Types of sensors and operating principle

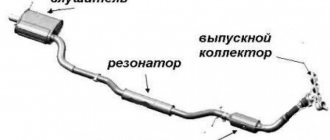

The lambda probe is installed in the exhaust system.

Sensors are divided into two types: two-point and broadband. The two-point sensor consists of ceramics, the elements of which are coated with zirconium dioxide on both sides. Installed in front of or behind the catalytic converter.

The principle of operation is to measure the level of oxygen concentration in the environment and exhaust gases. If the level changes and becomes different, a voltage is created at the ends of the sensor elements, from low to high. Low voltage is created if there is excess oxygen in the system.

Otherwise, if the system does not have the required level of oxygen, high voltage will be created. These signals are sent to the engine control unit, which distinguishes them by current strength.

The wideband sensor is a more modern design. It also has two ceramic elements. One of them can be called “pumping”. It is responsible for activating the process of pumping or removing air from the system.

The second element can be conventionally called “two-point”. The principle of operation is based on the fact that as long as there is the required amount of oxygen in the mixture, the current strength on the “pumping” element does not change and is transferred to the “two-point” element.

It, in turn, receiving a constant current from the “pumping” element, maintains a constant voltage between its elements and is inactive.

As soon as the oxygen level changes, the "pumping" element supplies the changed voltage to the "two-point". This, in turn, ensures either pumping air into the system or pumping it back.

A little about the design and principle of operation

Despite the fact that this sensor is supposed to determine the amount of oxygen in the exhaust gases, its design is not so complicated and has small dimensions.

Its main working elements are two electrodes - external and internal.

To ensure high sensitivity to oxygen molecules, the outer electrode is coated with platinum.

The second electrode is a galvanic element and is made of zirconium.

The peculiarity of this electrode is that the operating temperature at which it starts working must be at least 300 degrees.

Platinum easily traps oxygen molecules, while the voltage of the electrode itself changes.

The electronic unit interprets the voltage difference between the electrodes into percentage values of oxygen remaining.

Two types of lambda probes are produced, although they do not differ in appearance. One of the types is called two-point - this is a relatively simple sensor that is only capable of detecting the deviation of the amount of oxygen from the nominal value.

The second is broadband probes, which are capable of determining the deviation as a percentage, which has a positive effect on the operation of the electronic unit, and as a consequence of the engine itself.

Cars equipped with a catalyst are equipped with two lambda probes - one takes readings before the catalyst, and the second after.

Based on the readings, the electronic unit determines the performance of the catalyst.

This is a short description of the oxygen sensor and its operating principle.

Lambda probe on VAZ cars

Lada Priora Sedan Logbook Preparing for winter.

Starter VAZs use several types of sensors:

1. Bosch No. 0 258 005 133, Euro standard – 2. Installed on outdated models with an engine capacity of 1.5 liters. On later models with Euro 3 standard, this sensor was used as the first one, and was installed before the catalyst.

The second sensor was installed, which has a “return connector”. But you can find two identical sensors installed

2. Bosch No. 0 258 006537 was installed on cars manufactured since October 2004. They have a heating element in their structure.

Lambda probes produced are interchangeable with zirconium sensors of similar structure

Please note that a non-heated sensor can be replaced with a heated sensor. Not the other way around

Oxygen sensor malfunctions and error codes

Lada Priora Sedan constructor, assemble it yourself Logbook Mileage and clutch replacement

Among the possible breakdowns of the lambda probe, the following can be distinguished: loss of sensitivity, non-working heating. As a rule, the on-board computer will not show you a breakdown if the problem is loss of sensitivity. It’s another matter if the heating circuit breaks, then the malfunction will be recorded.

- Error P1115 - a breakdown has occurred in the heating circuit

- Error P1102 - low resistance on the oxygen heater

- Error P0141 - the heater has broken down on the second sensor

- Error P0140 – sensor number two has broken

- Error P0138 - the second sensor indicates an excessive signal level

- Error P0137 - the second sensor indicates a reduced signal level

- Error P0136 – there is a short circuit to ground of the second sensor

- Error P0135 - the heater on the first sensor has failed

- Error P0134 – the first sensor has no signal

- Error P0133 - the first sensor responds slowly to the request

- Error P0132 – there is little oxygen in the system, the signal is high at the first sensor

- Error P0131 – there is a lot of oxygen in the system, the signal is low at the first sensor

- Error P0130 - the first sensor sends incorrect signals

How to replace an oxygen sensor on a VAZ 2170-VAZ 2172

Lada Priora Sedan Logbook Replacing valve seals

When you come to a car shop or market, there will be a small but not small selection of oxygen sensors (If the store is specialized), some will come with a heating element, and some will not, Lada Priora cars are equipped with sensors with a heating element from the factory, therefore, when choosing, you will need to take exactly this one, it will be more expensive, but the whole point is as follows, the oxygen sensors begin to work normally only when they heat up to 300 ° C, at first, by the way, the car (Until it is warmed up) works at all according to other sensors, the oxygen sensor only comes into operation when it is warmed up and so that it does not warm up for a long time, this heating element is built into it, so don’t make a mistake when purchasing!

