07/17/2021 4,875 VAZ 2110

Author: Ivan Baranov

The efficiency of the fuel system of the VAZ 2110 depends on the quality of the fuel-air mixture. The MAF (mass air flow sensor) is responsible for monitoring the optimal ratio of air content in the combustible mixture of air on the VAZ 2110. The article describes the operating principle of the device, how to test it, and provides instructions on how to replace and repair the sensor yourself with a demonstration video and photo.

Appearance of the air flow sensor VAZ 2110 [Hide]

Principle of operation

The main task of the mass air flow sensor, also called a flow meter, is to calculate the required amount of fresh air entering the engine cylinders. The flow meter on the VAZ 2110 is located in the air duct behind the air filter, where it measures the amount and temperature of outside air.

Location of the flow meter on the VAZ 2110

The optimal ratio between fuel and air is 1:14. If the proportions do not meet the necessary parameters, then either excessive fuel consumption occurs or the vehicle’s power decreases. The mass air flow sensor controls that air flows in certain portions. It calculates how much air has entered and transmits this information to the ECU. Taking these readings into account, the computer calculates the required amount of fuel.

When you press the gas pedal, the amount of incoming air increases, and accordingly more fuel is consumed. If the car moves evenly, the portions of air and fuel entering the cylinders of the power unit are the same at each cycle. If the driver accelerates, the throttle valve opens and the volume of incoming air increases, and at the same time the load on the engine increases. If the gas pedal is released, the load drops.

Replacing the sensor - instructions

Using a screwdriver, unscrew the clamp of the air intake corrugation at the sensor outlet, pull it off and carefully inspect the internal surfaces of the sensor itself and the corrugation. These surfaces must be dry and clean; traces of condensation and oil are unacceptable. If the air filter is changed rarely, then dirt getting on the sensitive element of the sensor is the most common cause of its breakdown in VAZ cars.

There may be oil in the mass air flow sensor as a result of an increased oil level in the engine crankcase, or the oil sump of the crankcase ventilation system is clogged.

Next, unscrew the 2 screws of the sensor with a 10mm wrench and remove it from the air filter housing. There should be a rubber sealing ring on its front part (at the entrance edge). It prevents unfiltered air from being sucked into the intake tract through the sensor.

If the ring is out of place and stuck somewhere in the air filter housing, then there will be a thin layer of dust on the inlet mesh of the sensor itself. This is the second reason that destroys the mass air flow sensor ahead of time.

Correct assembly should take place in the following sequence: put a sealing rubber band on the sensor, check the sealing skirt, then insert everything together into the filter housing.

This concludes the visual check of the mass air flow sensor at home. You can check its operation 100% only with the help of special equipment in a car service center. For example, using a technique for assessing the oscillogram when the throttle is sharply opened to the cutoff mode (a motor tester is needed), or assessing the oscillogram when the ignition is turned on.

Resuscitation of a damaged air flow sensor is successful in no more than 5% of cases. In extreme cases, you can rinse with ethereal liquid to clean matrices and optics. It will evaporate without a trace. After making sure that there is no more dust or debris in the device, you can dry it thoroughly and put it back in place. Sometimes after such a simple procedure the device will work.

On most foreign cars, a mass air flow sensor was installed until 2000; subsequent generations of models began to be equipped with a pressure controller. Replacing a non-working sensor is simple and can be done on your own without any problems, you just need to buy a mass air flow sensor that matches the ECU firmware version. Its price is around 3,000 rubles, depending on the manufacturer.

Source

Basic faults

The mass air flow sensor rarely fails and requires repair, but it is important to know what the signs of its malfunction are:

- Fuel consumption increases. This can be determined by the on-board computer. If the flow meter malfunctions, fuel consumption increases by a liter or more.

- The car's power decreases.

- Uneven operation of the power unit. The car either accelerates slowly or picks up speed too quickly.

- The engine does not start or does not start the first time.

- Idle speed is floating.

The listed signs do not necessarily indicate a breakdown of the flow meter; the reasons may be the malfunction of other devices, which will require their repair. Therefore, it is necessary to check the serviceability of the flow meter.

How does the MAF work?

This device is a small wire made of platinum alloy. The size of this cord is only 70 microns. It is installed in a special tube, which is located in front of the throttle valve.

This wire is cooled under the air flow. To regulate the temperature between it and the air flow, electricity is applied to the wire. The charge level can be adjusted. The more the wire is blown, the more electricity is supplied.

Due to constant use, this wire is constantly covered in dirt. But modern sensors have a self-cleaning system. Dirt is one of the reasons why the device fails, but there are other signs of a malfunctioning MAF sensor. Although the design of the device is as simple and reliable as possible, it also fails. Its only drawback is that it is not suitable for repair. If the sensor fails, it is simply replaced with a new one.

Verification methods

There are several ways to check the mass air flow sensor with your own hands.

Shutdown

One way to check the flow meter is to turn it off. To do this, you need to remove the connector that connects the mass air flow sensor to the VAZ 2110 system.

Disconnecting the connector from the device

In this case, emergency mode is activated, the amount of air required is calculated based on the throttle position. If the car moves more dynamically with the sensor disabled, it needs to be replaced or repaired; perhaps cleaning will help.

Checking with a multimeter

To check, you need a multimeter and knowledge of repairs and how to handle the tester. The measuring device must be set to constant pressure measurement mode, designated by the letter V or DCV.

