Try it on!

The simplest, fairly quick and not so expensive way to get general information about the effectiveness of the suspension is to stop by a diagnostic stand, take measurements and listen to the verdict.

Another question is how precisely the verdict will apply directly to shock absorbers. The fact is that in the case of various kinds of “shaking” (of which there are more and more recently), the presence of at least one faulty element (not necessarily a shock absorber) will significantly affect the final results of the efficiency indicator. In addition, the algorithms by which the performance of the suspension are assessed differ, and diagnostics of one car on different stands can lead to the fact that the data obtained on the condition of the suspension may differ.

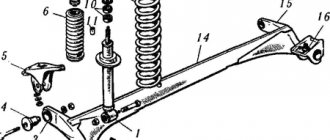

Checking shock absorbers of VAZ cars

The technical condition of shock absorbers on VAZ 2105, 2107, 2108, 2109, 21099, etc. cars can be checked in several ways.

The most complete and accurate check on a special diagnostic stand. It allows you to evaluate the vibration damping efficiency of the shock absorber. Without a stand, there are also several methods for subjectively assessing the condition of a car’s shock absorbers.

Preparatory work

— Before carrying out the inspection, it is necessary to visually assess the condition of the shock absorbers: the presence of fluid leaks, mechanical damage, mounting of the shock absorbers, the condition of their rubber bushings, rubber-metal hinges. In addition, the condition of the springs and suspension elements is checked. It is best to do this on a viewing hole or lift.

Shockabsorber-replacement-14_

There are known cases when, when diagnosing a car on a “shaky ride” with a working suspension and recently replaced shock absorbers, the data obtained indicated low residual effectiveness of the suspension. But during the “test drive” the car behaved perfectly. The reason is that the stand was not designed for more “hard” settings of the tuning series shock absorbers compared to the characteristics of the original products, as a result – a wrong verdict. Well, that happens.

A very important point! The final indicators may be influenced by such parameters as tire pressure, vehicle loading during diagnostics, small deviations from a straight line when driving to the stand (appearance of a deviation angle from the longitudinal axis), accidental installation of the vehicle on the handbrake, uneven loading of the vehicle during diagnostics, etc. .d. It will be a real pleasure for a careless repairman to “cheat” a client out of the cost of new shock absorbers, so that in the meantime, as if by accident, pump up his flat tire...

There is no single known correct method for diagnosing shock absorbers. Each case has its own specifics. Bon Voyage!

How to check shock absorbers for performance yourself: simple methods

Hello! Operating a car involves the need to constantly monitor and control its behavior, as well as the condition of the vehicle components. One of the key ones is the suspension. In this regard, I want to tell you how to check shock absorbers without outside help.

There is nothing complicated in carrying out diagnostic measures. And you can see this for yourself after reading the material. If the rear or front struts begin to wear out, or there are problems with the shock absorption system in the car, a check will let you know about this.

I advise you to do this while operating your car, as well as when buying a used car. By looking at the suspension you can understand the general condition of the car. If the car is new, there will definitely be no complaints about the suspension and shock absorber.

In total, we will consider 5 methods with you. 4 of them are performed independently. Another professional one, and involves testing on a bench.

Shock absorbers

If the car begins to behave differently than before, potholes and bumps have become more noticeable, and when driving at high speed it is unstable - it’s time to check the depreciation; perhaps the system has exhausted its resources. How to do this correctly?

Simple ways to check shock absorbers

Thanks to the inspection, you can assess the condition of the shock absorbers. If its body has oil stains, then a new pair of shock absorbers is needed. Why a couple? Because they change in pairs, either front or rear, or maybe all 4. Changing one at a time is strictly prohibited. Of course, you cannot check a gas shock absorber using this method, but there are other ways.

You can also check the shock absorbers directly while driving. If you move and hear knocking noises from the suspension, but are absolutely sure that it is in good working order, there is reason to think about replacing the shock absorbers. This method of checking shock absorbers is very useful when purchasing a car. After all, it is in no way possible to disguise the behavior of a car on the road.

