hum and howl when moving in tension & | Niva Chevrolet and Niva & | VK

Throughout its history, the model was equipped with a manual transmission. Initially it was a manual transmission-4, since 1995 the SUV engine has been combined with a five-speed gearbox labeled VAZ-21214, which is actually a manual transmission unit-21213 adapted for 1.7 and 1.8 liter injection engines. In 2013, the mechanics underwent major changes and received a new name 21214M .

However, along with the appearance of the new gearbox, constant conversations arose among car owners about where the howling and hum from the transmission on the Lada Niva comes from. Let's look into this issue further.

Eliminating vibration in Chevrolet Niva and Niva cars has become possible today

10.03.2008 11:13 As is known, the “chronic disease” of the Russian “NIVA” and “CHEVROLE NIVA” is increased vibration in the car interior, which can manifest itself to a greater or lesser extent in different driving modes. This fact does not in any way affect the universal love for the All-Road Vehicle and is often accepted as something inevitable. However, the desire to get rid of a “chronic disease” periodically visits the souls of the most active and persistent “nivovodov”.

Vibration and low-frequency hum are not as harmless as they might seem at first glance. In addition to negative feelings and discomfort, vibration can cause increased fatigue and irritability...

— What are the causes of vibration and hum?

— There are many reasons: from sound vibrations in the engine intake system to changes in the position of transmission elements under load. But 80% of vibrations in various vehicle driving modes are a consequence of insufficient balance of the driveshafts. Insufficient balance (large residual imbalance) of cardan shafts is a consequence of a significant displacement of the axis of the shaft pipe from the axis of its rotation (pipe runout), large backlashes in the hinges and splined joints. This means that if the shaft is assembled with large backlashes in the hinges and splines, if the runout of the shaft pipe exceeds 0.4 mm, the required level of balancing cannot be achieved. Usually the shaft pipe beats by 0.8 mm or more.

— Do you offer a solution to the problem?

- Yes. “AGAT Project” has introduced selective assembly technology, which makes it possible to assemble a shaft with a pipe runout of up to 0.25...0.4 mm. This shaft is balanced with very high precision. This allows you to get rid of vibration in the car interior when driving at any speed, including more than 120 km/h.

In 2010, AGAT Project LLC began producing cardan shafts with a splined part of increased dimensions. We hope for a significant increase in the service life of the shaft, since in operation, problems begin with wear and the formation of gaps in the spline connection, which entails the appearance of knocking in the transmission and vibration.

Preparations are underway for the production of cardan shafts for Gazelle cars. The shafts assembled at AGAT Project LLC are painted dark blue.

— How to achieve the best results?

— Have a successful and comfortable journey! AGAT Project LLC invites service stations, regional dealers, as well as anyone interested in eliminating vibration of a car of the NIVA, CHEVROLET NIVA, and, in the near future, GAZELLE models to cooperation, by replacing driveshafts.

2. Chain of stores "Navigator".

cell +7-9277-78-74-03. Quantity Commenting closed: Yes

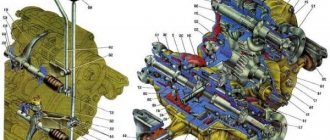

Features of the Lada Niva transmission

Without exaggeration, we can say that all-wheel drive brought world fame to the domestic car, but at the same time it became a real headache for car owners. Drivers literally unanimously claim that the previous four-speed gearbox was an order of magnitude more reliable than the five-speed unit. Apparently, the mechanics took the predecessor as the basis for the new modification and added a fifth gear unit, which basically causes serious trouble for the owners. In most cases, the block does not last even 30,000 kilometers, requiring premature repairs. In modification 21214M this is much easier, but there are still cases when the fifth gear fails.

Specifics. Flanges and helicopters.

