Fan connection 2108, 2109, 21099

Until 1998, on vehicles with the old fuse block 17.3722 (finger fuses), the fan circuit included a relay 113.3747. After 1998 there was no such relay.

Also, before 1998, the TM-108 switching sensor was used (the closing temperature of its contacts is 99 ± 3 ° C, the opening temperature is 94 ± 3 ° C), after 1998 the TM-108-10 with similar temperature ranges or its analogues from different manufacturers . The TM-108 sensor only works in conjunction with a relay amplified for high current. TM-108-10 can work with or without relay.

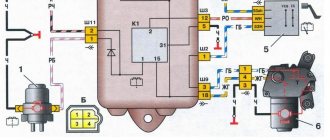

Scheme for switching on the engine cooling fan on a VAZ 2109 with mounting block 17.3722

K9. fan motor start relay. A. To terminal “30” of the generator

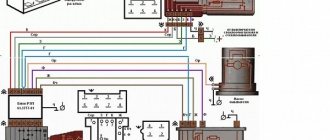

Scheme for switching on the engine cooling fan on a VAZ 2109 with mounting block 2114-3722010-60

A. To terminal “30” of the generator

Old style fuse box

Fuse block 2114-3722010-60

Each fuse in the power supply is responsible for a specific circuit, here is a summary table.

| Fuse number | Current strength | The chain he protects |

| F1 | 10A | Backup fuse |

| F2 | 10A | Turn signal indicators, hazard signal breaker (in hazard mode), hazard warning light |

| F3 | 10A | Rear brake lights, interior lighting |

| F4 | 20A | Rear window heating element, rear window heating switch contacts, carrying socket, cigarette lighter |

| F5 | 20A | Horn (horn), horn switch |

| F6 | 30A | Backup fuse |

| F7 | 30A | Heater fan electric motor, windshield washer electric motor, electric radiator fan relay, rear window heating relay, rear window heating indicator light, glove box light |

| F8 | 7.5A | Backup fuse |

| F9 | 7.5A | Backup fuse |

| F10 | 7.5A | Left side light |

| F11 | 7.5A | Right side lamp |

| F12 | 7.5A | Right low beam headlight |

| F13 | 7.5A | Left low beam headlight |

| F14 | 7.5A | Left high beam headlight, high beam indicator lamp |

| F15 | Right high beam headlight | |

| F16 | 15A | Turn signal indicators and emergency flasher relay-breaker (in the turn signal indication mode), turn signal indicator indicator lamp, rear reverse lights, gear motor and windshield wiper activation relay, oil pressure indicator lamp, hand brake indicator lamp, coolant temperature indicator, fuel level indicator, fuel reserve warning lamp, voltmeter |

What are the functions of the relay on the fuse box?

| Relay number | Functions |

| 1 | Performance of the front optics cleaning elements |

| 2 | Rear window washer motor performance |

| 3 | Protection against breakage of turn signal and light signaling lamps |

| 4 | Protection against failure of the windshield wiper motor |

| 5 | Allows you to determine the performance of the lamp |

| 6 | Rear window defogger overvoltage protection |

| 8 | High beam lamps |

| 9 | Low beam lamps |

| 11 | Responsible for the operation of the engine cooling fan. If this relay fails, the risk of engine overheating increases. |

| 12 | Klaxon operation |

Fuse block 17.3722

| № | A | Purpose |

| 1 | 8 | Right fog lamp |

| 2 | 8 | Left fog lamp |

| 3 | 8 | Headlight cleaners (at the moment of switching on) Headlight wiper switch relay (contacts) Headlight washer switch valve |

| 4 | 16 | Headlight wiper motor Headlight wiper relay (winding) Heater motor Window washer motor Rear window wiper motor Rear window washer timing relay Windshield and rear window washer activation valve Cooling system electric fan relay relay coil Coil of the rear window heating relay coil Rear window heating control lamp Wardrobe lighting lamp box |

