07/17/2021 10,530 VAZ 2109

Author: Ivan Baranov

Each car engine is equipped with a device for measuring the temperature of the power unit. This component allows the driver to detect overheating in time and eliminate this problem. What is the fan switch on sensor on a VAZ 2109 with a carburetor engine, what is its structure and how to replace it - read on.

[Hide]

Signs of a malfunction of the coolant temperature sensor (DTOZH)

The coolant temperature sensor (CTS) is not as simple as it might seem at first glance. Many people think that it is only responsible for turning the cooling fan on/off and displaying the coolant temperature on the dashboard. Therefore, if the engine malfunctions, they do not pay special attention to it. That is why I decided to write this article and talk about all the signs of a faulty DTOZH.

But first, a little explanation. There are two coolant temperature sensors (in some cases 3) - one gives a signal to the arrow on the dashboard, the second (2-pin) to the controller. Further we will talk only about the second sensor, which transmits information to the ECU.

And so, the first sign is poor engine starting when cold . How this happens is that the engine starts and immediately stalls. More or less works only with gas. After warming up this problem goes away. Why might this happen? The coolant temperature sensor may provide incorrect readings to the controller. For example, that the engine is already warmed up (temperature 90+ degrees). As you know, starting a cold engine requires more fuel than starting a hot one. And since the ECU “thinks” that the engine is hot, it gives it little fuel. This is what causes poor cold starting.

The second sign is poor engine starting when hot . Here everything is exactly the opposite. DTOZH may always submit underestimated readings, i.e. “tell” the controller that the engine is cold. This is normal for a cold start, but bad for a hot start. A hot engine will simply fill with gasoline. Here, by the way, error P0172 may appear - rich mixture. Check the spark plugs - they should be blackened.

The third sign is increased fuel consumption . This is a consequence that follows from the 2nd sign. If the engine is filled with gasoline, then consumption will naturally increase.

Fourth - random activation of the cooling fan . Those. The engine seems to be working normally, only sometimes the fan will turn on for no reason. This is already a direct sign of a malfunction of the coolant temperature sensor. The sensor may give erratic readings. Those. if the actual coolant temperature has increased by 1 degree, the sensor may “say” that it has increased by 4 degrees or may not react at all. So, if the temperature at which the fan turns on is 101 degrees, and the actual coolant temperature is 97 degrees (working), then, having jumped by 4 degrees, the sensor will “tell” the ECU that the temperature is already 101 degrees and it’s time to turn on the fan.

It’s worse if the opposite happens - the sensor can sometimes underestimate readings. The coolant temperature may already reach boiling point, and the sensor will “say” that the temperature is normal (for example, 95 degrees) and therefore the ECU will not turn on the fan. Thus, the fan may turn on when the engine is already boiling or may not turn on at all.

Replacement

It is not difficult to replace the DTOZH with your own hands on an injection VAZ 2109. Follow the step-by-step instructions to resolve any issues that may arise.

Removing the device

- First of all, check the condition of the fuses. It is not uncommon for them to burn out, which causes a failure of the coolant temperature sensor.

- Wait until the car has cooled down completely. Under no circumstances should you replace the DTOZH on a hot engine.

- Disconnect the wires going to your DTOZH. You just need to do this in a situation where, when you turn on the ignition, the temperature indicator needle begins to rise sharply and sometimes reaches the maximum level.

- If no changes occur with the arrow, the fault is not with the sensor itself, but with the wire going to it.

- If the needle starts to drop when you turn on the ignition, the coolant temperature sensor has failed and needs to be replaced.

- There is no need to remove half of the units to get to the DTOZH. Access to the device is free, there should be no problems.

- Drain the coolant from the system. This is an excellent reason to at the same time change the antifreeze for a new one, if necessary. If the coolant is fresh, use a clean container to drain it.

- Disconnect the wiring from the sensor.

- Using a socket, unscrew the regulator so that it can be easily removed by hand.

- Clean the device landing area. This usually accumulates a decent amount of dirt and dust, which can cause the new antifreeze temperature sensor to not work correctly.

- To clean, use any rag that does not leave behind lint or threads.

- Treat the nest with a degreaser.

- Insert the new regulator. The mistake of many is that, supposedly to increase the reliability of the installation, they seal the sensor with sealant. You shouldn’t do this, because this way the DTOZH can only work worse.

- Replace the power cord. Only if the check shows that it has a break or is damaged, it is better to replace the wire immediately. We do not recommend repairing it with electrical tape.