The results surprised even us, although it seems that nothing in this car should surprise us anymore. The photo shows the gearbox flange, also known as the transfer case flange. And it seems like a rotation part with an even number of splines and an even number of holes. But you can’t “take” an AvtoTAZ so easily. This part has a landing diameter (along the splines) and a mating plane. We made a device from the transfer case output shaft. We very carefully centered them for axial runout, and clamping the flanges, as we do on transfer cases and gearboxes, began to check them for runout of the end plane. The results are depressing. 20% of products DO NOT have runout. There were flanges where the runout reached 0.5 mm. To avoid doubts about spare parts, we removed the flanges from the conveyor machines, the result was the same. On checkpoint “helicopters” the picture is exactly the same.

Common Lada 4×4 transmission problems

You can often hear from drivers that the car’s transmission is constantly humming and crunching. Many people have to sort out the gearbox after 20 thousand km, and then carry out minor repairs every 10 thousand km. High-quality foreign additives and oils do not radically change the situation. Howling and humming are a characteristic feature not only of the Lada Niva, but also of other AvtoVAZ vehicles, for example Lada Granta and Lada Kalina. AvtoVAZ is aware of this problem. Unpleasant sounds and crunches in the operation of the transmission are explained by poor modification of the teeth of the gears and the main pair. In 2014, the unit was seriously modified, but the problem was never completely eliminated.

Representatives of the plant comment on the fatal problems of the gearbox:

With the current production culture, it is impossible to cope with extraneous sounds. Significant investments are required in the modernization of the machine fleet, since the current factory equipment does not allow processing gearbox gears with greater accuracy

The factory has been fighting the rumble and howl of the transfer case virtually from the very moment the car appeared. In 1999, the Niva was equipped with an improved transfer case with fine-module gears. The level of external noise was indeed reduced, but the question of reliability and endurance of the modernized unit arose. Today, the Lada Niva 21214-M is equipped with a sealed transfer case with an updated ventilation system and an open breather located in the engine compartment. The design eliminates the possibility of excess pressure forming in the crankcase. Serious changes have also occurred with the cardan shafts: now they are on CV joints with boots. The plant's new balancing stands now make it possible to equip cardans with greater geometric accuracy.

Why is the transfer case humming on a Chevrolet Niva?

Let's try to figure out the well-known problem of the NIVA car, the transfer case is humming, what to do and how to remove the unpleasant noise. I’ll say right away that the main cause of noise is in the transfer case levers; at the moment it can be eliminated by purchasing special silent levers (handles) or making their own analogues. This is what they look like:

The transfer case on a NIV can make noise both in a new car just purchased from a dealership, and in a car with high mileage. Gradually, the noise can increase, becoming simply unbearable at high speeds, even drowning out the music. Noise in NIV is normal, but if you are at 80 km. you can’t hear your interlocutor at an hour, you need to do something about it and fix the problem.

First, we correct the main cause of the noise, replacing the original switching levers with modified silent ones. They are assembled according to the principle of levers from the Chevrolet Niva, this is no longer a “bare” metal blank, special anti-noise bushings are inserted into the lever, which dampen vibration, preventing noise from penetrating into the cabin.

How to install silent RK levers on NIV with your own hands:

It is shown how to install the levers yourself, getting rid of the noise. For those who are too lazy to do everything themselves, auto services will charge about a thousand rubles for this procedure.

How to make silent transfer case levers with your own hands?

We remove our old levers. We put silicone gaskets or hoses on the place where they come into contact with the transfer case. We do this for thickening. To do this, heat the silicone in boiling water and immediately, while the hose or gasket (depending on what you have) has not cooled down, pull it onto the lever. Tested by my own experience, the unpleasant sound, howling at high frequencies disappears, since there is no metal-to-metal contact. However, it is worth noting that for some this method lasts for a long time, while others have to repeat this procedure periodically.

Below is a video review from a satisfied Niva owner who was able to overcome the hum from the transfer case by installing new levers:

Their effectiveness is clearly shown; the video includes sound with old levers and with new ones. In my opinion, the difference is noticeable.