The most effective way is extreme driving, it puts an excellent load on the racks. If during sudden movements the car does not maintain its trajectory and takes off, this is a clear sign of a malfunction of the equipment.

4. Traditional method in the form of rocking the car

Many car enthusiasts suggest checking by pressing on the fender of the car with a sharp release afterwards, and at the same time monitoring its swinging before taking the starting position. If it straightened out right away, great, but if it still swayed, bad. But using this method you can check the shock absorber strut for complete inoperability. If it is still functioning, but is already running out, this method will not tell you about it.

Why is it dangerous to use a car with faulty shock absorbers?

When turning at high speed, a car with faulty shock absorbers can become uncontrollable, change its trajectory, or even roll over at any time. Therefore, if a malfunction of the racks is detected, you should not tempt fate; it is better to replace the part to avoid serious troubles.

Verification methods

While operating your car, you may have some doubts about whether the current shock absorbers are suitable or not. They come in front and rear on cars.

Regardless of where and what elements are on your car, the testing methods to identify problems are identical for all. I will only add that the shock absorber can be oil, gas or gas-oil. If you want to know which one is better, write in the comments. We will prepare a separate material on this topic, where we will discuss the strengths and weaknesses of each design option for a car shock absorber.

The main advantage of the methods is that the test can be carried out without removing them. These are express tests of performance and current condition.

Yes, removing the shock absorber will give you a better understanding of what's going on with it. After all, problems with the suspension do not always mean that the shock absorber is faulty.

All procedures presented are applicable to any vehicle:

- for VAZ 2107;

- on Gazelle;

- Lade Priora;

- Hyundai Accent;

- Daewoo Lanos;

- Renault Logan;

- Prado 120;

- Nissan Almera;

- Kia Sportage;

- Chevrolet Aveo, etc.

VAZ 2110;

All ways to independently determine the malfunction of the shock absorber support or the shock absorber itself are divided into the following types:

- visual;

- rocking method;

- behavior;

- heat;

- bench test.

Now I propose to talk about each of them separately in order to clarify some of the nuances.

Visual method

For a visual inspection, you will need to carefully examine with your own eyes the condition of each of the shock absorbers installed on the machine. Here it is better to use a pit or overpass, and also take with you a portable source of good light.

There are several indirect signs indicating that the shock absorber is not working or its life is at its limit.

- If the machine has not been used for a long time, traces of corrosion appear on the surfaces of the shock absorbers;

- Most often, rust is noticed on visible areas of the stem;

- If there is rust, there is a high probability of oil seal wear;

- If there are traces of oil on the body, this is also a bad signal;

- This sign indicates depressurization;

- When an oil leak occurs, repairs sometimes help, but often the problem is eliminated by replacement;

- If you find traces of oil, wipe these areas with a dry cloth, and after a few days, look at these areas again;

- If oil reappears, they should be removed and replaced.

A leak of working fluid indicates that the integrity of the housing has been compromised. It's not worth using the car, but you can still use it for a while.

But the absence of corrosion and oil during a visual inspection does not guarantee that everything is fine with the shock absorber. There is still a possibility of wear and tear on the internal components of the structure.

Another method that allows you to diagnose a shock absorber malfunction. Often appears in various thematic videos. Quite easy to use and at the same time informative.

To check, you need to stand near the front or back of the car, depending on what elements you are checking, put two hands on the hood or trunk, and begin to actively swing up and down, pressing your hands to the body. It is better to do this near the wheel. When the swing is over, with a working shock absorber, the car should return to its original position without additional vibrations. If you let go of the car, but it continues to rock, this is a bad sign.

A functioning shock absorber allows vibrations to die out after just 1 or 2 swings without your participation. If the body shoots up sharply, this indicates a malfunction of the strut. And when you can’t rock the car at all, the problem is a jammed rod.

The method is not always effective, since some cars are difficult to physically rock. Plus, this technique diagnoses problems only with really worn shock absorbers.

Machine behavior

The next test option, in my opinion, is the best. Although the signs will still be indirect. If you notice at least one of the symptoms listed below, this is a reason to contact a car service for diagnosis.