- Pour coolant back into the system. Even if you changed the coolant a couple of months ago, it is better to replace it with a fresh one at the same time. It definitely won't get any worse.

- Start the engine and check the operation of the new TOZ sensor.

Replacing the DTOZ yourself is a fairly simple process. You don’t have to spend money on car service services, plus you’ll get the necessary experience in car repairs yourself.

Modern cars have a microcontroller to control the operation of all vehicle systems. In order for the microcontroller to receive information from various vehicle components, a large number of different sensors are installed on them. One sensor indicates the temperature in the cabin, another is responsible for exhaust toxicity, the third monitors the position of the headlights, the fourth determines whether the driver is sitting in the seat or not, and so on. It gets to the point of insanity: the low beam light on the car burns out, but it won’t start. The controller throws an error, which is also not so easy to decipher. This is understandable - this is the bread and butter of automaker service centers. In this regard, the old VAZ 2109 looks very attractive: they have very little electronics. Yes, and that one is very primitive. The coolant temperature sensor has failed - no problem, the generator does not work - also a problem, drive until the battery runs out. For modern foreign cars this is impossible: the controller will see a malfunction, prohibit the engine from operating and will require the driver to eliminate the malfunction. Compared to the injection model, the carburetor VAZ 2109 has fewer sensors. Of these, the only one that really affects engine operation is the Hall sensor. The remaining sensors are needed to inform the driver about the state of the vehicle systems, or to turn on/off actuators. Let's list the sensors of the VAZ 2109 carburetor: 1. Hall sensor 2. Coolant temperature sensor. 3. Oil pressure sensor. 4. Fan switch sensor. 5. Reverse sensor. 6. Parking brake sensor. 7. Throttle valve limit switch. 8. Speed sensor. * Many people mistakenly claim that the VAZ 2109 carburetor has an idle speed sensor. It is not true. The VAZ 2109 carburetor has an idle speed solenoid valve. A valve is not a sensor, it is an actuator. It does not transmit its signal, but rather receives control voltage from the idle speed economizer. 1. I would call the Hall sensor the most important sensor in the VAZ 2109.

Without it, the car engine will not start. Remove every single other sensor and the machine will work. It will not work without a Hall sensor. The purpose of the Hall sensor is to transmit pulses about the rotation of the engine camshaft to the commutator. The sensor is designed to determine the moment a spark is formed by the switch. Without it, there will be no spark and, accordingly, the engine will not start. The sensor is installed in the housing of the ignition distributor of the VAZ 2109 and connected directly to the switch. In case of malfunction, we can easily replace it. 2. The coolant temperature sensor is designed to display the engine temperature on the panel.

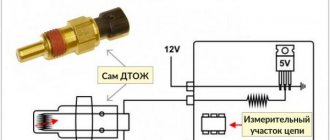

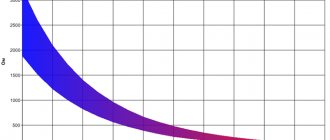

The coolant temperature sensor (hereinafter referred to as DTOZH) is a thermal resistance, that is, a resistance that varies with temperature. The engine is cold - the resistance of the coolant temperature indicator is high and the coolant temperature gauge needle does not move. As the engine warms up, the DTOZ resistance drops and the indicator needle rises vertically. If the temperature gauge stops showing the engine temperature, a DTO check is necessary. 3. The oil pressure sensor is designed to inform the driver about the presence of oil pressure in the lubrication system of the VAZ 2109 engine.

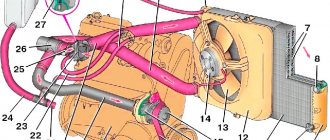

Classic VAZ 2109 models show oil pressure in the range from 0 to 5 atmospheres. VAZ 2109 shows only the PRESENCE of oil pressure, without indicating its value. 4. The fan switch sensor is installed in the radiator of the engine cooling system and is designed to turn on the fan when the coolant temperature is above 90 degrees.

The fan switch is a regular thermal switch that is closed at temperatures above 90 degrees and open at lower temperatures. 5. The reverse sensor is designed to turn on the reversing lights when reverse gear is engaged. This is also a regular limit switch, which is connected to ground when the driver engages the reverse gear of the VAZ 2109. 6. The parking brake sensor simply turns on the parking display lamp on the instrument panel of the VAZ 2109. Also a regular limit switch, activated by the parking brake lever. 7. The throttle limit switch is designed to determine whether the gas pedal is pressed or not. Connected to forced idle economizer.

