Clutch pedal squeaks - causes and solutions to the problem

Hi all. I recently talked about the reasons for clutch pedal failure, as well as ways to solve this phenomenon. Today I decided to supplement the series of articles about the clutch with another, no less relevant topic - the creaking of the clutch pedal.

You will learn about the reasons why the clutch pedal squeaks and how to get rid of it.

I’ll say right away that the creaking of a pedal, whether it’s a clutch or a brake, in most cases does not affect its functionality and, by and large, is a common irritant that infuriates many motorists. Creaking or grinding of pedals rarely indicates serious damage, but before you give up on it with the words “I still have nerves of iron,” I recommend making sure that the problem is really not worth attention.

Other causes of squeaking

What causes a hard clutch pedal?

tight clutch pedal: causes of malfunction tight prior clutch causes If everything is perfect in the calculations, and the unpleasant sound does not leave you behind, then you need to look for other culprits:

- Plastic pedal bushing. It can “get used” to the bracket and make squeaks. Everything is quite simple here, we are looking for the attachment point, it is probably loose. Let's pull it up. Then be sure to repeat the procedure with the cable

- Tip lead. You will notice this at the first stage. If it squeaks, then it needs to be changed. Fortunately, there are plenty of such parts on sale, and the replacement process itself is not difficult. Unscrewed the old one and screwed on the new one. Then again measure and adjust according to the instructions above

- Loss of input shaft lubrication. This is already a problem with the box itself. Here the solution is clear: lubricant.

If you have carried out all these repairs, but still haven’t gotten rid of the problem, then the best advice would be to visit a car service center or an official dealer. Tell the technician what you tried to fix on your own, but did not achieve results. Then he will immediately look in other places and will not spend much time on repairs.

Clutch pedal creaking - causes

The main reason in the vast majority of cases is the drive, which can be either mechanical or hydraulic. The force you exert on the pedals is transmitted to the clutch fork via a cable or hydraulic system. Despite the fact that hydraulic and mechanical drives have different designs, they have the same squeaking noise. On models such as: VAZ 2110, 2112, 2114, 2115, a mechanical cable clutch is installed. In some models, in order to compensate for friction lining wear, the manufacturer installs a mechanism that does not require adjustment. This clutch is equipped with: Priora, Granta, and also Kalina.

When the driver notices that the clutch pedal is creaking, this already indicates that the problem has reached a certain point. Creaking is associated with increased wear of working parts (for example, the fastening mechanism), moisture on the rubbing surfaces, as well as with other reasons for which increased friction occurs. Often pedal squeaking occurs due to the return mechanism.

Such sounds most often occur not when pressing, but when releasing the pedal, just at the moment when the clutch mechanism is released from the load. If we talk about the pedal assembly, then only the mechanical connections, as well as the return spring, can creak there. The problem of squeaking itself is unpleasant because it is extremely difficult to get to the pedal unit. Working in a confined space is not easy, so the work requires a lot of strength and patience.

The clutch pedal squeaks due to wear on the mounting mechanism. For most VAZ models, the pedals are mounted on suspension brackets and axles. Either a plastic bushing or lubricant is responsible for the pedal sliding on the axle. By and large, plastic bushings do not provide for the presence of lubricant, but if you add it, it will not be worse. A squeaking clutch pedal can occur even on new cars in which everything is working properly. You can remove squeaking and grinding noises by applying lubricant or replacing the bushing and spring; the most important thing is to find out exactly where the creaking is coming from. The lubrication itself is carried out after complete dismantling of the pedal block along with all mechanisms. The work is complicated by the fact that the dismantling process takes a lot of time and is considered very labor-intensive. If you don't want to remove all the pedals, you can try lubrication using a syringe. Apply oil to the rubbing parts, inside the bushings, and also where you think it is necessary. We remove the remaining lubricant with a rag, after which we check whether the clutch pedal squeaks or not.

If nothing has changed after lubrication, we can assume that the reason is the return spring. The spring may hit something or squeak on its own. We lubricate the spring, if necessary, with silicone grease or WD-40, but the effect will most likely be short-lived. Therefore, it is better to use more serious lubricants such as graphite or CV joint lubricant.

