When to change suspension springs?

One of the important elements of the suspension are springs. Determining when to change suspension springs is not difficult. You can carry out this procedure yourself or contact a service station.

If the springs fail while driving, every hole or bump on the road will be felt, vibrations, extraneous noises, and knocks will appear. In addition, the movement of a car with such a breakdown becomes unsafe for road users, so sagging or broken (with a broken coil) springs should be replaced immediately.

Why do springs break, symptoms of failure?

The spring looked almost new

The working environment of the suspension spring can be called complex, so during operation it is easy to damage the protective coating of the coiled body of the element and expose the steel, which can very quickly begin to corrode under the influence of salts. But most of all, the spring element suffers in winter, when water, salt and sand get between the coils, which leads to its damage.

Typical symptoms of a broken suspension spring:

Irregular knocking and vibration on uneven surfaces;

Characteristic dull impacts when turning the wheels strongly or intensive braking; There is a difference in the height of the car along the longitudinal axis (the left side is higher than the right, and vice versa) or between the front and rear parts; Strong rolls when driving and braking

Signs of sagging springs

There are a number of factors that will help determine whether the suspension springs are faulty, for example:

- Knocking noise while driving.

- Strong vibration.

- Reduced ground clearance without load

- Car sagging even from a small load.

- The car rolls to one side.

All of the above problems indicate that the suspension springs have failed. It is also worth carefully inspecting the springs: any area of corrosion is a likely site of future failure.

Where to buy Patron suspension springs?

Today, the market offers a wide range of auto parts from various manufacturers, which makes it difficult for consumers to decide on a brand and choose a truly high-quality product. The prices for original spare parts are quite high, and not every driver can afford to purchase them. Among the available alternatives, which are not inferior in quality to the original ones, PATRON spare parts, our own brand, stand out. You can purchase Patron suspension springs, as well as other automotive components, in the company’s stores, as well as at points of sale from official dealers of the brand.

Patron auto parts undergo strict quality control during the production process, which is confirmed by numerous certificates. Suspension springs of this brand are made exclusively from high-quality raw materials in compliance with all requirements for production technology. Car owners who purchase PATRON parts note their reliability and wear resistance.

From the outside, checking a car's suspension seems like a complex process that requires global technical knowledge and equipment proficiency. In fact, it is possible to check the suspension yourself - this does not require equipment or complex instruments. We will tell you in this article how to properly check the suspension yourself, and what conclusions you can draw after checking.

Installation Tips

- Is it possible to install parts of different classes?

Remember that the springs on the suspension must be of the same class. Let’s say you installed A-class parts on the front suspension, which means you also need to install “A” class on the rear suspension.

If a similar class is not available for the rear suspension, then in exceptional cases class “B” is assigned to the rear suspension.

If B-class springs are installed on the front suspension, then class “A” springs cannot be installed on the rear suspension.

Install suspensions of the same class on the left and right sides of the same axle.

- What springs are better to install on a VAZ 2107?

Before changing parts, make sure that it is really necessary. You can check it in the following way: standing at the front of the VAZ 2107, swing the body down. If it quickly rises to its original position, there is no need to replace the springs; they are in good condition. If the body does not rise and continues to sway, then replacement is necessary. In the same way you can check the rear suspension of the VAZ 2107.

To improve the aerodynamics of the VAZ 2107 and improve the sensitivity of the steering wheel, it is recommended to install stiffer springs than the original ones. You can buy those designed for VAZ 2104, cut off one turn. It is imperative that on a VAZ 2107 you need to change two at the same time, otherwise the car will lose stability on the roads.

It is not recommended to install reinforced rubber gaskets on 2107, because the spring will break through.

- Will Niva springs fit on a VAZ 2107?

If you want to make a sports tuning on the VAZ-2107, the suspension is made more rigid, this improves the quality of handling without reducing the level of comfort.

The rear springs are stiffer than the front ones. The factory ones are too soft, and the car quickly loses control, the bottom gets scratched on the road surface. To increase the stiffness of the suspension, it is recommended to install Niva springs on the VAZ 2107.

- What springs are better to install on a VAZ 2110?

On the VAZ 2110, the front spring often breaks due to poor quality roads, so it needs to be replaced. Moreover, you can do this yourself, without contacting a car service. All that remains is to find out what is best to choose from the range offered for the 2110.

On the front suspension of the VAZ-2110, as standard, 2108 springs are installed, on the rear suspension - 2110. In the absence of original parts, car enthusiasts are advised to install SS20 highway, the car rides smoothly and is stable when cornering.

- What springs are best to put on a Priora?

If the springs on the Priora have sagged, it is recommended to install new original ones from VAZ. Choose only the class depending on the goals of your tuning. Class "A" is more stringent. In the absence of the original one, according to car enthusiasts, it is better to install a kit with a lowering Eibach Pro-Kit (-30 mm).

