A LITTLE ABOUT THE OPERATION OF THE FUEL SENSOR

The latest developments by the designers of the automobile plant in Togliatti have brought the produced models closer to the best European models, but annoying, minor breakdowns can add “a fly in the ointment.” These fully include problems with the gasoline level sensor in the car tank.

It is located in the same block as the fuel pump. It includes a movable lever with a float, a resistor and a contact group, which turns on the signal lamp for the gasoline reserve in the tank. Among the most common malfunctions of this unit, the most common are problems such as resistor breakage, oxidation of the moving contact or output terminals. It is very rare that the float in the fuel level indicator loses its seal.

In any case, to repair or service this unit, it must be removed from the fuel tank. To perform this work, remove the rear seat cushion and upholstery that blocks access to the gas tank cap. When performing this operation, do not forget that you are working with a flammable substance. Fire safety rules must be strictly followed.

Unscrew all the screws securing the cover, move it slightly forward and remove it from the fuel tank. Before removing the fuel block, it is necessary to relieve the pressure in the fuel line. There are several ways to do this, and the simplest of them is to leave the car idle for about 4 hours.

Disconnect the wires and fuel line from the module, being careful not to spill any remaining gasoline in the hoses. You need to pull out the fuel pump carefully so as not to damage the float. Replacement of the fuel sensor is carried out using a screwdriver with a thin blade.

How does this happen:

- Use a screwdriver to move the locking ring and make it possible to remove the cover from the fuel module;

- Remove all the wires, release the latches on the cover and remove the sensor itself along the grooves;

- The next step is to remove the meter from the block.

To install a new fuel sensor, everything must be done in reverse order.

HOW THE REGULATOR WORKS

The fuel pressure regulator, or RDT VAZ for short, is a device in the form of a valve with a diaphragm. Its installation location is in the fuel supply rail (fuel rail). The membrane is “pressed” from both sides. On one side the pressure of gasoline presses, and on the other side a spring with air from the intake manifold “rests”.

Location of the RTD in the fuel rail

If the valve completely fails, dumping fuel back into the tank becomes impossible. The pressure of gasoline increases approximately twice, and this leads to increased consumption.

When the valve stops holding pressure, there will be free circulation of gasoline in the system, and this is a clear decrease in the operating fuel pressure. This will cause a loss of engine power.

PRESSURE IN THE FUEL LINE VAZ 2114

The pressure in the fuel line of an injection engine is an important parameter - if it is low, normal injection by injectors into the cylinders of an internal combustion engine (ICE) will not be ensured. And its high degree is also dangerous - fuel can flood the entire engine compartment, and then a fire will occur.

Car owners may have a question about how to check the pressure in the fuel rail, within what limits should the readings be, what is used to check it, and how to determine what may be faulty in the fuel line? So, in order.

VEHICLE DIAGRAM

First you should know how the fuel system (TS) works and what elements it consists of. The vehicle includes (elements in order, starting from gasoline intake to its direct injection):

- Gas tank (in the VAZ model 2114 it is located under the bottom of the trunk);

- Electric fuel pump (located in the gas tank);

- Coarse filter (represents a mesh that is located on the intake part of the pump);

- Fine filter (located immediately after the gas tank, located below the trunk, between the rear of the muffler and the fuel tank);

- Fuel rail or rail (TR), it distributes gasoline among the cylinders, it can be steel, aluminum or plastic;

- Injectors (there are four on model 2114);

- Fuel pressure regulator (it maintains the required gasoline pressure in the system for normal injection through the injectors into the cylinder).

All elements are connected to each other by a fuel line, and in the entire chain, after the pressure regulator (RDT), there is also a return hose through which excess gasoline is discharged into the tank. After the ignition is turned on, fuel passes through the system to the injectors (therefore, there is pressure in the system even when the ignition is on), and when the engine starts, the electronics send a command to the injectors, and gasoline enters the cylinders.