The cable creaks. In some cases, creaking, grinding and clicking noises are associated with malfunctions of the mechanical drive. The trouble in this case is that the cable can creak both outside and inside the cabin. Full lubrication of the cable along its entire length will help correct this situation. The procedure is not complicated and does not take much time, so if this is the reason, then you can consider yourself lucky. For convenience, the cable is disconnected from the clutch fork, after which it is lubricated from the engine compartment. If the cable is old and shows signs of wear, lubrication is hardly advisable, it would be better if you completely replace the clutch cable. Unprotected working surfaces of the cable that are outside the protective casing should be lubricated with waterproof grease.

The creaking of the compensating mechanism. If your car has such a mechanism (it is located under the hood or near the pedal), the new cable may make unpleasant sounds and clicks, similar to squeaking or grinding. The problem in this situation is due to the fact that the mechanism is not worn in and requires lubrication of the compensation mechanism.

If the creaking of the VAZ clutch pedal is not associated with any of the above problems, there is a suspicion that unpleasant sounds are generated in the crankcase area. Such a squeak can be produced, for example, by the clutch fork. The difficulty in this situation is that you can check whether the problem is or not only after completely dismantling the clutch. There are indeed some tricks, such as lubrication without removal, but they require certain skills and accuracy. The trick and dexterity lies in the ability to lubricate the fork with oil without removing the gearbox. However, if it is not the fork that is creaking, but another mechanism, most likely you cannot do without removal.

The fork is lubricated as follows. We take out the rubber plug, then fill the syringe with lubricant and carefully apply a few drops to the clutch fork axle. For cars whose forks do not have an axle, lubrication occurs a little differently. Using a powerful screwdriver or mounting tool, the fork is moved to the side, after which it is lubricated with a thick Litol-type lubricant at the point of contact of the fork with the rod.

Source: vaz-remont.ru

Solution

In almost all cases, the problem of a squeaking clutch pedal can be eliminated with the help of lubricant. To do this, you need to lubricate all intensively rubbing parts.

Experts recommend using thick grease (CV joint or something like that) as a lubricant. If the car was designed in such a way that it is impossible to get to the pedal elements or spring, do not despair - there is a way out. Use a slotted screwdriver for this. Apply a little lubricant to its metal part, after which you can reach the necessary places with a screwdriver.

There is also a possibility that the squeak does not come from the pedal, but from the clutch fork. During operation, it serves as a place for dirt and used lubricant to accumulate. Because of this, this unpleasant sound appears.

In order to eliminate squeaking in the clutch fork, it must be washed from dirt. Naturally, it is very difficult to reach it, so this must be done through the engine compartment. To clean, you can use carburetor cleaner - it will do the job perfectly. Once you have removed all the accumulated dirt, apply a coat of thick lubricant to the fork.

Other possible squeaks

In addition to the clutch pedal, the reasons for the appearance of squeaks we have already figured out, the reason may lie elsewhere. For example, if the clutch mechanism uses a cable drive, then it is often the cause of unpleasant sounds. If this is the case, simply changing the lubricant will not help solve the problem. To do this, it is necessary to replace the clutch cable.

If you hear a squeak somewhere from the engine, this indicates a faulty release bearing. To fix this problem, you will most likely need to replace the release bearing.

The clutch pedal may make peculiar noises due to the clutch actuator. This is due to the fact that all the work of the clutch is mechanical friction of the working parts. Naturally, the appearance of noise cannot be avoided. In order to get rid of annoying sounds, you will need to periodically lubricate the rubbing parts. Because you will not be able to control a constant level of lubrication - everything is washed off during operation.

There is a more difficult way out of this situation. Using a skilled turner, turn the bushing between the rubbing parts from a softer metal or polycarbonate. In this case, the occurrence of unpleasant sounds will stop, because the friction of different materials will not create such noise as two materials of the same density and structure create.