- When entering the road, the car begins to actively jump over uneven surfaces, which has not been observed before. Behavior is no longer so gentle;

- The car can also sway violently in different directions. When hitting a bump, the vibrations do not stop for a long time. This is especially noticeable for rear seat passengers;

- The car's response to steering has changed. It is not as clear and sensitive;

- The sound of a faulty suspension element appeared in the form of rattling or knocking. Especially when driving on uneven areas.

Just don’t think that the check needs to be carried out at high speed or when skidding. An average speed and an ordinary flat road are enough, on which you should perform several maneuvers such as a snake. Try to accelerate and stop.

Shock absorbers for the VAZ 2107 - tips for diagnosing and repairing the chassis

How to check shock absorbers on a VAZ 2107 and determine their condition

The VAZ 2107 car was very popular at one time, and is still in some demand due to its low price, but its reliability is far from the best. Owners often have to carry out repairs, so the sale of spare parts for the VAZ 2107 has become a good business for some auto shops.

Relatively often, motorists also repair the chassis of the VAZ 2107. It should be noted that, as a rule, shock absorbers in the chassis fail and auto mechanics recommend changing them every 40 thousand km, regardless of whether they have leaked or not. If you do not make this replacement, then certain difficulties may arise with driving the car, and its braking distance will be increased. It is advisable to change shock absorbers on a VAZ 2107 on a lift or inspection pit, but in emergency situations you can get by with just a jack.

A signal to replace the front shock absorbers on the “seven” may be the presence of oil leaks on the body or deformation of the shock absorber. To make sure that this device is faulty, you need to sharply press on its hard part and release it; if the body sank and returned to its original position without vibrations of the suspension, then the shock-absorbing part is in perfect order. But when the body continues to oscillate, this will indicate a malfunction of the shock absorber and the need to repair the chassis of the VAZ 2107. Experts advise contacting service centers to replace the shock absorbers.

The rear shock absorbers on a VAZ 2107 also need to be changed in case of a fluid leak. To check their condition, you need to sharply press on the rear wing of the car; if the shock absorber is in order, then the suspension should slowly sag, and then slowly return to its previous position.

The VAZ seven is technically simple, but many negative factors, including bad roads, lead to failure of shock absorbers, the suspension as a whole and other equipment. Today there is no consensus on which shock absorbers to install on this car, but still, experts advise buying spare parts in reputable stores. Before buying spare parts for the VAZ 2107, consider your driving style. For example, if shock absorbers are purchased, then speed fans can choose hard models, while soft shock absorbers are more suitable for lovers of quiet movement.

Source

How to diagnose car shock absorbers?

To determine the technical condition of the car, you need to diagnose the vehicle. This operation is included in the repair and maintenance of the machine. Among other actions, it is important to check the chassis and shock absorber strut - are there any problems with these components? Otherwise, when the machine moves, other components and assemblies will be subject to increased wear, since the shock absorbers will not dampen the impulses that arise during movement. In addition, this will cause discomfort to the driver and passengers and will also affect the driving performance of the car.

In order for the diagnosis to be objective, you need to know exactly how to check automobile shock absorber struts for performance.

How to check shock absorber struts?

Many inexperienced motorists do not know how to check the struts for faults. There are several ways to check shock absorbers:

Visual inspection

The operation can be performed without removing the wheels. It is important to consider that the front and rear struts are located next to the springs. In some cases, they come with them. There should be no oily smudges or traces of them on the flasks. These signs indicate that the rack is broken. You also need to inspect the rods. This operation is performed when driving the car onto a lift. The part must have no signs of corrosion or damage. The disadvantage of the method is that the test results will not be able to provide objective information on the condition of the suspension elements. The thing is that the racks may have internal defects that cannot be seen during a visual inspection, and as a result, the diagnosis will be incomplete. Important! If the cover is worn unevenly, this indicates a malfunction of the racks.