HOW AND WHAT TO CHECK THE PRESSURE IN THE VEHICLE

They check the pressure in the fuel rail of the VAZ 2114 with a pressure gauge - it is most convenient to connect it on the ramp, and not somewhere else in the line. At the rear of the ramp, in the direction of travel of the car, there is a fitting with a thread and a valve, closed with a plastic cap. When measuring, the pressure gauge adapter is screwed onto the fitting. The pressure gauge is easy to assemble yourself. For this you will need:

- The measuring device itself with an arrow - a tire pressure gauge with a maximum reading limit of 6 to 10 kgf/cm² is suitable;

- A piece of gasoline hose 50-70 cm long;

- A fitting for checking the pressure, which will be screwed into the ramp;

- Two clamps.

We assemble all the elements, tighten the clamps, and the pressure gauge is ready for use. That's it, now you can take measurements. To do this you will need tools:

- Wheel valve cap.

- Thin screwdriver or metal pin;

- A wrench with a fitting size (usually 17 mm):

- Pressure gauge.

To measure the pressure in the fuel rail, you need to:

- Turn off the engine, turn off the ignition;

- unscrew the cap, relieve pressure in the VAZ 2114 fuel rail by pressing the valve with a thin screwdriver;

- Unscrew the spool with the valve using the wheel valve cap. A rag will come in handy - when you dump it, fuel will spray out of the valve. To relieve pressure, you need to press the valve smoothly, releasing the pressure;

- secure the pressure gauge fitting with a wrench to the rail. Now you can start the internal combustion engine and measure the pressure in the fuel rail.

WHAT SHOULD BE THE INDICATORS IN THE PETROL HIGHWAY OF VAZ 2114

There are several modes in which you will need to check the pressure in the VAZ 2114 fuel rail in order to judge vehicle malfunctions. Make a measurement:

- When the ignition is turned on;

- At idle;

- On re-gassing of internal combustion engines;

- When the ignition is turned off.

The readings should be approximately like this:

- With the ignition on, approximately 3 kgf/cm²,

- During operation at idle speed from 2.8 to 3.2 kgf/cm²,

- When the engine speed increases, it can drop to 2.3-2.5 kgf/cm², when releasing the gas it returns to a reading of about 3 kgf/cm²,

- After stopping the engine, the pressure should drop very slowly. A rapid drop indicates a malfunction of the RTD.

Too low pressure in the fuel rail indicates that:

- The performance of the fuel pump has decreased,

- The fine filter is clogged,

- The RTD is faulty.

If the filter becomes clogged, the fuel injector rail also becomes clogged. In order to clean the vehicle of debris and dirt, it is necessary to remove the fuel rail and clean the injectors.

These parts are cleaned efficiently in car services where there is special equipment. The equipment includes a stand where they can be tested for injection performance. The clogged elements are then cleaned in the bathroom using ultrasound.

Removing the ramp to clean the injectors

You can clean the injectors yourself, but you will have to remove the rail in any case. Typically, car enthusiasts use a special liquid to clean carburetors.

OPERATIONAL CHECK

Let's briefly look at the question of how to check the fuel pressure regulator of a VAZ 2114. This fully applies to the VAZ 2113 and VAZ 2115 models. On carburetor engines, the gasoline supply could be checked by disconnecting the fuel hose from the carburetor to see the stream of gasoline supplied. On injection engines this technique is no longer acceptable. The VAZ 2114 fuel pressure regulator is checked by measuring the pressure of the supplied gasoline with a pressure gauge.

Let's look at how to check the fuel pressure regulator yourself in some detail:

- The plug on the fitting is unscrewed, and at the same time the ring that serves as a seal is checked for elasticity;

- The spool valve is unscrewed from the fitting in much the same way as from a tire;

- The pressure gauge is secured to the fitting with a clamp and the generated gasoline pressure is checked in different modes.

Gasoline pressure indicators are marked on the RTD body for comparison with the results obtained during testing. If the readings differ from the recommended ones, the VAZ fuel pressure regulator must be replaced.