Many owners of Lada Granta, Kalina and Priora notice the creaking of the clutch pedal. Moreover, this problem may arise after the first kilometers of driving. We will tell you about the possible causes of this disease, as well as ways to solve it.

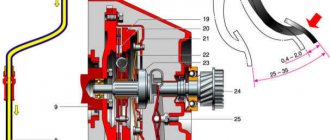

First, make sure your car's clutch is adjusted correctly. While holding the clutch cable end in an extended position, measure the size between the fork and the driver, it should be 27 mm. How to adjust the clutch cable is shown in the video:

https://youtube.com/watch?v=vYme_hsn6nM%23t%3D210

About 11% claim that the causes of clutch squeaking were in the clutch cable

Pay attention to the presence of a spring in the tension mechanism; Lada Kalina 2 and Lada Granta may not have it. It is worth noting that this spring is present on the clutch cable of the Lada Priora and the owners of these cars practically do not encounter a squeaking clutch pedal

If there is no spring, then it should be installed. Also, it would be a good idea to lubricate the clutch cable using a thin tube, or, if suitable, install a clutch cable from Lada Priora (catalog number: 21700-1602210).

Even less often (about 4% of owners) they solved the problem of a squeaking clutch pedal by lubricating the tip of the clutch cable. Apply lithol to the contact point between the plastic cable nut (No. 2) and the clutch fork (No. 1).

And about 3% of owners solved the problem with the help of lubricant (graphite) of the gearbox input shaft. To do this, you will have to remove the boot from the clutch fork lever (No. 6), and then lubricate it by inserting a tube from a lubricant can into the hole.

Most often (in 24% of cases), the creaking comes from the plastic pedal bushing, which rubs against the bracket. In this case, you should simply lubricate the rubbing areas with lithol.

In conclusion, I would like to note that it is better to start diagnosing a malfunction by determining the source (direction) of extraneous noise. Then you won't have to do extra work. Let us remind you that knocking noises on Lada cars can also come from the steering rack.

Engaging and disengaging a working clutch occurs silently. If squeaks and noises appear, it’s time for you to have the part diagnosed.

Clutch pedal creaking on a fresh Priora

Because You are not logged in. To come in.

Because you are not a trust user. How to become a trustee.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Because You are not logged in. To come in.

Advertisements on NN.RU – Auto

Extend the chassis (frame) on Gazelle Next, Gazelle farmer under a body of 4.2 m, 5.1 m and 6.2 m. Extend the frame on Gazelle Next, Gazelle Gas 3302. Price: 25,000 rubles.

A wide selection of hydraulic pumps and hydraulic motors of all series: spline hydraulic pump of right rotation. It is used in road construction and... Price: 1,000 rub.

A specialized company for the conversion of trucks produces extensions for man man, iveco and iveco truck tractors.

A specialized company for converting trucks into tow trucks invites you to install a tow truck platform on.

Source: www.nn.ru

Recommendations

Comments 25

Today I tried it, it didn’t help (( Granta Drive Active 60,000 mileage

A week later I started clicking again. Recently I was driving a Datsum taxi and it clicks like crazy and I sold it to Grant for fuck's sake

There is an opinion that after such an improvement the clutch cable breaks after a while. I don’t know if it’s a coincidence or not, but my cable broke in exactly this place, a couple of months after installing a piece of metal-plastic there. Although I can say in support that the clicking has stopped. And now the new one doesn’t crunch))

Crunched up to 47 thousand km. Then you can crunch and there are no more clicks or crunches. Everything became soft and quiet on its own

Interesting... My mileage is 43 thousand km. I should have waited))) out of curiosity, I’ll pull it out in a month and check it.

I’m not saying anything)) it happened to me personally)) I don’t even know if this will happen to you either or not)))

There was also such a problem. I replaced the spring with a stiffer one. It's been silent for six months now

Yesterday I set the gap to 27 mm and everything worked fine.

I'll check the gap and take it out for an experiment.

I had enough for a week

A week has passed, everything is ok. I read reviews of people who have been riding for 2 years and everything is ok. I'll also have to check the 27mm gap.