Checking damping properties

To implement this, you will need to rock the car. It is important that more than 1-2 presses on the wing of the car are not allowed. The method allows you to identify a completely failed suspension element. The important thing is that such a test will not allow you to evaluate the performance of the components if the rod is jammed. Then, as a rule, the buildup will not be successful.

Diagnostics while driving a car

Constant skidding, an acute reaction to even the slightest bumps or bumps, an increase in braking distance - as a rule, all this indicates problems with the suspension, including shock absorber struts. These problems put traffic safety at risk; such a suspension cannot be used.

Diagnostics by removing parts

The dismantled suspension element is installed vertically, relative to the ground. Next, you need to grab the upper rod and pull it out, then push it down. The working component will have strong resistance. If the rod moves freely, it means that the working fluid has run out or air has entered the mechanism. This check makes it clear that you should purchase a new set of racks.

Diagnostics on a vibration stand

One of the most reliable ways to detect suspension failure. The bottom line is that the device simulates the movement of a car on the road, thereby checking the racks and other mechanisms of the vehicle.

Before carrying out diagnostic work, you should wash the car and perform a number of preparatory measures. The vehicle must be driven to an overpass, inspection hole, or use a jack. Thoroughly wash the wheels and arches from dirt, and use a wire brush to clean these components from corrosion. In addition, diagnostics are performed in a well-lit, spacious room or outdoors, provided that the weather allows the work to be carried out comfortably.

Bench testing

If you are unsure of the accuracy and correctness of your own conclusions regarding the proper operation of the racks, it is recommended to rely on specialists who perform diagnostics on a vibration stand. Naturally, the verification procedure is paid, but with the help of verification, you can get an opinion from specialists and precise instructions for the next action.

We recommend:

Mud tires: what they are, what they are needed for, price and where to buy

To avoid wasting money, you should use the following tips:

- Check the computer settings by technicians to diagnose a specific vehicle model.

- Taking into account the age of the machine, the weight of the body, settings and standards may have certain discrepancies.

- Check wheel alignment and tire pressure before the test.

- Contact a good service center that suits you individually.

Checking the racks is not as simple as it might seem initially; it is a very difficult and laborious process, taking into account every little thing and detail.

How to diagnose new shock absorbers?

At the moment, in the automotive spare parts market, along with original parts, you can find a huge amount of counterfeit goods. The use of counterfeit components leads to rapid vehicle breakdown and also endangers the life and health of the driver and passengers. Therefore, when purchasing, you need to know how to check shock absorbers:

- Inspect the part, look for oil stains, defects, and contamination. If there are any, then you should refuse to purchase.

- Check the markings with those indicated in the manufacturer's catalogue. If they do not meet the standard, it means that a fake part is being sold, the quality of which remains in question.

- When purchasing gas shock absorbers, you need to bleed the rod. About five times. There should be no “sticking”, the movement of the part on a working shock absorber is smooth, the rod does not make unnecessary sounds.

- The stroke length of the rod should not deviate by more than 5 millimeters from the value declared by the manufacturer.

Important! Checking shock absorbers when purchasing is a mandatory operation, otherwise there is a high risk of purchasing a counterfeit product.

After completing the diagnostic operations, provided that no defects are identified, you can safely purchase the product. As a rule, such shock absorbers will last a long time.

How to check shock absorber struts yourself?

Every driver should know how to check the shock absorbers on a car. Do-it-yourself operations are performed using the following methods:

Visual inspection of the element

Using this method, you can find out about the main faults of the racks. If they are broken, then the suspension is unsuitable for further use. Malfunctions are indicated by drips, uneven tread wear, and rust on the rods.

Car rocking

When swinging, there should be resistance. If, when pressed, the car flexes easily and also accumulates easily, then there are problems with the suspension.

Dismantling the part

Allows you to perform certain actions with the shock absorber rod and strut. Defective elements checked in this way are usually subject to replacement.

Important! If you do not have confidence in your own abilities, then you should refuse to replace it yourself. After all, in case of failure, the situation can worsen.