8. The speed sensor is a gear shaft inserted into the gearbox and connected through a cable to the speedometer to display the speed of the VAZ 2109.

To home.

If you find any irregularities in the operation of the coolant temperature gauge on a VAZ 2109, you need to check its operation. Since this indicator works in conjunction with a temperature sensor, which, by changing the resistance, regulates the current in the circuit and, as a result, the readings on the device change. Vehicles with a “high” and “low” panel may have different indicators installed.

For low panel:

- When the resistance of the temperature sensor is 640-1320 Ohms, the indicator needle should be at the beginning of the scale, which will correspond to a cold engine.

- Further, when the sensor heats up and the resistance decreases to 77-89 Ohms, the needle should rise and stop before the red zone, which will correspond to the normal operating temperature of the engine.

- With subsequent heating and a decrease in resistance to 40-50 Ohms, the needle moves to the end of the red zone, that is, the temperature becomes critical.

For a pointer mounted on a high instrument panel , the resistance values should be as follows:

- With a resistance of 700 Ohms, which corresponds to a cold engine, the indicator needle should be at the beginning of the scale.

- When the resistance decreases to 77-89 Ohms, the needle moves to the beginning of the red zone.

Thus, having determined the resistance using a tester, identify deviations in the operation of the device and replace it with a new one. At this point, the repair work to check and replace the fluid temperature indicator on the VAZ 2109 car has been completed.

Checking the coolant temperature sensor

I will not show tables with sensor resistance values at a certain temperature, since I think this method of checking is not entirely accurate. The simplest and fastest way to check the DTOZH is to simply remove the chip from it. The engine will go into emergency mode, the fan will turn on, and the fuel mixture will be prepared based on the readings of other sensors. If at the same time the engine begins to work better, then the sensor definitely needs to be changed.

For the next check of the coolant temperature sensor, you will need diagnostic equipment. First, you need to check the temperature readings on a cold engine (for example, in the morning). The readings must correspond to the ambient temperature. A slight error of 3-4 degrees is allowed. And after starting the engine, the temperature should rise smoothly, without jumping between readings. Those. if the temperature was 33 degrees, and then suddenly became 35 or 36 degrees, this indicates a sensor malfunction.

How to change the coolant sensor

1. Open the hood and disconnect the battery terminal.

Read more: Where Volkswagen Golf is assembled for Russia

2. Remove the plug with wires from the external connector of the sensor and unscrew the sensor.

Many manuals suggest draining the coolant. This operation is not necessary since this action does not in any way affect the element replacement process. That is why draining the coolant is impractical and only increases the work time.

3. Install the new sensor and tighten its mounting cover. Connect the plug with wires to its connector.

4. Connect the battery terminal.

This completes the replacement of the coolant level sensor. As you noticed, this is not a complicated procedure at all and is performed without the help of car service specialists.

Note: If the coolant level in the tank has dropped to o or below, then when the ignition is turned on, the corresponding indicator lamp in the on-board control system display unit should light up. Otherwise, the display unit (see “On-board control system display unit - removal and installation”) or the coolant level sensor is faulty, or their circuit is faulty. The terminals in the sensor wiring harness block may have oxidized.

To complete the work, you will need a multimeter (in voltmeter and ohmmeter mode).

Coolant temperature sensor VAZ 21083, 21093, 21099, injector

The coolant temperature sensor (DTOZH) is an element of the electronic injection engine control system (ECM) of VAZ 21083, 21093, 21099 vehicles.

Based on its readings, the control unit (ECU) determines the thermal state of the engine and calculates the required amount of fuel mixture for injection and ensuring normal operation engine in different modes.

Coolant temperature sensor (DTOZH) VAZ 21083, 21093, 21099, injector

— Temperature sensor location

On VAZ 21083, 21093, 21099 vehicles with injection engines, the sensor is installed in the coolant outlet pipe between the thermostat and the block head.

— DTOZH device

It is a thermistor - a resistor with a negative temperature coefficient, the resistance of which changes with increasing or decreasing temperature. When heated, the resistance decreases, when cooled it increases. For example, at plus 100 gr. – resistance 180 Ohms, at minus 40 – resistance 100700 Ohms. On one side of the sensor there are two contacts; on the other (located in the coolant flow) there is a sensitive element.

Possible sensor malfunctions

The temperature sensor is usually installed between the cylinder head and the thermostat. It has two contacts. Each of them performs its specific function. So, the first one is needed to give readings to the control unit. The second one turns on the fan.

Note: next to it there is a single-contact sensor, which is usually confused with the second one.