1) Both sensors, diagnostic and regulating, are removed in exactly the same way, so we will show an example of replacement at the top one. At the beginning, if the car is warm, let it cool completely, because at engine operating temperature, the temperature of the exhaust manifold reaches about 300- 500 °C, and maybe more if the car sneaks into traffic jams in warm weather and thereby warms up, after the engine has cooled down, remove the wire that is attached to it from the negative terminal of the battery (If you do not know how to do this, then study the article under title: “Replacing the battery”, everything is described there in point 1) and then press the lock, which is indicated by an arrow in the photo below, and disconnect the wire block and the connector that comes from the oxygen sensor.

2) Remove the following wire from the oxygen sensor from the heat-insulating shield, it is attached to it by a latch, to remove it, you just need to squeeze the latch (Latch) with your hands and remove it from the hole in the shield as shown in the first picture in the photo below and finally using a wrench or a special socket that can be found in a car store (a high socket with a split sector, it’s called, a very convenient thing, if you work with cars in the future, then purchase it, but if you are replacing it only for yourself then you don’t need it, because you can do it with a wrench) unscrew the oxygen sensor itself as shown in the second picture, in the photo below:

The new sensor is installed in its place in the reverse order of removal; by the way, we recommend lubricating the threads of the sensor with good graphite grease before installation.

Checking the oxygen sensor:

1. Any sensor, any part needs to be checked before running to the store and buying a new one. To check the oxygen sensor, you will need to stock up on a voltmeter and a paper clip, or a laptop and a diagnostic cable. Let’s first start by describing the first option, it is as follows: find the signal wire coming from the oxygen sensor on the connector, it can be of any color, but as a rule it goes black, so if you have a black wire, you can try to start with it, namely, to it you will need to connect the positive wire coming from the voltmeter (Through you need to connect a paperclip), and throw the negative wire to ground (the car engine can be the ground) and after starting the car, you will need to look at the readings that the voltmeter will give, they should not go beyond 1 and should not stand at 0, that is, in In the area of 0.01-0.99, the readings should fluctuate, if this is the case, then the sensor is working, but if the readings with the engine running freeze at any mark (For example, 0.32), then the sensor is faulty and needs to be replaced.

This method of verification, which is indicated in paragraph 1, by the way, is also shown in the video, which is posted below:

2. Now the second method, which is done using a laptop, and it consists of the following, connect the laptop to the brains of the car via a diagnostic connector and wire, then start it up and set all the data on the oxygen sensors on the laptop through the appropriate program and make sure that they fluctuate and do not stand in one place, you can see in more detail how to carry out this procedure using the example of a Lada Kalina car, as shown in the video clip below.

You can clearly see the process of removing this sensor from the exhaust manifold of a car in the video clip located just below:

Is it true that if you turn off the oxygen sensor and reflash the car, it will drive significantly better?

It won’t go much faster, but it will also depend on who stitched the car, in addition, emissions into the atmosphere from the exhaust pipe will worsen, that is, they will be dirtier and thus the environment will suffer from this!

How to identify and eliminate problems with the Priora oxygen sensor?

Operation is checked using an oscilloscope. It is also possible to visually assess the condition, but the accuracy of certain problems will be minimal.

When inspecting the sensor, pay attention to the amount of carbon deposits. If the layer is even and very dark, then most likely the lambda probe should be replaced

The average and high price of the Priora oxygen sensor should not prevent you from repairing the lambda probe. Otherwise, the owner will need a larger investment in engine restoration.

Cleaning a ceramic rod can be done in several ways. The first of them is a chemical effect on carbon deposits and washing it with a special composition. The second is simpler and involves heating and sharply cooling a ceramic rod. True, the second method is less effective, so it should be used only in extreme cases.

To carry out chemical cleaning, you will need to purchase phosphoric acid, which does not leave a film. Otherwise, deposits on the sensor will appear again. The protective caps must be temporarily removed, or rather carefully cut off. Next, the ceramic rod is immersed in acid for about 15-20 minutes, and then simply dries.

For the second method, you can use a portable burner. The rod is held above it for literally a couple of minutes, then it is moved into the cold.

If there is no suitable portable refrigerator at hand or it is not possible to create cold, then the sensor is simply removed from the fire for a couple of minutes. With several repetitions of the procedure, the deposit simply falls off the rod. After the work is completed, the caps are installed in place and carefully welded in the cut areas.