Purpose of shock absorbers

Automobile shock absorbers (dampers) are a guarantor of driving comfort and safety. The main tasks of this element are to prevent the wheels from coming off the road, ensuring proper grip on the road surface and dampening body vibrations.

Twin shock absorbers on the VAZ 2107 provide proper traction

Such parts are most often replaced with spare parts of the same type, which can be purchased at automobile stores. Car owners determine the replacement period on their own, but do not delay this procedure, otherwise this can lead to premature wear.

Shock absorber design

The design of the damper depends on its type. The main part is a cylinder housed in a housing with ears. Inside there is a hydraulic composition (gas or a mixture of liquid and gas). There is also a piston connected to the rod. It contains the recoil valves and o-rings. With their help, the liquid in the cylinder is compressed and moves into the free space inside. The shock absorber is attached to the car body using a rod and a cushion, and to the suspension - using a cylinder. At the ends of the part there are special supports.

Design of single-pipe and double-pipe shock absorbers

The boot (casing) protects the inside of the cylinder and the rod from damage and dirt. To prevent liquid from spilling out of the cylinder, a special cuff equipped with a guide sleeve is attached to its upper part. The listed parts are included in the design of both the most complex and the simplest damper.

How are shock absorber struts diagnosed on a bench?

Diagnostics of shock absorbers on a stand is carried out in specialized service centers, the average cost of performing this work is one thousand rubles.

So, how do you test shock absorbers on a vibration stand? To do this, you will need to drive the car to a special platform, which begins to vibrate, thereby simulating road conditions. During this work, the racks, components and assemblies of the vehicle are checked. If problems are identified, the motorist will have to purchase new struts.

Important! It is recommended to carry out a complete diagnosis of the vehicle every 30-50 thousand kilometers, depending on the intensity of use of the vehicle.

Visual inspection of shock absorbers

Before checking the serviceability of the shock absorber using a more serious method, conduct a visual inspection of the unit. In practice, even this is enough to determine the malfunction and the need for repair. All that is required is to have good vision and pay maximum attention during the inspection process.

The presence of leaks or oily stains on the surface of the shock absorber allows us to conclude that the tightness of the product has deteriorated. In such a situation, rest assured that the product will soon require replacement. We also recommend reading the article on how to bleed shock absorbers before installation.

To confirm your assumption, wipe the shock absorbers with a dry and clean cloth, and inspect them after a few days. If traces of oil appear again, then final conclusions can be drawn.

Pay special attention to the boot and rebound buffer. If these parts show signs of leakage, then the shock absorber is in its last months. Don't forget about another important condition indicator - tires. Here, uneven wear is one of the key signs of failure.

If you ask a specialist how to check shock absorbers, he will definitely advise starting with the rod. If there are obvious signs of scuffs, rust or stains on the polished part of the product, then it is better to replace the product.

Consequences of shock absorbers failure

So, what problems does a motorist face when the suspension breaks down? As a rule, the list of consequences of shock absorber failure is as follows:

- Increased braking distance of the car, deterioration in handling, increased tire wear.

- Failure of bearings in the chassis of the car.

- Operation of faulty struts leads to destruction of the car body.

- An increase in the likelihood of an accident on the road, and as a result, a decrease in the safety of drivers and passengers.

Important! When purchasing new racks, you need to select the type of part that was previously used. As a rule, this will not cause problems when using the car, as a result of changes in the driving characteristics of the vehicle, and, as a result, the comfort and safety of the driver and passengers will remain at a consistently high level.

How to install a new damper: nuances of the replacement procedure

The damping parts of the car are never changed individually, moreover, those of them that are installed on the same axis must have the most approximate characteristics. It is advisable to install the same type of shock absorbers on both axles, otherwise it is extremely difficult to determine exactly how the car will behave on the road in a difficult situation.

Shock absorbers are always installed in pairs

The procedure for replacing these parts is not too complicated, but it requires certain skills and knowledge, as well as compliance with all manufacturer’s recommendations. In this case, the main difficulties remain souring of bolts, nuts and breaking of studs . If in the first case WD-40 lubricant and special extensions for tools help, then if the fastening is defective, you can replace the studs with ordinary bolts. To do this, a small hole is drilled into which a bolt is inserted. There is no particular load on the fastening site, so there is no point in worrying about the shock absorber breaking off.