The main purpose of the sensor is to cool the liquid, since the colder it is, the richer the fuel mixture. However, in some cases the sensor does not function well. Let's look at possible problems:

- The electrical contact located inside the sensor is torn or has a small crack. In the first case, the sensor burns out completely. In the second, it continues to work, but due to poor contact it gives incorrect or inaccurate data.

- Insulation violation. If the wiring is poorly insulated, this can lead to a small short circuit, and as a result, the sensor burns out.

- Broken wires near the sensor. As a result, the sensor loses the ability to influence the fan. Therefore, the second one does not turn on when it needs to. The result is overheating of the car.

Lada 2109 › Logbook › First problems. Coolant temperature sensor

The entry will be without photos, since I didn’t take any photos and didn’t think it could be useful. I’ll say right away: yes, in my particular case the whole problem was in the DTOZH. Neither the mass air flow sensor, nor the DPKV and TPS and cleaning the throttle valve also did not help

The car stalls while driving, kicks, increased speed

After I bought a nine, I discovered that it had high idle speeds, about 1500-1700, sometimes under 2000. At that time, I couldn’t check anything on the go, since I was still studying at a driving school, I didn’t have a license. As my good friend (also the previous owner of the car) told me, most likely the whole issue was in the mass air flow sensor, which consistently showed 1.035v, with the norm being 1-1.01v

Until I started driving it, I was also convinced of this. But on the second day of operation, interesting things began to happen: while the car was moving, when I pressed the gas pedal, it began to go crazy... It was shaking all over, the engine refused to turn, the speed dropped, and eventually the car stalled. It started up in about 30-40 seconds, with great difficulty. If, nevertheless, it started, then the revolutions were approximately at 1900 at idle, on a warm engine

In general, the problem was intermittent, and sometimes I could drive for half a day normally, but for other half days it started all over again

As I wrote earlier, I was sure that the mass air flow sensor was to blame for everything. I have no experience, so, to be sure, I asked several people, they all agreed on one thing

Okay, I called the dealership, found out about availability and price, and the next day I was about to go, when suddenly I had the urge to question the theory with the mass air flow sensor. I read a lot of forums and realized that a voltage of 1.035V is quite tolerable, people change the sensor with a voltage of 1.1V, and up to its value they do not experience any problems other than increased consumption

Okay, let's say we exclude the mass air flow sensor, then what do we have left? Injection machines are rich in various sensors, so I went deeper... I read about the possibility of poor contact of the crankshaft position sensor. I go out, open the hood, remove the chip from the sensor, and inspect it. Dirty, but looks healthy. I put it back, start it, the car turns at 1700, as it was. I fiddle with the sensor, it doesn’t stall, everything is fine. Okay, let's rule it out, read on

Malfunctions

There are several main malfunctions that lead to failure of the coolant temperature sensor. Namely:

In the summer, a failure in the operation of the diesel engine is rarely noticed, but in winter it becomes much more difficult to start the engine.

Signs of breakdown

How can you determine that the coolant temperature sensor has stopped working normally or has completely burned out?

Before making final conclusions regarding the breakdown or malfunction of the DTOZH on the VAZ 21099, be sure to carry out verification activities.

Examination

Today, VAZ 2109 car owners use two methods to check the condition of the coolant temperature sensor. Let's say right away that the second one is more reliable, but the first one is easier. Decide for yourself which of the methods presented below to use.

Verification method

Your actions

According to the table, check whether the resistance corresponds to that required at a particular temperature of coolant or boiling water.

Temperature (in degrees Celsius)

Resistance (Ohm)

If there are deviations from the norm, we conclude that the sensor no longer performs its functions properly and therefore requires mandatory replacement.

Signs of a malfunctioning coolant temperature sensor

Electronic devices for measuring the temperature of antifreeze circulating through the engine water jacket have been used on cars since Soviet times. The breakdown of this element has always been considered a serious problem, since without temperature control in the cooling system, the engine can easily overheat and damage the piston group. Therefore, it is important for a novice motorist to know how to identify the symptoms of a malfunction of a temperature sensor in time, and changing it will not be difficult.

Hall sensor VAZ 2109 (carburetor)

Its malfunction can cause problems in the carburetor. And it is very difficult to determine that this tiny detail is to blame. Perhaps, by the method of elimination. Sometimes they suggest checking its operation using a special device.