Friends, we need advice from experienced shnivy breeders! The problem is this: a new shniva has a mileage of 900 km, a noise has appeared in the transfer case, and it appears only when the car is cold and at a speed of more than 50 km/h, and disappears when the car warms up. It buzzes in gear and in neutral, and also if you turn it down, it also hums . What is this on a new car? Moreover, this is my 4th Niva, but I’ve never heard this on previous ones) The sound is asymmetrical, uneven, not very loud, similar to a howl. Maybe due to insufficient oil in the transfer case or bad oil poured into it?

Transfer case noise

Transfer case noise

Post by Kolebon » Feb 22, 2012, 10:15 pm

Re: Transfer case noise

Post by Vovchik » February 22, 2012, 11:05 pm

Re: Transfer case noise

Post by tatarin545 » Feb 22, 2012, 11:11 pm

Vovchik

Tatar is not a nationality, Tatar is a profession.

I am slowly looking for an engine block or the 2130 engine itself. 42-tooth RK gear, inexpensive! Niva Fora for experiments, can be written off!

Re: Transfer case noise

Post by Kolebon » Feb 22, 2012, 11:41 pm

Re: Transfer case noise

Post by tatarin545 » Feb 22, 2012, 11:54 pm

Tatar is not a nationality, Tatar is a profession.

I am slowly looking for an engine block or the 2130 engine itself. 42-tooth RK gear, inexpensive! Niva Fora for experiments, can be written off!

Re: Transfer case noise

Post by Kolebon » Feb 22, 2012, 11:58 pm

Re: Transfer case noise

Post by tatarin545 » Feb 23, 2012, 00:12

Tatar is not a nationality, Tatar is a profession.

I am slowly looking for an engine block or the 2130 engine itself. 42-tooth RK gear, inexpensive! Niva Fora for experiments, can be written off!

Re: Transfer case noise

Post by Kolebon » 23 Feb 2012, 00:14

Re: Transfer case noise

Post by YVAN » Sep 15, 2013, 12:23 pm

Re: Transfer case noise

Post by rendevor » Sep 15, 2013, 1:59 pm

Re: Transfer case noise

Post by YVAN » 15 Sep 2013, 14:37

Transfer case noise

Post by Alexey 30 » Oct 10, 2013, 10:09 am

Re: Transfer case noise

Post by Anton » Oct 10, 2013, 11:09

Alexey 30

Turn off the center differential lock (small lever away from you).

Transfer case noise

Post by Alexey 30 » 11 Oct 2013, 17:09

Re: Transfer case noise

Posted by marselle » Oct 30, 2013 3:38 pm

Re: Transfer case noise

Posted by marselle » Nov 13, 2013, 11:00 pm

Re: Transfer case noise

Post by ivm53 » April 25, 2015, 4:08 pm

Re: Transfer case noise

Post by Allbatross88 » 12 Aug 2015, 15:00

Re: Transfer case noise

Post by Captain » 12 Aug 2015, 15:33

Re: Transfer case noise

Post by Bliznets » June 19, 2021, 09:20

What to do with excess noise on the VAZ-2121?

Cardan shafts on CV joints have further reduced the level of vibration and noise, but they have actually become maintenance-free. If a serious breakdown occurs, the complete unit will need to be replaced. It's easy to guess that this is not a cheap unit. Operating the car in difficult conditions only increases the likelihood of damage to the boot, and this is fraught with serious financial costs. So, we get that the noise of the transfer case is a design feature of the car, which you either have to put up with or look for ways to resist. One of the ways is to install a subframe or the same CV joints on previous modifications of the car. Sometimes car owners try to combat howling and humming in the cabin by improving sound insulation. But usually a new Shumka does not help and becomes only a waste of money.

