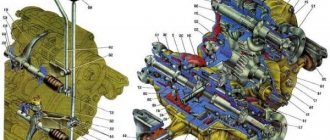

Suspension device

1 – brake disc; 2 – wheel hub; 3 – hairpin; 4 – lower ball joint; 5 – cap; 6 – housing of the external drive hinge; 7 – adjusting nut; 8 – conical bushing; 9 – hub bearings; 10 – oil seals; 11 – mud ring; 12 – rubber cushion of the stabilizer bar; 13 – clip for fastening the stabilizer bar; 14 – steering knuckle; 15 – body; 16 – stretching; 17 – protective cover of the ball pin; 18 – upper ball joint; 19 – shock absorber rod mounting pads; 20 – upper lever; 21 – cross member; 22 – adjusting washers; 23 – axis of the upper arm; 24 – rubber-metal hinge (silent block) of the upper arm; 25 – rebound buffer; 26 – bracket for rebound buffer; 27 – upper spring support cup; 28 – upper insulating gasket of the spring; 29 – spring; 30 – bolt securing the brace to the cross member; 31 – washers of the lower arm; 32 – axis of the lower arm; 33 – rubber-metal hinge of the lower arm; 34 – lower arm; 35 – lower insulating gasket of the spring; 36 – lower spring support cup; 37 – compression stroke buffer; 38 – shock absorber; 39 – bracket for fastening the stabilizer bar to the body; 40 – stabilizer bar.

Pros and cons of chassis

Significant advantages are:

- Components for the Chevrolet Niva chassis are always available at most dealers. The cost of these spare parts is much lower than that of competitors' cars.

- High maneuverability in all conditions.

- The chassis has a large departure angle of 350 degrees and entry angle of 370 degrees. The presence of such characteristics allows you to overcome any obstacles on the road.

- Smooth and easy movement on the highway.

- Soft ride in off-road conditions thanks to reduction gear and forced locking of the center differential.

Along with the benefits that the owner of Shnivy receives, he is also rewarded with the following disadvantages, by the way, coming from the advantages:

- Noticeable vibration of the body when driving, especially from the rear axle.

- High fuel consumption due to the heavy rear suspension and permanent all-wheel drive. For example, a car engine “eats” about 8 liters of gasoline on the highway and 14 liters in the city. Such consumption, for example, is equal to the fuel requirement for a Toyota LC 200.

- The chassis is equipped with poor quality seals, bushings, silent blocks and ball joints. You need to pay attention to these parts after 15,000-20,000 km.

- Wheels move to the side when driving after 25,000 km due to broken wheel bearings.

Also interesting: Chevrolet Niva front suspension diagram

Along with the benefits that the owner of Shnivy receives, he is also rewarded with the following disadvantages, by the way, coming from the advantages:

- Noticeable vibration of the body when driving, especially from the rear axle.

- High fuel consumption due to the heavy rear suspension and permanent all-wheel drive. For example, a car engine “eats” about 8 liters of gasoline on the highway and 14 liters in the city. Such consumption, for example, is equal to the fuel requirement for a Toyota LC 200.

- The chassis is equipped with poor quality seals, bushings, silent blocks and ball joints. You need to pay attention to these parts after 15,000-20,000 km.

- Wheels move to the side when driving after 25,000 km due to broken wheel bearings.

Key Features

The front suspension of the VAZ 2121 is independent, on steel wishbones, with coil springs, double-acting telescopic hydraulic shock absorbers and a stabilizer bar.

The upper and lower arms of the VAZ 2131 have a similar design: at the ends of the “fork” there are cylindrical eyes for rubber-metal hinges (silent blocks), and on the opposite side there is a platform with three holes for attaching a ball joint. On the front branch of the upper arm there is a boss into which the rebound buffer rests at maximum suspension travel, and on the lower arm there are four holes for attaching the lower spring support cup.

The ball joints of the upper and lower arms are interchangeable and unified with the upper ball joints of the suspension of rear-wheel drive VAZs. The support is attached to the lever along with the boot and the pressure plate with three bolts with spring washers and nuts. The threaded ends of the pins of both the upper and lower bearings point downwards and fit into the tapered holes of the steering knuckle. The pins are secured with self-locking nuts. Thus, the steering knuckle can rotate about an axis passing through the centers of the ball joint pins.