| 5 | 8 | Turn indicators in turn signal mode and the corresponding indicator lamp Rear lights (reversing lamps) Indicator lamp for fuel reserve, oil pressure, parking brake, brake fluid level, carburetor choke Voltmeter and indicator lamp for charging the battery Gearmotor and windshield wiper switch relay Generator excitation winding (at start-up) “STOP” indicator lamp Coolant temperature and fuel level indicators |

| 6 | 8 | Rear lights (brake lights) Body interior light Power windows and power window relay |

| 7 | 8 | License plate lights Engine compartment lamp Indicator lamp for turning on side lighting Instrument lighting lamp and cigarette lighter lamp Heater lever illumination panel |

| 8 | 16 | Engine cooling fan electric motor and its activation relay (contacts) Sound signal and its activation relay |

| 9 | 8 | Left headlight (side light) Left rear light (side light) |

| 10 | 8 | Right headlight (side light) Right rear light (side light) |

| 11 | 8 | Direction indicators and hazard warning relay (in hazard mode) Hazard warning lamp |

| 12 | 16 | Heated rear window element and heating relay Cigarette lighter Socket for portable lamp |

| 13 | 8 | Right headlight (high beam) |

| 14 | 8 | Left headlight (high beam) High beam indicator lamp |

| 15 | 8 | Left headlight (low beam) |

| 16 | 8 | Right headlight (low beam) |

| Relay | ||

| K1 | Rear window washer time relay (451.3747 / 2108-3747110, 2108-3747110-06) | |

| K2 | Relay-breaker for direction indicators and hazard warning lights (493.3747 / 2108-3747010-02) | |

| K3 | Windshield wiper relay breaker (522.3747 / 2108-3747710) | |

| K4 | Contact jumpers in place of the lamp integrity monitoring relay. Lamp integrity monitoring relay (4402.3747 / 21083-3747410, 21083-3747410-06) | |

| K5 | Headlight high beam relay (113.3747 / 2105-3747210-10, 2105-3747210-12) | |

| K6 | Headlight cleaner relay (112.3747 / 2105-3747210, 2105-3747210-02) | |

| K7 | Power window relay (13.3747 / 2105-3747210-10, 2105-3747210-12) | |

| K8 | Relay for turning on sound signals (13.3747 / 2105-3747210-10, 2105-3747210-12) | |

| K9 | Relay for turning on the electric cooling fan (13.3747 / 2105-3747210-10, 2105-3747210-12) | |

| K10 | Relay for turning on the heated rear window (13.3747 / 2105-3747210-10, 2105-3747210-12) | |

| K11 | Relay for low beam headlights (13.3747 / 2105-3747210-10, 2105-3747210-12) | |

If the cooling fan does not work

To drive the fan, a DC electric motor with permanent magnetic excitation ME-272 or similar is installed. Technical data of the electric fan and fan switch sensor:

The cooling fan may not turn on due to:

Fuse VO is located in the mounting block of the car's engine compartment and is marked F7 (20 A). The test is carried out using self-diagnosis included in the probe mode.

What to do if the wipers on the VAZ 21099 stop working?

The first thing that might come to mind is to replace the windshield wiper relay fuse in the mounting block. Bad advice would be to install a jumper. No need to do this! It’s better to immediately find a fuse of the appropriate rating, flat or cylindrical, depending on the type of mounting block and year of manufacture of the car, and check your assumption.

As a rule, injection models and carburetor VAZ 21099 after 1998 have a new type of fuse box. They are more modern and reliable.

Also, if the wipers fail, it would be a good idea to visually inspect the wiper relay itself. The relay contacts may burn out. If the problem is in the relay, the wipers will only work in the uppermost position of the steering column switch.

You can try removing the relay from the mounting block and cleaning the contacts with a file or sandpaper. Then insert it back, start the car and check the operation of the wipers. A working relay should click when operating.

If the relay is faulty, it must be replaced.