The principle of operation of an oxygen sensor on a car

This sensor also has another name. Lambda probe, what kind of design is it and where did the name come from? The sensor is based on a ceramic solid electrolyte made of zirconium dioxide, which is in turn coated with yttrium oxide. In total, conductive, porous platinum electrodes are sprayed on top of the ceramic element.

The principle of operation is similar to that of a galvanic cell. After installation in the exhaust manifold, it heats up in the exhaust gas flow to 400 - 300 degrees. It is in the heated state that the zirconium electrolyte acquires conductivity and ensures its normal functioning. The lambda probe is installed in such a way that one of the electrodes breathes external air - a mixture of exhaust gases. When the amount of oxygen changes on one of the electrodes, a potential difference occurs, which is transmitted in the form of a signal to the engine control system, which regulates the fuel supply in a scientific manner.

In injection about the ratios of elements in nature, stoichiometry, means lambda is the ratio of the actual amount of air to Because.

necessary, the oxygen sensor is included in the heating operation after the working element up to 350 degrees; their first samples tried to be placed as close as possible to the exhaust manifold. Over time, the sensor was built in and a heating element was upgraded into it, which brought it into working condition much faster, and now the question of where the lambda probe is located in the exhaust system is not so important. Structurally, a modern oxygen sensor consists of the following elements.

- Ceramic protective shields with tips and openings for sampling, on one side of the exhaust gases, on the other - atmospheric prisoners, air in the middle part in a ceramic insulator. They are the main working element of all This. The devices just have electrodes from which the potential difference is removed.

- A conductive heating element is located inside these tips.

- In the middle there is a part of the electrical signal current collector.

- All except for the elements of the sensitive parts of the ceramic tips, a metal housing with a thread is enclosed, which is designed to fix the sensor in the receiving pipe housing.

- Currently, modern sensors are equipped with a set of fixed wires and a sealing collar. Such four-wire sensors are called lambda probe. Two white wires are the heating system contact wires, one signal wire is black and black (or white) with a stripe - “more”. On early samples that are still used today, the potential difference was determined between the wire that went from the sensor to the ECU and the ground on the sensor housing. To do this, before screwing it into the mounting location, the sensor was coated with a specific conductive substance. lubricant caused sensitivity and burnout of the sensor due to exposure to high temperatures. This flaw has now been eliminated.

A set of oxygen sensor wires with its other end, through a plug box, is connected to the electronic on-board device, which requests data from the lambda probe about the state of the mixture with a frequency of 2 times per second at idle and more often when increasing speed. Analyzing the received data on the presence of oxygen in the exhaust gas mixture, the ECU adjusts the amount of fuel injected into the engine, making the mixture richer or leaner, depending on the oxygen signals received by the sensor. He strives for the optimal value of 14.7:1, which is included in his program.

The performance of the sensor is checked by testing with a measuring device. The lower level of the signal should be 0.1 - 0.2 V, the upper level should be within 0.8 - 0.9 V. The guaranteed performance of these sensors is very high. Signs of a lambda malfunction of a probe manufactured in accordance with GOST begin to appear no earlier than after a run of 80 thousand kilometers, and on average they can withstand a load of 160 thousand kilometers. However, according to VAZ service book 2114, replacing the oxygen sensor after a mileage of 80 thousand km is recommended. The fact is that although it continues to maintain its performance, its sensitivity is still significantly reduced, which means fuel consumption indicators, for example, are deteriorating.

Also check out

It is worth cleaning the injectors only when absolutely necessary. This is due to the fact that the ramp in which the injectors are mounted, and the injectors themselves, are the “heart” of the engine.

Spark plugs must be changed immediately when they fail. A planned update should be performed every 30 thousand kilometers. There are several indicators indicating the need for unscheduled replacement of spark plugs, namely: unstable operation

For example, let's look at a situation where the computer generates an error in the operation of the oxygen sensor (P0131 - low signal level of oxygen sensor 1). It is important to realize that the sensor monitors the condition of the system, and in cases where the mixture is lean, it gives you information about this. In this case, in replacing the oxygen sensor .

To better understand this issue, you can consider possible options.

- There is information that the mixture is “lean” and the voltage at the signal pin is too low.

To check, you need to increase the fuel supply; to do this, pinch the return drain hose. If it is not there, you can spray gasoline from a syringe into the intake manifold and evaluate the sensor’s response. If its indicators indicate an enriched mixture, replacing the lambda probe is pointless, since the root of the problem is in the fuel supply system, which most likely provides an insufficient amount of fuel.

- There is information about a “rich” mixture. To check, make an artificial suction by removing one of the vacuum hoses. If the oxygen sensor provides information about a decrease in voltage, it is working.