I generously lubricated the ratchet mechanism with graphite lubricant from Oilwright. Helped

Lubricated it didn't help. But it got rid of the squeak a little, yet the hose does not get rid of squeaks, but from clicks and gives softness to the pressure as the angle of travel of the cable changes.

This method is not for everyone, it didn’t help me, I replaced the cable with a new one, after 3k the same picture happened again. In the photo, three cars click, and one has an automatic machine.

I read your review. Well, the video helped me. Apparently it works for someone and everything is ok, for someone it doesn’t work and there’s no way to fix it.

Before I got behind the wheel of the Granta, I read the primer for it. The clicking noise is produced by the automatic wear compensator for the disc linings and the cable pull. It clicked every day for about two weeks, now if it clicks once every six months that’s it. Did not do anything!

I read your commentary before installation. It’s the click and not the clicks that I now have, listen to the video, but before it was all creaking and clicking. After driving for 2 months, it always feels silky and sometimes it even feels like the plastic is breaking with a crunch and being squeezed out. Now a week has passed and everything is ok. And one of the main advantages was the soft pedal. By this we simply change the angle of travel of the cable no more.

My pedal was always soft, there were clicks (on the new one) once for each squeeze. When I worked as a driving instructor, there were also clicks constantly, but one at a time, no more.

Now I also have one for squeezing. Well, I heard it myself.

I set the gap to 27 mm and filled the ratchet mechanism with oil from a syringe and silicone from a balloon. There were no clicks at the beginning of the stroke, and there was no squeaking.

Source: www.drive2.com

Clutch pedal on Priora

November 4, 2008, 16:00 #1

I bought the car in mid-December last year. Currently the mileage is 1800 km. Right now there is a problem that when the car warms up and drives for a while, then the clutch pedal starts clicking when it is released all the way. Has anyone encountered this and can you tell me what it could be?

February 6, 2009, 00:26 #2

I bought the car in October 2008. The clutch pedal started clicking when pressed after a month. It's most likely the pedal mounting bushing, but I haven't looked yet. When I look at it, I’ll tell you for sure.

February 23, 2009, 16:42 #3

Guys, I have the same thing, the clutch pedal clicks, I don’t know what to do! Tell me something?

February 23, 2009, 16:45 #4

there is a piece of plastic there that pulls the cable, so it clicks

23 February 2009, 19:41 #5

Over time it will get used, the clicks will be almost inaudible

23 February 2009, 21:26 #6

I also had clicks. It went away on its own and I didn’t even notice.

Naberezhnye Chelny RT

February 23, 2009, 10:03 pm #7

I also have this problem, it appears and disappears from time to time.

24 February 2009, 19:19 #8

It looks like it’s global, sometimes my skill also clicks.

March 2, 2009, 13:21 #9

I'm not the only one who has a clicking pedal in a Priora, I was told that when it clicks, the clutch cable is stretched, like a car. I don't know if this is true or not.

Vsevolozhsk Len. region

March 3, 2009, 5:22 pm #10

It really clicks when you're stuck in traffic jams. I lubricated the bushing and cable with CV joint grease - it became a little quieter and that’s it. Exactly global.

Clutch on Priora: design and principle of operation

The operation of the multi-stage gearbox mechanism is impossible without the coordinated actions of the clutch mechanisms. The start of movement and the braking process of any brand of car are carried out using these parts. The clutch pedal of Lada Priora, Tavria and other cars is suspended on an axle and is attached to the body using a bracket. Its service life depends on the correct position of the driver in the cabin. You should not keep your foot on the pedal for a long time, because the increasing load reduces the life of the clutch mechanisms.

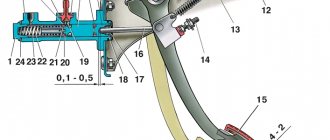

Replacing the clutch release fork Lada Priora, VAZ 2170, VAZ 2171, VAZ 2172

You will need: screwdriver, pliers.