Symptoms of RTD malfunction

A faulty VAZ-2114 fuel pressure regulator does not pose a critical threat, but its failure disrupts the stable operation of the engine. Symptoms of RTD failure may include:

- difficult starting of the power unit;

- unstable crankshaft speed at idle;

- reduction in engine power characteristics;

- loss of dynamics;

- the occurrence of “dips” when pressing the accelerator pedal;

- increase in fuel consumption.

Having discovered the listed signs of an RTD malfunction, you should diagnose the device and determine the cause of the failure.

ABOUT REPLACING RTD

Replacing the VAZ 2114 fuel pressure regulator is carried out with the engine cooled down and the pressure in the fuel system removed. Let's look at how to remove the fuel pressure regulator.

To do this you need:

- Disconnect the battery terminals;

- Remove the brake booster hose;

- Unscrew the nuts on the gasoline drain pipe. In this case, you must carefully unscrew the nut and hold the hose. There may be gasoline left in the system ;

- It is necessary to securely fasten the washer and tube;

- After unscrewing the bolt installed on the clamping bar, remove it;

- You should slightly loosen the nut holding the regulator and drain tube;

- Remove the screws that connect the RTD and the ramp;

- Remove the nut with care and you can remove the RTD with the ramp.

The new regulator is installed on the fuel rail in the reverse order.

The operation of replacing the regulator will not pose any particular problems for experienced car enthusiasts, but if there is even the slightest doubt about your competence, it is better to turn to specialists.

Pressure regulators today do not belong to the category of particularly scarce spare parts. You can purchase them in retail chains, car markets, and service centers. The cost of the regulator can range from 500 to 700 rubles.

Purpose of the regulator

A device such as the VAZ 2114 fuel pressure regulator is designed to maintain the same level and, if necessary, correct the gasoline pressure in the system. Structurally, it is a mechanism of a membrane and a valve located inside the fuel rail (also known as the fuel supply rail). On one side, the pressure of gasoline presses on the regulator membrane, and on the other, a spring.

If the fuel pressure in the system is too high, the valve opens and excess gasoline is dumped back into the gas tank, after which the pressure returns to normal.

If the turbocharger becomes jammed, releasing gasoline (and with it excess pressure) becomes impossible. As a result, the total pressure in the fuel system increases by 2 or more times, which entails severe excess fuel consumption.

In a situation where the valve completely stops holding the fuel pressure, there is a constant discharge of gasoline and its free circulation through the system. This, in turn, leads to a sharp drop in pressure and, as a consequence, a strong drop in engine power. For the same reason, starting the engine (especially after a long stay) becomes difficult; you have to spin the starter for a long time before the engine starts.

As you can see from the above, a jammed or, conversely, weakened pressure regulator valve cannot lead to anything good. That is why, at the first sign of a malfunction, the entire device should be replaced. We’ll talk about how to do this correctly below, but first let’s say a few words about checking the device yourself.

Check and signs of malfunction of the VAZ-2115 fuel pressure regulator

It is most difficult for novice motorists to monitor the condition of their car. They do not yet know the main signs of failure of its parts and often miss the first manifestations of malfunctions. The manufacturer installed a weak fuel pressure regulator on the VAZ-2115. Therefore, it is important to learn how to check it and replace it.

Why is this device needed?

The regulator, responsible for maintaining normal fuel pressure in the system, is in direct interaction with the power unit. According to its location, it can be located in the fuel tank or in the rail (this is where you will be able to find the regulator if you have an injection VAZ-2115). The reason for the failure of this element is often the low quality of gasoline. If you fill up at gas stations with greatly reduced prices, then it is not surprising that very soon the regulator will fail.

The fuel flows through the injectors to the intake manifold, and it is important that its pressure does not change at this moment. The regulator measures the volume of fuel required for engine operation, and also monitors the pressure in the fuel rail and intake manifold.

The main task of the RTD is to maintain the pressure difference at the same level, as well as monitor the indicators.