- Make a suction, while compressing the “return”. If the sensor signal is unchanged (within 0.45 V), or the indicators change weakly and slowly, a malfunction of the lambda probe can be diagnosed. If the voltage at the signal output changes in a timely manner, and the reaction to changes in the mixture is quick and clear, then the sensor is in perfect order.

Car owners can easily determine the degree of wear of the CD. The principle of this is the steepness of the transition fronts from a lean mixture to a rich one, and vice versa. If the sensor is working properly, it will respond to an almost vertical transition (when viewed by a motor tester). The response of a worn sensor is slow, so the transition fronts are flat. If during diagnostics you discover the second situation, the oxygen sensor must be replaced.

In addition, based on the poor response of the lambda probe, you can figure out another fairly common phenomenon. Misfires, accompanied by the release of a mixture of air and fuel from the exhaust tract, are regarded by the oxygen sensor as an excessive oxygen content in the exhaust gases. The consequence of this is that replacing the sensor does not improve the current situation, and the new lambda probe shows errors.

Worth checking out:

The presence of any problems in the engine is indicated by: reduced engine power, excessively high fuel consumption, black smoke from the exhaust pipe. Perhaps the cause of such problems lies in the coking of the engine

You should pay attention to air leaks into the exhaust system before the compressor. The lambda probe reacts to oxygen, so if there is an air fistula near it, data will appear about an excess of oxygen, that is, a “poor” mixture. At this point the mixture may be too rich. In this case, the ECU, based on the sensor readings, will enrich it. That is, the situation that has arisen will turn out to be quite paradoxical: there is information about a “lean mixture” error, but the gas analyzer transmits the opposite information.

Worth checking out:

Over time, brands of carburetors such as Solex, Ozon and Weber, which were equipped with old VAZ models, have not lost popularity. On the contrary, they have become even more popular than before.

- Do not mistake a malfunction of the ECM (electronic engine management system) for a malfunction of the lambda probe .

- The oxygen sensor should be diagnosed by monitoring the voltage with a scanner or motor tester at its signal output.

- A specially lean or enriched mixture makes it possible to monitor the probe’s reaction, from which one can conclude whether it is working or not.

- The performance of the lambda probe can be monitored by the severity of the voltage surges. It can also be used to predict its future service life.

- You should not conclude that the lambda probe is faulty based on the errors generated by it and the ECU.

VAZ 2114 signs of lambda probe malfunction

AutoFlit.ru

Lambda probe restoration

xn--2111-43da1a8c.xn--p1ai

Signs of a malfunction of the VAZ 2114 knock sensor. List and comments from the service station

- The engine begins to throttle. This is to say that the DD does not send signals to the control system, and it does not adjust the ignition timing;

- The dynamics noticeably deteriorate, the car begins to stall when accelerating;

- Acceleration becomes slow, the engine roars, and the car picks up speed slowly;

- The "Check Engine" comes on when you take off, when you roll downhill, and when you accelerate. Moreover, if the “Check” lights up only when the ignition is turned on, and goes out after 6 seconds, this is normal: the “brains” test all the components of the car.

- Code 0325 indicates that there is a break in the power wire. The most common version of what happened is oxidation of the contacts; the wiring itself breaks extremely rarely. Cleaning the terminals will eliminate the problem in most cases. However, if after processing the error does not disappear, you need to check the timing belt: it means it has jumped several teeth. After marking it, the problem disappears;

- 0328 in most cases signals a malfunction of high-voltage wires, but in some cases it can again indicate a belt jump;

- 0326 and 0327 indicate a low signal coming from the knock sensor. There are 2 options here: either the DD tightening has become loose, or the contacts have again oxidized.

- Turn off the ignition and climb under the hood;

- If there is a 2-pin knock sensor, the nut is twisted with a 13 wrench; if it is a 1-pin, use a 22 wrench;

- The multimeter (or voltmeter) is set to operate with a maximum of 200 MV;

- The electrodes of the device are connected to the DD terminals. It is officially believed that the voltmeter reading (they say there is voltage) is sufficient. However, experienced drivers do not think so: the sensor must respond to shocks caused by detonation. Therefore, additional research is carried out: the sensor is lightly tapped with the handle of a screwdriver; During impacts, the meter readings should change. If they remain constant, the DD requires replacement.

AutoFlit.ru

AutoFlit.ru

How does a lambda probe affect engine operation, its signs of malfunction

The lambda oxygen sensor has a direct impact on the stable operation of the engine by maintaining the desired mixture composition for engine operation:

- the engine is stable, without hesitation, idling at running speed;

- when you sharply press the gas pedal, a timely adjustment occurs in the engine mixture supply corresponding to the changing speed, so there are no jerks or tripping;

- The best-burnt exhaust gases are released into the atmosphere due to the efficient operation of the catalyst, which burns harmful exhaust gases in the pipe.