1. Remove the clutch release bearing of the Priora car (see “Replacing the clutch release bearing of the Lada Priora”).

2

Carefully pry up the rubber protective cover 1 with a screwdriver and remove it from the fork lever 2 of the priora clutch release. Replace a torn or loose protective cover.

3. Squeezing the locking tabs on the inside of the Lada Priora clutch housing with pliers and prying them from the outside with a screwdriver, remove the plastic bushing of the fork axle. Replace the plastic fork axle bushing if it is severely worn or if the locking tabs are damaged.

4. Lifting the fork, remove its axle from the bushing pressed into the clutch housing of the VAZ 2170 and remove the fork by removing the axle, and then the lever from the holes in the clutch housing of the Lada Priora.

5. Remove the spring clip from the fork by squeezing its ends. Replace a broken or loose spring retainer.

6. Replace the Prior clutch release fork if fork lever 1 is bent or cracked or fork legs 2 are badly worn at the points of contact with the VAZ 2172 bearing clutch.

7. Press out the worn metal bushing, then press in the new one until it stops.

8. Before installing the fork, lubricate the metal and plastic bushings with grease.

9. Install the Lada Priora clutch release fork in the reverse order of removal

Make sure that the protrusion on the plastic bushing fits into the groove on the clutch housing of the VAZ 2171, and its petals securely fix the bushing in the crankcase from falling out

Source

Priora clutch device

The clutch briefly connects the engine and transmission when changing gears and for continuous transmission of torque when the vehicle is moving. The transmission remains intact and is subject to overloads. Clutch designs are frictional, hydraulic and electromagnetic.

The most common type is friction. It is located under the hood of the car. Magnetic polarity is used by electromagnetic, and the pressure of the working fluid is hydraulic. The clutch mechanism includes the following parts:

- basket;

- pressure plate assembly;

- driven disk;

- release bearing.

Each vehicle has a dry-type single-plate clutch with a central pressure spring, which is disengaged using a backlash-free cable drive with an automatic cable adjustment mechanism. The basket is a steel casing that contains a diaphragm-type pressure spring and a disk mounted on 3 pairs of plates. The basket is attached with 6 bolts to the flywheel and closed with an aluminum crater.

The upper part of the clutch pedal resembles a double-armed lever, at the end of which there is a finger. The drive cable for turning off the part is connected to it. The length of the cable is adjusted by a ratchet mechanism. The cable is in a metal sheath and has a polyethylene coating. Using a bracket, which serves as a limiter for the clutch pedal travel, its upper end is attached to the pedal assembly. A corrugated cover covers the lower end of the cable.

It is activated using a fork that rotates in two bushings. The upper one can be removed, but the lower one is tightly pressed into the clutch crater. When turning the fork, the driver exerts a force on the compression spring through the ball bearing. It is located on the clutch release clutch and is connected to the drive fork using a U-shaped spring. In a Priora car there is a sensor that will best indicate clutch malfunctions.

Instructions for adjusting the clutch on a VAZ 2114

Before starting work, we recommend that you familiarize yourself in general terms with what the system itself in the VAZ 2114 is and what specific functions it performs in the car.

Structure and functions of clutch

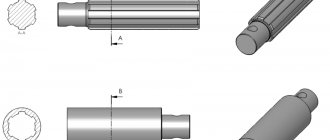

The mechanical drive of the VAZ 2114, when compared with hydraulics, has a much simpler, but equally durable design. It consists of:

- cable, adjustable in length in the sheath;

Cable location

- pedals that control the clutch from the passenger compartment;

- a device that controls the position and free play of the pedal;

- lever structure that transmits force from the pedal to the clutch fork.

The introduction of a cable into the design of the VAZ 2114 made it possible to eliminate complications with hydraulics, for example, very frequent leakage of fluid.

Symptoms of a problem

Obvious signs indicating that the clutch system needs adjustment are:

difficulties with turning on speeds; extraneous sounds when squeezing; worsening traction; incomplete inclusion; slipping, underpressure.

Usually, adjusting the pedal is enough to correct the situation.