Before installing new parts, they must be pumped . This is necessary because air may get into the inside of the component. This is one of the reasons for the incorrect operation of the part, the appearance of extraneous noise, and knocking while driving. There is a risk of failure of the piston damper system.

Bleeding new shock absorbers before installation

After bleeding, all shock absorbers are checked as follows:

- The rod, which is in the upper position, is pressed sharply and briefly.

- The part reacts smoothly and gently in response.

Once bleeding is complete, keep the shock absorber in the rod-up position until it is installed in the vehicle.

When replacing dampers, experts advise checking the rubber boots. If they are faulty, summer dirt and winter salt can cause damage to the piston surface and failure of the seals. This will result in gas or lubricant leakage.

How to check shock absorbers on a car for performance, video

Regardless of what kind of chassis is in the vehicle, shock absorbers are invariably present there. A shock absorber is a damping element that serves to soften oscillatory movements during suspension operation. The nature of its work is based on the change of mechanical energy into thermal energy. There are two types of shock absorbing devices:

The shock-absorbing device is in close connection with the other components and assemblies of the suspension system (spring, spring, cushion and torsion shaft). But due to constant loads and the presence of a certain resource, suspension elements become faulty - and the shock-absorbing device is no exception. In this article we will talk about how to check the shock absorber for performance; the video will help you correctly and quickly cope with all the actions yourself.

What are the consequences of a faulty shock absorber?

Shock absorbers (dampers) are devices that serve to dampen vibrations while a car is moving (damping) by converting mechanical energy into thermal energy. Shock absorbers operate in conjunction with such vehicle suspension elements as springs, springs, torsion shafts, cushions, etc.

Diagnostics of shock absorbers must be carried out systematically by the driver. Why, you ask, because MOT was passed, and everything was fine. Unfortunately, like everything in this world, shock absorbers tend to fail. And the sooner the driver notices a shock absorber malfunction, the less money will then be spent on restoring the consequences.

The most important thing is for you to remember that systematically checking the shock absorbers yourself takes a couple of minutes, and can save you from troubles with other car systems.

Why is it necessary to have a working shock absorber?

The running capacity of this element is approximately 60 thousand km. Basically, this figure depends on the condition of the roads, but the driving style of the car is no less important. But often the shock-absorbing device malfunctions much earlier - it can break at any time. And this leads to the most dire consequences for both the driver and other road users.

To replace a shock absorber, it is important to be guided not by the technical characteristics declared by the manufacturer, but solely by its condition.

Shock Absorber Strut and Shock Absorber

With a shock absorber that is in poor condition, the tires will wear unevenly. The car will skid when driving at high speeds. In addition, a faulty device will affect the life of the wheel bearings. Their price is quite high, and on many vehicles this element is supplied assembled. And in this case, the amount spent on repairs may cost the car owner a pretty penny.

But that is not all. A damaged shock-absorbing element on a car causes an increase in braking distance. In turn, this affects safety. And naturally, comfort while driving decreases. Since a broken device will no longer soften impacts, they go directly to the suspension and body elements, which also reduces their working resources. This is why it is extremely necessary to have an unbroken shock absorbing element.

Next, we want to tell you how to carry out verification in different ways.

Causes of shock absorber malfunction

The causes of failure are usually natural factors, including:

- Aging of shock-absorbing fluid (oil). Like other technological fluids in a car, the oil in the shock absorber gradually gains moisture and loses its performance properties. Naturally, this leads to the fact that the shock absorber begins to work harder than it worked before. However, it must be understood that fluid aging does not happen overnight, with the exception of a rupture of the seal on the shock absorber body.

- Torn seal. In particular, the sealing of the piston and the inner walls of the working cylinder. The oil seal can rupture due to external factors or simply due to the aging process. It, like any rubber seal, becomes tanned over time and begins to leak liquid. Because of this, oil leaks from the shock absorber, as well as moisture from the outside entering the oil, which leads to a deterioration in its performance.