VAZ cooling fan connection diagram

All basic electrical diagrams and modifications for connecting the liquid cooling fan (CO) in VAZ cars of various models are given. What is the essence of VO’s work? The electric motor with an impeller on the shaft is installed in a rectangular metal frame, with which it is attached to the rear of the radiator. When voltage (12V) is applied to the actuator contacts, it begins to work, rotating the blades and creating a directed air flow that actually cools the antifreeze or antifreeze.

Replacing an electric fan in a car

Checking the cooling system

What to do if the VAZ 21099 carburetor cooling fan does not work? As soon as the car owner noticed the first signs of overheating, i.e. the temperature sensor arrow has approached the red zone, but the carburetor has not yet started pouring smoke from under the hood of the VAZ 21099, you need to check the cooling system.

Check all wire connections

Step-by-step instructions for checking the cooling system.

READ How to Adjust the Mirrors of a VAZ 2109

New model power supply

Here the mounting block diagram is arranged a little differently, but it is more relevant for owners of the VAZ 2109, since most of the nines that have survived to this day are modernized versions.

The scheme is relevant for both carburetor and injection types of engines.

Fuse number

Rated current

The electrical circuit for which it is responsible

Radiator fan relay winding, electrical circuit of switch and heater motor

Hazard warning switch in turn signal mode, turn signal switch, turn signal switch, turn signal warning light, turn signal warning light, reverse optics switch, reverse lights, tachometer, voltmeter, gasoline level indicator, gasoline level sensor, gasoline level warning light, pointer coolant temperature, temperature sensor, warning lamp and emergency oil pressure sensor, brake emergency lamp, brake system hydraulic switch, hand brake switch

Brake light switch and bulbs, interior lighting

Room lighting lamps, indicator lamp for switching on the dimensions, lamp for illuminating the heater and cigarette lighter handles, glove compartment lamp, switch and lamp for instrument panel illumination

Horn, horn switch, radiator fan motor

Left side lamp, left rear side lamp

Right side lamp, right rear side lamp, fog light switch, fog light indicator light

Turn signal switch and breaker, turn signal lamps, warning lamp in emergency mode

Cigarette lighter, socket for carrying lamp

High beam right headlight

Main beam of the left headlight, high-range optics warning lamp

Low beam right headlight

Low beam left headlight

New power supply

As for the relay in the mounting block of the new model for the VAZ 2109, the pinout is as follows.

Relay number

Its functions

Without it, the rear window washer motor will not work.

Responsible for the operation of turn signal lamps and light signaling

Provides operation of the windshield wiper

Protects brake lights and vehicle dimensions

Provides operation of high beam lights

Guarantees operation of the optics washer device

Protects the power window motor if your vehicle has one.

Sound signal or just a horn

Protects against high voltage going to the engine cooling fan

Responsible for the operation of the rear window heating device

Provides operation of low beam lights

It is necessary not only to understand the location of a particular fuse or relay, but also to know how to replace a failed element.

Scheme for switching on the cooling fan of a VAZ 2110 carburetor engine.

The circuit diagram for switching on the VAZ 2110 cooling fan to the carburetor and injection is different. On cars with a carburetor engine, a thermobiometallic sensor TM-108 is used, and on cars with an injection engine, the controller is controlled.

When the fan is controlled by a sensor, the switching temperature depends on the sensor installation temperature, which is indicated on the housing. If the fan does not turn on when the temperature rises to the operating temperature of the sensor, you need to check from the very beginning whether the sensor is working correctly. To check, it is enough to close the contacts on the sensor, and if it is triggered, you must replace the sensor. If the fan does not work after shorting the terminals, check the cooling fan

and fuse integrity.

Fan control

If a VAZ 2109 car is equipped with an engine with distributed injection and an injector , then the sensor-switch familiar to the owners of the carburetor model does not exist. The fan is turned on and off by the ECU controller. This controller receives information from the coolant temperature sensor (CTS), which is installed in the outlet pipe between the thermostat and the cylinder head. The sensor is used to monitor not only the operation of the fan, but also the engine. Including:

To determine the temperature of the VAZ 2109 DTOZH, a thermistor is used in the injector. a resistor whose resistance depends on temperature. VAZ 2109 uses a thermistor with a negative temperature coefficient. This means that as the temperature increases, its resistance decreases.