You can modify the car as follows:

It is not at all necessary to do all this work on the car. It all depends on the owner’s requirements, assigned tasks and operating conditions. A subframe under the manual transmission and transfer case will reduce vibrations and extraneous sounds emitted by the units to a minimum. It is a natural way to protect the transfer case and increases the possibility of adjustment along the axes. Numerous tests have shown that this particular method of combating howling and humming is the most effective. Typically, the kit is made of structural steel, which allows you to accelerate the car without excessive noise up to 140 km/h, provided that you have the appropriate motor.

Complete sound insulation of the interior with high-quality sound-absorbing materials is advisable if at least one job from the presented list of ways to combat car noise has been previously completed. The operating comfort of the machine can be increased with the help of double-row imported bearings and seals pressed into the rear cover of the transfer case and the front axle disengagement clutch. Such a kit can not only eliminate hum, howl and vibration, but also prevent oil leaks on the transfer case flanges. In general, there are not so few real and effective ways to improve the comfort of an SUV.

If you cover the entire engine with Shumka

The guys from Garage 54 conducted an experiment by gluing noise-insulating materials (vibration dampers and thermal and noise insulation) directly onto the Zhiguli engine.

We checked the noise level using an application on a smartphone:

- Engine without sound insulation - 98 dB.

- Engine with vibration dampers - 88 dB.

- Engine with vibration dampers and heat and noise insulation - 82 dB.

As a result, engine noise decreased, but not significantly.

To get a “quiet engine” you don’t need to modify it. This should all be included at the design stage. You can slightly reduce the vibrations and noise of intake/exhaust gases during a major overhaul (select a ShPG with a minimal difference in the weight of the pistons and connecting rods, sharpen the crankshaft, camshaft, polish the cylinder block, change the exhaust, etc.) But you won’t change anything radically, because .To. The quiet engine is designed from scratch.

Are you worried about engine noise on LADA cars? What soundproofing method did you choose?

Source

Incorrect gearbox adjustment

This hum has a very different character and it is impossible to say anything unambiguous. It is definitely absent when driving in neutral and means the death of the gearbox.

The problem is that the gearbox is adjusted once and for its entire service life. There are no planned works of this nature, and if the hum has already appeared, then the adjustment will not be able to help. The whole point of the adjustment comes down to finding the position of the main pair, in which there is no noise and howling, and also ensures a long service life of the bridge. Not all masters are able to do this competently, so a hum that appears means that you are late.

However, the hum immediately after assembling the gearbox can be cured by adjustment.

Photos taken from the Internet!

Problems with the box

The Niva Chevrolet car, and in particular its gearbox element, as they say, is good, but with its own “peculiarities”. Somewhere after the first 50 thousand km, the device begins to show its teeth. There may be a hum or unusual noise. Such “features” make it clear that the bearings or gears are worn out. If you watch the gearbox for some time, you can determine what exactly needs to be replaced. What other problems can occur with the gearbox?

For each item listed above, there are reasons and ways to solve them. But today we will look at a specific problem - the knocking of the Niva Chevrolet gearbox and we will carry out the repair ourselves.

A knocking sound when the car is moving or when warming up indicates that the bearings, gears, shaft (primary) or axial ones in the gearbox have worn out. Actually, determining what exactly was the reason is sometimes very difficult. And if you do not have the opportunity to completely replace the gearbox, then your only option is to remove the device manually, disassemble it and carry out minor repairs.

Main pair wear

Howl, hum or just “singing” of the rear axle. It only appears under load or in a certain position when pressing the gas pedal. Definitely disappears when the gas is released when engine braking is performed. If the malfunction is at the initial stage, then the hum may disappear as you press the gas pedal harder and disappear at speeds of 110-120 kilometers per hour. But it doesn’t disappear, we just stop hearing it.

It first manifests itself at a speed of 70-80 km/h, but gradually the bar will drop to 40. Do not believe those who say that this hum can be eliminated by adjustment. Most likely, they do not understand anything about such mechanisms.