Checking the pressure regulator

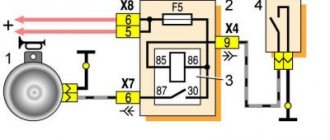

You can check the performance of the VAZ 2114 RDT using a pressure gauge. It should be connected between the fitting and the gas hose, having first disconnected the vacuum hose.

Connect in the following order:

- Unscrew the fitting plug.

- Unscrew the spool from the inner cavity of the fitting.

- Connect the pressure gauge hose to the fitting.

- Secure the hose with a clamp.

It is important to note that before checking the functionality of the regulator, all fuel system hoses should be inspected for damage. Even if there are small holes or cracks, the pressure measurements will be incorrect.

Measurements are performed in four different modes, in which the pressure should be equal to:

- immediately after turning on the ignition - 3 atm or a little more;

- at idle - about 2.5 atm;

- with the fuel pressure pipe removed from the regulator - 3.3 atm;

- with the return flow hose completely pinched - about 7 atm.

If the measurement results correspond to the values given above, then the regulator is working; if not, it will have to be replaced.

It is worth noting that the main reasons leading to regulator failure are either a very long downtime of the car or low quality gasoline.

If you don’t have a pressure gauge at hand, you can determine the failure of the device by a number of indirect signs, namely:

- difficulty starting the engine;

- Unstable engine operation at low and idle speeds. “Podgazovka” practically does not add power;

- sudden jumps in speed, most often at idle;

- jerking of the car while driving, unstable behavior on the road;

- loss of acceleration and speed jumps after changing gears;

- a strong increase in fuel consumption;

- traces of fuel, leaks on the fuel system hoses (however, replacing hoses and clamps does not give the desired result).

All these signs, especially if they manifest themselves in complex ways, are a direct indication for replacing the pressure regulator.

What is the sorcerer on the VAZ 2114 and where is it located?

This strange name “sorcerer” was given to car owners by the brake force regulator. This device first appeared in 1970. This is probably not accidental, because the behavior of a vehicle on the road depends on this mechanism: the length of the braking distance, whether the car will skid when turning and by how much. During braking, the load on the front and rear axles is distributed unevenly, therefore, in order to equalize the force between the axles for effective braking, dynamic correction of the braking process is required. This correction is performed by the brake force regulator. This small detail prevents the rear wheels from locking before the front wheels, and thereby prevents the car from skidding during braking. If the sorcerer is faulty or incorrectly adjusted, the machine may even overturn. The figure below shows the design of the brake regulator. And below is its schematic representation: The brake torque regulator on the VAZ 2114 is located under the rear body, on the left rear wheel side, near the rear suspension beam. The VAZ-2107 and other “classic” models also have this mechanism, but it is located on the right side. New vehicles equipped with anti-lock braking devices and EBD electronic brake force distribution do not use the sorcerer. Understanding how the sorcerer works will help the car owner configure it correctly and operate it in the future. The sorcerer distributes the braking forces as follows: during sharp braking, the front is pressed to the bottom, and the rear is raised. In this case, the rod moves and thereby closes the flow of brake fluid to the rear brake cylinders. The spring holds the valve, preventing it from closing completely, so the rear wheel locking is activated, but a little later than the front ones. Ideally, the rear wheels should brake half a second after the front wheels.

Replacing the device

In order to replace the VAZ 2114 fuel pressure sensor with a new one, you need to turn off the car’s engine and wait until it cools completely (replacing it while the engine is hot or, especially, running is strictly prohibited).

After the engine has cooled down, drain the fuel from the system and perform the following steps:

- Disconnect the negative terminal from the battery.

- Remove the vacuum brake booster hose.

- Unscrew the nuts on the gasoline drain pipe, supporting the hose with your hand.

- Connect the washer to the tube using a rubber ring.

- Unscrew the screw securing the clamping bar.

- Remove the clamping bar.

- Slightly unscrew the nut holding the drain tube and pressure regulator.

- Remove the screws securing the regulator to the fuel rail.

- Unscrew the fastening nut and remove the regulator from the fuel rail.