Preparatory work

First of all, you need to choose a flat area. Conduct a visual inspection of the cable; it may have damaged strands; if there are any, it is necessary to replace it, because then it may come apart like a rope, which will reduce all repair work to zero.

Adjustment

The adjustment procedure itself is quite simple and there is no need for special knowledge and skills. The whole process consists of adjusting the length of the cable sheath in relation to the adjustment unit, as a result of which the characteristics of the pedal stroke change. If you reduce the length of the shell, then, accordingly, the working stroke of the pedal will decrease, and, naturally, if you increase the length of the shell, its stroke will also increase

It is important to determine the moment at which the pedal begins to move the 125-135 millimeters required for us

The length of the VAZ 2114 cable sheath is changed using the nuts located at the end of the control unit. From the very beginning, you need to loosen the lock nut, and then tighten or unscrew the adjusting nut. If you tighten the nut, the pedal will begin to rise little by little and, as a result, its stroke will begin to increase. If you unscrew the nuts, the pedal will begin to approach the floor of the car. It is better to carry out such work with an assistant. Once all work is completed, tighten the locking nut.

Troubleshooting clutch problems

The reason for an uncomfortable ride and the beginning of the moment of movement is a very tight pressing or, even worse, a loose clutch pedal, which can lead to the creation of an emergency situation on the roads. What is better: replacement or repair?

The design feature of the clutch is such that when the angle of inclination of the disc spring changes during wear, more force must be applied to press. In this case, the cable may break, the release bearing may be damaged, and the clutch pedal clicks and creaks. All these problems can be fixed.

To replace the cable, it is better to first remove the air filter. Using keys, remove the cable along with the wiring from the groove of the lever. To make repair work easier, it is better to first pull the clutch pedal towards you and remove it. Now you can freely remove the cable sealing cover and remove the wiring from the tip. When reinstalling, its end should be at the same level as the new, serviceable one.

Clutch sensor

It happens that when switching gears, the car for some reason begins to jump and twitch. The same signs are observed at low speeds. The whole reason is that the clutch sensor is faulty. It is located in the cabin, at the place where the clutch pedal axis is attached, and only on those cars that use E-gas. They often lack a throttle position and idle speed sensor.

A magnet that rotates with the drive gear and two Hall sensors, which convert changes in the magnetic field into an electrical signal and transmit it to the control unit, these are the components of the clutch sensor. With the help of such a signal, the electronic unit can show a real picture of the magnitude of the clutch stroke. The sensor works on the same principle as the gear shift indicator.

When driving, there is a load on the clutch pedal, a signal about the state of which will be transmitted by the sensor. It will determine the speed of the crankshaft and the engaged gear. If such a signal is not received, then it’s time to change the sensor. An open circuit, a short circuit in the electrical circuit, an abnormal clutch pedal height, a malfunction of the switch - all these indicators can be tracked by the sensor using a signal.

Clutch pedal play

Sometimes you can hear the clutch pedal clicking, or suddenly notice that it is not fixed and dangles, creaks unpleasantly. Why? There are several reasons.

Cause

| № | |

| 1 | Malfunction of the plastic sleeve |

| 2 | Wiring tip requiring lubrication |

| 3 | Lack of lubrication of the input shaft in the box |

| 4 | Pressed driven disk |

The cable, backlash-free clutch release drive of the Lada Priora has a ratcheting mechanism. In this case, adjustment for operation is not necessary at all. This mechanism has a small switch that makes a click, just like a computer mouse. You can adjust the cable yourself, and the clicks will disappear on their own.

The most common reason for a squeaking pedal is lack of lubrication. This can be solved by purchasing graphite lubricant in a can and carefully treating the parts. The Priora manufacturers modified the cable tensioning mechanism and installed a small spring on it. If the lubricant is lost, it causes a certain sound when pressed. The cable mechanism is also equipped with a metal bracket, which, under certain operating conditions, causes clicks.

