot be checked by rocking it. The only sign of wear for them is the appearance of a knocking sound when moving.

But it is still possible to further verify that the unit is faulty.

To do this, ask an assistant to turn the steering wheel in different directions. At the same time, we put our hand to the spring.

If the bearing is heavily worn, then wedging may appear in it, which will be reflected well into the spring in the form of vibration and mild “shooting”.

How much will it cost to replace a support bearing on a Priora?

The cost of the “support” for the LADA Priora model starts from 300 Russian. rub. This is exactly how much you will have to pay for an original spare part with catalog number 2170-2902821. However, you can also purchase more advanced spare parts from others, you can pay attention to “TRACK”, “SS-20” and also “FENOX” have proven themselves well. Their cost is more expensive, about 800 Russian. rub. for 1 piece

If you need to replace the entire upper support, you will have to pay an amount of 1200-3000 Russian. rub.