Multimeter for testing

To understand the operation of the mass air flow sensor, you need to know its pinout:

- a pink or red-black wire leads to the central unit;

- green wire – grounding;

- The white-gray wire is intended for voltage output;

- The yellow wire is used to supply current to the signal input.

Having dealt with the wires, you can start testing:

- First you need to turn on the multimeter, set the voltage to 20 V, and install the wires with electrodes in the appropriate connectors.

- For ease of connection, it is recommended to use two pins. They need to be inserted into the holes from which the green and yellow wires come out, and the tester electrodes must be connected to them.

- Now you need to turn on the ignition and measure the voltage. The voltage on the new sensor is 0.9-1.0 V.

Over time, the voltage increases as the resistors wear out and the resistance drops.

The higher the voltage reading, the higher the wear on the device:

- good condition – 1.01-1.02 V;

- normal state - 1.02-1.03 V;

- the device will soon stop functioning - 1.0-1.04 V;

- imminent death means a voltage reading of 1.04-1.05 V;

- replacement of the device is necessary if the readings are 1.05 or higher.

You can find out the MAF voltage using the on-board computer. To do this, you need to go to the “voltage with mass air flow sensor” section, we must find the indicator “U mass air flow sensor”.

Visual inspection

For a visual check, you should inspect the corrugation and the mass air flow sensor. If traces of condensation or grease are found, they may cause the appliance to malfunction. Sometimes cleaning the dirt helps restore the device's functionality and avoid repairs. Dirt accumulates due to infrequent air filter changes.

Grease spots appear if the oil sump is clogged or the oil level in the crankcase exceeds the permissible level; this may be a sign of a malfunction of the mass air flow sensor. If the reason is contamination, then all elements need to be washed or cleaned (video author - Alexey Romanov).

After cleaning, we proceed to a visual inspection of the sensor itself. There is a rubber O-ring on the front of the flow meter that serves as a seal to prevent unfiltered air from entering through the inlet.

If the ring has moved or remains on the filter, dust may accumulate on the mesh. Such contamination may well be the cause of a malfunction of the sensing element.

How to check the mass air flow sensor on a VAZ 2110 with a multimeter

Important! All disconnections and connections of connectors are made with the battery disconnected.

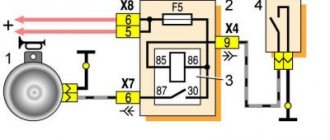

A. _ Checking the wiring harness and contacts. At this stage, the interaction between the ECU and the mass air flow sensor is tested. Performed with the connector removed and the ignition key in the “ON” position. You need to know the pinout of the sensor connector on the ECU side:

- Contact No. 1 is not involved in the test.

- Contact No. 2 - 12 volt power supply. A deviation of even 0.5 volts is not acceptable.

- Contact No. 3 - “ground”, mass.

- Contact No. 4 - 5 volt sensor power supply. Likewise: deviations are not allowed.

B. _ After making sure that the cable harness is intact and the ECU is working, we check the signal voltage on the connected flow meter. Turn the ignition key to the “ON” position and do not start the engine! We connect a digital multimeter to ground and contact No. 5 of the air flow sensor.

The multimeter is set to 2 volt measurement mode with an error of 1/100 volt. These readings accurately indicate the condition of the flow meter, so the accuracy class of the tester must be high.

If the device shows a voltage within 0.99-1.02 V, your flow meter is new or in excellent condition.

Readings from 1.03 to 1.05 volts are acceptable, but the air flow sensor will soon fail. You can still drive with such a sensor, but the quality of the fuel-air mixture will be far from ideal.

If there is no voltage or its level is above 1.05 V, the flow meter is faulty and requires replacement.

Advice: you should not skimp on replacing the mass air flow sensor. Excessive fuel consumption and increased engine wear will cover all the imaginary benefits.

Replacement and installation instructions

If cleaning the system elements does not help and the cause of the malfunction is a broken mass air flow sensor, you can replace it yourself.

The procedure for replacing the mass air flow sensor on a VAZ 2110 with your own hands consists of the following steps:

- First of all, you need to turn off the engine and remove the ignition key.

- Next, remove the flow meter connector.

- After unscrewing the screws securing the clamps, you need to disconnect the hose of the intake pipe, which is attached to the air filter housing.

Disconnected intake pipe hose - Next, remove the mass air flow sensor. Before installing a new consumable, you should clean or rinse its seat.

- Assembly is carried out in reverse order.

This completes replacing the flow meter on a VAZ 2110 with your own hands. You can check the engine's operation by driving a short distance.

Loading …

What does a DMRV failure lead to?

Faulty mass air flow sensor

may lead to the following manifestations of vehicle operation.

- The engine does not start (this is very rare and on VAZ cars the mass air flow sensor is not capable of affecting the engine’s operation so much; moreover, if you turn it off completely, the on-board computer will set the default value)

- Changes in idle speed - they may increase or, on the contrary, decrease

- Increased fuel consumption with decreased acceleration dynamics. (incorrect readings from the mass air flow sensor interfere with the correct preparation of the fuel-air mixture).

- The most obvious sign of trouble is the Check Engine light on the dashboard.

In general, monitor the technical condition of your car and carry out all possible scheduled work on time to prevent engine breakdowns, including timely oil and filter changes.