To ensure normal operating conditions for the sensor and extend its life, it is necessary to comply with a number of conditions:

- Use only the gasoline that is recommended for the 2114 VAZ.

- When working with additives, check their approval and quality for use.

- Under no circumstances should you use sealants, especially silicone, for mounting the sensor.

- Do not allow multiple startup attempts within a short period of time and disable it.

- Do not timing the spark plug when checking cylinder operation.

- Do not allow the exhaust system to overheat due to burnt or accumulated fuel in it; the sensor can only withstand temperatures up to 950 degrees.

- Do not wash any tips made from chemically active liquids.

- Ensure tightness at the junction of the sensor and the pipe.

which, based on the signs, can be determined that the VAZ 2114 oxygen sensor needs to be replaced can be small:

- While on gas, the engine runs unstably, the speed fluctuates or the engine stalls;

- there is an increased steady fuel consumption under standard conditions;

- the dynamic characteristics of the car have deteriorated;

- characteristic cracking of the catalyst after turning off the engine, and also a specific smell of rotten eggs due to the catalyst getting into contact with a large amount of unburned gasoline;

- on-board signal to the computer about errors associated with failures in the lambda probe.

Most often, with a faulty oxygen sensor, all of the listed symptoms should appear and when a situation arises with its replacement, the question will arise which oxygen sensor is on the 2114 VAZ. Depending on the year of manufacture of the car, the exhaust system can contain both single-wire sensors the size of the sensors from the body, and four-wire ones. The price of a VAZ 2114 lambda probe in this case can range from 1,200 to 3,000 thousand rubles.

If, after removal, a strong deposit is detected on the sensor and it shows that the potential difference is not very different from the permissible ones, then this deposit can be removed. To do this, heat the sensor very strongly, and then sharply carbonate it. Cool it should crack and fall off, cover it with a soft bone.

https://youtube.com/watch?v=ns_4VPtpVH8

Some motorists are interested in how car mechanics can disable the VAZ Sama lambda probe. 2114 the procedure is not complicated, but its necessity is highly doubtful. In this case, the ECU begins to supply gasoline for injection at average values, and this will immediately affect stable engine operation, increased fuel consumption and deterioration of exhaust characteristics. Not to mention the fact that the on-board computer will need to be re-flashed, since it will constantly produce an error associated with the absence of the Source sensor.

How to unscrew the lambda probe video

The 1st lambda probe was stuck tightly ((I soaked it and sprayed it with everything... I bought a special oxygen sensor remover, but it really doesn’t work... Maybe someone has encountered this and now knows the right way to deal with this?

40

on all machines, I did this: heat it up, then unscrew it, heat not the sensor itself, but around it

So I look at this and think, has anyone tried the old-fashioned method? chisel and hammer! Just tap on the sensor and then unscrew it! Those that are stuck must first be peeled off from each other somehow)))))

And for reference, IODINE helps the threaded connection to deteriorate.

I tried the old-fashioned method, but it turns out very painfully and not always. Next time I'll try using IODINE. for reference: I used vinegar

Vinegar is also interesting, but IODINE is a more reactive dog!

But tell me how to apply the oid, should it be mixed or in what form should it be used?

You pour it directly onto the connection in its pure form, it is not necessary to heat it, it dissolves the metal salt. Twist until dry.

Thank you! I'll try it just in case

I will if my hint helps you.

I also suffered with it, unscrewed it, and ended up tearing off the sensor, but when it was hot, I also removed the heat shield. need a big lever

Source: https://skoda-rapid.ru/avtomobili/kak-otkrutit-ljambda-zond-video/

Causes of malfunction and obvious signs

As a rule, the following reasons lead to malfunction of the sensor:

- Some aggressive liquid, such as antifreeze or brake fluid, gets on the sensor.

- Problems may begin if the owner used chemically active agents when cleaning the regulator body.

- If the car fuel contains a large amount of lead compounds.

- In case of significant overheating of the regulator, which occurs either due to the use of low quality fuel or due to a clogged filter.

Regulator malfunctions can be judged by obvious external signs. It's easy to notice

It is enough to pay attention to the following points:

- Fuel consumption has increased sharply.

- The car jerks jerkily, even when the engine is warm.

- The color and smell of the exhaust gases have changed.

- The operation of the catalyst is disrupted.

steps

In turn, experts see two main stages in the deterioration of the sensor.

At the first stage of sensor malfunction, there is an increase in the engine response time to pressing the gas pedal. The power unit reacts sluggishly, when you press the accelerator the “check” starts blinking, the pedal is lowered and the blinking stops. At this stage of the malfunction, the driver notices a deterioration in traction, acceleration dynamics and an increase in fuel consumption (not yet significant). As a rule, this stage of regulator malfunction can last about a year.