Where is the Fan Relay for VAZ 2109 Injector?

VAZ 2110 cooling fan switching diagram

To maintain the engine temperature, the VAZ 2110 fan cooling circuit is used. The fan motor turns on and off automatically.

General characteristics of the model

90s dream car

The dimensions of the car have changed slightly due to the lengthening of the wing and enlargement of the hood. In addition, there is a completely new, improved VAZ radiator grille and, of course, an updated instrument panel. The length of the VAZ 21099 compared to other cars in this group has increased by 20 cm.

The VAZ 21099, like other models of this family, has many advantages:

- has excellent controllability when driving;

- Stable on completely different types of roads.

In 2004, production of this car model was discontinued, but production in Ukraine continues.

VAZ 21099 cars come in two types.

The VAZ 21099 has a carburetor, as in the injectors of the VAZ 21099, the layout of the fuel supply system is almost the same.

Quite often, the owners of this car are faced with one problem: the VAZ 21099 carburetor cooling fan does not work.

Cooling system VAZ 2109

The liquid cooling system of the injector of the VAZ 2109 automobile engine is a closed-cycle system with forced circulation of coolant (coolant). The system consists of the following blocks:

Fan operation is critical in hot weather when filming in slow motion. Under these conditions, engine overheating is especially likely, and, accordingly, high-quality fan operation is required. The cooling air flow must be directed correctly to the radiator. If the VAZ 2109 injector cooling fan does not work, the cooling system may “boil”.

Scheme

The entire line of VAZ 2109 cars can be divided into two branches - those produced before 1998 and those produced after 1998.

Older cars are equipped with fuse blocks whose marking is 17.3722. This power supply consists of a housing and an engineering board. Wire contacts, fuses and relays are soldered to the board.

The required mounting block is also located the same everywhere - in the engine compartment opposite the driver's seat, almost under the windshield.

Location

Differences

Are there any differences between the old and new versions of the power supply? Of course. They are as follows:

- The parts of the mounting block are marked differently;

- The fuse ratings are different;

- The new power supply does not have a relay for the cooling system fan motor and a time relay for the rear window washer device.

Fan diagnostics

In order to check the operation of the unit, you will need a one and a half meter wire, preferably with “crocodiles” at the ends. With the engine off, connect the positive terminal of the battery directly to the fan terminal. The working unit should begin to rotate. If not, then this is a malfunction. If the cooling fan does not turn on when the engine overheats, although diagnostics show that they are working, you should check the DTOZH.

During the test, you will need an ohmmeter to measure the resistance of the sensor. An ohmmeter is included in any, even the simplest portable digital multimeter. The procedure is as follows:

READ How to Replace the Starter Bushing on a VAZ 2109

If for some reason the sensor resistance is not normal, the part must be replaced. And if this is the case, but the unit does not turn on, something is not working in the electronic engine control unit. You should contact a service station. You will need special equipment to diagnose and flash your computer.

Dismantling and replacement

If one or another equipment fails, you must first check the condition of the fuse responsible for it.

In practice, removing and removing an unusable fuse or relay is not difficult. To do this you need:

- Raise the hood and disconnect the minus from the battery. Since you are working with the fuse box responsible for electrical equipment, the car should not be energized at this moment;

- Find the mounting block. It is located in the engine compartment opposite the driver's seat directly under the windshield. The top of the block is covered with a plastic cover. To remove it, simply press the latches on the sides;

- Remove the cover and look at the back side. There is an electrical diagram showing the location of one or another fuse or relay. Just find the element that is responsible for the failed equipment according to the tables above;

- Remove the fuse. All mounting blocks are equipped with special pliers. Manually removing fuses is not recommended. The relays are removed by gently rocking up and down;

- Replace the failed component.

Fuse failure is determined by the melted filament. These are fusible elements that melt and make contacts, preventing equipment from being damaged by excessive voltage.

That's it, all that remains is to replace the fuse block element, close the cover, replace the battery terminal and check the functionality of the equipment.