- Deformation of the valve mechanism plates. This process is also natural and occurs on an ongoing basis, albeit at different speeds. Thus, the rate of deformation depends on two main factors - the quality of the shock absorber (the quality of the metal of the plates) and the operating conditions of the machine (naturally, a significant impact load leads to premature deformation).

- Gas leak. This is true for gas-filled shock absorbers. The idea here is the same as for oil-filled devices. Gas here performs a damping function, and if it is not there, then the shock absorber will not work.

- Failure of silent blocks. They wear out due to natural reasons, losing their elasticity and performance. These components are practically not subject to repair, so if they fail, they simply need to be replaced (if possible, or the shock absorbers must be completely changed).

This is interesting: Tuning Niva 2121 with your own hands: body, interior, suspension

Visual inspection

Is it possible to determine if a device is faulty without removing it from the car? Yes, you can! And this is the cheapest, but, unfortunately, not very reliable way...

- It is necessary to visually inspect the rear and front shock absorbing elements . The devices are located behind the wheel springs. Although another option is possible, when the shock absorbers are supplied assembled with springs (MacPherson strut suspension). Evaluate its appearance. There should be no oily traces or other smudges on the surface of the flask. If they are, then your device has a breakdown.

- Inspect the rods (the inspection is carried out with the wheels in the hanging position) - it is better to do this by using a lift. If there is no access to it, then you should lift the car from the required side using a jack and pry off the boot. The rod should shine - rust on it indicates a faulty part.

- A breakdown of the shock-absorbing device can also be indicated by the tire itself . Assess the condition of the treads. All should show almost the same amount of wear.

Visual inspection of the shock absorber

Disadvantages of visual diagnostics

Unfortunately, a malfunction can only be determined by visual inspection in 50% of cases. Since incorrect operation of this element is usually caused by wear of its internal parts. But it is impossible to establish them during a routine inspection. Outwardly, you can only see the consequence of the malfunction - oily smudges, which, by the way, do not always appear, or eaten away protectors.

Checking damping properties

The steps for this method are as follows:

- The machine must be in a calm state.

- The car must be placed on a level surface.

- One of its sides is vigorously swung by the hands and it is checked at what time interval the car body stops swaying.

This method, for obvious reasons, can only be used on passenger cars.

It is acceptable to do 1-2 swings. If the car continues to “walk”, then the shock absorbers are faulty.

Checking the shock absorber by swinging

Minus of car rocking

The negative side of the described method is that this way you can only identify a completely unusable shock-absorbing element . Although this is the fastest and cheapest (most likely even free) diagnostic option. The second caveat is that the device does not always “play.” It happens that the rods simply jam. In such a situation, it will not be possible to rock the car.

Checking shock absorbers using the example of VAZ 2101-07

Shock absorbers can be checked in several ways:

- Visual. If you find fluid leaks, then your shock absorbers are faulty, remove them from the VAZ 2101-2107 for repair or replacement, we recommend specialized workshops; — subjectively — If you notice while driving that the efficiency of vibration damping of the car is reduced or frequent hard shocks appear during rebound and compression (“breakdowns”) of the suspension, your shock absorbers are also not working properly, you need to remove them for repair or replacement. Also, a subjective express check of shock absorbers can be carried out, as shown in the photo, points 1-5; — the most correct thing would be to check shock absorbers on specialized stands (both shock absorbers installed on a VAZ 2101-2107 car and those dismantled).

1. Place the VAZ 2101-2107 car on a flat floor in the garage or a level area. The engine must be turned off and the gearbox must be in first or reverse gear. Do not use the handbrake.

2. Rock the car by the wing (angle) up and down with an amplitude of at least 45-50 mm. 3. At the lowest point, release your hands. 4. The shock absorber is working only if the VAZ 2101-2107 car made one upward oscillation, then half a downward stroke and stopped. 5. Next, repeat steps 2-4 for the remaining three shock absorbers.