The second stage is much sadder. Most car owners at this stage think about why this oxygen sensor is actually needed. Normal acceleration disappears completely, the car “stumbles” even on a completely flat road. Another distinctive feature of the second stage is a decrease in the speed of the power unit, even when the accelerator is pressed to the floor. In this case, popping noises may be heard in the intake manifold.

To be completely sure, it is recommended to start the car “cold”. If the oxygen sensor is faulty on the second severity scale, the car will only run perfectly for the first few minutes. When the device starts functioning, sending signals to the ECU, problems will immediately arise.

Typical faults and solutions

| Malfunctions | Remedies |

| Unstable operation of the power unit at idle speed | Checking the integrity of electrical wiring. Replacing the lambda probe |

| Excessive fuel consumption | Replacing the DC with a new one |

| Reduced acceleration dynamics | —/— |

| After stopping the engine, a characteristic crackling sound is heard in the area where the catalytic filler is located. | Cleaning the catalyst, replacing it with a new one, preventing DC |

| Exceeding the operating temperature of the standard catalytic collector | Catalyst clogging, prevention, replacement with a new one |

| Indication of engine operation error “SNESK ENGINE” on the dashboard | —/— |

| Sensor error "P0140" | —/— |

Operating principle of the oxygen sensor

The principle of the oxygen sensor on the Priora is as follows: for the parameters for correcting the travel time of the electronic injection signals of the system, data on the composition of oxygen (exhaust) in oxygen gases is taken into account. It is this data and the sensor that represents the oxygen concentration of the Priora, which chemically reacts with the exhaust gases during transport.

In order for this electrochemical reaction to occur, a potential difference is created at the output terminals of the device. voltage drops Changes in voltage determine the oxygen content and air-fuel mixture quality. Changes occur in parameters ranging from 0.1 V, indicating a high oxygen content and a lean mixture, to 0.9 V, indicating a low oxygen content and an enriched consistency.

For optimal operation of the vehicle, the temperature value of the oxygen sensor, the price of which is affordable for most Russian motorists, should not be less than 300°C. Taking this into account, to heat the dynamic device after starting the power sensor, a heating type component is integrated into the oxygen installations on the Priora.

By fixing the voltage at the output of the device, the controller selects a command signal to correct the air-fuel mixture to the fuel atomization components. system for lean mixture readings, i.e. the potential difference is at a minimum value, the controller commands the incoming consistency to be enriched, and with the parameters enriched at, i.e. mixture of maximum potential difference values, the command is sent to deplete it.

In short, a standard lambda sensor (oxygen probe) makes it possible to estimate the unspent oxygen concentration in the exhaust mixture, and based on these studies, the on-board computer changes the consistency of the air-fuel mixture. Occurring malfunctions of the oxygen sensor result in incorrect operation of the vehicle's power plant. Often on car enthusiast forums one comes across the question: Is the oxygen sensor installed on the Priora? car For Lada Priora, only the BOSCH LS6537 sensor is acceptable for installation.

Operating principle of the oxygen sensor

The principle of operation of the oxygen sensor on the Priora is as follows: to correct the parameters of the transmission time of electronic signals of the injection system, data on the composition of oxygen (oxygen) in the exhaust gases is taken into account. It is this data that is represented by the Priora oxygen concentration sensor, which enters into a chemical reaction with the exhaust gases of the vehicle.

During the course of this electrochemical reaction, a potential difference is created at the output contacts of the device. Changes in voltage drop determine the oxygen content and the quality of the air-fuel mixture. Changes occur in parameters from 0.1 V, indicating increased oxygen content and a lean mixture, to 0.9 V, indicating low oxygen content and a rich mixture.

For optimal operation of the vehicle, the temperature value of the oxygen sensor, the price of which is affordable for most Russian motorists, must be at least 300C. Taking this into account, for dynamic heating of the device after starting the power plant, a heating-type component is integrated into the oxygen sensor on the Priora.

By fixing the voltage at the output of the device, the controller selects a command signal to correct the fuel-air mixture to the atomization components of the fuel system. When the lean mixture reading is indicated, i.e. the potential difference is at a minimum value, the controller commands to enrich the incoming mixture, and with the parameters of the enriched mixture, i.e. at maximum values of the potential difference, a command is received to deplete it.

How to check

oxygen sensor (

lambda probe

) Several methods.

https://youtube.com/watch?v=hXI5whguE1c

In short, a standard oxygen sensor (lambda probe) makes it possible to estimate the concentration of unspent oxygen in the exhaust mixture, and based on these studies, the on-board computer changes the consistency of the fuel-air mixture. Malfunctions of the oxygen sensor result in incorrect operation of the vehicle's power plant. The question often comes up on car enthusiast forums, which oxygen sensor is installed on the Priora? For the Lada Priora car, only the BOSCH LS6537 sensor is acceptable for installation.