The new regulator should be installed in exactly the same order, but in reverse order. To replace a failed sensor, you should purchase a device of exactly the same model (the price of the regulators is not so high and is about 500 rubles). You can buy a new sensor at almost any auto store.

Operating principle and design of hybrid engines

How to install fuel pressure regulator VAZ 2110

The operating principle of hybrid engines is based on combining the capabilities of an internal combustion engine and an electric motor. The gasoline unit develops maximum torque at high speeds, while the electric engine develops maximum torque at low speeds. Combining installations makes it possible to exclude mechanical energy conversion mechanisms from the design, increase the efficiency of the power unit and reduce fuel consumption.

Complete design

A car with a hybrid engine is designed differently than conventional cars with an internal combustion engine. Here under the bottom are:

- internal combustion engine;

- one or more electric motors;

- battery pack.

- An electronic unit with an inverter is installed to control and convert energy.

The source of energy in a hybrid engine is an internal combustion engine running on gasoline or diesel. The power converted by the generator starts the traction motor and charges the batteries. It is from the battery pack that the electric motor receives additional power if there is not enough generator energy.

The inverter converts the high-voltage battery's DC current into higher-voltage 3-phase alternating current. Energy is used for:

- electric motor control;

- reverse conversion of current from the generator to recharge the battery;

- on-board power supply.

Structurally, the inverter is a housing with a set of electronic boards and transistor assemblies.

We will consider the general principle of operation of a hybrid car below.

Engine operation

The mode of joint operation of the internal combustion engine and the electric motor depends on the design of the hybrid power unit and the driving mode of the vehicle. So, when starting to move, the gasoline engine does not always need to be started. The car will move due to the operation of an electric motor powered by a battery.

The electric motor keeps the car running at idle speed: when parked at a traffic light or at a temporary stop. At this time, the internal combustion engine is turned off as long as there is enough electric power. Usually the gasoline engine is connected at a speed of 60 km/h. Under heavy loads, for example, driving up a hill, you will need double effort from both units. In this mode, the car can travel more than 500 km.

What's distinctive is how the hybrid engine operates during braking. The braking system of a conventional internal combustion engine vehicle converts kinetic energy into thermal energy, dissipating it in the air. Hybrids are equipped with a recuperation system, i.e. return. When the vehicle slows down, the electric motor switches to generator mode, supplying electrical energy to the battery.

Fuel pressure control

So I started to get annoyed that the car starts 3 times in the morning. Many people said “kill it.” But it would be nice if -20 was overboard, and even then, people are launching... In general, I re-read all possible forums, watched a bunch of videos. I compared the readings of the outside temperature sensor and the DTOZH, they were the same. DMRV. his numbers are normal...

Based on what I had read and, again, my observations, I was leaning towards a pump or RTD. I didn’t have a pressure gauge, so I went to a man over the weekend and he measured it for me - 3.7 (system without return). When the gas was turned on, it jumped up to a little more than 4. As he said, it’s not ideal, but the pump is alive and the pressure supposedly holds after the engine is stopped. (I didn’t see it myself, because I was sitting inside the car; by the time I got out, he had already removed the pressure gauge). Naturally, no one has measured how long it lasts. I was told to “start with the temperature sensor.” However, this topic with RTD still haunted me.

On Monday I picked up a new RTD from the store. His appearance, of course, confused me. Made in rank yet. It cost 400 rubles and is designed for 400 kpa. I came home, removed the pump, installed the RTD, and put it back. I turn the key and the car refuses to start. I go to the ramp, press the spool - it’s empty. What the hell. It was late and there was nothing left to do but return the old RTD to its place. I didn’t want to walk to work in the morning, and I still have to return the part. I saw some dirt on the mesh of the old RTD, so I sprayed it with carb cleaner and installed it. Started up. And it seemed to me that the speed was kept as even as ever.