The windshield wiper kit consists of a gearmotor (an electric motor with a gearbox), arms and brushes.

The movement of the brushes is parallel. The electric motor of the cleaner is excited by permanent magnets, three-brush, with two rotation speeds

To protect the electric motor from overloads when the brushes freeze to the glass or there is high resistance to their movement, a thermobimetallic fuse is installed in the wiper

Fig. 1 Scheme for connecting the windshield cleaner and washer: 1 - electric motor for the windshield washer; 2 - electric motor for windshield wiper; 3 - mounting block; 4 - ignition switch; 5 - ignition switch unloading relay; 6 – windshield wiper and washer switch; Short circuit – windshield wiper relay; A - to power supplies; B - the order of conditional numbering of the plugs in the block of the wiper motor

The circuit diagram for switching on the purifier is shown in Fig. 1.

The cleaner has three operating modes: I – intermittent mode, carried out in positions II and III of switch lever 3

This mode is provided by an electronic relay K3 type 525 3747 installed in the mounting block.

This relay also turns on the wiper gear motor (low speed) when the windshield washer II is turned on - mode - constant, with low speed of movement of the brushes, carried out in position IV of switch lever 6.

In this case, the supply voltage is supplied to the electric motor brush located in the geometric neutral III - mode - constant, with a high speed of movement of the brushes. Occurs in position V of the switch lever 6. In this case, the supply voltage is supplied to the brush, offset from the geometric neutral

A relay is used to unload the contacts of the ignition switch

Causes of fan malfunction

There are times when the radiator cooling fan runs constantly. This is also wrong. What to do in this case? What is the cause of the problem?

The temperature sensor may be damaged. This is indicated by a constantly burning light sensor. In this case, simply replace the temperature sensor or injection system unit. The relay may need to be replaced. Also, the contacts on the radiator switches that trigger the relay may not open. To solve the problem, you will need to replace the thermal relay.

You will need to remove it to determine the cause of the fan failure.

90 degrees and remove it.

Fan motor connection diagram

If your car breaks down, regardless of whether the fan or something else stops working, you should contact a specialized workshop. Experienced technicians will always find the cause of the problem, select the necessary spare parts, sensors and carry out repairs.

Of course, many car owners want to repair their cars themselves; it gives them great pleasure and requires minimal costs. But in this case, there is a risk of making a mistake in choosing parts and making the correct diagnosis. A car enthusiast can spend a lot of time and effort, but as a result do not get the desired result. To prevent this from happening, it is better to contact a specialist.

The car is installed on a VAZ-2109. two fans

.

The first, more powerful one, is installed in the engine cooling

to increase air flow through the radiator core.

fan is installed in front of the heater radiator (“furnace”)

, its task is to pump heated or unheated air into the car. Both fans are driven by DC motors.

The fan, which is installed in a hole in the housing covering the radiator core, has a sensor for automatically turning on the engine in the electrical connection circuit. This sensor is screwed into a threaded hole located in the right radiator reservoir because the coolant temperature will be at its highest when the thermostat is activated. The fan turns on without a driver. The sensor should operate when the operating temperature of the antifreeze exceeds 90-95 degrees and send a signal to the relay to turn on the engine located in the mounting block. The electrical circuit for turning on the electric motor is protected by fuses No. 4 and No. 8 on mounting blocks of type 17. 3722.

If your VAZ-2109 car has a mounting block of type 2114-3722010-60, then the fan motor is turned on directly from the power sensor, without the participation of a relay. It's just not in the mounting block at all. The electrical circuit is protected by a fuse marked No. 5. If these electrical circuits are faulty, the fan will not turn on. The driver will determine this by reading the coolant temperature gauge. The arrow of this pointer will point to the red area of the scale. In this case, it is necessary to reduce the load on the engine to idle speed, turn on the interior heater fan and open the tap, supply coolant to the stove radiator, start driving until it stops completely, and eliminate the malfunction. reasons for the malfunction.