How to check the oxygen concentration sensor

You can check the oxygen sensor only if you have an oscilloscope. Other devices can only indirectly prove signs of a malfunction in Priora, and on the basis of fairly complex tests. In a car, the signs of a malfunctioning oxygen sensor are as follows:

- increased fuel consumption;

- decreased engine performance;

- unstable idle speed of the power plant;

- defects of the catalytic converter.

Such malfunctions of the oxygen sensor mainly determine the range of defects of this electrochemical device. In addition, an error displayed on the ECU display may be directly related to defects in the heater electrical circuit. Due to the fact that the oxygen sensor (lambda probe) of the Prior does not receive a sufficient degree of heating, the on-board computer will issue incorrect impulses. The fuel mixture will not meet the required concentration, which will result in excessive fuel consumption, unstable engine idling, the car will lose dynamism, etc.

Once the oxygen sensor (lambda probe) of the Priora reaches the required temperature value, all signs of incorrect operation of the power plant eliminate themselves. The maximum service life of the oxygen concentration sensor in practical driving reaches 100-150 thousand km, but the service life between repairs expires after a distance of 60-80 thousand km.

The response of the device, and, consequently, its readings, is aimed at the difference between the oxygen concentration in the vehicle exhaust and its content in the atmospheric air, which is transformed into the output potential difference. Because oxygen does not completely burn even in exhaust gases and is present in the catalyst chamber, then for a correct assessment another similar device is used, located behind the catalytic chamber.

In the first minutes of starting the engine, the on-board computer corrects the fuel-air mixture according to the average. Once the Priora oxygen concentration sensor is heated to operating temperature, the electronics unit installs it into the general operation scheme of the vehicle.

Methods for diagnosing an oxygen sensor

Oxygen sensor

Experts advise checking the correct operation of the lambda probe every 10,000 km, even if there are no problems with the operation of the device.

Diagnostics begins with checking the reliability of the connection between the terminal and the sensor and for the presence of mechanical damage. Next, unscrew the lambda probe from the manifold and inspect the protective casing. Small deposits are cleaned.

If, during a visual inspection, traces of soot, strong white, gray or shiny deposits were detected on the protective tube of the oxygen sensor, the lambda probe should be replaced

How to check a lambda probe with a multimeter (tester)

The sensor is checked for functionality using the following parameters:

- Heating circuit voltage;

- "Reference" voltage;

- Heater condition;

- Sensor signal.

Connection diagram to the lambda probe depending on its type

The presence of voltage in the heating circuit is determined with a multimeter or voltmeter in the following sequence:

- Without removing the connector from the sensor, turn on the ignition.

- The probes are connected to the heating circuit.

- The readings on the device must match the voltage on the battery - 12V.

“+” goes to the sensor from the battery through the fuse. In its absence, this circuit is called.

“—” comes from the control unit. If it is not detected, check the terminals of the lambda probe - ECU circuit.

The reference voltage measurements are carried out using the same devices. Sequencing:

- Turn on the ignition.

- Measure the voltage between the signal wire and ground.

- The device should show 0.45 V.

To check the heater, set the multimeter to ohmmeter mode. Diagnostic stages:

- Remove the connector from the device.

- Measure the resistance between the heater contacts.

- The readings on different oxygen pumps are different, but should not go beyond 2-10 ohms.

A voltmeter or multimeter is used to check the sensor signal. For this:

- They start the engine.

- Warm it up to operating temperature.

- The probes of the device are connected to the signal wire and the ground wire.

- Engine speed is increased to 3000 rpm.

- Monitor voltage measurements. Jumps should be observed in the range from 0.1 V to 0.9 V.

If during at least one of the checks the indicators differ from the norm, the sensor is faulty and needs to be replaced.

Video: checking the lambda probe with a tester

Checking with an oscilloscope

The main advantage of this lambda probe diagnostic over checking with a voltmeter and multimeter is the recording of the time between similar changes in the output voltage. It should not exceed 120 ms.

- The probe of the device is connected to the signal wire.

- The engine is warmed up to operating temperature.

- Engine speed is increased to 2000-2600 rpm.

- Based on the oscilloscope readings, the performance of the oxygen sensor is determined.

Diagnostics with an oscilloscope gives the most complete picture of the operation of the lambda probe

Exceeding the time indicator or crossing the voltage limits of the lower 0.1 V and upper 0.9 V indicates a faulty oxygen sensor.

Video: diagnosing an oxygen sensor with an oscilloscope

Other verification methods

If the car has an on-board system, then the “CHECK ENGINE” signal, which generates a certain error, can be used to diagnose the condition of the lambda probe.