Because You are not logged in. To come in.

Because you are not a trust user. How to become a trustee.

Because The topic is archived.

Features of replacing the shock absorber on a VAZ 2104

A lot of general materials have already been written about replacing shock absorbers, which offer repair algorithms. However, now we will also talk about more subtle things that will help you save not only time, but also money. First, before replacing the shock absorber, you need to dismantle the old one. There is nothing complicated about this. The fastening here is with two screws. It should be noted that the top bolt is welded in; there is no need to hold it. But the situation with the bottom bolt is different: it has a nut on one side, and the bolt head on the other. Therefore, you need to hold it on both sides.

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Source

Troubleshooting on the go

This method is considered one of the most reliable. Because it allows you to understand whether the shock-absorbing device is working correctly.

How to check?

It is necessary to carefully monitor the behavior of the vehicle. If:

- The car constantly “throws” to the side.

- The vehicle reacts “reluctantly” to steering wheel turns.

- The car rocks on the smallest bumps.

- In large holes you can hear the typical thuds. But they may not always appear due to broken pistons. Perhaps the silent blocks on which the shock absorbers are mounted at the top and bottom are worn out.

- Having carried out such a diagnosis, it is worth testing the car while cornering. The vehicle should not roll much.

Checking the shock absorber while driving

If one or several of the above symptoms are detected, draw the conclusion that the shock absorber requires replacement.

Manage!

If, while driving, the car suddenly gains some independence - it yaws on uneven surfaces, sways in all directions, and reluctantly responds to the steering wheel, then most likely the shock absorbers are to blame. Contrary to popular belief, this manifests itself not only at high speeds, but even if the speedometer shows quite “urban” numbers. At the same time, there is no need to write a pretzel on the road - in a quiet place, exercises such as acceleration, braking, snaking are quite enough... In any case, if the car’s handling has deteriorated over time, you should contact competent specialists for diagnostics.

For example, you can see in this video how cars with working shock absorbers behave and those without.

Checking the removed shock absorber

Dismantling allows you to determine exactly which of the 4 damping devices is faulty. The removed elements are installed in a vertical position.

Checking the rear shock absorbers

- The lower bracket of the damping device must be secured with your feet.

- We take the device at the top by the stem.

- We pull it towards us and send it down again.

A properly functioning damping device has good resistance.

And if the rod moves without any effort and without tension, then the shock absorber has failed.

There is a lack of working fluid in the shock absorber, or there is air inside (this does not apply to gas-filled elements).

Dismantled shock absorber

Checking the front shock absorbers and struts

The rear and front shock absorbers have a similar design. The check is carried out according to the scheme described above. If the rod moves easily, then the device is faulty and should be replaced.

Checking the car on a vibration stand

For the reason that it is not always possible to identify a malfunction on your own or without removing the element, you can contact the service. Here, trained craftsmen will perform it with high professionalism.

How are shock absorber struts checked without removing them from the vehicle?

To do this, you should drive the car onto a special vibration stand. The price of this diagnostic is a thousand or more rubles. This service is also good because not only the strut/shock absorber, but also other elements of the chassis and the brake system are subject to professional inspection. On the vibration stand, road irregularities are simulated, which will allow you to correctly determine the breakdown of a specific mechanism. In addition, this makes it possible to determine the serviceability of bearings (ball and wheel) by checking the lateral rolling of the machine.

The stand has a huge number of sensors that transmit information every second to the main computer.

Vibration test

Advantages of testing with a vibration stand

- the highest accuracy in identifying the slightest faults;

- minimum amount of time.

In addition, owners of freight transport cannot do without this service. Because it is impossible to rock a large car. On a vibration stand it will be possible to establish the problem in its entirety. The only downside is the low prevalence of auto repair shops with similar equipment, even in big cities. In addition, the cost of the service for some car owners can be quite high.

So, we have given several ways to check shock absorbers for malfunctions; you just have to choose the most relevant one for you.

And in order to make driving safe and get by with low repair costs, regularly check not only the shock absorbers, but also other components of your car!