- What springs are better to install on a VAZ 2114?

The VAZ 2114 suspension is quite durable, and the need to replace parts occurs quite rarely. Therefore, not all car owners of 2114 cars know what is best to choose from the wide range offered on the markets.

Sometimes springs from 2112 are installed on a VAZ 2114, they are a little stiffer, designed for a larger weight of the car, so they raise the 2112 slightly - by 2-3 cm, which means that in this way you can increase cross-country ability. If, on the contrary, there is a desire to lower the car, then it is recommended to purchase an Eibach, with the front ones being -5 and the rear ones -7, so that the car does not ride up.

So, the choice of springs for VAZ is quite wide, the main thing is to choose the correct stiffness characteristics according to the load on the car and operating conditions. You will find a variety of advice on forums and blogs. Of course, it is better to first consult with specialists. Refusal of original parts in favor of other manufacturers may be dictated by the desire to improve the driving performance of the car, but be sure to compare the cost of tuning and the result obtained.

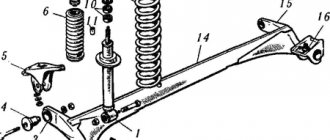

How to check the front suspension

Most cars have a standard McPherson front suspension. The most expensive part of the suspension are the struts and shock absorbers. In terms of difficulty of replacement, the following are the silent blocks of the stabilizer and levers. The easiest and cheapest thing to change is the ball joints of the front suspension.

When checking the front suspension, first of all, inspect the anthers and rubber covers of the parts, and then proceed to inspect the silent blocks, balls and all of the above. Inspect the mounting bolts and tie rod ends. If you find a part whose cover is damaged, you will need to replace the part.

Carefully inspect all rubber seals; they should not have mechanical damage. Separately examine the parts adjacent to the body - here you need to inspect more carefully due to poorer visibility.

The shock absorber will show oil leaks - the first signs of a malfunction. They can be noticed before sounds occur when the car rocks. If the car swings instead of the vibrations being dampened, this will also mean wear on the shock absorber, but at a more advanced stage - again, replacement is required.

Determine the problem by eye

When the springs are heavily worn, they sag, and all that is required in this case is to inspect the car, paying attention to its fit. The car is lower than it should be - a sure sign of “fatigue” shock absorber springs. This also makes it impossible to adjust the wheel camber.

Ball joints are checked in an inspection hole; this is somewhat more difficult, as it requires the ability to look under the car, as well as the presence of a mount. Press the lower control arm bushings and check how they move up and down. If there are no backlashes, and the rubber on the parts is intact, then everything is in order and you don’t have to worry.

Driving and on the move

Some defects are diagnosed while driving, or simply from behind the wheel in a static position. Problems with the steering rack are diagnosed by turning the steering wheel to the side and rocking the rack. Usually the cause of problems with this mechanism is wear of the guide bushing.

Steering rods and ends are also checked by moving the steering wheel, but not once, and from side to side. In this case, you will need an assistant, since while moving the steering wheel you need to hold on to the steering tips and rods - they should not play. If there is play, it means the tips are faulty and require replacement.

The easiest way to determine the condition of the hub bearing is while driving - in the event of a malfunction, it emits a loud and uniform hum; it will be difficult not to hear it even with good sound insulation of the car. The condition of the wheel bearing can be determined by hanging it: spin the wheel, or swing it at the top point, and check for play.

Since you have taken to studying the car's suspension seriously and asked the car seller for a test drive, test the outer CV joints that make a cracking noise when turning sharply with acceleration. Carry out a maneuver and listen to how the car reacts.

How to check the rear suspension

The main part of the components and assemblies is concentrated in the front suspension, so it is easier to check the rear suspension. On most budget cars the rear suspension is dependent, its most expensive part is the struts; on medium (budget) cars they last about 100 thousand kilometers, after which they begin to “get tired”.

There is nothing else significant or critical in the rear suspension, except for the silent blocks, which are practically eternal (again, look at the condition of the rubber bands). If the rear suspension is independent, its design is somewhat more complicated, but the essence does not change - apart from the struts and silent blocks, there is nothing fatal, but in an independent suspension they wear out faster, and this is more noticeable.

It is best to check the rear suspension together with the front during a test drive; here the sounds and behavior of the car will best tell you about the situation - whether something “clunks” or not, and how it absorbs it - whether it sways on bumps or not. If the car rocks on uneven surfaces not only up and down, but also sideways, this indicates that the suspension is damaged and repairs are urgently needed. This also means that the car was not looked after or looked after at all, and it is better not to buy such a car.

How old springs can quickly “kill” shock absorbers and suspension: review and solution to the problem

Did you know that motorists are increasingly faced with one extremely interesting problem, which is not only difficult to identify during a technical inspection, but is not always possible to feel after an immediate breakdown?