Source

Installing a clutch from a VAZ 2123 Chevrolet Niva

The ChevroNiva uses many components that have been taken and “refined” compared to a regular Niva. We are ready to return it to its place - with the advantages of the ChevroNiva! The list of advantages consists of items such as a large working surface area; a flywheel that does not require additional balancing; and finally, the effort when pressing the clutch pedal has now become at least two times less.

The proposed RCS unit is of a self-regulating type, for the so-called backlash-free clutch drive. No adjustment is needed and there is a large power reserve in both directions. The RCS rod has a fixed length, constant pressure;

About complete soundproofing of the cabin

For sound insulation, automotive sound-absorbing materials of the highest quality from the Vikar and STP brands are used. Thanks to this treatment of the car body, it is possible to reduce the noise level in the cabin to three dB.

- < Back

- Forward >

Howl and hum from the transmission on Lada Niva: we figure out what the problem is and how to fix it

The domestic small-class SUV Lada Niva, or Lada 4×4, or simply VAZ-2121 has been produced by the Tolyatti automobile plant for more than four decades. The model is in high demand not only among Russian car enthusiasts, but also among drivers in many other countries. The increased interest in the car is due to its uniqueness: an all-metal body instead of a classic frame structure, all-wheel drive with a center differential. Previously, few cars could boast of such a design, and those that were produced with such a transmission scheme were, as a rule, much heavier, larger and several times more expensive.

Throughout its history, the model was equipped with a manual transmission. Initially it was a manual transmission-4, since 1995 the SUV engine has been combined with a five-speed gearbox labeled VAZ-21214, which is actually a manual transmission unit-21213 adapted for 1.7 and 1.8 liter injection engines. In 2013, the mechanics underwent major changes and received a new name 21214M . However, along with the appearance of the new gearbox, constant conversations arose among car owners about where the howling and hum from the transmission on the Lada Niva comes from. Let's look into this issue further.

We get rid of vibration and extraneous sounds of the Niva transfer case forever

Let's start by diving into the materiel. Transfer case (TC) is a separate unit of an all-wheel drive vehicle, which provides multi-mode power distribution from the engine to the front and rear axles.

Externally, this is a mechanism located under the bottom of the car, in the body of which a multiplier (divider) is placed in series to obtain an intermediate gear ratio in the transmission and a splitter of one power flow into two. It is with the help of this device and its controls (levers) that go into the vehicle interior that the LADA 4×4 driver selects the all-wheel drive operating mode.

The RK directly connects the front driveshaft and the intermediate shaft (shaft) with the vibration damper to the vehicle’s gearbox. As is probably already clear from the description, this element is connected to the rear axle of the car via a rear propeller shaft.

Back

We study problems and repair methods

Any car owner definitely doesn’t need to be told why howling and humming are bad. Vibration of the transfer case on a Niva at low speed is quite common. The driver, of course, gradually gets used to many extraneous sounds in the car, but the noise level is high enough to make it impossible to carry on a conversation with passengers while traveling. Due to excessive noise pollution, you will inevitably have to deal with the problem.

Vibration and how to deal with it

The main reason for the occurrence of unnecessary sounds is multi-frequency vibrations of the components of the transmission. In general, the vibration of the transfer case on a Niva is one of the most common cornerstones that other car owners are forced to fight (or put up with) constantly.

- Check the cushions (supports) on which the power unit, gearbox and other parts are attached to the body, including the muffler. Any worn-out pad or rubber band can easily cause excessive shaking of the iron and accompanying rumble. It is better to replace worn silent blocks and pillows immediately.

- Be sure to pay attention to the intermediate shaft (inlet shaft). If you see signs of “fatigue” - change the elements that have become unusable, or the entire part!

- Examine the condition of the driveshafts. The “old” version of the cardan allows you to service (repair) the part, for example, by replacing broken crosspieces. In the case of CV joint driveshafts, you will have to replace a completely non-functional element. As for driveshafts on constant velocity joints (CV joints), this design is more expensive, but it has an undeniable advantage - it is easy to dismantle and install back, and this operation does not disturb the balancing of the driveshafts.