On Tuesday morning it started with half a stick. She didn't go deaf. I was delighted. I went to work. At lunchtime I returned the purchased RDT. It's Wednesday. And again in the morning, immediately after the first start, the engine stalled. Second try - the same thing. 3 times is fine. After work I bought this fucking pressure gauge and decided to let it be. And I immediately took the RDT. It’s 380 and looks like a Russian one))) I connected a pressure gauge (I still have an old RTD). I turn on the ignition, the arrow also jumped to 3.7 and immediately quickly went to 0. What the hell.

I understand that my theory about the malfunction of the RTD was justified. I installed a new one. I'm measuring again. It got pumped up even closer to 4. When wound up, it was also a little more than 4 and the needle didn’t jerk as much as with the old one. However, after stopping, the pressure also went to 0, but it dropped slowly. And as I suspect, it was the pressure gauge itself that was lowering through the outlet; a little gasoline flowed from it.

That's how it is with the old RTD. I didn’t record it with the new one.

Old RTD

I'll look at her behavior tomorrow.

New RTD

Replacing the fuel pressure regulator on a VAZ 2114

On cars, a fuel pressure regulator is necessary to maintain the required level of fuel pressure inside the fuel system. This directly affects the injectors when switching the power unit to different operating modes. The regulator allows you to control and change the load on the motor.

So, when the pressure in the intake pipe increases, the regulator increases the fuel pressure. If the pressure in the pipe drops, then the device reduces the pressure accordingly. To get rid of excess fuel, the valve on the device opens slightly, from where gasoline flows back into the gas tank of your VAZ 2114.

Fuel pressure sensor VAZ 2114: main functions

Like most pressure sensors, this one is also a membrane type. Installed in the fuel rail, next to the injectors. Its function is to maintain pressure in the rail in a certain operating range. This is especially true not for a steady state, but for a changing operating mode. Using the regulator, the load on the engine is adjusted. Let’s say that when the pressure in the intake tract decreases, the pressure of the air-fuel mixture increases. And vice versa - when it increases, it decreases. Three important points can be highlighted:

- It changes the pressure when it also changes up or down in the intake tract.

- Allows you to maintain the pressure in the VAZ 2114 ramp in a certain range.

- Under various operating modes, the internal combustion engine helps compensate for loads.

Signs of breakdown

The car itself often informs the driver that problems have arisen in a particular system. Therefore, the main task of the car owner is to learn to recognize these signs. Thus, determining the cause of the breakdown and eliminating it becomes a matter of technology.

Regulator problems

Signs of a malfunctioning fuel pressure regulator include:

- Fuel consumption increases;

- When idling, the engine suddenly stops;

- While driving, there is a significant decrease in engine power;

- It is possible to start the engine with a certain effort.

Valve problems

Loosening the nut

- If the valve of this device fails, excess fuel will not be able to pour back into the gas tank, causing the pressure in the fuel system to increase to higher values. The norm is 2.5 kg/cm2. As a result, the amount of gasoline entering the combustion chamber will increase, which is why it will not be able to burn completely.

- If the valve stops holding back the pressure, fuel will move freely throughout the entire fuel system, which will result in a drop in pressure. By increasing the speed, you simply won’t have enough fuel to accelerate. Engine power will drop noticeably. When the car stops, the pressure is maintained if the valve is working properly. But since it cannot withstand the pressure, in order to start the engine again, you will have to turn the starter for a long time in order to achieve the required level of pressure.

COMPONENTS OF THE FUEL SYSTEM

Signs of a malfunctioning absolute pressure sensor. what to pay attention to? »

The VAZ 2114 fuel system consists of the following main elements:

- Gas tank;

- Fuel pump;

- Gasoline filtration devices;

- Pipeline system;

- Fuel rail;

- Injectors;

- Waste disposal unit.

Fuel system diagram

Let's analyze each component separately.

GAS TANK

The VAZ 2114 gas tank is a container made of two equal metal parts. A neck is removed from the tank into which gasoline is poured. The neck is connected to the tank via a rubber pipe and clamps.