What kind of problem is this peculiar? It probably occurs in a very small and unimportant system of the car. Well, if you only consider that the springs of a car are an insignificant and unimportant detail. Yes, as it turns out, more and more often owners of old cars are faced with breakdowns of the suspension springs of their cars. But this is only one side of the problem. According to the second, there are already frequent cases of springs breaking on relatively new cars, literally a few years after the car leaves the factory gates. Moreover, the first signs of the beginning epidemic of breakdowns were found in Europe, which is relatively good in terms of road quality. In particular, the problem is observed in Poland.

So what happens to one of the main suspension elements? But before answering this question, let’s first quickly remember what a car spring is and why it is needed.

Springs play a very important role in the suspension, because we are talking about suppressing shocks and overloads caused by the movement of unsprung masses (wheels, brakes, suspension elements), that is, ensuring comfort while driving, safety and maintaining a given ground clearance under the bottom of the vehicle.

Springs also reduce the forces acting on the suspension. Without springs, the car would be completely impossible to drive. For example, without shock absorbers you can at least drive slowly, but without springs it is almost impossible to do this! Why is such an important element discussed so little in reviews? Why don't they pay him enough attention?

Everything is quite prosaic. First: since coiled elements do not require maintenance, they wear out very slowly, and until mechanical and very significant damage occurs, it will be difficult for the driver to feel the difference when driving between a new spring and one that has traveled a hundred or two thousand kilometers.

Yes, the car will slowly lose ground clearance all this time, but that seems to be the whole difference. You are unlikely to feel any mechanical deterioration in handling.

The tag will tell you that these springs were on the car from the very beginning.

But what’s more interesting is that even cracking of the spring coils cannot cause major complications in the car’s handling, since damage usually occurs at the very end of the winding, at the place where the spring is fastened to the body or suspension, the so-called spring socket.

In addition, the length of the spring itself does not change significantly even after breaking until both parts of the spring move relative to each other. Only after this the height of one of the wheels drops slightly, which, however, may also go unnoticed by the motorist.

Main suspension parts

It is best to check the main components and parts of the suspension while driving; the sounds will tell you in detail whether there are any malfunctions. The car needs to be driven over uneven surfaces, such as rails or bumps, but without fanaticism, so as not to damage the vehicle.

The main components, the condition of which you need to know:

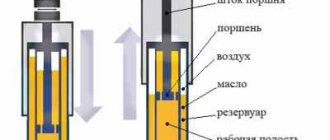

- Shock absorber - serves to dampen vibrations. If the car rocks strongly, the shock absorber is faulty.

- A spring is an integral part of the shock absorber; if it sags or bursts, the car becomes significantly lower than the factory setting.

- The ball joint is mounted on the lever on one side, and on the steering knuckle on the other. Responsible for turning the steering wheel.

- Lower arm – attached to the body at two points, ensures the operation of the suspension. There are silent blocks at the attachment points to the body.

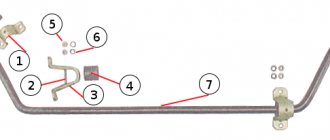

- Stabilizer link - connects the stabilizer and the strut, thus connecting it to the suspension.

- Steering rack - transmits force from the steering wheel to the steering knuckles. When turning the steering wheel, there should be no play and no extraneous sounds.

The suspension itself will tell you about the main points, but if you want to know everything in detail, then it’s better not only to look under the car and ride it, but also contact service specialists who, using a lift, will be able to examine the condition of the suspension parts and tell you exactly what there is a problem.

KYB-Russia › Blog › When and why to change springs

How to understand that it is time to change the springs and what to expect for a car enthusiast who does not do this.

The spring itself is responsible for the vehicle's ground clearance and the rapid return of the wheel to the supporting surface while in motion. At the same time, the spring and shock absorber should be perceived as a single whole; one part without the other does not make sense, and they are designed for a specific model in pairs.

When the wheel hits a convex bump, the spring compresses and transmits a softened impulse to the body. At this moment, the shock absorber compensates for inertial swing by converting the kinetic energy of vibrations of the body and unsprung masses into heat, which is dissipated in the atmosphere through viscous friction inside the fluid. The spring then returns the wheel to the optimal contact position and provides traction. The better the balance between the shock absorber and spring, the more confident the grip on the surface, the higher the level of safety and comfort.

Over time, the spring “gets tired”: it loses elasticity, suffers from corrosion and breaks. Unfortunately, not always without consequences. Sagging springs reduce the operating time of shock absorbers by approximately half due to increased shock loads and a shift in the piston stroke range. Broken or sagging springs impair ride comfort and directly affect safety. The main risks are changes in wheel alignment angles, which are accompanied by any change in the effective length of the springs, and an increased risk of spring breakage in motion - for example, in a tense turn. In order not to change shock absorbers and suspension elements too often, to enjoy a soft and safe ride, it is enough to know a few signs of problems with springs. Let's talk about them.