- It would be a good idea to pay attention to the placement of the transfer case. If an additional (third) RC mount is installed, unscrew it from the box; there is no need to unscrew it from the body. Set the transfer case to neutral, start the car and in fourth gear, rev it up to about 3-4 thousand revolutions. It must stabilize and, as they say, find its place. Turn off the car and secure the mechanism.

Features of the Lada Niva transmission

Without exaggeration, we can say that all-wheel drive brought world fame to the domestic car, but at the same time it became a real headache for car owners. Drivers literally unanimously claim that the previous four-speed gearbox was an order of magnitude more reliable than the five-speed unit. Apparently, the mechanics took the predecessor as the basis for the new modification and added a fifth gear unit, which basically causes serious trouble for the owners. In most cases, the block does not last even 30,000 kilometers, requiring premature repairs. In modification 21214M this is much easier, but there are still cases when the fifth gear fails.

The gearbox and transfer case are two units connected to each other by a short intermediate shaft with a rubber vibration damper. Without this design, there would probably be much less vibration, but you just have to put up with the design features of the SUV's transmission. Another possible source of vibration is the rear driveshaft, which thus makes it known that an imbalance has occurred. But we note that on a fully functional car, vibrations are either not felt at all or are felt only slightly. If a problem appears, then it’s time to undergo diagnostics and find the cause of the malfunction.

Dismantling and assembling the Niva Chevrolet gearbox

IN WHAT sequence should you start dismantling the gearbox on a Chevrolet Niva? #AlexeyZakharov. Auto repair

Having pressed in the 1st gear gear bushing until it stops,

The manual transmission has a complex design, replacing it is quite expensive. Therefore, if repairs are possible, the owners...

Remove the key from the groove of the secondary shaft.

Drain the oil from the gearbox as described. Zoom Secondary bearing for manual transmission repair of Niva Chevrolet, replaced with a new one. It was not difficult to replace the synchronizer locking rings, but securing it all with spring washers became the most confusing task. If you decide to replace them, then you will need to pierce the bearing and the secondary shaft down, remove the clutch housing and check the spring washer.

To do this, just listen to the car. When is box repair required?

View topic

Of course, I also rely on experts, but it will be much more difficult for them to give the correct answer. Really, it will help not only me, but also others.

How to remove the front gearbox on a Chevrolet Niva

I’ll probably even make a good video for YouTube on how to solve this problem, because right now there are no instructions. By the way, one friend on the forum wrote about the same problem, not here. He replaced the transfer case with a new one - it didn’t help. I rebuilt the gearbox - it didn't help. I checked the gearboxes - it didn't help. And then he dropped the topic. Maybe this information will also help. If you drive in neutral, there is no hum. There is also a funny thing - on the second one there may or may not be a buzz as the stars rise in the sky. In order to at least somehow clarify why and how I decided to crawl under the car while it was standing on a hillock with its wheels. He turned on the neutral on the gearbox and began to pull the cardan shafts.

Read more: Changing silent blocks in the field

The rear play is at most 10 degrees. The front play is significantly more degrees. Well, I decided that the gap between the gears is in the gearbox or in the transfer case.

But I accidentally noticed that when I twist the cardan, the drives that go to the wheels also spin, and immediately, that is, if there is a gap, it is barely noticeable, at least with this type of diagnosis. I didn’t even think about the wheels right away, I decided that it was a transfer case and calmed down.

But then I realized that I was in neutral and there shouldn’t be any resistance from the transfer case. I put it in 1st gear - the play is no more than that of the rear driveshaft.

And just then I was faced with the fact that I don’t know how the front axle, or rather the drives, works. I looked at the book, leafed through the pictures, but I still have little idea what could be buzzing there, or whether it’s there at all.

I did not apply thread sealant. It was also discovered that the splines on the cardan were filled with epoxy, which is why they did it.