FUEL PUMP

The fuel pump is located directly in the tank. It has a fuel level sensor, which transmits information about the current amount of gasoline to the ECU. The gasoline pump is connected to a line through which gasoline is transported to the fuel rail. The fuel pump itself consists of several parts - coarse filters, wiring and an electric motor, which pumps fuel. As evidenced by reviews from owners of fourteenth cars, fuel pumps from the German company BOSCH have proven themselves to be the best.

FILTRATION DEVICE

The VAZ 2114 fuel injection system very much depends on the quality of the filter devices used. A bad filter will significantly reduce both the efficiency and the longevity of the entire system.

On the fourteenth, non-separable filters with a working element made of paper are installed. Such filters clog quite quickly, and they need to be changed at least once every 10-15 thousand kilometers.

FUEL RAIL

The fuel rail is located on the intake manifold housing. Its design consists of two parts, separated by a spring-loaded diaphragm. The first is the fuel one, in which the required level of gasoline pressure is set, the second is the air one, air is pumped into it, due to which the diaphragm compresses the fuel chamber and changes the pressure level in it.

Ramp

PIPING AND HOSES SYSTEM

To circulate gasoline from the gas tank to the injectors, the fourteenth uses steel fuel lines located on the bottom of the car. The VAZ 2114 fuel supply system also provides for a return pipeline through which excess gasoline from the injectors is returned back to the gas tank.

VAZ 2114 owners are advised to carefully monitor the condition of the fuel line in order to avoid gasoline leaks. Pipes should be checked regularly for deformation and corrosion.

INJECTORS

Injectors are valves actuated by electromagnetic control. They have a sprayer, with the help of which fuel under pressure is supplied directly to the combustion chambers.

Injectors are one of the most problematic parts of the fuel supply system of the fourteenth (as well as VAZ 2115 and VAZ 2113), the service life of which directly depends on the quality of the gasoline used. If the fine filter does not fully perform its functions, the injectors will become clogged, and from time to time you will need to clean them at a service station (doing this at home is very problematic).

A critical failure of the injectors is a short circuit or break in the winding, after which it is necessary to replace the failed part.

WASTE DISPOSAL UNIT

The EURO-3 environmental safety standard, to which the VAZ 2114 complies, provides for the presence of a gasoline vapor recovery chamber, for which the fourteenth uses an adsorber with activated carbon. The adsorber is connected to a throttle assembly, from which all resulting vapors are sucked out.

Adsorber

Checking the head pressure

To determine if your fuel pressure regulator is faulty, it will have to be thoroughly checked. If you have experience, this work can be easily done with your own hands. If you don’t have the skills, it’s better to go to a service station.

The quality and efficiency of the regulator can be determined independently using a pressure gauge. You will use it to measure the pressure in the system.

Diagnostics is performed in three modes. Before starting the inspection, be sure to make sure that there is no damage in the fuel line and that fuel is not leaking anywhere. If there is damage to the line, checking the pressure pressure will not give an objective result.

After checking the line and making sure that it is solid and has no defects, proceed to measurements in four modes.

| Diagnostic mode | Standard pressure indicator |

| Check when ignition is turned on | 2.5 Atm |

| Idle check | 3 atm |

| Checking with the tube removed from the regulator | 3.3 Atm |

| Checking if the return flow tube is pinched | 7 atm |

You will need to connect a pressure gauge to the gap between the fitting and the fuel hose, disconnecting the vacuum hose.

By pressing the gas pedal, the parameter will first rise to 3 Atm, but then drop to the normal 2.5 Atm. But this is only provided that the device that regulates the fuel pressure in the system works well and has no malfunctions.

If the pressure does not begin to increase during the check, replace the vacuum hose and take repeated measurements with it. If there are no changes in measurements, this indicates a malfunction of the regulator. There is no point in repairing it. It’s easier to immediately replace the device with a new one, and one of the highest quality and reliability.

For reference. Almost all valves indicate optimal readings. Compare the obtained measurement data with them when checking.

Why does the device fail?

Fuel pipe

The regulator stops working normally mainly for two reasons.

- Low-grade fuel is used, which contains a large amount of water.

- The car sits idle for a long time, is not used and does not start even for the purpose of prevention.