Five clear indications for replacing springs

1️⃣ The car sank on one of the wheels, you can see the difference in the distance from the ground to the arch of the wheels of one axle. On one side of the axis the distance is normal, on the other it is clearly less. Let's imagine that we are talking about the front axle and you are the driver. It feels like a flat tire, but the tire is absolutely intact.

Most likely, a whole coil is broken. In this case, visual diagnostics - inspection on a lift - will help with making an accurate diagnosis. Note that such symptoms can also be caused by a damaged spring fastener to the body. For example, a broken spring cup. In this case, you need to cook the body - springs and shock absorbers have nothing to do with it.

2️⃣ Extraneous noise appeared in the suspension without external signs of wear on shock absorbers and springs. This happens when half a turn breaks off. A piece of the spring dangles in the cup, the ground clearance is maintained, but there is a squeak. It is the remaining part of the spring that is rubbed against the debris and makes dull scraping sounds.

3️⃣ The car has become closer to the ground even with an average load, and if you load the trunk well, there is almost no suspension compression left. Mud flaps touch the asphalt, and excessively frequent contact with speed bumps is possible.

The spring has sagged and can no longer hold the usual load. A typical age-related problem, but it also happens when the car is frequently overloaded.

4️⃣ Many motorists have a usual parking spot where they usually park adult children or spouses. Over time, the suspension springs lose their load-bearing capacity and the ground clearance decreases slightly, but the driver most often does not notice this. Note to car enthusiasts: if one fine morning, after the passenger has boarded in its usual place, the door hits the curb or buries itself in a flowerbed, it’s worth checking the springs.

5️⃣ Traces of corrosion on the springs when inspecting the suspension and areas from which the paintwork has peeled off. Climate conditions, careless installation, road reagents, faulty shock absorbers and contacts between coils damage the protective coating of the spring. This leads to corrosion. It weakens the metal structure, which eventually leads to failure.

Implicit indications for replacing springs

More rigid suspension operation, frequent breakdowns of shock absorbers. Let's say you have a crossover and you don't observe anything of what we described above. With high ground clearance, it is not so noticeable that the car has sagged, but this is critical for the springs. You have already changed shock absorbers, bump stops, silent blocks, but you still feel shocks on uneven surfaces. If you do not change the springs, the new parts will last 2 times less. And this is natural, because the compression stroke of the suspension has been reduced due to worn springs. The body, glued glass suffers from acceleration peaks, and “crickets” take up residence in the cabin.

Replacing springs along with shock absorbers

To change or not is an individual question. The spring can run 300 thousand km, or maybe 40. The third generation Honda CR-V, for example, is an excellent car, but the springs on it only run 50 thousand km due to miscalculations in the design and material of standard parts. The situation is similar with the Outlander XL, Citroen C-Crosser and Peugeot 4007 (essentially the same car). Sometimes the problem of premature spring subsidence is a feature of a particular model and nothing can be done about it.

If we are talking about an average car, then the approximate service life of a set of springs can be considered a mileage of 120-150 thousand km, which approximately corresponds to two sets of shock absorbers. We strongly recommend installing the third one with new springs. This is especially true for cars purchased on the secondary market. Often, before selling them, they check the mileage and the likelihood that the springs are from the factory and the shock absorbers have already been changed is very high.

“Well, God bless her if she breaks, it’s okay”

It depends on your luck. A broken thread can rip a tire, damage a brake hose, or break a suspension part. It can also fly out from under your wheel and into the windshield of someone who is following you.

Change the springs if: — The ground clearance has changed or the car begins to sag significantly under load; — there are traces of corrosion or damage to the paintwork; - you have owned the car for a long time and are changing the struts for the third time; — changing shock absorbers on a car that you bought on the secondary market; especially if there is a suspicion of a twisted mileage.

In the next article we will talk about how to change springs correctly and many interesting points about buffers, spacers and other suspension modifications. Check back next week and subscribe if you haven't already.

We are launching a competition among our subscribers. The winners receive a 24-hour car promotion and a page background from KYB.

Conditions: 1. Be subscribed to our blog. 2. Have a record in the logbook about your experience using KYB springs. The more detailed and informative the entry, the better. 3. Leave a link to your post in the comments to this article. 4. Be among the first 50.

We will sum up the results on April 15, good luck!

Some of the reviews describe the installation of springs not selected from the catalog. We do not support this method, so we exclude the authors of these reviews from the list of winners.

The promotion will take place within 2 weeks. Important:

if you have several cars, write to nikkondrabaev which specific car you plan to promote.

The competition continues. Details are in the next article.

Source