Sometimes when you press the pedal you may notice that it falls down without much effort and does not return to its original position or even dangles or clicks. This means that the mechanical drive cable has broken and urgently needs to be replaced. Perhaps the spring flew off and burst or the power fork broke. If air gets into the hydraulic drive system, the clutch pedal clicks. In these cases, repairs are possible only in service centers or workshops.

Signs of a bad clutch

People who regularly drive a car immediately realize that something is wrong with it and the pedal has become tighter. In addition, problems can be determined by other factors:

- when you press the pedal, sharp grinding sounds appear that are uncharacteristic of normal operation of the system;

- the lever is pressed jerkily, there is no smooth movement;

- the free play of the pedal has to be adjusted frequently;

- when the pressure is released, the clutch engages jerkily;

- the clutch is slipping - this can be indicated by the smell of burning clutches and an increase in fuel consumption.

At the same time, for some cars a hard pedal is the norm, this applies to old domestic models - “classics”. But if tightness occurs in relatively new cars, both Russian-made and foreign, this is a reason to carry out diagnostics.

Sachs clutch

The production of clutches for various car brands also has its own innovations. The clutch, like all other mechanisms, wears out quickly, and every driver wonders how to choose the right mechanism. Driving style and operating conditions are directly proportional to service life. Therefore, Sachs specialists, taking into account all the wishes of drivers, have released completely new, environmentally tested flywheels, release bearings, clutch discs and slave cylinders, compact clutch units and other equally interesting design solutions. These new products include:

- MZ type clutch basket with pull-out action.

- XTend with automatic wear compensation.

- Dual-mass flywheel ZMS.

- Release bearing type CSC.

- Ultra-compact clutch unit (for sports cars).

Which clutch to install is up to you, but if the driver takes good care of his car, replacement can be done after 100,000 km. The clutch pedal is a kind of indicator of the technical condition of the engine and transmission.

It signals various malfunctions and requires prevention and constant monitoring. Competent and correct replacement of the clutch, using all the capabilities of these designs will extend the life of your car.

Source: 1ladapriora.ru

How to eliminate clutch squeaking in Renault Logan/Sandero?

The clutch is a highly loaded unit in a car! As a result of constant work, the mechanisms wear out and may produce extraneous sounds. If you hear squeaks or the pedal becomes too hard to press, then you need to inspect the clutch mechanism.

What could be the reasons for a squeaking clutch?

The clutch in Renault Logan and Sandero cars may make extraneous sounds for the following reasons:

- worn clutch cable

- clutch fork stop dirty

- Worn release bearing/clutch disc/clutch basket

First of all, determine by ear where the sound is coming from. If the sound comes from the pedal assembly, check the clutch cable for breaks or wear. Cable wear is one of the most common problems that lead to tight clutch release or squeaking in the pedal area. It happens that the cable itself begins to move along with the braid jacket and when it jams, a squeaking sound results. I recommend that at the first sign of tight squeezing or squeaking, immediately replace the clutch cable.

If the script is heard from the engine compartment and after replacing the cable the clutch is still pressed tightly with a squeak, then dirt has probably gotten onto the clutch fork stop. If so, then you can get away with simple cleaning and lubrication:

- Remove the clutch cable from the fork

- Remove the rubber boot from the clutch fork base

- Move the clutch fork to the left until there is space between it and the stop

- Clean the stop with a screwdriver and lubricate it with Litol or CV joint-24 lubricant.

Be careful: never lubricate the shaft on which the release bearing runs. It must be dry. Otherwise, clutch waste products (ferodo) will stick to the lubricant and act as an abrasive, wearing out the clutch.

To eliminate the creaking of the clutch fork, remove the protective boot and clean and lubricate the stop.

If, after replacing the clutch cable and cleaning the fork stop, the sound continues to annoy you, then it is likely that the release bearing is jammed or the release plate and clutch basket are worn out. In this case, only replacing or repairing the clutch mechanism will help.

How to remove crackling, crunching and squeaking noises from the clutch pedal on a Lada Granta

Good day to you, dear friends. Today we will talk about how to remove extraneous sounds (crunches, squeaks, crackles) when working with the clutch pedal of a Lada Granta.