The suspension arms, in turn, can rotate on their axes within the range of the rubber-metal hinges of the VAZ 2131 (limited by their elasticity). The upper arm axle has two holes and threads on both ends. Bolts pass through the holes, securing the axle to the suspension cross member. There are washers installed on the bolts between the axle and the cross member to adjust the camber angles and the longitudinal inclination of the wheel axis (see below).

The threaded ends of the axle fit into the rubber-metal hinges of the lever. There are washers on both sides of each hinge: the smaller one (flat) is on the inside, the larger one (convex outward) is on the outside. The self-locking nuts of the upper arm axle are finally tightened only when the suspension is compressed (on a loaded vehicle), otherwise the hinge will not be installed correctly and will quickly fail.

The lower arm axle is a bolt that passes through a bushing in the suspension cross member and the rubber-to-metal joints of the arm. Just like the upper ones, the lower hinges are tightened between two washers, but another thrust washer (thick) adjacent to the bushing, and several adjusting ones (thin) are added between the inner washer and the bushing. The thickness of the washers package is selected at the factory; when dismantling the suspension, you must remember their number and location. Changing the number and location of washers is permissible only if it is necessary to restore the suspension geometry of the VAZ 2121, Niva 2131 (for example, after an accident, replacing a cross member, etc.).

In this case, the distance between the outer washer and the flange of the bushing of the rubber-metal hinge after tightening its nut should be in the range of 3–7.5 mm. In the event that it is impossible to adjust the longitudinal inclination of the steering axis (see below) with working suspension parts, you can move some of the washers from one end of the lever to the other.

The cross member of the VAZ 2121 suspension is a curved steel tubular beam, to which forged steel brackets are welded on both sides. In the lower part of the bracket there is a bushing for the lower arm axis, and the upper part is made as a vertical platform with four pairs of holes for mounting bolts.

The top pair of bolts secures the upper arm axle to the crossmember. The second one from the top tightens the engine mount bracket, cross member, spar and rebound buffer bracket. The third pair of bolts secures the engine mount bracket, cross member, and upper suspension spring mount. And finally, the fourth is the cross member and the upper suspension spring support. To ensure reliability, the nuts securing the upper suspension spring support are welded to the protruding threaded part of the bolts after tightening.

Two brackets with holes are also welded to the lower rear part of the Niva 2121 cross member. Niva 2131 braces (steel rods) are bolted to them, increasing the longitudinal rigidity of the structure. The rear (threaded) ends of the guy wires are attached to the bracket on the car body with two nuts and washers. When installing the extension, tighten the inner nut until the washer touches the bracket, and the outer nut - with the recommended torque.

The Niva 2121 suspension spring rests on the lower insulating gasket and the upper support cup. A rubber gasket is installed between the upper support cup and the upper spring support. The upper support is fastened with four bolts to the suspension cross member, two bolts to the body spar (welded into the spar) and another to the rebound buffer bracket (the latter is welded into the support itself). The compression buffer support strut is also welded to the upper spring support (it faces down).

At maximum suspension travel, the compression buffer rests on the lower arm, and the rebound buffer rests on the tide on the upper arm. The lower spring support cup is attached to the lower arm with four bolts, nuts and spring washers. The mounting brackets for the lower end of the shock absorber and anti-roll bar (behind the spring) are also welded to the lower cup.

Since a rubber-metal hinge is pressed into the shock absorber eye, the lower mounting bolt can only be tightened while the vehicle is under load. The upper end of the shock absorber is attached to a bracket on the car body through two rubber cushions with a nut and washers. It can be tightened in any suspension position.

The anti-roll bar is a curved spring steel rod. It reduces the roll of the Niva 2121 car when cornering. Through rubber pads, pressed by steel clips, it is secured at two points to the body and to the brackets on the lower spring support cups.

Repair of the Niva 2131 suspension mainly consists of replacing worn and damaged parts. Pay special attention to the condition of the protective covers of the ball joints (boots). If they are torn, immediately replace the covers and lubricant, otherwise the support will quickly fail. Play in the upper support can be determined by rocking the wheel with the suspension compressed (to do this, place a 230 mm high block under the lower arm closer to the ball joint).