Troubleshooting

To find problems, we suggest you use the appropriate methods.

- Pump fuel into the system, turn off the ignition and monitor the behavior of the pressure gauge. In a normal situation, the pressure drops to 0.7 Bar and stops at this level. If the regulator fails, the pressure gauge will tend to zero. The problem may lie in the device itself, or in the fuel pump motor valve.

- Increase the engine speed to 3 thousand and again look at the pressure gauge readings. If the arrow points down, the fuel pump is broken. It needs to be replaced.

- If the pump takes a long time to build up pressure, the problem lies in the filter or mesh of the tank, which is clogged with debris.

Replacement

Replacement process

By following the instructions step by step, you can independently remove and install a new fuel pressure regulator without any problems.

- Work on dismantling the device can only be carried out if the engine is cold. If you just drove into the garage, give the car some time to cool down.

- When the engine is running, high pressure remains inside the system, so it must be reduced before work.

- Disconnect the negative terminal from the battery to avoid electric shock and damage to the wiring.

- Remove the vacuum hose.

- Unscrew the nuts on the drain pipe and gradually reduce the fuel pressure level in this way. Be sure to hold the hose fitting with one hand.

- The tube and the washer are connected to each other by a regular rubber ring.

- The screw that holds the clamping bar is unscrewed.

- Now this very bar can be put aside for a while.

- Slightly unscrew the fixing nut that holds the drain tube and the regulator itself.

- Remove the fastening screws of the regulator holding it to the ramp.

- Carefully remove the nut, which will ultimately allow you to remove the object we are looking for.

- Install the new device by following the reverse dismantling sequence.

Be sure to check the fuel pressure in the injectors with the engine off, ignition on and the electric fuel pump on. During normal operation of the device, the pressure should be about 300 kPa. If the level you checked is below normal, this can lead to disruption of the functionality of the entire engine power system. Therefore, be careful, do the work step by step, and do not forget about the importance of each stage of repair.

Replacing the fuel pressure regulating device yourself is not difficult. Just keep in mind that for optimal engine operation after replacement, you will need to not only follow the sequence of work and do everything as competently as possible, but also use a new, high-quality device as a replacement. The regulator is not expensive, so such repairs will not entail significant costs for your VAZ 2114.

How to change the fuel pressure regulator on a VAZ 2114

Withdrawal procedure

- The first step is to relieve the fuel pressure in the fuel line.

- Then remove the air supply hose to the throttle valve.

- Using a screwdriver, unscrew the screw securing the pressure plate and remove it.

- Disconnect the hose from the fuel pressure regulator.

- Using a 24mm wrench, unscrew the nut of the fuel drain pipe.

- Using a 5 mm hex wrench, unscrew the 2 bolts securing the regulator to the fuel rail.

- Remove the pressure regulator.

- Before installing the regulator, check the condition of the O-rings at the connections. Damaged rings need to be replaced.

- Lubricate the O-rings with oil and install the pressure regulator in place.

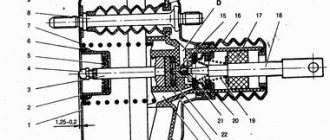

Features of the 2111 (1.5i) engine power system

Location of elements of the 2111 (1.5i) engine power supply system in the engine compartment:

1 - receiver; 2 — vacuum supply hose to the fuel pressure regulator; 3 — throttle assembly; 4 - fuel rail; 5 — fuel pressure regulator; 6 — air supply hose to the throttle valve; 7 - adsorber; 8 — air filter; 9, 10 and 11 — hoses of the crankcase ventilation system; 12 — throttle valve drive cable; 13 — diagnostic fitting

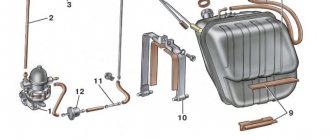

Fuel pump

combined with the fuel level indicator sensor into a single unit -

a fuel module

(often called an electric fuel pump). The pressure pump delivers fuel from the tank through the fuel filter to the fuel rail.