The malfunction manifested itself, one might say, abruptly—it just started growling in neutral. I blame it on the loose shank nut. Can the box and pendant be immediately discarded from consideration?

We think there is no need to guess about the box, cardan or gearbox. You need to lift the car, accelerate it and listen from below which of the units is making noise. Rock the gearbox shank to check for any play due to a loose nut. That is, both faults are determined manually? Therefore, if the reason is that the bearings are not tightened, then it turns out that the problem can be solved very simply - by simply tightening the nut.

As for the special wrench, I remembered the correct name - it's a torque wrench. Loose bearings can be determined without unscrewing anything by lifting the car on a lift.

And it is impossible to confuse these two faults: undertightening and overtightening. It’s like looking at a tire that’s flattened to the rim and wondering whether it’s over-inflated or under-inflated... From here the conclusion was that they’re guessing... Your sound is similar in description to either a shank bearing that’s not fully tightened, possibly a faulty bearing, or the hum of an incorrectly adjusted pair. We already discussed this at the beginning of the conversation. If the bearings are not tight enough, this can be corrected by tightening the adjusting nut; mind you, this is not at all easy!

Knock in the transfer case of the new Chevrolet Niva. Straight from the factory » diabloarea.ru – Your autopulse

To do this, heat the silicone in boiling water and immediately pull the hose or gasket, depending on what you have, onto the lever until it has cooled down.

Rumble in RK Niva Chevrolet

To avoid problems finding the cause, first check and tighten the support fasteners; Vibration can be caused by jamming of the joints on the cardan shafts. But I am a mechanic of at least 3 categories, and in some cases 4 and 5.

Let's try to figure out the well-known problem of the NIVA car, the transfer case is humming, what to do and how to remove it...

The kit is manufactured in a factory using structural steel; 2.

Plus, during the subsequent replacement of CV joints, unlike cardan shafts with a cross, their balancing is not disturbed. Let's consider all the main symptoms of a malfunction, as well as ways to eliminate them, in more detail. Most often this happens due to damage to the sealing gaskets.

I drove it without a cardan with a differential lock - the same howl. They didn’t remove the rear one, although it would have been necessary, but in order to remove it, you have to lower the transfer case, they thought that the problem was in the transfer case.

We checked the cardan play - everything is fine. We removed the transfer case and removed the cover from the rear axle. It looks like there are some abrasions.

In general, it was annoying that the bearing is pressed ONLY by the cover, because the bearing rotates freely around the seat on the housing, but they said that this is normal, although I’m not at all sure.

Film it, do something, put it on, go, get upset, film it again... and so on ten times until you give up.

The best thing to do is to put the transfer case on a stand that can create a load and find by sound what whistles and squeals, but... what is not there is not there. The only thing left is trial and error. I’ve done part of the journey, and in certain circles it seems to be customary to learn from other people’s mistakes. Firstly, the nasty sounds come only in high gear and only under load.

Secondly, the new transfer case whistles, it’s not so disgusting, but it becomes more disgusting already in the process. Noise in NIV is normal, but if you are at 80 km.

Howling transfer case Niva Chevrolet

First, we correct the main cause of the noise, replacing the original switching levers with modified silent ones. They are assembled according to the principle of levers from the Chevrolet Niva, this is no longer a “bare” metal blank, special anti-noise bushings are inserted into the lever, which dampen vibration, preventing noise from penetrating into the cabin. It is shown how to install the levers yourself, getting rid of the noise.

And in terms of handling, the Niva is head and shoulders above any of them, and the more maneuverable frankly tuned versions of the G-Wagen like AEMJ or Brabus, which are already far from the asphalt, don’t count. Also, the list of advantages includes ease of use, availability of parts and components, both in terms of price and the fact that they can be found at every step!