List of lambda probe errors

In order for the lambda probe to work for a long time and efficiently, it is necessary to fill the car only with high-quality fuel. Scheduled and timely diagnostics of the oxygen sensor will help to detect its malfunction in time. This measure can extend the life of not only the sensor itself, but also the catalyst.

Unfortunately, not all car owners know what a lambda probe is and why it is needed. A lambda probe is an oxygen sensor that allows the electronic system to monitor and balance the correct ratio of air and gasoline in the combustion chambers. It is able to promptly correct the structure of the fuel mixture and prevent destabilization of the engine operating process.

This rather fragile device is located in a very aggressive environment, so its operation must be constantly monitored, since if it breaks down, further use of the car is impossible. Periodic checking of the lambda probe will guarantee stable operation of the vehicle.

Lambda probe check.

To check the functionality of the oxygen sensor, you will need: factory instructions that will tell you where the lambda probe is located, an oscilloscope and a digital voltmeter. These are the main supporting tools. The engine should be warmed up while testing the device. How to check the lambda probe yourself? It's as simple as flushing the injector.

Study the manufacturer's instructions for the basic parameters of the oxygen sensor. Check the indicators that are affected by unstable operation of the lambda probe: on-board voltage, ignition timing, operation of the fuel supply system

Also pay attention to the appearance of the mechanisms, in particular the presence or absence of mechanical damage to the housing and wiring. Look in the engine compartment and find the lambda probe. Inspect it for external contamination

If the tip of the lambda probe is covered with a layer of soot, lead or a white-gray coating, then most likely it will need to be replaced. The damage to the device by deposits is caused by poor-quality fuel composition. If the probe tip is clean, continue checking further. Disconnect the oxygen sensor from the block and connect it to a digital voltmeter. Start the car and, by pressing the gas pedal, increase the engine speed to 2500 rpm. Using a device for enriching the fuel mixture, reduce the speed to 200 per minute. If your vehicle is equipped with an electronically controlled fuel system, remove the vacuum tube from the fuel pressure regulator. Look at the voltmeter reading. If the instrument needle approaches the 0.9 W mark, it means the lambda probe is in working condition. A malfunction of the sensor is indicated by the lack of response from the voltmeter, and its readings are less than 0.8 W. Do a lean mixture test. To do this, take a vacuum tube and provoke an air leak. If the oxygen sensor is working properly, the digital voltmeter reading will be at 0.2 W or lower. Check the operation of the lambda probe in dynamics. To do this, connect the sensor to the connector of the fuel supply system, and install a voltmeter parallel to it. Increase engine speed to 1500 rpm. The voltmeter readings with a working sensor should be at 0.5 W. Another value indicates a failure of the lambda probe.

Correct dismantling and installation of a new lambda probe sensor.

- First, disconnect the sensor wire from the electrical wiring. Carry out the procedure with a cold engine and the ignition off. To replace an old device, use a sensor with the same markings as the previous one.

- Using a suitable wrench, unscrew the old sensor. It is best to remove the device with the ignition on, and, accordingly, the hot sensor and fuel pipe, otherwise there is a risk of breaking the thread, since in a cold state the metal contracts and must be unscrewed with considerable effort. When steam appears from the holes, you can turn off the engine. It will be easier to unscrew further.

- Screw the new lambda probe as far as it will go to create a good seal.

- Connect the electrical wiring.

- Check the functionality of the new oxygen sensor using an oscilloscope, digital voltmeter, or ohmmeter at an engine temperature of 350 C.

You will learn how to repair the exhaust system in our other article.

Checking the Sensor

To check the phase sensor, you must use a multimeter. Using this device you can check almost all sensors in the car.

Step by step verification process:

- Turn on the ignition on the car, check the voltage on the battery and make sure that it corresponds to the operating voltage of 11.8-12.6V. To check the voltage, you need to set the switch on the multimeter to constant voltage mode, on the 20V division scale.

- Now you need to check the power supply to the sensor necessary for its operation. To do this, remove the connector from the sensor and connect a multimeter to it. We connect one multimeter probe to ground, the second to the central connector of the block - the voltage should be 12 V. The outermost connectors of the block should show up to 5V.

- After the sensor's power supply circuit has been checked and no damage has been detected, it is necessary to begin checking the DF itself. To check it, it must be removed from the cylinder head. After dismantling, we connect the sensor to the connector and check the voltage on the back side of the block with multimeter probes. At contact “B” the voltage value should be at least 0.9V. Then you need a small metal plate, which needs to be inserted into the slot of the sensor and when the plate is in the sensor, the voltage on the multimeter should drop to 0.4V. If all parameters match, then the Priora phase sensor is working. If the parameters differ, then the sensor must be replaced, since it is not repairable.