To diagnose the condition of the lower hinge, remove the wheel and, inserting a mounting blade between the steering knuckle and the support body, create a variable load, feeling the movement of the support pin through the boot. Replace rubber-metal hinges (silent blocks) when the rubber bulges, tears, cracks or severe wear.

When replacing springs, make sure that they are of the same class (class A - without markings, class B - with a black stripe on the outer surface of the coils, has a shorter length under load). It is allowed to install class A springs on the front suspension and class B springs on the rear, but not vice versa.

Compatibility of springs from Niva and Shnivy

The time comes when the springs on a Chevrolet Niva need to be replaced. First you need to figure out which suspension elements are best to install so that they provide the expected properties.

The springs on the Chevrolet Niva from the regular Niva VAZ-2123 are not suitable. The reason for this is the differences in length. Let's consider the main technical parameters of these elements.

| Parameter name | VAZ-2121 Niva | VAZ-2123 Chevrolet Niva |

| Front | ||

| Bar diameter | 15.2 mm | 15.7 mm |

| Length | 278 mm | 313 mm |

| Rigidity | 74.42 kg/cm | 75 kg/cm |

| Load | 815 kg | 815 kg |

| Rear | ||

| Bar diameter | 13 mm | 13.9 mm |

| Length | 434 mm | 410 mm |

| Rigidity | 22.44 kg/cm | 30 kg/cm |

| Load | 483 kg | 483 kg |

Also interesting: VAZ 2121 Niva front suspension

From the comparison table it is clear that the free length of the parts in question does not correspond, which is the reason for the impossibility of installation, since the springs from the Niva are shorter.

Knock in the front axle.

As with a cardan drive, the resulting noise can be caused by a malfunction of the front axle. But this check can only be carried out with special equipment, so it is necessary to first exclude possible damage to rubber bushings, seals and silent blocks, since they are the most vulnerable components of the system, subject to frequent loads.

Read news about the new Niva

- Lada 4×4 Bronto - sales stopped, new details » Lada.Online - all the most interesting and useful about LADA cars

- Description of the instrument panel Lada 4×4 (VAZ 2121, 2131) » Lada.Online - all the most interesting and useful about LADA cars

- Chevrolet Niva gasoline consumption per 100 km

- Buy LADA (VAZ) 2131 (4×4) 2021 in Rostov-on-Don, low price for Lada 2131 (4×4) 2021 on the Avto.ru website

- Fuses Niva 21214 injector «

- The new large Lada 4×4 Niva “Bigster” 2021-2022 based on the Dacia Bigster was shown for the first time. The SUV has changed beyond recognition

- New Niva Chevrolet Lux 2021 - review of GLC equipment

- Niva Chevrolet alarm connection points "

And also interesting: Off-road preparation of the field for beginners. | JIPSTROY

Independent Wheel Bearing Clearance Repair

If you feel or feel vibration in the steering column while driving, then most likely the clearance on the front wheels in the bearings of the hub itself has increased, so their service life will be reduced, and the tires will begin to wear unevenly. And if there is no gap at all, then the hub will rotate tightly, which will also lead to a decrease in service life, so its gap should be greater than zero fifteen ml. Adjustment of the front bearings is carried out using a wheelbrace wrench, a twenty-seven wrench and a hammer.

- A wheel that is in a suspended state should be rocked; if there is play, the gap must be adjusted. After this, press the brake pedal and rock the wheel; if there is no play, then there is a gap in the bearings.

- It is necessary to dismantle the decorative cap and unscrew the lock nut from the hub, and hold it with a wrench to prevent it from turning. When repairing the chassis while adjusting the hub, it is advisable to install new hub nuts, since even after adjustment there is a high probability that the old ones will take their original place, which will not allow them to be properly locked. If this is not possible, then you can take the nut from Drugov’s car.

- Then you need to twist the hub nut so that the torque is 19.6 Nm. turning the hub several times, ninety degrees in two directions, will install the bearing itself. After this, loosen the adjusting nut and tighten it to 6.8 Nm. Having done all this, simply unscrew the nut twenty-five degrees.

- After everything is done, change the collar of the nut on the pin of the external drive joint.

- After the adjustment is made, check how the wheels rotate; if they rotate easily, then everything is fine. The final check can be made only after driving several kilometers without braking, assessing how the hub heats up.

Also interesting: Chevrolet Niva suspension: front, rear, device and tuning