Of course, AvtoVAZ and General Motors have fixed many bugs since the days of the good old Niva, and yet, despite all the above advantages, the car also has big disadvantages, for example, vibrations of the universal joints and transfer case, not the best quality of factory parts and the absence of any noise insulation measures . So, for this purpose, we propose to make the following modifications in your workshop: Of the above modifications, any of them contributes to a significant improvement of certain characteristics and an increase in the comfort of Niva operation and maintenance.

A subframe for alternatively mounting the transfer case has a number of advantages.

NIVA 4x4. How to remove the noise from the transfer case? See for yourself!!!

The owner of this car may experience many different breakdowns. Knocking is far from the only cause for concern. Let's look at all the main symptoms of a malfunction, as well as ways to eliminate them, in more detail. Often similar signs appear when other parts wear out.

Installing cardan shafts on CV joints

Sometimes there may be a persistent vibration of the floor, as well as the chairs. This happens in all driving modes. The problem is the elasticity of the transfer case clutch. This is due to the low-quality rubber from which it is made. Due to temperature changes, the coupling cracks and loses its properties. This problem is treated by installing a new part.

Vibrations during start-up and acceleration are also frequent companions of the Chevrolet Niva. They are usually observed in the area of the front seats. There may be several reasons for this problem: The rear engine mount is loose.

w210, Mercedes, telephone, standard

Source: https://diabloarea.ru/niva-shevrole/shumy-v-razdatke-niva-shevrole.html

Common Lada 4×4 transmission problems

You can often hear from drivers that the car’s transmission is constantly humming and crunching. Many people have to sort out the gearbox after 20 thousand km, and then carry out minor repairs every 10 thousand km. High-quality foreign additives and oils do not radically change the situation. Howling and humming are a characteristic feature not only of the Lada Niva, but also of other AvtoVAZ vehicles, for example Lada Granta and Lada Kalina. AvtoVAZ is aware of this problem. Unpleasant sounds and crunches in the operation of the transmission are explained by poor modification of the teeth of the gears and the main pair. In 2014, the unit was seriously modified, but the problem was never completely eliminated.

Representatives of the plant comment on the fatal problems of the gearbox:

With the current production culture, it is impossible to cope with extraneous sounds. Significant investments are required in the modernization of the machine fleet, since the current factory equipment does not allow processing gearbox gears with greater accuracy

The factory has been fighting the rumble and howl of the transfer case virtually from the very moment the car appeared. In 1999, the Niva was equipped with an improved transfer case with fine-module gears. The level of external noise was indeed reduced, but the question of reliability and endurance of the modernized unit arose. Today, the Lada Niva 21214-M is equipped with a sealed transfer case with an updated ventilation system and an open breather located in the engine compartment. The design eliminates the possibility of excess pressure forming in the crankcase. Serious changes have also occurred with the cardan shafts: now they are on CV joints with boots. The plant's new balancing stands now make it possible to equip cardans with greater geometric accuracy.

Possible faults

The need to adjust the elements of the front axle is assessed by the presence of noise and vibrations that occur in various operating modes of the VAZ 21214. Thus, conditionally acoustic signs can be divided into two groups: • Constantly recorded; • Fixed during braking with the help of an internal combustion engine or acceleration.

The nature of the sounds may resemble: • Howling (wear of the main pair); • Crunching, “trolleybus” hum (destruction or overtightening of the shank bearings, unscrewed drive shaft nut, axle bearings, incorrect adjustment of the gearbox gears); • Intermittent “shuffling” (differential bearing). The difficulty of diagnosis lies in the abundance of extraneous noise produced by other components of the car.

Handout pillows.

In this new detail, we are completely on the side of the AvtoTAZ designers. A detail that can truly be called tuning. There is a lot of “rubber meat” and the design already works completely differently. We recommend replacing the old-style transfer case cushions with new-style ones as soon as possible. On many sites dedicated to the Niva, these pillows are advertised as spare parts for the Niva-Urban, and they ask for a lot of money. Meanwhile, this part is simply installed on the M-ki. Catalog number 21214-1801012-02.