Mechanics are generally a “sick” topic for domestic cars produced by VAZ. While making generally reliable and unpretentious gearboxes, assemblers sometimes make mistakes: they do not set the clutch pedals correctly, they spare lubricants on the working elements of the mechanisms, and they disrupt technological processes.

As a result, the consumer is forced to deal with extraneous noise when working with the clutch pedal and the gearbox as a whole. Today I will tell you what to do if the clutch pedal crunches or makes other unpleasant sounds.

Why does a squeak occur when the clutch is released?

Replacing spark plugs on Lada Priora, Kalina and Grant cars (8 valves)

Very often, along with a squeak, other problems associated with the clutch pedal may arise. Basically, the pedal can be hard to move and is pressed jerkily.

Why does a squeak occur when releasing the clutch:

- In this case, it is necessary to urgently undergo diagnostics, since with further operation of the car, the fork or the cable that connects the clutch pedal to the car parts under the hood may break.

- Most often, the squeak appears when the clutch pedal is released, that is, at moments when there is no pressure on it. When all the mechanisms are under pressure, they work more smoothly. As soon as the pressure decreases, a squeak occurs.

- There are several options to solve the problem. Of course, it is best to remove the pedal, disassemble it and lubricate all the components. However, this manipulation takes a lot of time; even experienced car enthusiasts can do the job for half a day.

Adjustment

How to remove extraneous sounds from the clutch pedal on a Lada Granta?

As everyone knows, the clutch cable drive circuit on the Lada Granta is equipped with an automatic tensioner (wear compensator) of the clutch cable.

As conceived by the designers, such a scheme simplifies the operation of the car; the owner no longer needs to independently adjust the gap on the clutch fork and adjust the clutch pedal. But nevertheless, problems still occur: the clutch clicks or creaks when pressed. Most often, assemblers are to blame for incorrectly setting the working gap on the clutch fork and skimping on lubricants during assembly. As a result, we get extraneous noise when working with the pedal.

In order to deal with the problem, you need to carry out a set of simple measures. First, we need to adjust the clearance on the clutch fork. This can be done either with or without removing the air filter housing.

If you decide to remove the filter housing, then you need to: remove the cold air intake pipe and the air supply pipe to the receiver, remove the wiring from the mass air flow sensor, disconnect the wiring harnesses that are attached to the housing and, releasing the rubber stops, remove the housing from the engine compartment .

To set the gap on the clutch fork, you need to pull the clutch cable all the way in the direction of travel of the car, and by unscrewing and wrapping the plastic wing, set a gap of 27 millimeters between the wing and the clutch fork.

After we have set a guaranteed working gap on the fork, we need to lubricate the elements in the pedal assembly. WD-40 will do the job. We need to apply lubricant to the clutch bushing and the plastic wear compensation ratchet. Also, if necessary, you can apply lubricant to the clutch cable sheath.

By performing this simple series of actions, you are guaranteed to get rid of noise when operating the clutch pedal and set the mechanism to the optimal level of operation. If the noise remains when you press the pedal, I advise you to contact an official service center, since the presence of such noise after all the necessary work may be a signal of a malfunction that will require replacement of the cable or pedal assembly.

How to stop squeaking when pressing the clutch?

Often the cause of a squeak is a cable on which the lubricant has dried. If it is not old, there is no need to completely dismantle it. Just take a syringe and lubricate the cable from the hood and interior.

How to remove squeaking noise when pressing the clutch:

- Push the nozzle of the lubricant bottle deep under the casing and inject the oil. After carrying out the manipulation, do not forget to treat the casing joint with a water-repellent agent to prevent water from entering.

- Usually aerosols help little in such cases, since they do not completely penetrate under the casing. Two drops of oil will save the situation and eliminate the squeak. It is more difficult if the creaking does not occur in the pedal itself, but in the clutch mechanism.

- Typically, this situation is often observed in VAZ cars, where the creaking is caused by the clutch fork and bushing. Lubrication in this area is very difficult due to limited access.

Control pedals