A simple way to check the performance of the Hall sensor of a VAZ 2109 (carburetor)

Take a sample with a light bulb. Its plus and minus (these are the extreme contacts) on the plug are connected to the distributor. There should be a gap between the center wire and ground. After this, you need to close the “minus” and the center. terminal. A spark will appear on the wire or spark plug. If it appears, the Hall sensor needs to be changed. If not, check further.

However, it also happens that the sensor works, but incorrectly. Here you can find out only by replacing.

If you do not know where the Hall sensor is located on a VAZ 2109 (carburetor), the photo below will help you.

"Hall sensor" number 8 in this photo

The price for a VAZ 2109 Hall sensor (carburetor) is usually low - about 120 rubles.

This photo shows a VAZ 2108 breaker plate with a Hall sensor:

Fan switch on VAZ 2109 (carburetor)

If you are interested in replacing the VAZ 2109 carburetor fan switch sensor, many are interested in whether it is possible to change it without draining all the coolant?

The answer is yes. But you will lose some coolant during the replacement process. This sensor is essentially an ordinary thermostat. There are special toggle switches on sale that can be used to turn it on forcibly.

Fan switch on VAZ 2109 (carburetor)

Sometimes you just need to take everything apart and clean it. Dirt and scale may get on the sensor. In any of these cases, even if you need to change the sensor, there is nothing wrong with that. The part itself is very cheap; it can be replaced either by the driver himself or by car workshop workers.

You can also read on this topic:

What to do if the idle speed of a VAZ 2109 (carburetor) fluctuates?

Accelerator pump for carburetor VAZ 2109 (Solex) for acceleration

VAZ 2109 (carburetor) does not start, what should I do?

The idle speed sensor for VAZ 2114 costs about 350 rubles

Mitsubishi Pajero 3rd generation 1999-2006 with monocoque body

Share on social networks

Alex S January 9, 2014

Published in: Useful tips and car devices

Tags: Advice for motorists

Operating principle and functions of the device

The design and operating principle of the temperature meter have changed little since its first use on a car. Due to modern materials used in the manufacture of the sensor, it has decreased in size, and the accuracy of the readings has increased. The device is a thermal variable resistor enclosed inside a metal case with a threaded tip . When heated, the thermoelement reduces the resistance of the electrical circuit, which allows the electronic control unit (otherwise known as the controller, ECU) to determine the temperature of the coolant.

The following functions depend on the operation of the temperature sensor:

The design of a modern car may provide for the installation of several heating meters responsible for certain functions. Their location varies:

It is not difficult to distinguish thermocouples from other types of sensors . All devices built into the engine cooling system and connected by wires to the controller are designed for temperature measurements. The only point: when you start looking for the location of the temperature meter for the purpose of checking, do not confuse the device with the knock sensor built directly into the cylinder block. When a machine has several thermal elements, their functions are usually distributed as follows:

Most low- and mid-price cars use one temperature sensor that performs all functions simultaneously. Usually it is located on the thermostat housing or on the upper radiator pipe .

What symptoms indicate problems with the sensor?

During long-term operation of the car, obvious and indirect signs may be observed indicating problems with the temperature sensor or its electrical circuit. The first ones directly indicate the need to check the functionality of the device:

If your car exhibits the listed signs of a malfunction of the coolant temperature sensor, then feel free to proceed to diagnosing it and fixing the problem, which will be discussed below. Indirect symptoms may indicate a breakdown of the meter or other elements of the cooling system or power unit. Here are the most common ones:

The serviceability of an electronic temperature meter can be checked at home. If indirect symptoms of a malfunction are observed, the test will help to identify them or exclude them from a number of parts that are “under suspicion.” If you successfully check the problem, you will have to look elsewhere or contact the nearest auto repair shop.

Video “Visual instructions for replacing the device”

You can learn how to replace the sensor yourself at home from the video below (the author of the video is Thoughts and advice from Mustafa Murtazaev).

The cooling system is responsible for the optimal temperature regime of the power plant, at which the power output is maximum. This system includes a radiator cooling jacket and pipes through which fluid circulates. Circulation is provided by a pump driven by the crankshaft.

Various types of coolant temperature sensors

The system also includes a thermostat, which ensures quick warm-up of the engine by shutting off the pipeline going to the radiator, while the liquid circulates only inside the cooling jacket. When a certain temperature is reached, the thermostat opens the pipe, after which the liquid circulates in a large circle, including the radiator.

The radiator cools the heated liquid. To cool the liquid faster, a fan is installed on the radiator, which creates additional air flow. But this fan does not always work; it turns on only when the liquid temperature exceeds a certain value.