You should start looking for the causes of malfunctions with the engine start sensor

fan. To do this, open the hood and disconnect the terminal from the sensor. To further test the sensor, you will need a piece of wire to short the two wires going to the terminal. Wrap the jumper with electrical tape to prevent it from touching the weight of the vehicle. Turn the ignition on and if everything else is fine, the fan will start. Moreover, in this case, it will work, it will work continuously as long as the ignition is on.

If the fan on the VAZ 2109 does not work, open the cover of the mounting block and check the serviceability of fuses No. 5 on block 2114-3722010-60 and No. 4, No. 8 on block 17. 3722. Look for the fuse number markings at the top of the cover. After making sure that the fuses are good and the fan is still not working, you need to check its motor.

To do this, you will need two insulated wires to connect the fan motor terminals directly to the battery. If the fan starts to operate, make sure that the air flow is under the hood of the car, and not vice versa. If the connection is incorrect, change the polarity of the wires connected to the battery. This can help you get to the repair site, and you can turn off the fan motor only by disconnecting the wires from the battery. In this case, the reason that the fan does not turn on will be either a faulty relay or faulty wiring.

Prolonged driving on an overheated engine when the VAZ 2109 injector cooling fan is not working is fraught with serious consequences. The engine may knock or jam, and then major repairs will be necessary. Therefore, if the temperature gauge needle moves steadily into the red zone, immediately turn on the heater at full power, stop in a safe place and allow the engine to cool. Do not open the expansion tank cap on a hot engine; overheated antifreeze may spill.

Sources:

https://avtoblokrele.ru/vaz/blok-predohranitelej-vaz-2109-2108-21099.html https://litezona.ru/rele-ventiljatora-vaz-2109-inzhektor-gde/

Starter activation relay VAZ 21083 (21093, 21099)

On a VAZ 21083 (21093, 21099) car and similar ones, the starter is turned on not directly, but through a relay.

Purpose of the VAZ 21083 starter activation relay

The starter switch relay is designed to reduce the load on the ignition switch contacts when starting the engine with the starter. Since the starter is the most powerful consumer of electrical energy in the electrical equipment of a car, if it was turned on directly, the ignition switch would burn out very quickly.

Where is the VAZ 21083 (21093, 21099) starter relay installed?

The starter relay for the VAZ 21083 (21093, 21099) car is installed on the engine compartment panel.

Where is the starter relay installed?

Starter activation relay device

The starter activation relay consists of a coil (copper wire winding) with a magnetic core located inside.

How does the starter relay work?

After turning the key in the ignition switch to the “Starter” (II) position, its contacts “30” and “50” close. Voltage is supplied to the starter activation relay (relay contact “85”). It is triggered (the contacts inside the relay are closed) and supplies voltage to terminal “50” of the starter traction (retractor) relay. The retractor is activated and the starter turns.

Starter activation relay wiring diagram

Starter relay malfunction

The most common malfunction of the switching relay is when the starter stops turning on.

Oxidation of relay contacts or ground

"Open" in the relay windings

Relay burnout due to short circuit

A “break” in the electrical circuit may also occur, which should be taken into account when diagnosing a malfunction.

“Culprits” of the malfunction of the VAZ 21083 starter relay

A faulty relay must be replaced with a new one; if the contacts are oxidized, we clean them and check its operation.

Applicability of the starter activation relay on VAZ 21083, 21093, 21099 vehicles

In the electrical circuit for switching on the starter of a VAZ 21083 (21093, 21099) car, a starter switch relay 111.3747-10, 97.3747-10 and their analogs are used.

Characteristics of the starter enable relay 111.3747-10

Rated voltage - 12 V

Operation voltage: no more than 8 V

Release voltage - 1.5 - 5.5 V

Load current - 20/30 A

Winding resistance - 85±5 Ohm

Notes and additions

The starter is the most powerful consumer of electrical energy in a car's electrical equipment (1.3 kW). When starting the engine, the current consumed by it can reach 400 A, which is a lot. Therefore, all connections in its electrical circuit must have reliable contact. Otherwise, the starter may “shoe.”